Trace Engineering C35 - REV B User manual

Installation and Operation Guide

C-Series

Multifunction DC Controllers

©2000 Xantrex Technology Inc. P/N 975-0004-01-01 Rev. 11/00

©2000 Xantrex Technology Inc.

©2000 Xantrex Technology Inc.

Section Description Page

1. INTRODUCTION ............................................................. 1

Operating Modes

Photovoltaic Charge Control Mode

Automatic PV Array Night Disconnect

Diversion Control Mode

DC Load Control Mode

2. FEATURES ..................................................................... 5

Over-Temperature Protection

Electronic Over-Current Protection

attery Temperature Compensation

LED Status Indicator

Charge or Diversion Control Mode Indications

Solid Green

linking Green

Load Control Indications

Solid Red

linking Red

Slowing linking Orange

Equalization Mode Indication

Alternating Red and Green

Error Mode Indication

Fast linking Orange

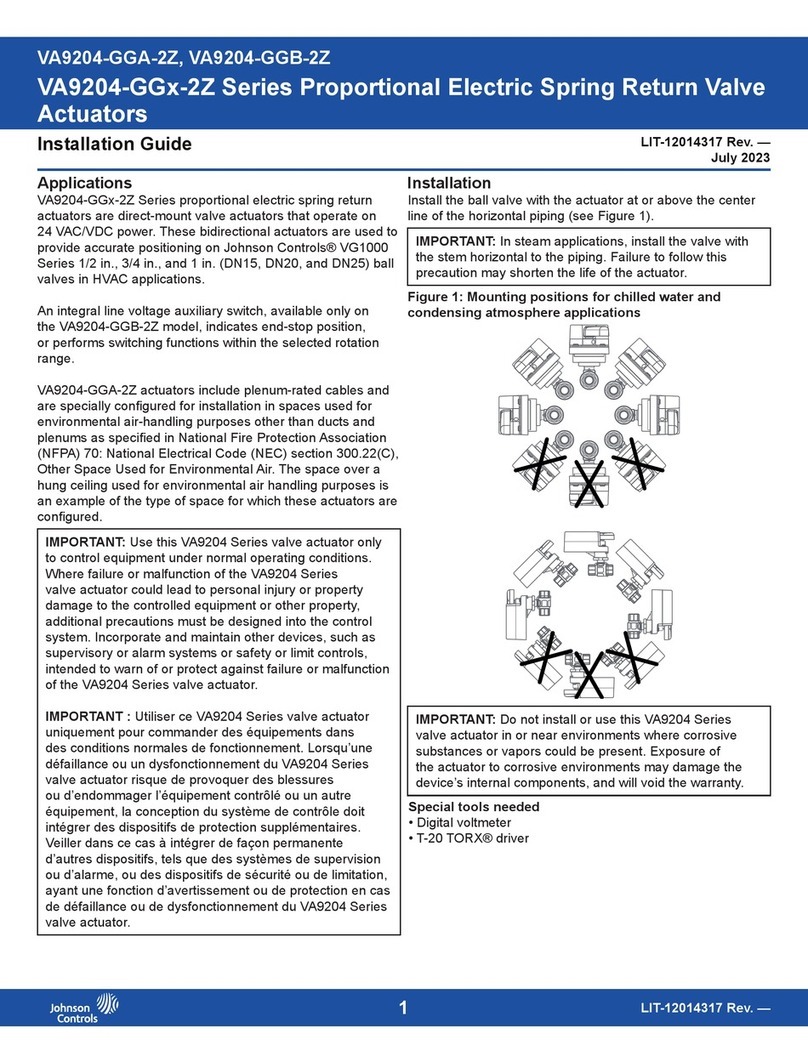

3. INSTALLATION ............................................................... 10

Mounting

Wiring

Minimum Recommended Wire Size

Maximum One-way Distance and Wire Size

PV Charge Control Mode Cabling

Diversion Control Mode Cabling

DC Load Control Mode Cabling

Grounding

Configuring the C-Series

Automatic/Manual attery Equalization and

Low Voltage Reconnect

Operating Mode

Reset Switch

Voltage

C-Series

Multifunction DC Controllers

Table of Contents

i

©2000 Xantrex Technology Inc.

Section Description Page

3. INSTALLATION (continued)

Adjusting the C-Series

Setting Voltage Parameters

Testpoints for Voltage Settings

Equalization

Manual Equalization

Automatic Equalization

Temperature Compensation

Setting LVR and LVD (Load Control Mode)

Setting Diversion Control Mode

4. OPTIONS ........................................................................ 35

C-Series LCD Meter Displays

Installing the DVM/C40

Mounting the CM/R

5. OPERATION ................................................................... 38

Three-Stage attery Charging

ulk

Absorption

Float

Equalization

6. BATTERIES .................................................................... 41

Automotive atteries

Maintenance-Free atteries

Deep-Cycle atteries

Sealed atteries

NiCad and NiFe atteries

attery Sizing

8. DIVERSION LOADS ....................................................... 43

Charge Controller

Load Controller

Diversion Charge Controller

Diversion Load Types

9. SPECIFICATIONS .......................................................... 46

10. SERVICE INFORMATION .............................................. 47

11. WARRANTY .................................................................... 48

ii

Table of Contents (Continued)

©2000 Xantrex Technology Inc. iii

IMPORTANT SAFETY INSTRUCTIONS

This manual contains important safety instructions that should be

followed during the installation and maintenance of this product.

To reduce the risk of electrical shock, and to ensure the safe installation

and operation of this product, the following safety symbols have been placed

throughout this manual to indicate dangerous conditions and important safety

instructions.

WARNING - A dangerous voltage or condition exists in this area.

Use extreme caution when performing these tasks.

AVERTISSEMENT - Une tension ou condition dangereuse

existe dans cette zone. Faire preuve dextrême prudence lors de la

réalisation de ces tâches.

CAUTION - This procedure is critical to the safe installation or

operation of the unit. Follow these instructions closely.

ATTENTION - Cette procédure est essentielle à linstallation ou

lutilisation de lunité en toute sécurité. Suivre ces instructions de près.

NOTE - This statement is important. Follow instructions closely.

NOTE - Cette déclaration est importante. Suivre les instructions

deprès.

·All electrical work must be done in accordance with local, national, and/or

international electrical codes.

·efore installing or using this device, read all instructions and cautionary

markings located in (or on) the manual, the inverter, the controller, the

batteries, and the PV array.

·Do not expose this unit to rain, snow or liquids of any type. This product is

designed only for indoor mounting.

·To reduce the chance of short-circuits when installing or working with the

inverter, the controller, the batteries, or the PV array, use insulated tools.

·Remove all jewelry such as rings, bracelets, necklaces, etc., while

installing this system. This will greatly reduce the chance of accidental

exposure to live circuits.

·The controller contains more than one live circuit (batteries and PV array).

Power may be present at more than one source.

·This product contains no user serviceable parts. Do not attempt to repair

this unit unless fully qualified.

SAVE THESE INSTRUCTIONS !

©2000 Xantrex Technology Inc.

iv

BATTERY SAFETY INFORMATION

·Always wear eye protection, such as safety glasses, when working with

batteries.

·Remove all loose jewelry before working with batteries.

·Never work alone. Have someone assist you with the installation or be

close enough to come to your aid when working with batteries.

·Always use proper lifting techniques when handling batteries.

·Always use identical types of batteries.

·Never install old or untested batteries. Check each batterys date code or

label to ensure age and type.

·atteries are temperature sensitive. For optimum performance, they

should be installed in a stable temperature environment.

·atteries should be installed in a well vented area to prevent the possible

buildup of explosive gasses. If the batteries are installed inside an

enclosure, vent its highest point to the outdoors.

·When installing batteries, allow at least 1 inch of air space between

batteries to promote cooling and ventilation.

·NEVER smoke in the vicinity of a battery or generator.

·Always connect the batteries first, then connect the cables to the inverter

or controller. This will greatly reduce the chance of spark in the vicinity of

the batteries.

·Use insulated tools when working with batteries.

·When connecting batteries, always verify proper voltage and polarity.

·Do not short-circuit battery cables. Fire or explosion can occur.

·In the event of exposure to battery electrolyte, wash the area with soap

and water. If acid enters the eyes, flood them with running cold water for

at least 15 minutes and get immediate medical attention.

·Always recycle old batteries. Contact your local recycling center for proper

disposal information.

©2000 Xantrex Technology Inc.

Introduction

The C35/C40/C60 (C-Series) controllers are among the finest controllers

available and can be used with 12, 24, or 48 volt DC systems (depending upon

model) as PV charge controllers, DC diversion controllers, or DC load

controllers (low voltage disconnect). These capabilities make the C-Series the

only DC controllers youll need! Numerous standard features are provided to

maximize the performance of the system:

·Solid-state Pulse Width Modulated (PWM) charging process with three-

stage control, temperature compensation, and manual or automatic

equalization to maximizes system performance and increase battery life.

·Meets National Electrical Code (NEC) and other international controller

specifications.

·UL listed for the U.S. (UL Standard 1741 (draft) 1998), and Canada

(CSA-C22.2 No. 107.1-95).

·Electronic overload and short circuit protection with automatic and manual

reset capability increases the reliability of unattended systems by eliminating

blown fuses and tripped circuit breakers.

·Field adjustment of charge setpoints is provided by rotary controls with

removable knobs, reducing the potential for setpoint tampering. Calibrated

scales and test points allow precise adjustments of settings.

·Optional external battery temperature compensation sensor ( TS) for

automatic adjustment of charge setpoints (required by UL draft standard

1741 and strongly recommended for sealed batteries).

·Over-temperature protection for the electronic circuitry when used in hot

environments (over 113 °F/45 °C).

·Indoor-type, powder-coated enclosure for wall mounting.

·Multicolor LED with easy to read mode/status label.

·Optional LCD meter for remote or direct mounting on the controller. May be

mounted up to 1000 feet away.

·2-year limited warranty.

1.0 INTRODUCTION

1

©2000 Xantrex Technology Inc.

Operating Modes

The C-Series controller can operate as either a photovoltaic charge

controller, a diversion controller, or a DC load controller. The controller cannot

operate in more than one mode at the same time. If several modes are required

in a system, a dedicated controller must be used for each mode.

Photovoltaic Charge Control

When this mode is selected, the status LED will indicate either blinking

green or solid green. It will alternate red/green when in equalization mode.

Diversion Control Mode

When this mode is selected, the status LED will indicate either blinking

green or solid green.

DC Load Control Mode

When this mode is selected, the status LED will typically indicate blinking

red or solid red as the controller turns the DC loads OFF when battery

voltage is low.

Photovoltaic Charge Co trol Mode

Depending on the model, the controller can regulate up to 60 amps of

continuous photovoltaic (PV) array current at 12 or 24 volts (C60), or 12, 24 or

48volts DC (C40) for charging batteries. This rating includes the NEC required

deratings. When used in this mode, ensure that the operating mode jumper is

on the charge control pins. To enable the Photovoltaic Charge Control Mode,

see Configuring the CSeries in the installation section of this manual.

If the PV arrays output increases above the rated amp level due to

reflection or edge of cloud effect, the controller will continue to operate until the

heatsink reaches a maximum safe operating temperature. This will take several

minutes to occur depending upon the ambient temperature involved. When the

heatsink reaches the maximum safe temperature, the controller will reduce the

current, cooling the transistors and the heatsink.

If the current from the PV array reaches 85 amps, the controller will turn off

to protect the circuitry. In the event of a shutdown, the controller automatically

resets itself after 10 minutes (if overcurrent condition is no longer present).

The C-Series charge controller rapidly cycles the current source on-and-off

to control the charging current and voltage of the battery. This occurs in both the

charge control mode and the diversion control mode. The amount of time the

current source is connected to the battery is varied to control the average current

flow. This is often referred to as pulse width modulation (PWM) and allows the

current to be tapered, rather than coarsely turning the current off and on as with

relay type PV array charge controllers.

1.0 INTRODUCTION

2

©2000 Xantrex Technology Inc.

Automatic PV Array Night Disco ect

At night, the PV array is automatically disconnected from the battery to

prevent reverse leakage of power. This eliminates the need for a blocking

diode between the battery and the PV array. If thin-film or amorphous solar

modules are being used, diodes may still be required to prevent damage from

partial shading conditions. Check the documentation provided with the PV

modules.

Diversio Co trol Mode

The C-Series can operate as a diversion control to manage battery charging

from alternative-energy sources such as wind or hydroelectric generators.

Systems utilizing solar arrays do not have a requirement for diversion loads since

a solar module can be open-circuited without damage. However, even with a

solar based system it may be desirable to use excess power to operate DC

loads. When used in this way, the C-Series controls a diversion load to redirect

the excess power generated instead of allowing it to flow into the battery. This

prevents damage to the charging source from an over-speed condition which

could occur if the charging source is suddenly disconnected from all loads as

series relay regulators do. Consult your dealer for load and regulator size

recommendations.

When the controller operates as a diversion regulator, it provides three-

stage regulation of battery voltage, with temperature compensation and auto-

matic or manual equalization. See the Three-Stage Battery Charging section

for more information on this process.

Diversion mode requires a separate dump load to regulate the battery.

This load must be able to absorb more power than the charging source is able to

produce at its peak output, or the DC voltage will become unregulated. The

dump load must be available for the diversion of power at all times. Resistive-

type heating elements are the best diversion loads. Special direct current

water heating elements are available. Light bulbs and motors are not recom-

mended as diversion loads because they are unreliable.

When used in diversion mode, ensure that the operating mode jumpers are

on the charge control pins. See Configuring the CSeries in Section 3 of this

manual.

Current draw of the diversion load is very important. Problems may arise

from operating with a load that is too small or too large. A diversion load that is

too small will not be able to absorb all the excess power from the current source

once the batteries are full.

Diversion loads in excess of 85 amps are capable of absorbing more power

than the C-Series is designed to handle, resulting in an over-current shut down.

During this time, the unit will not regulate electrical flow in the system, and battery

damage may result.

A diversion load that draws about 25% more current than the charging

sources maximum output capability is usually suitable for use with the C-Series.

1.0 INTRODUCTION

3

©2000 Xantrex Technology Inc.

DC Load Co trol Mode

The C-Series can also operate as a load control (also called a low voltage

disconnect) to manage the discharging of the battery. A load controller

prevents damage to the battery from over-discharge during periods of poor

weather or excessive loads.

When used in load control mode, ensure that the operating mode jumpers

are on the load control pins. See Configuring the C-Series section of this

booklet.

The controller delays disconnecting the DC loads for 6 minutes after the

voltage drops below the low voltage disconnect (LVD) setting. Loads are

either automatically or manually reconnected when battery voltage exceeds the

low-voltage reconnect (LVR) setting for 6 minutes. The EQUALIZE jumper

determines manual or automatic reconnect when the C-Series is used as a load

controller.

When used as a DC load controller, the settings of the LVR and LVD are

controlled by two rotary potentiometers on the circuit board. The scale on the

adjustment potentiometers differ from the scale used for other functions. A

decal with the appropriate adjustment scale is included with the C-Series and

shown below. Place this scale over the pots when using the C-Series as a

load controller. Do not temperature-compensate these settings. Do not install

the optional battery temperature compensation sensor.

DC Load

Battery C-Series

Controller

1.0 INTRODUCTION

4

Figure 1

Sticker Displaying Load Control Voltage Settings

Attach sticker over

potentiometers for

Load Control Settings

©2000 Xantrex Technology Inc.

Features

The C-Series features include over-temperature protection, electronic over-

current protection, and automatic battery temperature compensation.

Over-Temperature Protectio

The temperature of the controllers transistors is continuously monitored.

This protects the charge controller from damage in high temperature

environments. If excessive temperatures are detected while operating in

charge or diversion control mode, the controllers transistors are rapidly turned

off and on to reduce the charge rate. This will reduce the transistor

temperature.

As a load controller, the load is disconnected before the transistors reach

an excessive temperature. Once the temperature has dropped, the loads are

reconnected. When the over-temperature protection system has caused the

controller to shutdown, the status LED will be orange and will blink fast (about

once a second). This is the same indication shown during an over-current

condition.

Electro ic Over-Curre t Protectio

During operation, the C-Series controllers continuously monitor the current

flowing through it. If the current exceeds 85 amps, the transistor switches are

opened, stopping the flow of electricity. The detection circuitry is faster than

breakers or fuses, and they will not trip or blow when a fault occurs. When

the over-current protection system is activated, the status LED will indicate

orange and will blink fast (about once a second). This is the same indication as

produced by an over temperature condition.

The C-Series controllers automatically resets the over-current protection

system every 6 minutes. If an overload or short circuit is still present, the

controller will shut off and wait another 6 minutes. This will occur continuously

until the problem is corrected.

The reset switch on the right side of the controller allows the user to

manually reconnect the PV array or DC loads after an over-current condition

occurs. Hold the reset switch for 5 seconds to return to normal operation. If

the controller is unable to restart, check the wiring and reduce the loads

connected. There may be a delay after manually pressing the reset switch

before reconnecting the PV array.

The shunt used to measure the current flow in the C-Series is located in

the positive conductor of the circuit allowing greater flexibility in system

grounding. The negative terminals are all common to one another.

2.0 FEATURES

5

©2000 Xantrex Technology Inc.

Battery Temperature Compe satio

The optional plug-in external attery Temperature Sensor ( TS)

automatically fine tunes the charging process of the C-Series. The TS is

required by UL Standard 1741 and UL approval is based on its installation.

However, do not install the battery temperature sensor if you are using the

C-Series as a DC load controller. The TS may be extended by using a

standard phone cable with RJ-11 plugs.

If the temperature sensor is installed, the regulation setpoints should be

adjusted for a battery at room temperature (2327 °C/7480 °F). The C-Series

adjusts the ULK and FLOAT setpoints 30 mV per degree Celsius for a 6-cell,

lead-acid type battery and 20 mV per degree Celsius for a 10-cell, NiCad type

battery, as required per UL Standard 1741. For 24 and 48 volt systems, the

compensation is twice and four times the values listed respectively. See Table 1.

If the temperature sensor is NOT installed, the setpoints should be adjusted

for the temperature of the battery during operation. Seasonal adjustment of the

setpoints may be necessary to prevent battery damage and to ensure proper

charging. If the battery temperature sensor is installed, no seasonal adjustments

are required (see Temperature Compensation in this manual).

If the wiring to the sensor is damaged and the wires are shorted or cut, the

system will return to the non-temperature compensated settings.

Install the TS on the side of the battery below the electrolyte level. It is

best to place the sensor between batteries and place the batteries in an insulated

box to reduce the influence of the ambient temperature outside the battery

enclosure. Ventilate the battery box at the highest point to prevent hydrogen

accumulation.

2.0 FEATURES

6

Table 1

Charger Setpoint Temperature Compensation

TRAHCNOITASNEPMOCERUTAREPMETTNIOPTESREGRAHC

epyTyrettaB

egatloVmetsyS

CDV21CDV42CDV84

dicAdaeLC°/stlov030.0C°/stlov060.0C°/stlov021.0

daCiNC°/stlov020.0C°/stlov040.0C°/stlov080.0

©2000 Xantrex Technology Inc.

LED Status I dicator

A multi-color LED indicates the operating status of the controller. A color-

coded label is included on the cover of the controller explaining the status LEDs

operation. When the controller is in Charge Control mode, the LED will be

green. When in Load Control mode, the LED will be red. An orange LED

indicates an error or a load disconnect condition. When battery equalization is

in process, the LED alternates between red and green.

NOTE: The green and red color of the LED only indicates the particular

operating mode and the battery voltage level. It does not indicate whether the

charging source is functioning properly.

2.0 FEATURES

7

Green Blink Charge Control Mode

Green Solid Battery Charged

Green

Red Blink Load Control Mode

Red Solid Battery Discharged

Red

C35

C40

C60

12/24 VDC

12/24/48 VDC

12/24 VDC

35 Amp Controller

40 Amp Controller

60 Amp Controller

/

Alternating - Equalization Enabled

5916-195th STREET NE ARLINGTON WASHINGTON 98223 TELEPHONE(360)435-8826 FAX(360)435-2229

STATUS

Charge / Load Controller

Orange Blink Slow Load Disconnected

Overload/Overtemp

Orange Blink Fast

Multicolor LED Indicator

Table 2

Battery Voltage LED Indications

Figure 1

CSeries Front Panel Label

)rotacidnIsutatSDELgnisU(EGATLOVYRETTAB

)edoMnoisreviD/egrahC(DELneerG DEL SUTATS )edoMlortnoCdaoL(DELdeR

gnitteSTAOLFtayrettaB NOsyawlA )DVL=setunim6rof(gnitteSDVLtayrettaB

gnitteSKLUBtayrettaB sknilB5 51.0> DVLevoba 03.0> DVLevoba 54.0> DVLevoba

)-(suniMgnitteSkluB )+(sulPgnitteSDVL

CDV52.0CDV05.0CDV00.1 sknilB4 CDV51.0CDV03.0CDV54.0

CDV05.0CDV00.1CDV00.2 sknilB3 CDV03.0CDV06.0CDV09.0

CDV57.0CDV05.1CDV00.3 sknilB2 CDV54.0CDV09.0CDV53.1

57.0> kluBwoleb 05.1> kluBwoleb 00.3> kluBwoleb knilB1 54.0> DVLevoba 09.0> DVLevoba 53.1> DVLevoba

stlov21stlov42stlov84egatloVCDstlov21stlov42stlov84

©2000 Xantrex Technology Inc.

Charge Co trol or Diversio Co trol Mode I dicatio s

Solid Green

The battery is being charged in the FLOAT stage. The status LED remains

ON solid unless the batteries drop below the float voltage setting for an

accumulative period of one hour. This allows the user to confirm that the

system reached the float stage during the charging process when checked at

the end of the day. Reaching the float stage frequently is a good indication of

proper system operation and will maximize battery life and performance.

Blinking Green

The controller is in the CHARGE CONTROL or DIVERSION CONTROL

mode and the battery is not fully charged. As the battery voltage approaches

the ULK setting, the status LED will blink green several times (up to five) and

then pause, indicating the battery voltage is approaching the bulk setting and

provides an indication of the battery condition. Refer to Table 2 on the previous

page to determine the battery voltage.

NOTE: A single green flash indicates the battery is below the bulk voltage

setting. It does NOT indicate the batteries are charging.

Load Co trol I dicatio s

Solid Red

The controller is in the DC LOAD CONTROL mode and the battery

voltage has reached the Low Voltage Disconnect (LVD) setting. After a

6-minute delay, DC loads will be disconnected unless the user reduces the

loads to a point that the battery voltage exceeds the LVD setting.

Blinking Red

As battery voltage approaches the LVD setting, the LED will blink red

several times (up to five) and then pause providing an indication of battery

voltage. Refer to Table 2 on the previous page to determine the battery voltage.

Slow Blinking Orange

The controller is in the DC LOAD CONTROL mode and has disconnected

the loads due to reaching the LVD setting. The user can press the reset switch for

a maximum 10-minute grace period, or can wait until the voltage rises above

the Low Voltage Reconnect (LVR) setting to allow an automatic reset to occur.

2.0 FEATURES

8

©2000 Xantrex Technology Inc.

Equalizatio Mode I dicatio

Alternating Red and Green

The controller is in the EQUALIZE mode. It will automatically stop the

equalization process after accumulating two hours of operation at a voltage

above the ULK setting. The user can stop the equalization process at any time

by pressing the reset switch until the status LED stops alternating red and green.

Error Mode I dicatio

Fast Blinking Orange

The controller detected an over-current or an over-temperature condition

and the loads are disconnected. The controller will try to automatically restart

the loads after a 6-minute delay. If the controller will not restart, turn off all

loads and press the reset switch. If it then restarts, the loads may be too large.

A delay up to five seconds may occur before the controller attempts to restart

after pressing the reset switch.

2.0 FEATURES

9

©2000 Xantrex Technology Inc.

Installation

The C-Series controllers are state-of-the-art precision electronic

instruments. Installation, environment, mounting, and wiring must be

accomplished in accordance with applicable local and national electrical codes.

The instructions that follow are applicable to the typical installation. For special

applications, consult a qualified electrician or your Trace dealer. Installation

procedures will vary according to your specific application.

Mou ti g

The C-Series controllers are designed for indoor mounting. Care should be

taken in selecting a location and when mounting the enclosure. Avoid mounting

it in direct sunlight in order to reduce heating of the enclosure and subsequent

high operating temperatures. The enclosure should be mounted vertically on

awall.

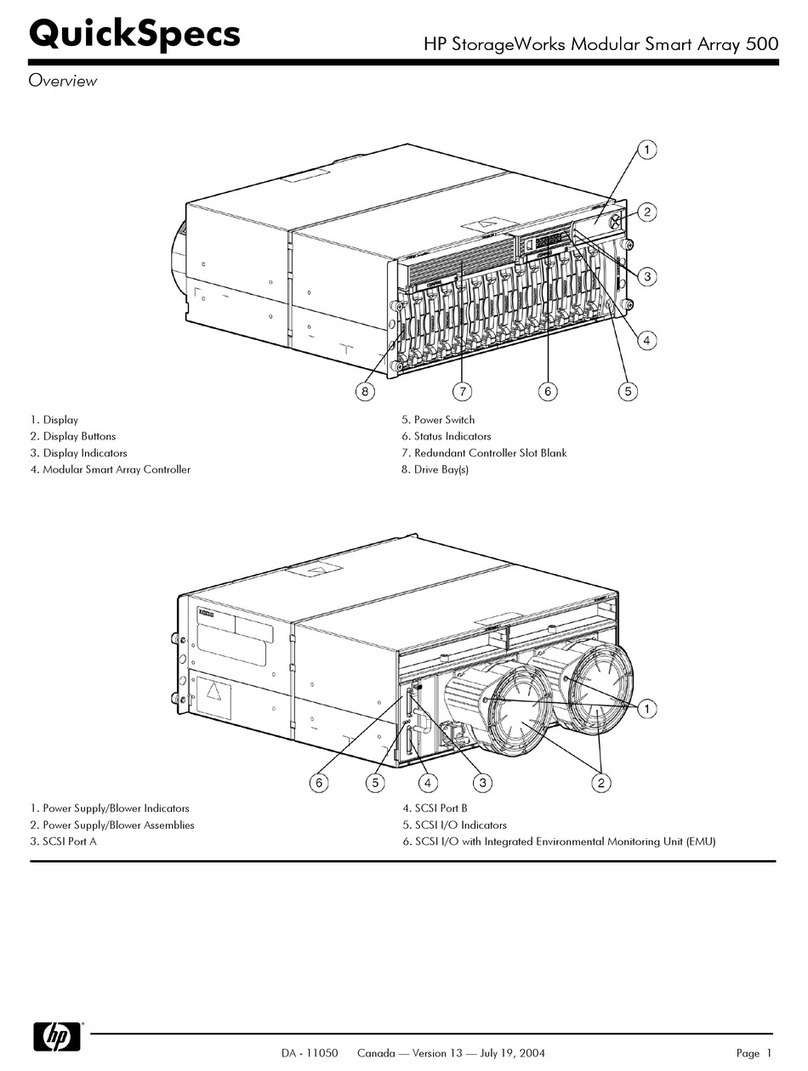

Mounting and enclosure dimensions are shown in Figure 2 (the C-35

controller does not feature an external heat sink). Remove the faceplate on the

controller and locate the upper two screw locations on the wall. The back of

the enclosure is provided with keyholes for mounting. Leave the screw heads

backed out approximately 1/4 inch (6 mm) or less. Place the controller onto the

screws and pull it down into the keyhole slots. Then insert the two lower

screws to lock the enclosure onto the wall. Provide either strain-relief clamps

or conduit to prevent damage to the circuit board and terminal block from pulling

on the wires. The cover should be replaced and retained with the screws

provided (#10-32 x 3/8" SMS).

In outdoor installations, the C-Series units must be installed in a rainproof

enclosure to eliminate exposure to rain or water-spray. The use of conformal-

coated circuit boards, plated terminals, powder-coated metal components, and

stainless steel fasteners improves tolerance to hostile environments.

CAUTION: INSTALL THE C-SERIES CONTROLLER IN A DRY, PROTECTED

LOCATION AWAY FROM SOURCES OF HIGH TEMPERATURE, MOISTURE,

AND VIBRATION. EXPOSURE TO SALTWATER IS PARTICULARLY

DESTRUCTIVE. CORROSION OF THE CIRCUIT BOARD IS NOT COVERED BY

THE WARRANTY.

3.0 INSTALLATION

10

©2000 Xantrex Technology Inc.

8

3.0 INSTALLATION

11

Heatsink not included

on C-35.

Figure 2

CSeries Dimensions

Do not locate the C-Series controller in a sealed compartment with the

batteries. atteries can vent hydrogen sulfide gas, which is corrosive to

electronic equipment. atteries also generate hydrogen and oxygen gas that

can explode when exposed to a spark.

If using sealed batteries, the controller can be mounted in the same

enclosure as long as it is adequately ventilated.

©2000 Xantrex Technology Inc.

Wiri g

Disconnect battery and PV sources before wiring. Set the voltage

selection jumper to the appropriate setting before energizing the system (see

User Configuration Options for instructions). Incorrect settings may result in

damage to the system as charging regulation will not occur. Torque the

terminals to 20 inch-pounds for 14-10 AWG (25 for 8 AWG, 35 for 6 AWG) once

the wires have been installed. Replace the cover.

3.0 INSTALLATION

12

Figure 3

Voltage Selection Jumper

Battery ositive + V +/Load + Common Negatives

Figure 4

Battery Connection Terminals

NOTE: Regardless of configuration, only the positive conductor from a PV array

OR a DC load may be connected to the terminal marked PV POS/LOAD.

12 Volt osition

24 Volt osition

12 Volt osition

24 Volt osition

48 Volt osition

(C40 only)

C40 C35 and C60

©2000 Xantrex Technology Inc.

Mi imum Recomme ded Wire Size

The minimum recommended wire gauge is #8 AWG (for C35 and C40) with

a 75 °C insulation rating and #6 AWG, 90 °C wire for the C60. The terminals on

the C-Series will accept up to #2 AWG (33.6 mm2) copper or aluminum wire,

however, UL specifications only allow the use of up to #6 AWG (13.3 mm2 )

maximum. No crimp-on terminals or lugs are required.

Each model of the CSeries controller is rated for a maximum continuous

current of 35, 40 or 60 amps. Since PV outputs can vary due to the array size

or sunlight striking it, the safe minimum wire size should be based on the

maximum current ratings. The NEC requires conductors and over-current

devices be operated at no more than 80% of their rating. Refer to Table 3

below for a listing of the minimum wire size to use for each model.

RELLORTNOCEZISERIWMUMINIM ECIVEDTNERRUC-REVO GNITAR

53CGWA8#spma54

04CGWA8#spma05

*06C)eriwC°09(GWA6#)ytud%001detsil(spma06

**06C)eriwC°57(GWA4#)ytud%001detsil(spma06

Table 3

Minimum Wire Size

NOTE: *To meet UL requirements, use #6 AWG, 90 °C wire and a 60 amp LISTED

100% DUTY over-current device for the C60 controller.

** Not approved by UL for direct connection into the controller. Use a splicer

block as specified below and #6 AWG (90 °C wire) to connect to the

controllerterminals.

If there is a significant distance between the PV array and the controller

and/or the controller and the battery, larger wires can be used to reduce the

voltage drop and improve performance. Refer to Table 4.

To use a larger size wire, use a splicer block (terminal block) intended for

this purpose. This allows the larger cable size from the batteries to be

spliced to the smaller wire size connected to the controller. Split-bolt kerneys

can also be used for wire splices. Follow manufactures recommendations for

torque and mounting (if required). Splicer blocks and split-bolt kerneys are

available from alternative energy suppliers.

13

3.0 INSTALLATION

©2000 Xantrex Technology Inc.

Maximum O e-way Dista ce a d Wire Size

NOTE: NEC article 690 and local electrical codes should be consulted for wire

sizing and any additional installation requirements. For a C60 use a 60 amp,

100% Continuous Duty breaker and #6 AWG, 90 °C wire. Larger wire sizes

may be used to improve performance, but are NOT approved by UL to be

installed in the controller (use a splicer block as previously described on

page13 of this manual). Match the breaker to the wire if using larger

gaugewire.

Refer to Table 4 and find your maximum current in the left column, and the

one way distance from your power source (feet/meters) to the C-Series controller

(or the distance from the C-Series controller to your load) on the same line, then

read the wire size required at the top of the column.

The wiring, over-current protection devices (fuses and circuit breakers) and

installation methods used must conform to all national and local electrical codes

requirements.

Wiring should be protected from physical damage with conduit or a strain

relief clamp. You should pull the temperature sensor cable through the conduit

first as the connector may not fit if other wires have been pulled first.

As a minimum, a 60 amp DC rated current limiting fuse or circuit breaker

should be provided near the battery for protection from short circuits. To meet

NEC requirements, use a 60 amp circuit breaker listed for 100% duty for the C60.

To meet UL requirements, use #6 AWG copper wires rated for 90 °C for the C60.

14

3.0 INSTALLATION

This manual suits for next models

6

Other Trace Engineering Controllers manuals

Popular Controllers manuals by other brands

TANDBERG

TANDBERG D13691.03 user manual

Argo

Argo IR Series Installation manual and operating instructions

Allen-Bradley

Allen-Bradley PowerFlex 750 Series Programming manual

Advantech

Advantech PCA-6781 Startup manual

Johnson Controls

Johnson Controls VA9204-GG-2Z Series installation guide

Shure

Shure STEM HUB EXPRESS user guide