Trocen AWC7824 User manual

AWC7824 motion controller

User manual

Laser motion controller series

RV1.3

2022.03.3

www.sztrocen.com/www.awc608.com

©2016 Trocen All Rights Reserved

AWC7824 motion controller user manual

WWW.SZTROCEN.COM

1

Copyright statement

Shenzhen Trocen Automation Technology Co.Ltd(hereinafter referred to as

Trocen)reserves the right to modify the products and product specifications in this

manual without prior notice.

Trocen shall not be liable for any direct, indirect, special, incidental or

consequential loss or liability arising out of the improper use of this manual or this

product .

Trocen owns the patent right, copyright and other intellectual property rights of

this product and its software. Without authorization, it shall not directly or indirectly

reproduce,manufacture,process or use the product and relevant parts thereof.

Machines in motion are dangerous.

It is the responsibility of the user to design effective error handling and

security protection mechanisms during the use of the machine.

Trocen shall have no obligation orres ponsibility for any incidental or

consequential damages caused thereby.

Contact us

Shenzhen Trocen Automation Technology Co.LTD

Address :1st Floor, Building4, Zhiheng Strategic Industrial Park, Nantou Pass,

Nanshan District, Shenzhen city, Guangdong Province, China.

Thephonenumber : 0755-27958262

Fax: 0755-27447913-608

Email: [email protected]

Url: www.sztrocen.com/www. awc608.com

AWC7824 motion controller user manual

WWW.SZTROCEN.COM

2

Document Version

The version

The revision date

V1.1

2020/07/20

V1.2

2020/08/26

V1.3

2020/08/27

Preface

Thank you for choosing Trocen motion controller! In return for customers, we

will be first-class quality motion controller, perfect after-sales service, efficient

technical support, to help you complete the production of equipment.

More information about Trocen products

The company's website is www.sztrocen.com/www.awc608.com. You can find

out more about our company and products on our website, including: company

profile, product introduction, technical support and latest releases, etc.

You can also call 0755-27958262 for more information about the company and

its products.

Technical support and after-sales service

You can obtain our technical support and after-sales service through the

following ways:

Email: [email protected]

The phone number: 0755-27958262

Sent a letter to: 1stFloor, Building4, Zhiheng Strategic Industrial Park, Nantou

Pass, Nanshan District, Shenzhen city, Guangdong Province, China.

Shenzhen Trocen Automation Technology Co. Ltd.

Zip code: 518100

AWC7824 motion controller user manual

WWW.SZTROCEN.COM

3

Use

By reading this instruction, the user can understand the basic

operation of the AWC7824 control card.

Using the object

This manual is applicable to engineers who have a certain

understanding of mechanical automation operation such as laser

machines.

The main content

The basic operation and use of AWC7813 panel are introduced in

detail. This manual is based on version 1.20.8.12. There are subtle

differences between the versions.

The certification statement

CE certification statement

This product has passed the EU CE (Communate Europpene) safety certification,

has passed the corresponding conformity assessment procedure and the

manufacturer's conformity declaration, and complies with the relevant EU directives.

ROHS certification statement

The product has been certified safe by European Union legislation, the Directive

on Restriction of Certain Hazardous Substances in Electronic And electrical

Equipment, which conforms to the relevant European Union environmental

regulations.

AWC7824 motion controller user manual

WWW.SZTROCEN.COM

4

FCC certification statement

The product has been certified by the Federal Communications Commission

for safety and complies with U.S. electronic product safety regulations.

The relevant documents

《LaserCAD instructions》

AWC7824 motion controller user manual

WWW.SZTROCEN.COM

5

Catalogue

1. Product Description ............................................................................................. 10

1.1 Features ....................................................................................................... 10

1.2 AWC78XX Series Comparison. .................................................................. 11

1.3 Term/abbreviation ....................................................................................... 12

1.4 AWC7824 accessories composition .........................................................13

1.4.1 AWC7824 all accessories and connection diagram ............................ 13

1.4.2 List of accessories. .............................................................................. 14

1.5 Appearance and size of panel. .......................................................................15

1.6 Appearance and size of wiring board. ........................................................... 15

2. Hardware interface introduction ............................................................................. 18

2.1 Control system electrical wiring diagram ...................................................... 18

2.2 Wiring board unit port description and wiring diagram ................................18

2.2.1 Power port. ......................................................................................... 18

2.2.2 Universal input port ............................................................................19

2.2.3 Universal output port ......................................................................... 20

2.2.4 Laser power control port .................................................................... 21

2.2.5 Motor driver control port ................................................................... 22

2.2.6 Limit signal input port. ........................................................................23

2.3 Mainboard interface description ...................................................................26

2.3.1 U Disk interface ................................................................................26

2.3.2 USB interface. .................................................................................. 27

2.3.3 Ethernet interface ...............................................................................29

2.3.4 Panel and terminal board interface .................................................... 29

3. Human Machine Interface Introduction .................................................................. 31

3.1 Main Interface Preview ..................................................................................32

3.2 Function key area ...........................................................................................34

3.2.1 Reset ................................................................................................... 34

3.2.2 File .......................................................................................................34

3.2.3 Menu ...................................................................................................35

3.2.4 More. .................................................................................................. 36

3.2.5 Laser ....................................................................................................36

3.2.6 Box. ..................................................................................................... 37

3.2.7 Origin .................................................................................................. 37

3.2.8 Stop ................................................................................................... 38

3.2.9 Start. ....................................................................................................38

3.2.10 Pause .................................................................................................39

3.2.11 Interface switching ............................................................................40

3.3 Direction key area ..........................................................................................40

3.3.1 X, Y axis movement keys. .................................................................40

AWC7824 motion controller user manual

WWW.SZTROCEN.COM

6

3.3.2 Fast and slow movement switch key.................................................. 41

3.3.3 Z axis Movement Button ..................................................................42

3.4 Processing time display area ......................................................................... 43

3.5 Status display area ......................................................................................... 44

3.5.1 Lockscreen, unlockscreen ................................................................... 44

3.6 Coordinate display area ................................................................................. 45

3.6.1 The coordinate system with the machine zero in the upper left corner

..................................................................................................................... 45

3.6.2 The coordinate system with the machine zero in the upper right

corner ...........................................................................................................46

3.6.3 The coordinate system with the machine zero in the lower left corner

..................................................................................................................... 46

3.6.4 The coordinate system with the machine zero in the lower right

corner ...........................................................................................................47

3.7 Current processing file name display area .................................................... 47

3.7.1 The properties of the processing file ..................................................47

3.7.2 Layer parameters of processing files .................................................. 49

3.8 Count display area. ........................................................................................ 51

3.9 Speed display area ......................................................................................... 53

3.9.1 Quickly modify the key move speed instand by mode .......................53

3.9.2 Modify the speed of the file being processed .................................... 54

3.10 Power display area. ......................................................................................55

3.10.1 Modify Laser power ..........................................................................55

3.10.2 Modify the power of the file being processed ................................. 57

3.11 File operations. ............................................................................................ 58

3.12 U disk transfer files and mainboard upgrade. .......................................... 60

3.12.1 Use U disk to transfer files to mainboard ......................................... 60

3.12.2 Upgrade the mainboard ................................................................... 61

3.13 Origin Manage .......................................................................................... 62

3.13.1 Set origin coordinates ....................................................................... 63

3.13.2 Move the laser head to the set origin .............................................. 63

3.14 Motion Parameters Settings ........................................................................ 64

3.14.1 Description of each parameter .........................................................65

3.14.1.1 Space Speed ...........................................................................66

3.14.1.2 Cut Jerk .................................................................................. 66

3.14.1.3 Space Jerk. ............................................................................. 66

3.14.1.4 Min Acc. ................................................................................. 67

3.14.1.5 Engrave Acc ............................................................................67

3.14.1.6 Start Speed .............................................................................68

3.14.1.7 Speed Factor .......................................................................... 68

3.14.2 Example analysis ............................................................................... 69

AWC7824 motion controller user manual

WWW.SZTROCEN.COM

7

3.14.2.1 Wavy lines appear when cutting arcs .................................... 69

3.14.2.2Wavy lines appear at the beginning and corners of the cutting

............................................................................................................. 69

3.15 Common Parameters Settings ..................................................................... 70

3.15.1 Work Mode ....................................................................................... 70

3.15.1.1 Go Origin After Reset. ............................................................71

3.15.1.2 Origin Mode. ..........................................................................71

3.15.1.3 Go Back Position .................................................................... 72

3.15.1.4 Count Mode ........................................................................... 72

3.15.2 Common Parameters........................................................................ 74

3.15.2.1 AutoFocus Distance(mm) ................................................... 78

3.15.2.2 KeyMove’Speed(mm/s) ...................................................... 78

3.15.2.3 RunBox’Speed(mm/s) ......................................................... 79

3.15.2.4 CutBox’Speed(mm/s) ..........................................................79

3.15.2.5 Blow Open Delay(s) ................................................................79

3.15.2.6 Blow Close Delay(s). ...............................................................79

3.15.3 Axis Speed Parameters..................................................................... 80

3.15.3.1 Z Work Speed(mm/s). ......................................................... 81

3.15.3.2 X Y Home Speed(mm/s) ......................................................81

3.15.3.3 Z Home Speed(mm/s.......................................................... 81

3.15.4 Rotate Engraving & Cutting ...............................................................82

3.16 Manufacturer Parameters Settings ..............................................................86

3.16.1 Axis Parameters (take X axis as an example) .................................... 86

3.16.1.1 Distance Per Pulse(um) ..........................................................88

3.16.1.2 Valid Pulse Edge ..................................................................... 91

3.16.1.3 Datum Direction .....................................................................91

3.16.1.4 Key Direction ..........................................................................92

3.16.1.5 Limit-Switch Valid Level ......................................................... 92

3.16.1.6 Range(mm). ........................................................................... 93

3.16.1.7 Start Speed .............................................................................93

3.16.1.8 Max Acc ..................................................................................93

3.16.1.9 Max Speed ............................................................................. 93

3.16.1.10 Zero Offset ........................................................................... 94

3.16.2 Laser Parameters. ............................................................................. 94

3.16.2.1 Laser Mode. ........................................................................... 95

3.16.2.2 TTL Valid Level ........................................................................96

3.16.2.3 PWM Frequency(hz) .............................................................. 96

3.16.2.4 Max Power(%) ........................................................................96

3.16.2.5 RF Min Power(%) ................................................................... 97

3.16.2.6 Laser 1 Water Protect. ........................................................... 97

3.16.3 IO Parameters................................................................................ 97

AWC7824 motion controller user manual

WWW.SZTROCEN.COM

8

3.16.3.1 Foot Switch ............................................................................ 98

3.16.3.2 Open Protection .....................................................................99

3.16.3.3 Input Valid Level ............................................................... 101

3.16.4 Auto Reset Settings. ........................................................................100

3.16.5 HardLimit Settings ...........................................................................102

3.16.6 Function Configuration. .................................................................. 109

3.16.6.1 Z-Axis For Autofocus ......................................................... 111

3.16.6.2 Y&Z Double-Driver Control.. ............................................. 114

3.17 Network Settings ....................................................................................... 116

3.18 Language ....................................................................................................118

3.19 System Version ...........................................................................................120

3.20 Input Test. .................................................................................................. 120

3.21 Output Test. ............................................................................................... 121

3.22 Cut Box. ......................................................................................................122

3.23 Axis Reset. ..................................................................................................124

3.24 Key Moving ................................................................................................ 125

3.25 Z AutoFocus, X&Y to Origin and Continue to Previous Work ................126

3.25.1 Run Z AutoFocus function ...............................................................127

3.25.2 Set X&Y to Origin ............................................................................ 129

3.25.3 Continue to Previous Work .............................................................129

4. Frequently Asked Questions .................................................................................. 132

4.1 What kind of U disk can the system read? .................................................. 132

4.2 Why does the prompt "Engrave beyond border limit!"appear................... 133

4.3 Why doe sthe prompt "Beyond border limit ! Continue?"appear .............. 134

4.4 Why does the prompt "Beyond border limit!"appear .................................138

4.5 Why does the prompt"Trigger limit!"appear .............................................. 138

4.6 Why does the prompt "Nofile!"appear ....................................................... 139

4.7 Why does the prompt To select the file!"appear.........................................140

4.8 Why does the prompt"Continue to work?"appear......................................141

4.9Why does the button movement speeds low down after turning on the

rotary engraving function? ................................................................................ 142

4.10 Why does the prompt"water protect!"appear ..........................................142

4.11 Why does the prompt"opened protected!"appear ...................................143

5. Operation process description. ..............................................................................145

5.1 Machine installation and debugging process. ............................................. 145

5.2 Basic steps of using the laser machine to cut graphs .................................. 146

AWC7824 motion controller user manual

WWW.SZTROCEN.COM

9

1.Product description

Features

AWC78XX Series comparison

Terms/abbreviations

AWC7824 accessories composition

Appearance and size of panel

Appearance and size of wiring

board

1.产品介绍

AWC7824 motion controller user manual

WWW.SZTROCEN.COM

10

1. Product Description

1.1 Features

AWC7824 is a general-purpose motion controller used in laser cutting, laser

engraving and other fields, suitable for all kinds of small and medium power laser

cutting and engraving equipment .AWC7824 motion controller works with LaserCAD

software

AWC7824 motion controller has the following features::

5-inch TFT LCD touch screen ,intuitive and simple operation interface

Two road laser control

Four-roads motion axis control (X axis, Y axis, Z axis ,U axis )

Using high-speed DSP main control chip, fast calculation

speed,advanced motion algorithm

All optocouplers isolate external electromagnetic interference, and the

system works stably and reliably

Support U disk, network and USB communication methods

Support Z-axis autofocus, Y-axis dual drive function

Support full blowing, work blowing, layer blowing

Support double-head mutual movement, support over size cutting

Support Y-axis drum cutting, Y@U-axis synchronous feeding, Y-axis double

limit

Support U-axis automatic feeding or optional U-axis as rotation axis

Support dispensing function

Support system startup delay, choose whether to turn off the system

sound

AWC7824 motion controller user manual

WWW.SZTROCEN.COM

11

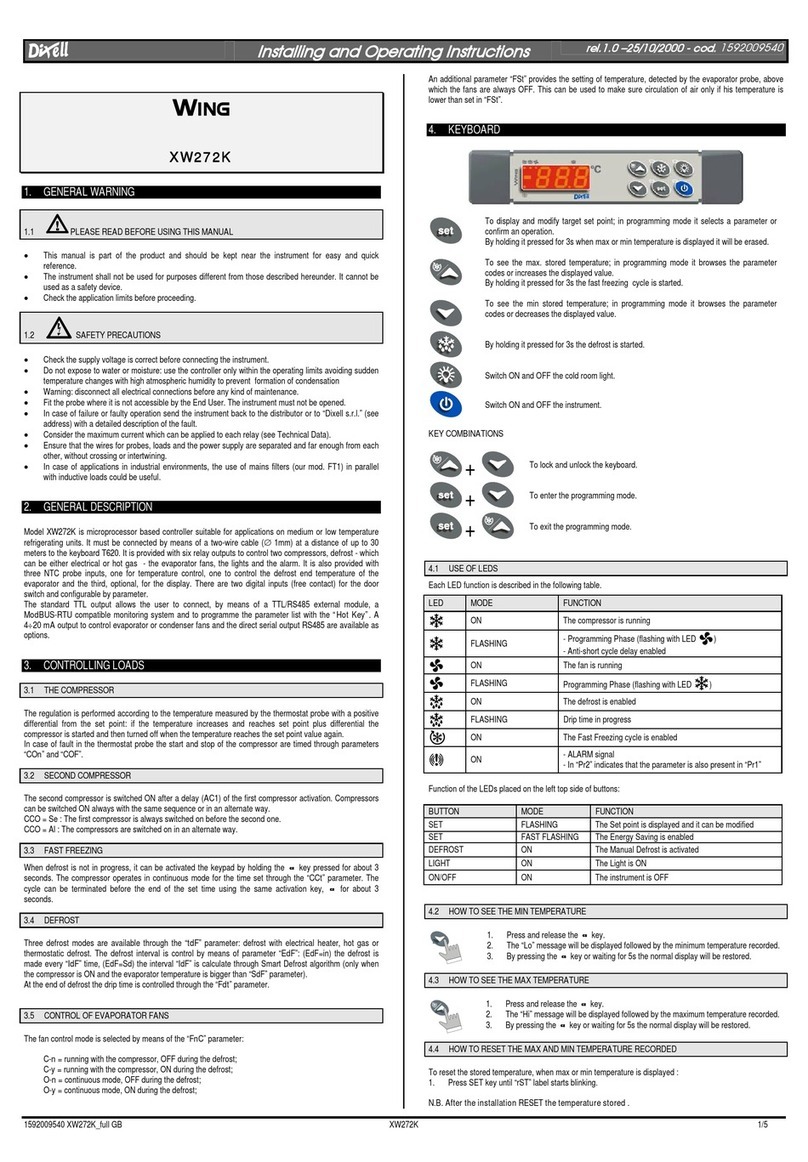

1.2 AWC78XX Series Comparison

AWC78XX Series comparison

AWC7813

AWC7824

AWC7846

Hardware

screen

5-inch touch

screen

5-inch touch

screen

5-inch touch

screen

Universal output port

8roads

8roads

8roads

Universal input port

6roads

6roads

6roads

Control axis

3axes

4axes

6axes

Control laser

1road

2road

4roads

Memory size

128M

128M

128M

Data transmission method

Network communication,USB communication,U

disk

Support laser

Various DC lasers,RF lasers,CO2 lasers

Function

Input test interface

Yes

Yes

Yes

Output test interface

Yes

Yes

Yes

Button speed and slow

movement function

Yes

Yes

Yes

Single axis quick reset operation

Yes

Yes

Yes

Quickly return to the positioning

point

Yes

Yes

Yes

Modify power and speed online

Yes

Yes

Yes

Modify layer parameters offline

Yes

Yes

Yes

Modify file processing attributes

offline

Yes

Yes

Yes

Modify factory parameters

Yes

Yes

Yes

Counting function

Yes

Yes

Yes

Graphic preview of processing

files

Yes

Yes

Yes

Processing file completion

progress display

Yes

Yes

Yes

Real-time follow-up display of

cutting file graphics

Yes

Yes

Yes

Multi-head shift number

No

2roads

4roads

AWC7824 motion controller user manual

WWW.SZTROCEN.COM

12

Dispensing function

No

Yes

Yes

Z-axis auto focus function

Yes

Yes

Yes

Y-axis dual drive function

Yes

Yes

Yes

Continue cutting function

Yes

Yes

Yes

Main board online upgrade

Yes

Yes

Yes

Automatic feeding,Y/U

synchronous feeding

No

Yes

Yes

Over-format cutting

No

Yes

Yes

Drum cutting function

No

Yes

Yes

Blow by layer

Yes

Yes

Yes

Dispensing function

No

Yes

Yes

Y-axis double limit

No

Yes

Yes

System startup delay

No

Yes

Yes

Turn off system sound

yes

Yes

Yes

Set the U axis as the rotation

axis

No

Yes

Yes

1.3 Term/abbreviation

Table 1-3 Explanation of terms and abbreviations

Term/abbreviation

explain

PC software

Laser CAD software is dedicated software for Trocen laser

motion controller.

TFT LCD panel

LCD panel

Control panel

Panel (Mainboard)

Refers to the 5-inch TFT color LCD touch control panel.The

panel is used for specific display and control operations

and is an important part of the system.

Wiring board(base

plate)

The wiring board is a control board that controlling

integrated signal input and output and connecting motor

driver.

System hardware

The physical objects visible to the

AWC7824 motion controller user manual

WWW.SZTROCEN.COM

13

system,including:panel,wiring board,wires,etc.

1.4 AWC7824 accessories composition

After receiving the product, please confirm whether the product and accessories are

complete. If there is any missing, please contact Shenzhen Trocen Automation

Technology Co.Ltd. after-sales customer service.

1.4.1 AWC7824 all accessories and connection diagram

AWC7824 motion controller user manual

WWW.SZTROCEN.COM

14

1.4.2 List of accessories

Table 1-4-2 Product list

Name

Appearance

Description

Panel

(1piece)

AWC7824 Control panel

Wiring board

(1piece)

AWC7824 Wiring board (base plate)

USB cable

(1piece/3m)

Used by the computer to load files to

the panel

Cable

(1piece/5m)

Used by the computer to load files to

the panel

CN Cable

(1piece/1.6m)

Connect the CN1 port of the panel and

wiring board

USB extension

cable

(1piece/0.5m)

AWC7824 motion controller user manual

WWW.SZTROCEN.COM

15

Network

extension

cord(1piece/0.5m)

Screw (2pcs)

Used to fix the panel

1.5 Appearance and size of panel

Figure 1-5-1 Panel appearance display

Figure 1-5-2 Panel size diagram

1.6 Appearance and size of wiring board

Figure 1-6-1 Appearance display of wiring board

5-inch touch screen

U Disk Jack

AWC7824 motion controller user manual

WWW.SZTROCEN.COM

16

209mm

Figure 1-6-2 Wiring board size diagram

195mm

2.硬件接口介绍

AWC7824 motion controller user manual

WWW.SZTROCEN.COM

17

2.Hardware interface introduction

Control system electrical wiring diagram

Wiring board unit port description

and wiring diagram

Mainboard interface description

AWC7824 motion controller user manual

WWW.SZTROCEN.COM

18

2. Hardware interface introduction

2.1 Control system electrical wiring diagram

2.2 Control system electrical wiring diagram

2.2.1 Power port

It is used to supply power to the wiring board and the panel. When connecting,

be careful to the positive and negative poles. Generally need DC24V 3A switching

power supply.

AWC7824 motion controller user manual

WWW.SZTROCEN.COM

19

Terminal number

Terminal name

Description

1

24V

24V power supply positive

2

GND

24V power ground

2.2.2 Universal input port

The wiring board provides two sets of input signal terminals for the collection of

input signals. The default value of all input valid signals is 0V,and the default value of

waiting signal is 24V when not working.

Terminal group

Silk screen

Description

6P terminals

24V

24V power supply positive output

IN4

Reserved input signal

IN3

Reserved input signal

IN2

Foot switch signal

IN1

Open protection signal

GND

Power ground-output signal

4P terminals

24V

24V power supply positive output

IN6

Reserved input signal

IN5

Reserved input signal

External earth-output signal

The signal input electrical wiring diagram is as follows:

IN1:door open

IN2:foot pedal

close on contact

Table of contents

Other Trocen Controllers manuals

Popular Controllers manuals by other brands

MidNite Solar

MidNite Solar Classic 250 owner's manual

National Instruments

National Instruments PXI-8186 installation guide

TANDBERG

TANDBERG Border Controller user guide

Sony

Sony JumboTron operating instructions

Meaco

Meaco LAE quick start guide

Endress+Hauser

Endress+Hauser Liquiline CM442 Brief operating instructions