Product Code: 3054

Made in China to TQB Brands Pty Ltd specifications.

Visit us at www.tqbbrands.com.au Page | 5

3. BEFORE USE

Prior to each use conduct a visual inspection by checking for abnormal conditions, such as

cracked joints and damaged, loose, or missing parts.

4. OPERATION

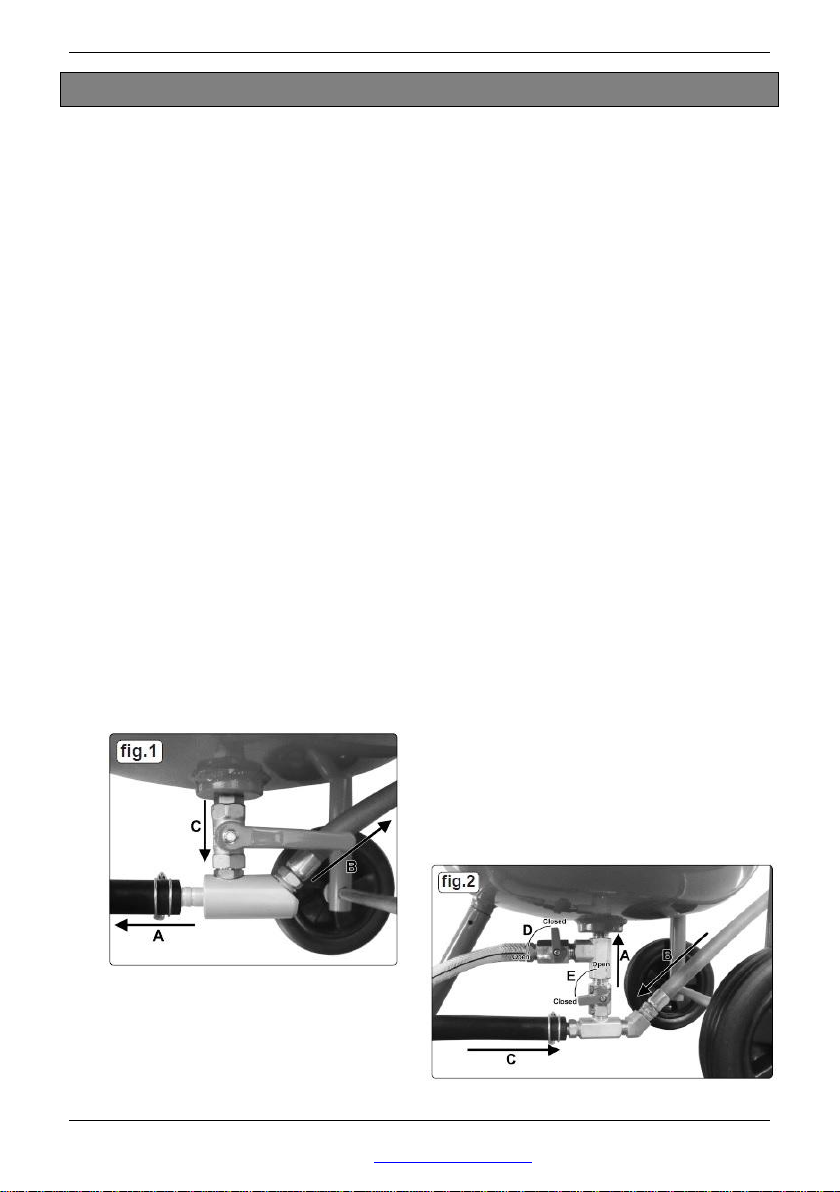

Using the Soda Blasting Manifold

1. Before blasting ensure both valves on the manifold are in the closed position (fig.2).

2. After following the correct procedure in the manual for 3060, 3008 and 3032, open

the lower soda metering valve (fig.2E).

3. If at some point the blaster gets clogged up, close the lower valve and open the

exhaust valve (fig.2D), only open for a short time and ensure the hose is directed into

a container or away from people and the work piece.

NOTE: Please refer to the manual for 3008 and 3032 for all maintenance instructions.

5. STORAGE

This Soda blasting retro fit kit should always be stored in a dry location.

6. MAINTENANCE

Turn off, or disconnect from, air supply before servicing or performing any maintenance

and when unit is not in use. Failure to comply with this instruction may damage the unit

and will invalidate your warranty.

Replace or repair damaged parts. Use recommended parts only. Non authorised parts

may be dangerous and will invalidate the warranty.

Keep the soda blasting retro fit kit clean for best and safest performance.

7. SERVICE & REPAIR

Any Soda blasting retro fit kit found damaged in any way, or found to be worn or operates

abnormally should be removed from service until repaired by an authorised service agent.

Owners and / or operators should be aware that repair of this product may require

specialised equipment and knowledge. Only authorised parts, labels and decals shall be

used on this equipment. Annual inspection of the soda blasting retro fit kit is

recommended and can be made by an authorised repair facility to ensure that your

equipment is in optimum condition and that the equipment has the correct decals and

safety labels specified by the manufacturer.