TradeWeld TIG 200 DC User manual

1

2

CONTENTS

Contents & Explanation of Symbols ······················································································2

Safety Warning & Duty Cycle Explained ·················································································3

Machine Description & Technical Specification ·······································································4

Accessories ·······················································································································5

Installation & Operation ·······································································································6

Front Panel layout & TIG Welding Tips···················································································7

Operating Precautions·········································································································8

Maintenance·······················································································································9

Troubleshooting & Fault Finding & TIG Welding······································································10

TIG 200D Explosion Diagrams & Part List···············································································11

Warranty & Owners Records·································································································12

EXPLANATION OF SYMBOLS

The rating plate on your machine and/or the manual may show certain symbols.

These represent important information about the product or instructions on its use.

Conforms to relevant safety standards.

To reduce the risk of injury, user must read instruction manual.

Do not dispose of old appliances with domestic rubbish.

Wear hearing protection.

Wear eye protection.

Wear respiratory protection.

Attention.

Caution

3

SAFETY WARNING

In the process of welding, there could be possibilities of injury, so please take

protection into consideration during operation. For more details please read the

Operator Safety Guide, which complies with the preventive requirements of the

manufacturer.

Electric shock——Can kill !

Set the earth fitting according to applying standard.

Do not touch the bare electric parts and electrode with uncovered skin, wet gloves or clothes.

Make sure you are insulated from the ground and the work piece.

Think safety first.

Gases and fumes——May be a health hazard!

Keep your head out of the gases and fumes produced by welding.

When welding, ventilators or air extractors should be used to avoid breathing in the gases.

Wear suitable respiratory protection

Arc rays——Harmful to your eyes and will burn your skin.

Wear suitable protective mask, light filter and protective garment to protect eyes and body.

Prepare suitable protective mask or curtain to protect bystanders.

Fire——Fire extinguishing equipment kept nearby!

Cutting spark may cause fire, make sure there are no flammable materials or liquids around the working area.

Noise——Excessive noises will be harmful to your hearing.

Use ear protector or others means to protect ear.

Warn bystanders that noise is harmful to hearing.

Malfunction——Use qualified technician to repair machine.

If faulty during installation and operation, please follow this manual instruction on fault finding.

If you fail to fully understand the manual, or fail to solve the problem with the instructions, you should contact the

suppliers or the service centre for professional help.

DUTY CYCLE 60%

Duty Cycle is a percentage of 10 minutes that the unit can weld at rated load without overheating. If unit overheats,

thermostat(s) opens, output stops and the cooling fan runs. Wait fifteen minutes for unit to cool down. Reduce

amperage, or duty cycle before welding again.

Exceeding the duty cycle can damage the machine and void the warranty

CAUTION

WORKING LONGER THAN RATED DUTY CYCLE

CAN DAMAGE MACHINE AND VOID WARRANTY

4

MACHINE DESCRIPTION

Thank you for purchasing a TRADEweld product. The TRADEweld TIG 200 DC Inverter is

manufactured to the highest standards.

Adopting the most advanced inverter technology, it uses power Inverters and PWM technology,

which works by rectifying the mains AC input voltage. The rectified input voltage is then inverted

and filtered to a smooth DC current. The smoothed DC current is then sent through power

switches (Mosphets) which convert it back to a high frequency AC voltage. The AC voltage is then

stepped down by a transformer and rectified to DC. The rectified DC is then filtered and smooth for

a usable power output for welding.

The development of inverter welding equipment has massive benefits which include greatly

reduced size and weight, greater power efficiency, multi-process capabilities and many more. The

inverter welder’s power source produces a much stronger and concentrated stable arc which

results in better quality and more efficient welds.

With the High frequency and gas valve added to the inverter welding machine, it makes TIG

welding easer to master.

The TIG 200D is a constant current DC MMA & TIG inverter welder. It can TIG weld stainless steel,

carbon steel, copper, and can also be used for standard arc (MMA) welding.

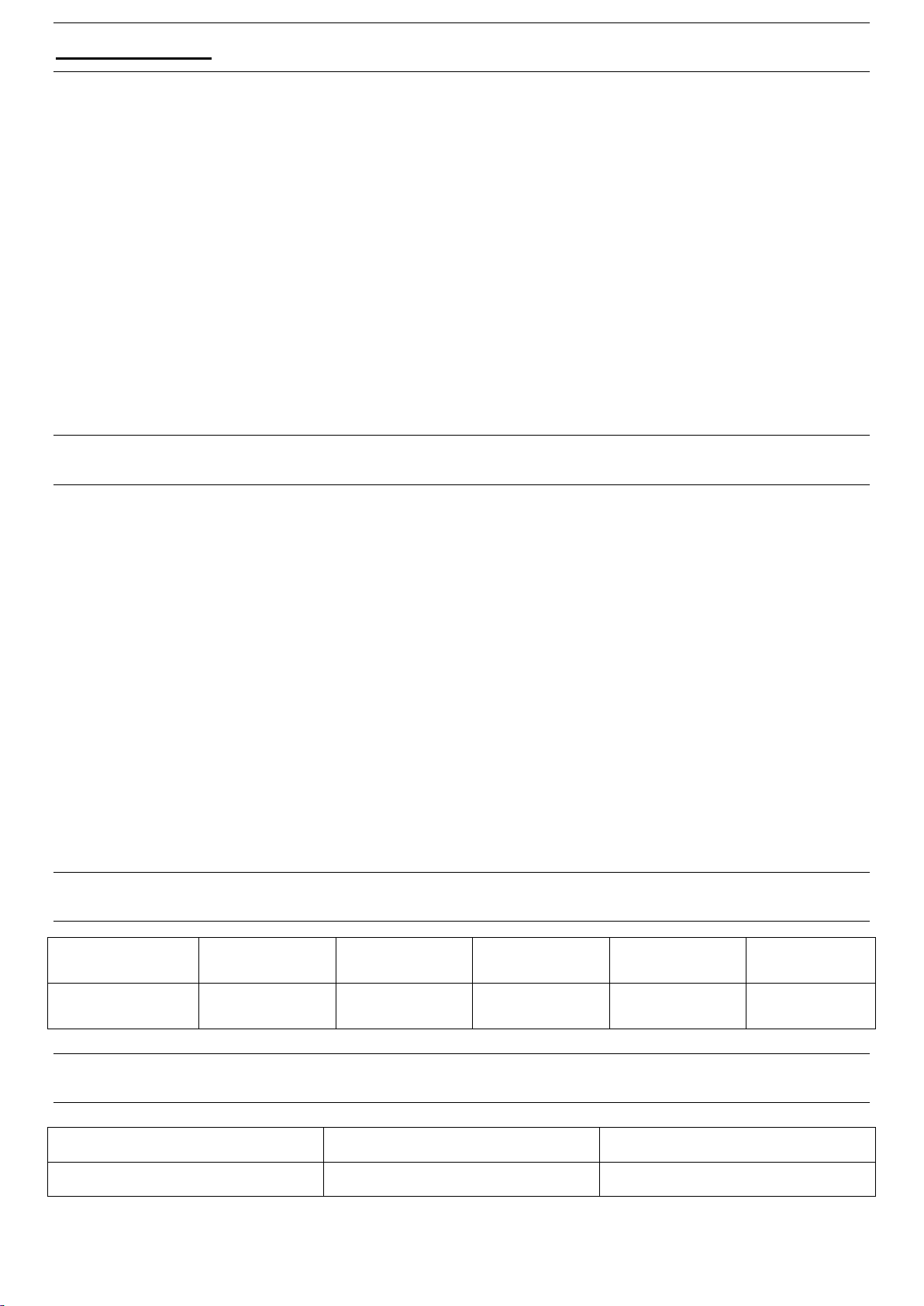

TECHNICAL SPECIFICATIONS

MODEL

TIG 200D

Rated Input Voltage

AC220V±10%

1Phase

Frequency(Hz)

50/60

Input Current ( A )

TIG

MMA

28

38.1

Output voltage (V)

TIG

MMA

18

27.2

Output Current (A)

TIG

MMA

10 –200

30 –180

No load Voltage DC (V)

50-80

VRD (Volt safe)

Yes - 20V

High Frequency Start

yes

Duty Cycle

60%

Efficiency(%)

80

Power Factor

0.73

Protection Class

IP21

Dimension L x W x H (mm)

465×345×360

Weight (kg)

13.6

5

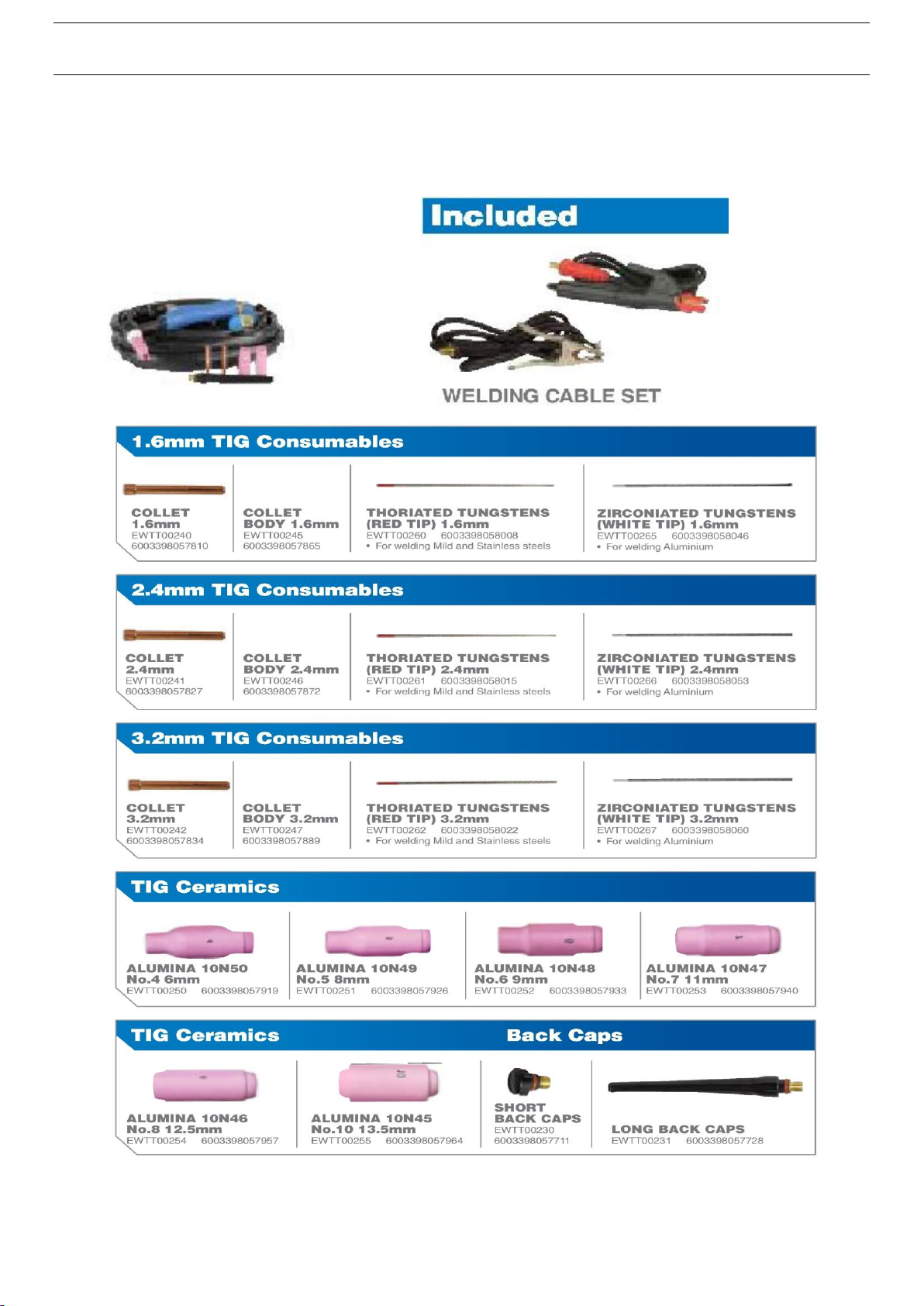

ACCESSORIES & CONSUMABLES

Supplied with the TIG 200D in the box is the following:

1 x WP17 torch 1 x earth clamp and cable

1 x 2m gas pipe 1 x electrode holder and cable

2 x hose clamp

WP17 TIG TORCH

EWTT00200

6

INSTALLATION

1. MMA: The electrode holder and earth clamp are easily connected to the machine by inserting the quick connector

and twisting it clockwise. Always ensure a tight fit. Please pay attention to the connection polarity.

Generally, Reverse Polarity is used in which the welders electrode holder will be connected in the “+” Positive

Terminal while the earth clamp in the “-”Negative Terminal. The welder does have the ability to be used for

Straight Polarity or Reverse Polarity. We recommend you connect the polarity in accordance with the electrode

recommendations. If the polarity is connected incorrectly it will cause an unstable arc, spatter, and/or the electrode

to stick. If these symptoms occur change the polarity.

2. TIG torch: Fit the gas and power cable nut to the center connector on the front panel, and fasten clockwise and

the trigger plug to the front panel; connect the earth cable quick connector to the right side dinse connector.

3. Connect the Gas hose to the back of the machine and to the Argon regulator and fit the regulator to an Argon gas

bottle. (NB: Secure the gas bottle to a gas trolley or wall to prevent falling over)

4. Turn the machine on via the ON OFF switch located at the rear of the machine, digital current meter is on, fan

begins to rotate.

NB: When TIG welding disconnect the electrode holder or when MMA welding disconnect the TIG torch.

OPERATION

MMA:

1. On the front panel select MMA process.

2. Adjust welding current and make sure the welding current is adequate for the thickness of the material.

3. Strike an arc by touching the electrode to the work piece.

TIG:

1. On the front panel select TIG process.

2. Open the valve of the argon gas cylinder and adjust the flow rate to 10 –15 LPM Liters per minute.

3. Select the gas post flow of 2 or 5 seconds. (2s - for short or low amperage welds, 5s for long or high amp welding)

4. Press the switch on torch, the gas valve clicks and HF can be heard in the machine, at the same time Argon gas

will flow from the TIG torch. NOTES: Trigger the torch to disperse air out the pipes and to let the Argon gas flow

through. After welding Argon gas will still flow out for several seconds (Post flow) in order to protect the welding

spot and to cool the tungsten.

5. Adjust welding current and make sure the welding current is adequate for the thickness of the material.

6. The welding tungsten is held 2 to 4mm away from the material, press the torch trigger an arc will jump from the

tungsten to the work piece striking an arc the HF sound will stop. DC TIG welding is very quiet weld.

ELECTRODE CHART GUIDELINE

TIG CHART GUIDELINE

1.6mm Thoriated Tungsten

2.4mm Thoriated Tungsten

3.2mm Thoriated Tungsten

10 –120 A

80 –180 A

150 –320 A

Electrode size

6013

2.0 mm

2.5 mm

3.2 mm

4.0 mm

5.0 mm

Amperage

50 –80 A

60 –100 A

100 –140 A

150 –210 A

200 –280 A

7

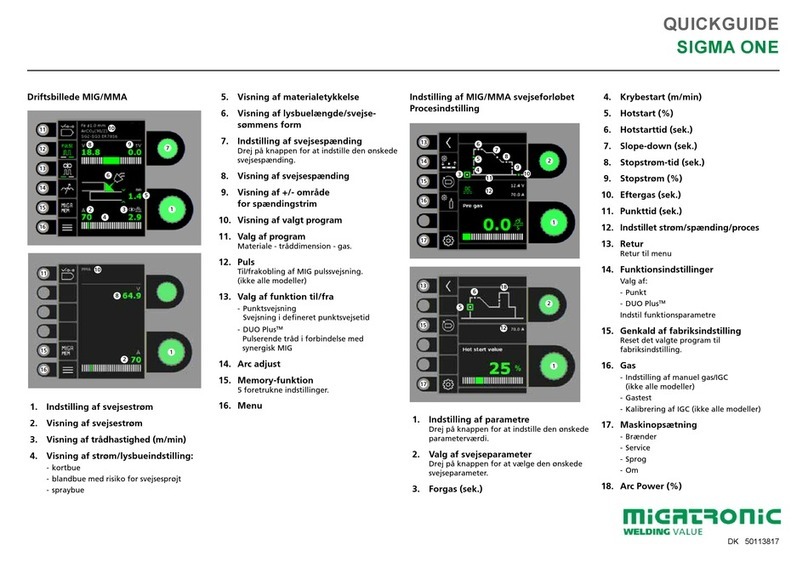

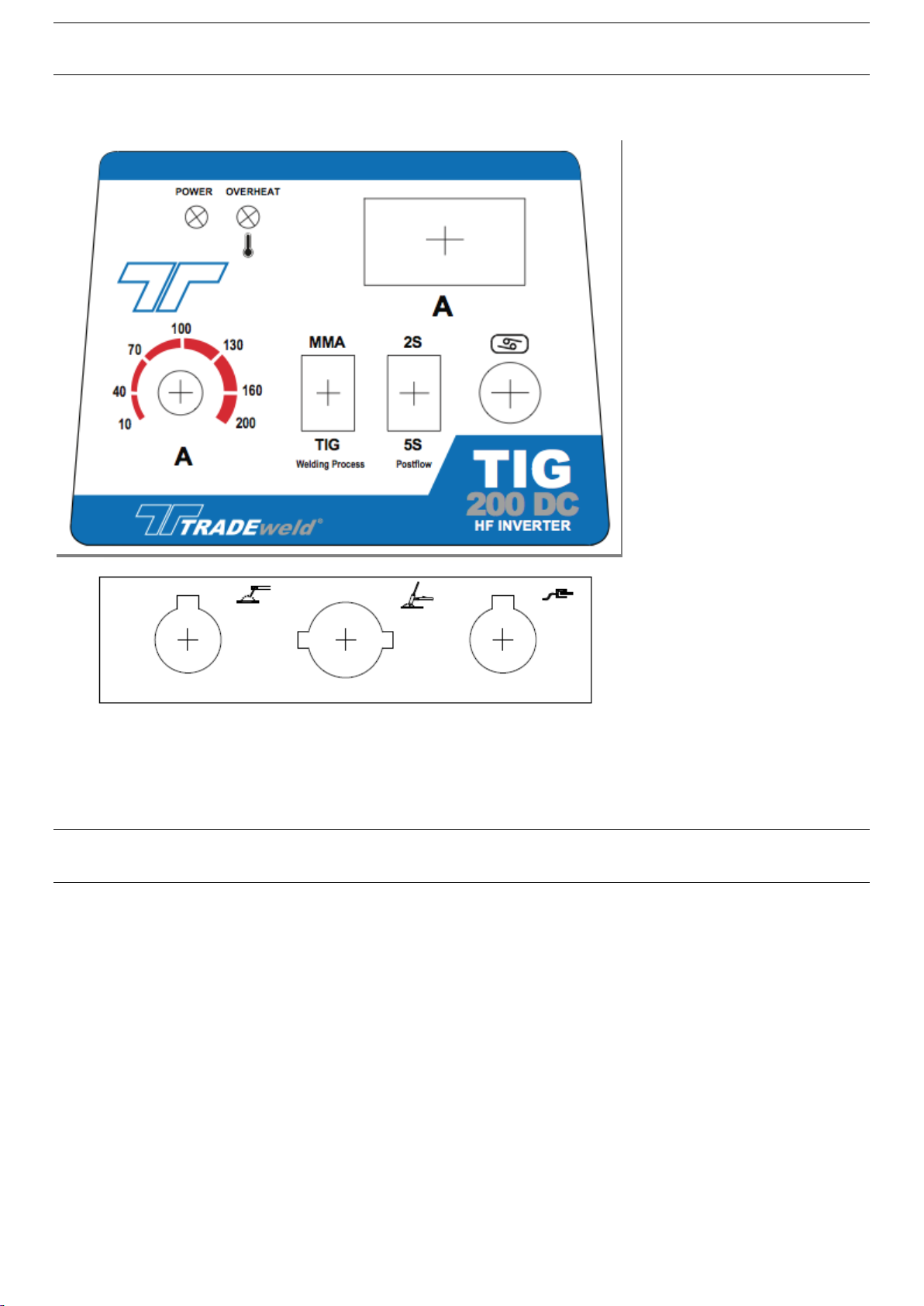

FRONT PANEL LAYOUT TIG 200D

TIG WELDING TIPS

Sharpen tungsten point length to 1.5 times the thick ness of the tungsten.

Make sure grinding marks are in line with the tip.

Weld in the same direction the gas is flowing. (Leaves smoke marks if pulling)

Dip the filler rode in front of the pool (in front of direction you are moving)

Practice on same type material you are going to weld on.

If tungsten burns away too fast –lower the amperage or use thicker tungsten.

8

OPERATING PRECAUTIONS

1. Operating Environment

a. The machine can perform in environments where conditions are dry with a max humidity of 60%.

b. Ambient temperature should be between -10 to +40 degrees centigrade.

c. Avoid operating machine in direct sunshine, rain, or snow.

d. Avoid operating the machine in environments where there is pollution or high concentrations of dust or

corrosiveness gas in the air.

2. Proper Ventilation

All users must ensure proper ventilation of the welder. The welder is powerful and compact which generates high

currents and heat. Wind alone cannot ensure proper cooling so it is advisable to place a fan to cool down the machine

during hot weather or continuous usage in order to keep the components working for a long shelf life. Make sure the

machines vents or built-in fans are not blocked or covered and it’s receiving proper ventilation. Keep the welder at a

minimum of 30cm from any objects to ensure proper ventilation.

3. Avoid Overvoltage

The specific power voltage can be found in the main technical specification chart listed above or on the rear plate of

the machine. The automatic voltage compensation circuit will ensure that the welding current is functioning in the

correct range. If the power voltage is exceeded from the max allowed value it will damage the components of the

machine.

4. Avoid Overloading

Limit the welding current strictly to the max allowable duty cycle. Do not exceed the max load because overloading

can damage and burn up the machine.

5. Duty Cycle

Duty cycle refers to the percentage of the working time against a 10-minute work cycle. For example, if the welder has

a 60% duty cycle at 200A this means you can run the welder at 200A for 6 min in a 10 min work cycle. The remaining

4 minutes will be needed to let the machine cool down. If the welding current decreases, the duty cycle will increase

and vice versa.

Do not operate over the recommended duty cycle of the welding machines or damage will occur to the machine that is

irreversible. When output exceeds the duty cycle limit, the temperature within the welding machine will rise and the

protective circuit will cut off the power source output. The power output will then resume operation only when the

equipment has cooled down to normal temperature.

Note: Continuous overload operation will damage the welding power source. In these cases, the damage is not

covered by warranty repair.

WARNING! This machine produces an electromagnetic field during operation. This field may under some

circumstances interfere with active or passive medical implants. To reduce the risk of serious or fatal injury, we

recommend persons with medical implants to consult their physician and the medical implant manufacturer before

operating this machine.

9

MAINTENANCE

1. Remove dust with dry, clean compressed air regularly, if the welding

machine is operated in an area where the air is polluted with smoke and

dust, the machine needs to be cleaned regularly, remove dust monthly.

2. Pressure of compressed air must not be more than 5 bars in order to

prevent damage to small components inside the machine.

3. Check inside the welding machine regularly and make sure the output

terminals are connected tightly and connectors are not damaged. If burnt,

loose or damaged please tighten or replace if necessary. Beware of moving

parts.

4. Avoid water and steam entering into the machine, if the welding machine

dose get wet please dry inside the machine and check the insulation of

machine.

5. If the welding machine will not be operated for long periods it should be

put into a box or covered and stored in a cool dry area.

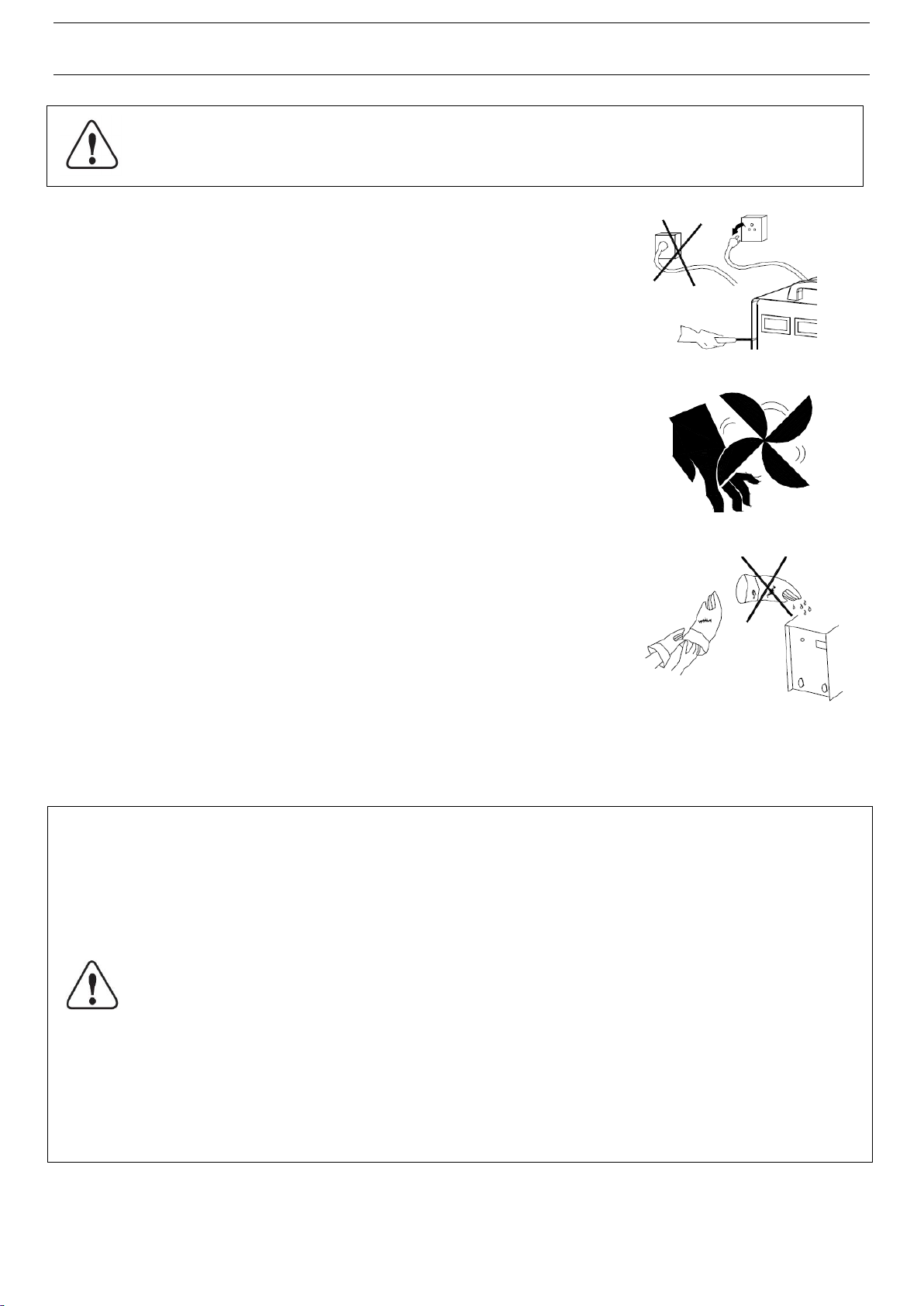

WARNING!

Before maintenance and checking, power must be turned off,

Before opening the cover disconnect the machine from electricity!

WARNING!

This machine is mainly used in the welding industry. It will produce Electric

& Magnetic fields, so the operator should insure proper protection/screening

is used

Earth leakage-circuit breaker should be used with this machine!!!

During welding, DO NOT pull out or insert any plugs or cables, it can lead to

life-threatening danger and cause damage to the machine.

Before connecting cables make sure the power is off.

The correct way is to connect the cables to the machine first, and make sure

they are firmly tightened and then connect the power plug to the power

source.

10

TROUBLESHOOTING AND FAULT FINDING

Notes: only attempt to repair this machine if you have knowledge and understanding of electronic components and the

dangers of electricity and components holding a charge of high voltage electricity. Before maintenance contact us for

authorization is suggested.

DO NOT REPAIR OR MODIFY MACHINE IF STILL UNDER WARRANTY

If the machine fails to work after maintenance and checks, please contact your local distributor or our

after-sale service center.

WARNING! Experimentation and careless maintenance may lead to more

problems to the machine. This will make formal diagnostic and repair more

difficult. When the machine is open there may be exposed connections

containing life-threatening voltages. Any direct or indirect touch will cause

electric shock, and severe electric shock will lead to death.

Faults

Remedy

Porosity in the

weld

The cause of porosity is from oxygen (air) contaminating the weld. To prevent this check the

following:

1) Make sure the valve of Argon cylinder is opened and has enough pressure.

2) Check if the flow meter is opened and has enough flow .User can choose different flow

rates according to welding current in order to save gas .But too little gas flow may cause

porosity because not enough shielding gas is covering the welding spot. We suggest that

flow of argon must be kept minimum 10L/min.

3) Check if torch or gas hose is not blocked, damaged, pinched, melted or has any holes.

4) The welding material might be contaminated with oil or dirt.

5) Strong wind will lower the welding quality.

Power indicator is

not lit, fan does

not work and no

welding output

1. Make sure power switch is working.

2. Check connections from ON switch to power board are in good condition, check continuity

of ON OFF switch.

3. Check if the plug point you are using is working.

4. Check if supply voltage is correct

5. Auxiliary power board might be faulty.

6. Control board might be faulty.

Power indicator is

lit, fan works, no

welding output

1. Check if all cables are connected properly.

2. Output connector is disconnected or damaged.

3. Control circuit might be faulty.

QC (Quality

Control) indicator

is on permanently

1. Can be in overheat protection; wait for 15 minutes.

2. Maybe it is overcurrent protection, turn machine off for 30 seconds then switch on again. If

still not working there is a fault on the MOS board.

3. Mosphets on control board might be faulty.

4. Fast recovery diodes or transformer might be faulty.

Output Current is

not stabilized

1. Supply voltage is not stable.

2. 1K Potentiometer might be damaged?

3. There is harmful interference from supply voltage or other equipment?

4. Bad connections - Hot/bad connections or points on earth cable or electrode holder can

cause current to drop or be unstable.

Sound of HF

cannot be heard,

and arc welding

mode works.

1. Primary cable of H.F. transformer is not connected to power board firmly.

2. TIG / MMA Switch is damaged, replace it.

4. Check if HF control board components are damage, replace it.

11

TIG 200D EXPLOSION DIAGRAM

PART LIST TIG 200D

NO.

NAME

PART NO.

NO.

NAME

PART NO.

NO.

NAME

PART NO.

NO.

NAME

PART NO.

1

POT KNOB

EWS00013

8

GAS & POWER

CONNECTOR

EWPCB00066

16

AIR FLOW ENCLOSURE

23

SWITCH FILTER PCB

PHB-10-A

2

POT 1K/2W

EWS00014

9

OUTPUT PANEL

STICKER

17

FAN 220V

EW00101

24

LED BOARD

3

SELECTOR SWITCH

10

LEFT FOOT PAD

18

GROUND TERMINAL

25

MACHINE COVER

4

2 PIN MIC PLUG

EW0005

11

CHASIE FRAME

19

CROSS BEAMS

26

REAR PLASTIC COVER

2 PIN CABLE PLUG

EW00049

12

RIGHT FOOT PAD

20

CENTRE PCB PDB-09

EWPCB00056

27

HANDLE

5

DIGITAL DISPLAY

EWPCB00057

13

SOLENOID VALVE 220V

EW00054

TOP BOARD PMB-12

EWPCB00018

28

FRONT PLASTIC COVER

6

FRONT STICKER

14

CABLE GLAND

21

POWER BOARD PD-05

EWPCB00012

7

10-25 DINSE SOCKETS

EWC00060

15

POWER CABLE

22

ON / OFF SWITCH

EWS00017

12

WARRANTY

L&G Tool and Machinery Distributors warrant to the original purchaser only, that this product is free from

defects in material and workmanship. Subject to certain exceptions, L&G Tools & Machinery Distributors will

repair or replace any part on this product which, after examination, is determined by us to be defective in

material or workmanship for a period of twelve (12) months after the date of purchase unless otherwise noted.

Return of the product and all its accessories to the Retailer is required, together with a copy of the proof of

purchase should be included with the returned product. This warranty does not apply to damage that L&G Tool

and Machinery Distributors determines to be from repairs made or attempted by anyone other than L&G Tool

and Machinery Distributors authorized agents, misuse, alterations, abuse, normal wear and tear, lack of

maintenance, or accidents. This warranty does not include items considered as consumables.

Statutory Rights

This warranty is in addition to and in no way affects your statutory rights

Distributed

by

L&G Tool

&Machinery Distributors Limited

6

Kyalami Rd Westmead 3610 P.O. Box 15313 Westmead 3608 Telephone: 031-7176800, Fax:

031-7176868

OWNER’S RECORD

Please complete and retain with your personal records.

Model Name: Serial Number:

Purchase Date: (Date which equipment was delivered to original customer)

Distributor: Invoice Number:

Address:

City:

Country: Postal:

This manual suits for next models

1

Table of contents

Other TradeWeld Welding System manuals

Popular Welding System manuals by other brands

Lincoln Electric

Lincoln Electric PRO-CUT IM637-A Operator's manual

HURNER

HURNER HST-S-315 2.0 user manual

INNO Instrument

INNO Instrument IFS-10 user manual

Miller

Miller Millermatic 250X owner's manual

CEVIK PRO

CEVIK PRO CE-TITANCEL 210 instruction manual

Telwin

Telwin TECHNOMIG 240 WAVE instruction manual