Trafox SUPERINTEND IM-04PV User manual

Superintend IM-04PV Manual v10.571 English Rights to modify the content reserved

© Copyright Muuntosähkö Oy - Trafox 3.2.2022

SUPERINTEND IM-04PV

IMD Insulation Monitoring device for non-grounded (IT) electrical

networks for photovoltaic applications

Instructions for installation and use v10.571

PV

AC/DC

2© Copyright Muuntosähkö Oy –Trafox Superintend IMD

http://www.trafox.fi

Table of Contents

INSTRUCTIONS ..................................................................................................3

SYSTEM DESCRIPTION .......................................................................................4

INSTALLATION ...................................................................................................4

PHYSICAL CONNECTION ..................................................................................... 4

DEVICE MOUNTING............................................................................................ 4

RS-485 NETWORK CONNECTION ......................................................................... 7

SYSTEM CONFIGURATION ................................................................................... 7

USE ....................................................................................................................8

GENERAL .......................................................................................................... 8

IM-04PV UNIT ................................................................................................... 8

MENU STRUCTURE.......................................................................................... 9

MONITOR MENU ........................................................................................... 11

ALARM MENU ............................................................................................... 12

SETUP MENU................................................................................................ 14

ERRORS ...................................................................................................... 16

MODBUS RTU REMOTE CONTROL ................................................................... 16

TECHNICAL SPECIFICATIONS...........................................................................19

IM-04PV UNIT ................................................................................................. 19

HVC-15.100 UNIT ............................................................................................ 19

HVC-15.1000 UNIT .......................................................................................... 20

HVC-15.2000 UNIT .......................................................................................... 20

MECHANICAL DIMENSIONS ............................................................................... 21

Superintend IMD © Copyright Muuntosähkö Oy - Trafox 3

http://www.trafox.fi

INSTRUCTIONS

These instructions for use are intended for trained electrical engineering professionals.

The IM-04PV devices are marked with the symbol shown below, which indicates that if

the device has been installed incorrectly or used in violation of instructions, safety could

be jeopardised. The description of the symbol is presented in this manual instead of on

the device due to space constraints. Such sections are marked with the symbol shown

below.

A symbol indicating possible danger. A description of the symbol may be

placed on the device or provided in the instructions for use.

4© Copyright Muuntosähkö Oy –Trafox Superintend IMD

http://www.trafox.fi

SYSTEM DESCRIPTION

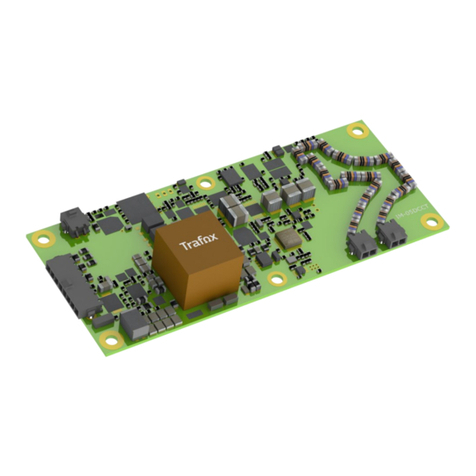

IM-04PV is a device with which the insulation resistance and capacitance of floating

electricity networks can be measured and monitored in photovoltaic applications. A high

voltage coupling device HVC-15.100, HVC-15.1000 or HVC-15.2000 (later abbreviated as

HVC-15.*) is mandatory and it must be used between the IM-04PV and the network to

be monitored. The type of the high voltage coupling device shall be selected so that

maximum leakage capacitance of the network will not exceed the rated maximum

capacitance of the coupling device (HVC-15.100: 100 uF; HVC-15.1000: 1000 uF; HVC-

15.2000: 2000 uF).

INSTALLATION

PHYSICAL CONNECTION

The devices are connected to the electrical network, which may contain

dangerous voltage. The device may be installed by a trained electrical

engineering professional only. The device contains no user-serviceable parts

and must not be opened. Using the device in violation of these instructions

may compromise safety.

The IM-04PV unit is the main unit of the system and is installed in the switchboard. Two

IM-04PV devices may not be installed galvanically in the same network, for example on

the same DC network. The connection is performed as presented in Figure 1. The

installation and wiring should be performed in accordance with standards IEC 60364 as

well as EN 50110. The operating voltage connection of IM-04PV must always be

equipped with a coupler or a line protection switch so that the electricity supply can be

disconnected for the duration of maintenance work, for example. The location of the

disconnectors must be clearly marked in the switchboard. The coupler or line protection

switch should also control a relay or contactor, which separates the measuring wires

from the network to be measured. The IM-04PV device is equipped with an internal 1 A

fuse. In spite of this, the wires of the operating voltage supply should still be protected

with an external fuse. A suitable size is, for example, 6 A. In a DC operating voltage

supply, an external Schurter 0001.2503 (T800mA) fuse should be used.

DEVICE MOUNTING

The IM-04PV and HVC-15.* devices are intended for installation in a DIN TS35 rail in

accordance with standard IEC 60715. They are installed by inserting the upper edge of

the DIN TS35 rail in the groove intended for the DIN TS35 rail on the back of the device

and by pushing the bottom edge of the device backward until the retaining latch clicks

into place.

The IM-04PV unit comes with the connections shown in the following table. The shaded

parts are optional and are installed as needed, while installing the other parts is

mandatory.

Superintend IMD © Copyright Muuntosähkö Oy - Trafox 5

http://www.trafox.fi

Category

Connector

Description

Operating

voltage

connection

Protective earth, to be connected to the earthing circuit connector

+/L

110…240 VAC, 48…62 Hz phase conductor, internal fuse 1A slow

+/-110…300 VDC, use an external fuse Schurter 0001.2503 (T800mA)

-/N

110…240 VAC neutral conductor

-/+110…300 VDC

RS-

485

SH

RS-485 cable shield / ground

A

RS-485 data+ (two-way data)

B

RS-485 data- (two-way data)

Measuring

connectors

TG

Alarm terminal of protective earth, to be connected to the PE rail

MG

Electronics protective earth, to be connected to the PE rail

M1

Connection 1 to HVC-15.*

M2

Connection 2 to HVC-15.*

ISOL.

Not used

Alarm relays

INS. ALARM NO

Alarm relay of the insulation resistance. NO-COM is an open circuit when

the alarm in inactive and closes when the alarm is active. NC-COM

functions in a reverse manner. Max load 250VAC/3A or 30VDC 3A

INS. ALARM NC

INS. ALARM COM

INS. WARN. NO

Pre-alarm relay of the insulation resistance. NO-COM is an open circuit

when the alarm in inactive and closes when the alarm is active. NC-

COM functions in a reverse manner. Max load 250VAC/3A or 30VDC 3A

INS. WARN. NC

INS. WARN. COM

The high voltage coupler HVC-15.* must always be installed between IM-

04PV and the network to be monitored. The network must not be connected

directly to IM-04PV.

The HVC-15.100 and HVC-15.1000 units to be installed in the switchboard have the

following connections, all of which must always be installed.

Connector

Description

M1

Connection 1 to IM-04PV

M2

Connection 2 to IM-04PV

L1

Connection 1 of the network to be monitored; Max 1081VAC/1500VDC

L2

Connection 2 of the network to be monitored; Max 1081VAC/1500VDC

The HVC-15.2000 unit to be installed in the switchboard has the following connections,

all of which must always be installed.

Description

Protective earth, to be connected to the earthing circuit connector

M1

Connection 1 to IM-04PV

M2

Connection 2 to IM-04PV

L1

Connection 1 of the network to be monitored; Max 1081VAC/1500VDC

L2

Connection 2 of the network to be monitored; Max 1081VAC/1500VDC

Superintend IMD © Copyright Muuntosähkö Oy - Trafox 7

http://www.trafox.fi

RS-485 NETWORK CONNECTION

The IM-04PV unit includes a RS-485 bus connection with Modbus RTU protocol for

remote monitoring and controlling.

The IM-04PV unit functions as a slave device. A unique address must be set for it

(SETUP→MB Addr).

The RS-485 bus must form an uninterrupted chain, which is open at both ends, and

contains no branches. Thus, a maximum of two RS-485 cables are installed in any unit:

in other words, an incoming and an outgoing cable. A terminator is installed in the first

and the last unit. If the IM-04PV unit is the first or last device of the bus, an external

terminating resistor of 120 Ω must be connected between the terminals A and B. In all

other units, the terminator must not be installed.

The cable shield is connected to the SH terminal of the IM-04PV unit.

SYSTEM CONFIGURATION

The most sensible configuration order for the settings is as follows:

•Set the correct time (SETUP→Time).

•Set the alarm parameters (SETUP→InsLimit, PrInsLim, StDelay).

•When needed, set the Modbus address (SETUP→MB Addr).

•If needed, enable the automatic alarm acknowledgement (SETUP→AutoRst).

A more detailed description of the configuration is provided in the Manual section “SETUP

menu”.

8© Copyright Muuntosähkö Oy –Trafox Superintend IMD

http://www.trafox.fi

USE

GENERAL

The Superintend IMD PV system based on the IM-04PV unit includes the following

components:

•The IM-04PV unit is the central unit of the system. It performs the

measurements independently and controls the alarm relays. The IM-04PV unit is

installed in the switchboard.

•The HVC-15.* unit is a high voltage coupling device. It is needed between the

IM-04PV and the network to be monitored. The HVC-15.* unit is installed in the

switchboard.

IM-04PV UNIT

The IM-04PV unit is the central unit of the system. The IM-04PV contains the user

interface of the entire system. The error notifications are displayed on the screen of the

IM-04PV, and the fault information can be forwarded to another user-defined system

through the alarm and pre-alarm relays. All alarm parameters are set through the user

interface of the IM-04PV system.

Measurement values can be monitored and settings can be changed using the Modbus

RTU protocol via the IM-04PV unit’s RS-485 connection. For this purpose, the device

must be connected to a RS-485 bus and the Modbus address must have been configured

in the Setup menu.

The IM-04PV unit independently measures the insulation resistance and capacitance of

the IT network to be monitored, in relation to protective earth. The measurement is

performed by feeding two summed low frequency alternating voltages between the

network and the PE conductor. These generate a low current that travels through the

insulation resistance and capacitance to be measured. The insulation resistance and

capacitance are calculated by FFT analysing the current and then measuring the

amplitude and phase.

Superintend IMD © Copyright Muuntosähkö Oy - Trafox 9

http://www.trafox.fi

The system functioning can be tested by pressing the T button of the IM-04PV unit when

the IM-04PV unit displays the Monitor menu. The device will test the functioning of the

internal measurement circuit. More detailed information on this is provided in the

description of the Monitor menu.

MENU STRUCTURE

The menus of the IM-04PV unit have three main levels: MONITOR, SETUP and ALARM.

The button is used to navigate between the main levels when the topmost parameter

of each menu is highlighted on the screen.

The menus can be browsed down with the button. Access to the Setup menu is

password-protected.

The Monitor menu is the default of the IM-04PV unit, to which the system returns in 20

minutes after the last time a button was pressed, or after a sufficient number of presses

on the button in any screen mode.

•The Monitor menu mainly has one level. All information to be displayed can be

viewed by browsing the menu with the button.

10 © Copyright Muuntosähkö Oy –Trafox Superintend IMD

http://www.trafox.fi

•The Alarm menu has two levels. The first level displays the reason for the alarm

and the second level shows the alarm start time, the measured parameters, and

alarm limits.

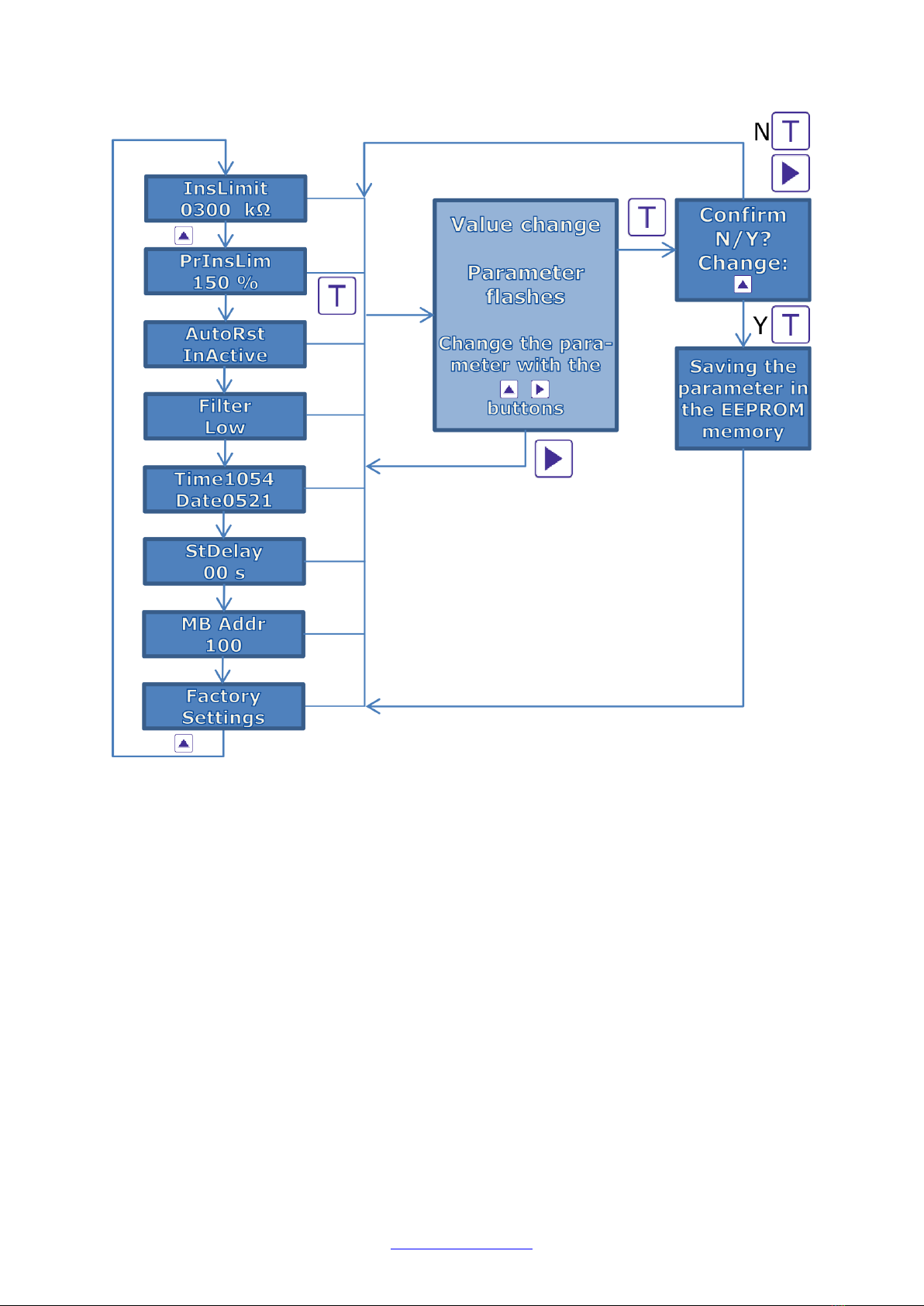

•The Setup menu mainly has two levels. The first level displays the valid

parameter, which can be changed on the second level.

Hereafter, the screen modes are called as follows:

•The main level of the menu is the topmost menu level (MONITOR, SETUP and

ALARM)

•The menu level is the sub-level of the aforementioned, and it is browsed using

the button

•The screen mode is the mode following the menu level, and it displays the value

of the parameter/time; also displays a stopped AutoScroll mode. The screen

mode can be accessed from the menu level by pressing the T button.

•The AutoScroll mode is in use in the Setup menu items where there are several

parameters to display. In that case, the displayed parameters change every few

seconds. You can stop the display with the button and return from the screen

mode to the AutoScroll mode with the button. Use the T button to go to the

edit mode or screen mode.

•The Edit mode is a Setup menu mode where the parameters to be displayed can

be changed. In the Edit mode, the parameter to be changed flashes and it can be

changed with the button. If there are several parameters to be changed in the

same screen, you can move to the next one by pressing the button. After the

editing is completed, press the T button, after which the values given must be

approved by selecting “Yes” in the Confirm menu and pressing T. By selecting

“No” or pressing the button in the conformation stage you return to the

previous mode without saving the changes.

As a rule, the buttons function as follows:

Moving to the next parameter on the menu level and screen level. Increases the

parameter on the edit level. In the AutoScroll mode, stops the display.

Moving to the next menu on the main level. Moves to the next editable

parameter on the edit level. Also a general “reject button”. Returns to the

previous mode from all modes. Pressing the button an appropriate number of

times takes you to the default mode of the main menu (insulation

resistance/capacitance) from any mode.

A general “approval button”. On the menu level, takes you to the AutoScroll or

edit mode. On the edit level, approves the changes made. Pressing the button

in the first three items of the Monitor menu and approving the start of the test

begins the system test.

Superintend IMD © Copyright Muuntosähkö Oy - Trafox 11

http://www.trafox.fi

MONITOR MENU

The Monitor menu is the default menu of the IM-04PV unit during use. All modes of the

menu always return to the topmost item on the Monitor menu after 20 minutes from the

last press of a button.

The following measured parameters are available in the Monitor menu screen:

•IT network’s insulation resistance and capacitance in relation to protective earth.

Displayed in kOhms and micro farads.

•Time and date

•All fixed alarms can be acknowledged on one go.

•Firmware version

The default display is insulation resistance and capacitance. Other parameters and

functions can be viewed by using the button.

The system test is started from the Monitor menu by pressing T and then selecting Y in

the Start test menu and pressing T. This starts the test of the internal measurement

circuit of the IM-04PV unit. If the test is completed successfully, the screen displays

momentarily the text Test OK; otherwise the text shown in Test FAILED, and an

insulation fault alarm is given to indicate that the insulation resistance can no longer be

measured.

The Monitor menu functions as follows:

12 © Copyright Muuntosähkö Oy –Trafox Superintend IMD

http://www.trafox.fi

ALARM MENU

The alarm menu has two levels. The menu level shows if the alarm is active (ALARM),

inactive but not acknowledged (OLD ALRM) or if the situation is normal (OK). The

screen mode shows the value, alarm limit and time of the parameter that caused the

alarm.

If the start-up delay has been enabled (SETUP→StDelay), the alarms cannot be

activated before the set start-up delay has been elapsed after powering on the unit.

An alarm always indicates that the fault in question is still active. An active fault cannot

be acknowledged until the issue that caused it has been fixed. The fixed fault is

acknowledged when its time is checked and the T button is pressed. The button takes

you back to the menu level without acknowledging the fault.

All fixed faults can also be acknowledged on one go by means of the Alarm reset function

in the Monitor menu.

If the automatic alarm acknowledgement has been enabled (SETUP→AutoRst), the faults

are acknowledged automatically as soon as they are fixed.

Superintend IMD © Copyright Muuntosähkö Oy - Trafox 13

http://www.trafox.fi

All alarms except pre-insulation (PreInsul) alarm are indicated by the red LED light

ALARM, which BLINKS in fault situations and is on STEADILY if the fault has been fixed

but not acknowledged (the OLD ALRM mode). The alarms which are related to

disconnected measurement wires or internal errors, are indicated also with the red

STATUS light. The pre-insulation alarm is indicated in the same way with the red LED

light WARN.

The insulation resistance fault activates IMMEDIATELY when the measured parameter

drops below the alarm limit. The alarms have a five-percent hysteresis. In other words,

an alarm becomes active when the set limit is reached, but it is deactivated only when

the measured value deviates by 5% in a safe direction from the limit given.

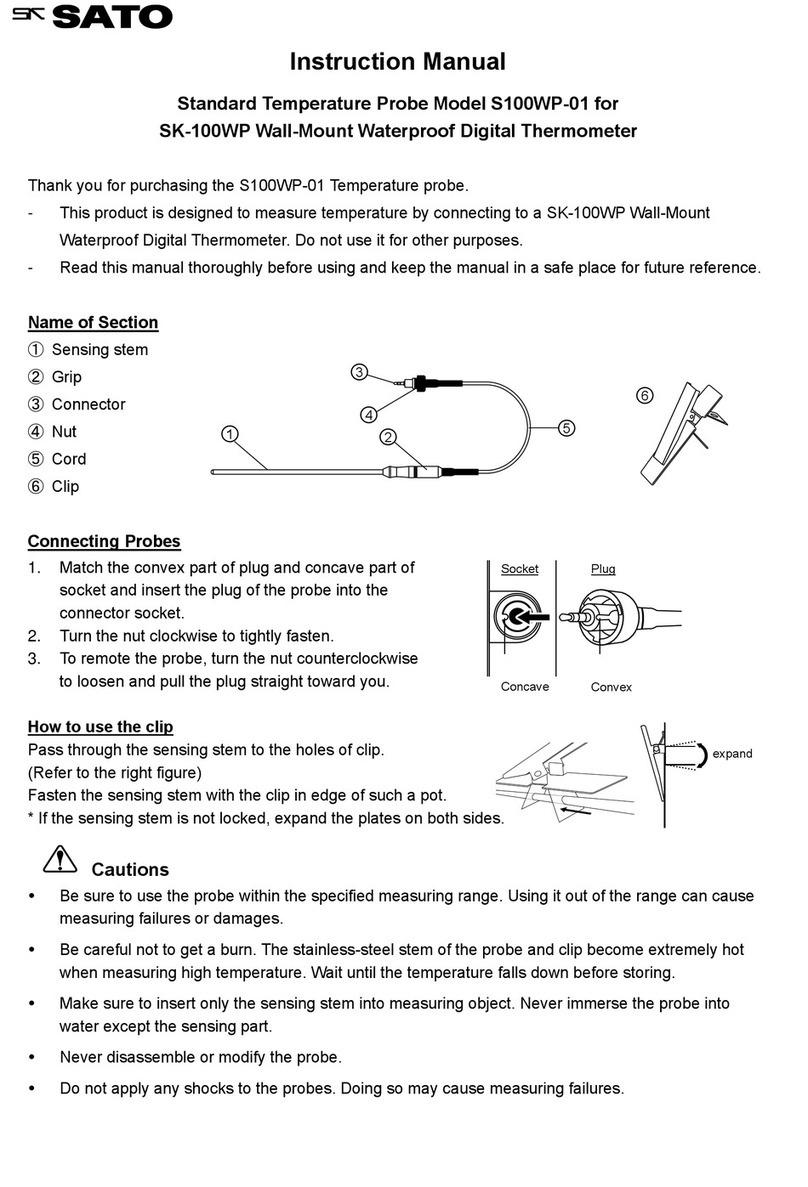

The screen mode of each parameter alternately displays the following:

•On the top row, the value / fault limit of the parameter that caused the fault, and

on the bottom row, the current status: OK, ALARM or OLD ALRM

•Fault start time and date

If the fault has been deactivated and becomes active again, the start time of the active

fault is displayed. In the OK mode, nothing is displayed in the screen mode.

The screen always displays the measured quantity (the smallest value measured during

the fault) / fault limit of the fault first, followed by the fault start time.

The insulation fault alarm is active.

The smallest insulation resistance measured during the fault is

850 kΩ and the alarm limit is 900 kΩ.

The insulation fault alarm has been deactivated but not

acknowledged.

14 © Copyright Muuntosähkö Oy –Trafox Superintend IMD

http://www.trafox.fi

The smallest insulation resistance measured during the fault, the alarm limit's set value

and the fault start time are displayed.

The Insulat. and PreInsul alarms are active if the measured insulation resistance is

smaller than the alarm or pre-alarm limit.

The Sys Test alarm is active if the manual system test fails. In that case, the insulation

resistance can not be measured either, so an insulation resistance alarm is also given.

The Gnd Fail alarm is active if the TG or MG wire of the IM-04PV unit is disconnected. In

that case, the insulation resistance can not be measured either, so an insulation

resistance alarm is also given.

SETUP MENU

The Setup menu can be used to change system settings, alarm limits, time etc.

The Setup menu is password-protected and accessed as follows:

•Go to the Setup menu in the main menu. The screen displays “Enter Setup”.

Press T.

•Change the blinking number with the button and press the button to move

to the next digit. Enter the three digits and press T. After this, you can navigate

the menu with the button.

•The button takes you to the initial mode.

The password is “123”.

All information on the settings of the device alarm limits and the system are saved in the

internal EEPROM memory of the IM-04PV unit.

Superintend IMD © Copyright Muuntosähkö Oy - Trafox 15

http://www.trafox.fi

The following parameters can be changed in the Setup menu:

•INSULATION LIMIT: Alarm limit of the insulation resistance. If the measured

value is lower than the alarm limit, an alarm is given. The setup range is 10…100

kΩ with 10 kΩ intervals and 100 kΩ…1,000 kΩ with 50 kΩ intervals.

•PRE INSULATION LIMIT: The pre-insulation limit of the insulation resistance.

Given as a percentage of the insulation limit. Activates the INS. WARN. relay.

The setup range is 100…200%, at 10% intervals.

•AUTOMATIC ALARM ACKNOWLEDGEMENT: This setting determines whether

all the alarms shall be acknowledged automatically as soon as they are

deactivated.

•Filter: Not in use.

•TIME: The time and date of the real time clock.

•START-UP DELAY: The delay after powering on the unit during which the alarms

will not be generated. The setup range is 0…60 s.

16 © Copyright Muuntosähkö Oy –Trafox Superintend IMD

http://www.trafox.fi

•MODBUS ADDRESS: The Modbus slave address of the unit. The setup range is

1…247.

•FACTORY SETTINGS: Returns all settings to their original values.

ERRORS

The following table lists the functioning of the IM-04PV unit in various error situations.

Error

IM-04PV

ALARM

LEDs

IM-04PV

ALARM

menu

Alarm

relay

The IM-04PV unit without

operating voltage

ALM WRN

Insulation fault (R under

InsLimit)

ALARM

Insulat.

ALM

Insulation fault (R under

PrInsLim)

WARN

PreInsul

WRN

The IM-04PV unit TG wire

is disconnected

STATUS ALARM

Gnd Fail

ALM

The IM-04PV unit MG wire

is disconnected

STATUS ALARM

Gnd Fail

ALM

System fault (manual

test)

STATUS ALARM

Sys Test

ALM

Alarm relays:

•ALM insulation alarm

•WRN insulation pre-alarm

Error situations are displayed by means of ALARM LEDs and the alarm menu of the IM-

04PV unit. A blinking LED always means that an alarm is active, and a steady indicator

indicates a fixed and unacknowledged fault.

MODBUS RTU REMOTE CONTROL

When a suitable Modbus address has been set for the IM-04PV unit, the device can be

connected to a RS-485 bus. The unit's Modbus RTU slave functionality is now ready for

use. The unit’s Modbus RTU register map is provided below. The Modbus functions to be

used are Read Holding Registers (0x03) and Write Multiple Registers (0x10).

Superintend IMD © Copyright Muuntosähkö Oy - Trafox 17

http://www.trafox.fi

Register

R/W

Name

Type

Unit

Description

1

R

Measured insulation resistance

uint16

kOhm

The measurement result is provided as kOhms. The

register value 100 corresponds to insulation

resistance of 100,000 ohms. At the fastest, it

updates in seconds and at the slowest in hundreds of

seconds, depending on the measurement frequency

used.

2

R

Measured capacitance

uint16

0.1

uF

The measurement result is provided as 0.1uF

intervals. The register value 5 corresponds to

capacitance of 0.5uF. It is updated at the same time

as the insulation resistance.

5

R/W

Limit parameter of the

insulation resistance alarm

uint16

kOhm

Read and written in kOhms. The register value 100

corresponds to 100,000 ohms. The minimum,

maximum and interval values are in channels 16, 17

and 18.

6

R/W

The limit parameter of the

insulation resistance pre-alarm.

uint16

%

Read and written in percentages. The register value

150 corresponds to 150%. The minimum, maximum

and interval values are in channels 19, 20 and 21.

10

R/W

Start-up delay, a device

parameter

uint16

s

Read and written in seconds. The register value 2

corresponds to 2 seconds. The minimum, maximum

and interval values are in channels 31, 32 and 33.

11

R

Password of the local user

interface

uint16

none

A three-digit password. Range 000…999. Default

value 123. When needed, this can be used to prevent

the parameters from being set through the Modbus

RTU.

12

R

Device alarm and status

register

uint16

none

Bit mask:

0x0001 = a fault or alarm related to insulation

resistance, corresponds to the INSULATION alarm

LED of the local user interface

0x0002 = insulation resistance pre-alarm

0x0004 = system test fault

0x0010 = fault in the TG or MG wire

0x0100 = system test active

0x0200 = internal calibration active (the insulation

level measurement values are invalid)

the statuses remain active until their cause has been

eliminated

13

R/W

Start of the device system test

uint16

none

Start of the system test. Value 1 starts the test,

other values are not taken into account. IM-04PV

resets the request after reading it.

15

R/W

Joint acknowledgement of

alarms

uint16

none

Joint acknowledgement of unacknowledged alarms.

Value 1 acknowledges all alarms, other values are

not taken into account. IM-04PV resets the request

after reading it. This does not acknowledge/inactivate

active alarms.

16

R

The lowest allowed value of the

limit parameter of the insulation

resistance alarm

uint16

kOhm

10

17

R

The highest allowed value of the

limit parameter of the insulation

resistance alarm

uint16

kOhm

1000

18

R

The resolution (jog) of the limit

parameter of the insulation

resistance alarm

uint16

kOhm

50 if insulation resistance alarm limit 100 kOhm or

above

10 if insulation resistance alarm limit below 100

kOhm

19

R

The lowest allowed value of the

limit parameter of the insulation

resistance pre-alarm

uint16

%

100

20

R

The highest allowed value of the

limit parameter of the insulation

resistance pre-alarm

uint16

%

200

21

R

The resolution (jog) of the limit

parameter of the insulation

resistance pre-alarm

uint16

%

10

31

R

Start-up delay, the lowest

allowed value of the device

parameter

uint16

s

0

18 © Copyright Muuntosähkö Oy –Trafox Superintend IMD

http://www.trafox.fi

32

R

Start-up delay, the highest

allowed value of the device

parameter

uint16

s

60

33

R

Start-up delay, the device

parameter resolution (jog)

uint16

s

1

34

R

Status register of the

unacknowledged alarms of the

device

uint16

none

Bit mask:

0x0001 = a fault or alarm related to insulation

resistance is inactivated, corresponds to the

INSULATION alarm LED of the local user interface

0x0002 = insulation resistance pre-alarm deactivated

0x0004 = system test fault deactivated

0x0010 = fault in the TG or MG wire deactivated

the statuses will activate when the corresponding

active alarm has been deactivated and remain active

until the cause has been acknowledged

Superintend IMD © Copyright Muuntosähkö Oy - Trafox 19

http://www.trafox.fi

TECHNICAL SPECIFICATIONS

IM-04PV UNIT

Voltage ranges

•Operating voltage [US]:

110…240VAC, frequency 48…62 Hz

110…300VDC (use an external fuse Schurter 0001.2503 (T800mA))

•Frequency range of the network to be monitored: DC, 10…460Hz

•Input power: 3W. Internal fuse of the operating voltage: 1AT

Monitoring of the insulation level:

•Measurement voltage [Um]: ± 25Vp

•Alarm limit [Ran]: 10kΩ…1MΩ

•Hysteresis: 5%

•Start-up delay: 0…60s

Alarm switches

•5A (NO) / 3A (NC) @ 30VDC for resistive load

•5A (NO) / 3A (NC) @ 277VAC for resistive load

•Maximum power: 1400VA / 150W (NO) and 850VA / 90W (NC)

•Insulation strength between contacts: 1000VAC 50/60Hz 1 min

•Useful life: 100,000 connections with the maximum nominal load

Other details

•Operating temperature: 0…50ºC, relative humidity: < 90%, non-condensing

•IP class (front panel): IP40

•IP class (other casing): IP20

•Connector tightening torque: 0.45…0.5 Nm

•Weight: 180 g

•Not suitable for connecting in parallel

•EMC standards: EN61326-2-4, EN55011, EN61000-4-2, EN61000-4-3, EN61000-

4-4, EN61000-4-5, EN61000-4-6, EN61000-4-11

•Other standards: IEC61557-8, IEC61010-1:2010-3

HVC-15.100 UNIT

Voltage ranges

•Maximum voltage at the measurement connectors L1 and L2 [UN]: 1500VDC or

1081VAC

•Maximum leakage capacitance: 100 uF

20 © Copyright Muuntosähkö Oy –Trafox Superintend IMD

http://www.trafox.fi

Monitoring of the insulation level:

•Measurement circuit impedance: 308kΩ

•Relative uncertainty:

o10kΩ…1MΩ: ±15%

o5kΩ…10kΩ: ±3kΩ

Other details

•Operating temperature: 0…50ºC, relative humidity: < 90%, non-condensing

•IP class (front panel): IP40

•IP class (other casing): IP20

•Connector tightening torque: 0.5…0.6 Nm

•Weight: 94 g

HVC-15.1000 UNIT

Voltage ranges

•Maximum voltage at the measurement connectors L1 and L2 [UN]: 1500VDC or

1081VAC

•Maximum leakage capacitance: 1000 uF

Monitoring of the insulation level:

•Measurement circuit impedance: 99kΩ

•Relative uncertainty:

o10kΩ…1MΩ: ±15%

o5kΩ…10kΩ: ±3kΩ

Other details

•Operating temperature: 0…50ºC, relative humidity: < 90%, non-condensing

•IP class (front panel): IP40

•IP class (other casing): IP20

•Connector tightening torque: 0.5…0.6 Nm

•Weight: 201 g

HVC-15.2000 UNIT

Voltage ranges

•Maximum voltage at the measurement connectors L1 and L2 [UN]: 1500VDC or

1081VAC

•Maximum leakage capacitance: 2000 uF

Table of contents

Other Trafox Measuring Instrument manuals