®

page 2

T-12-T

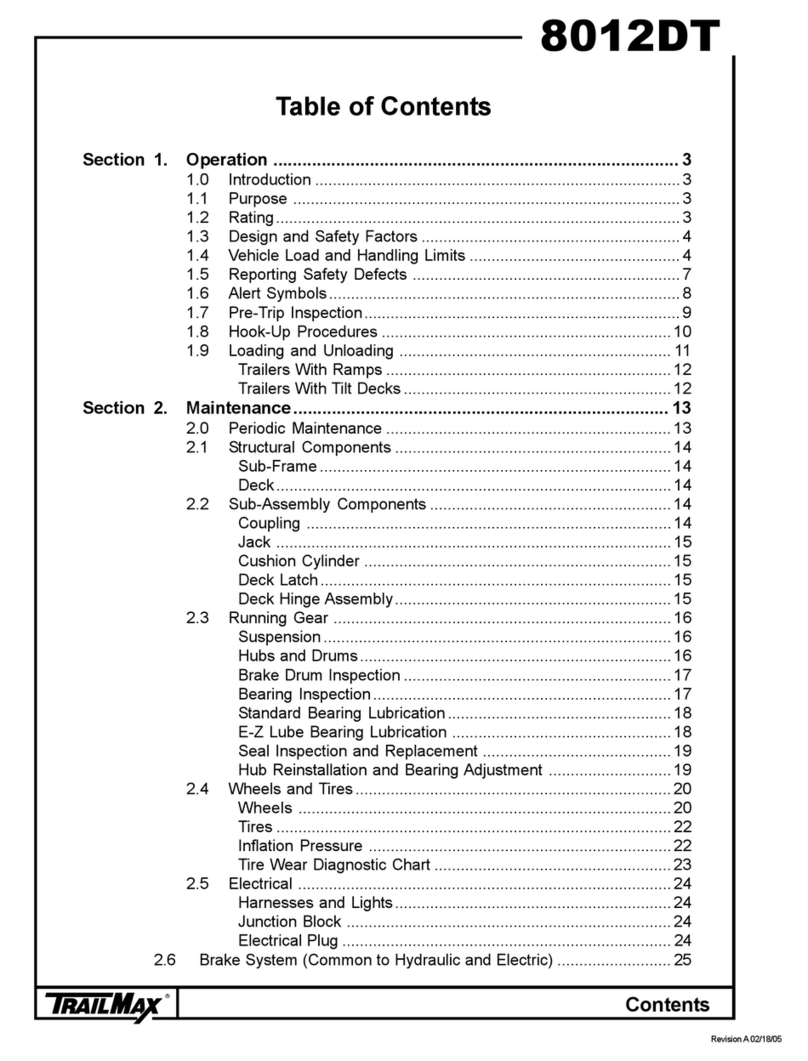

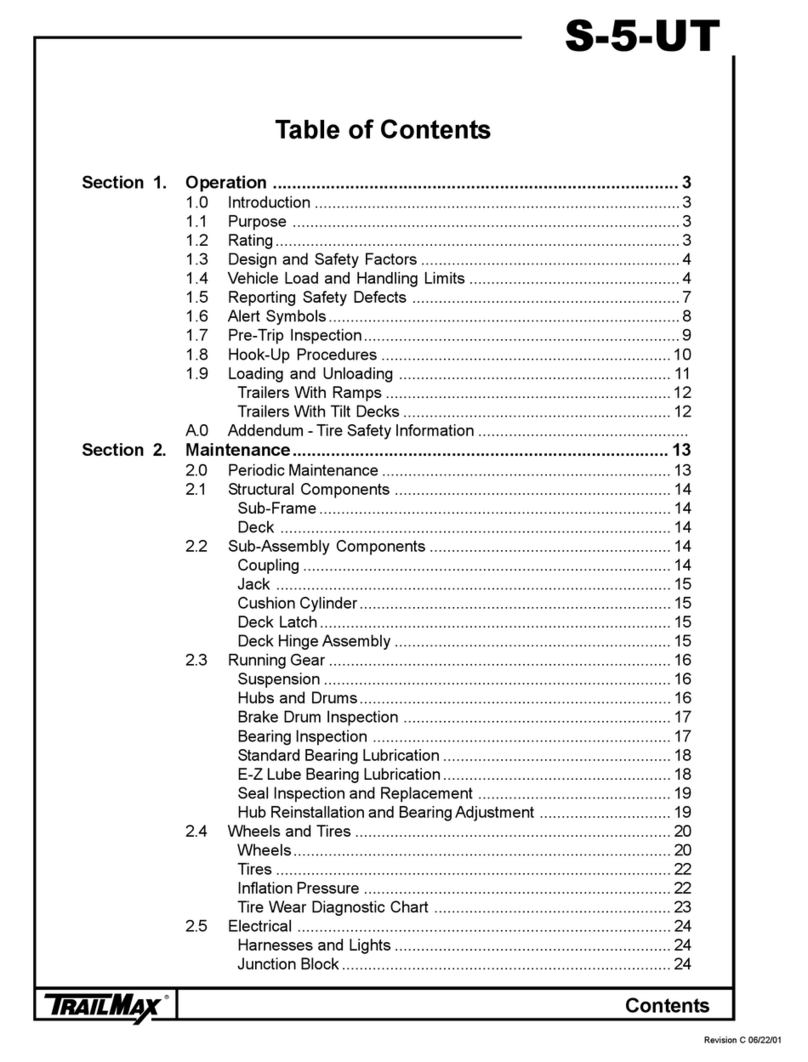

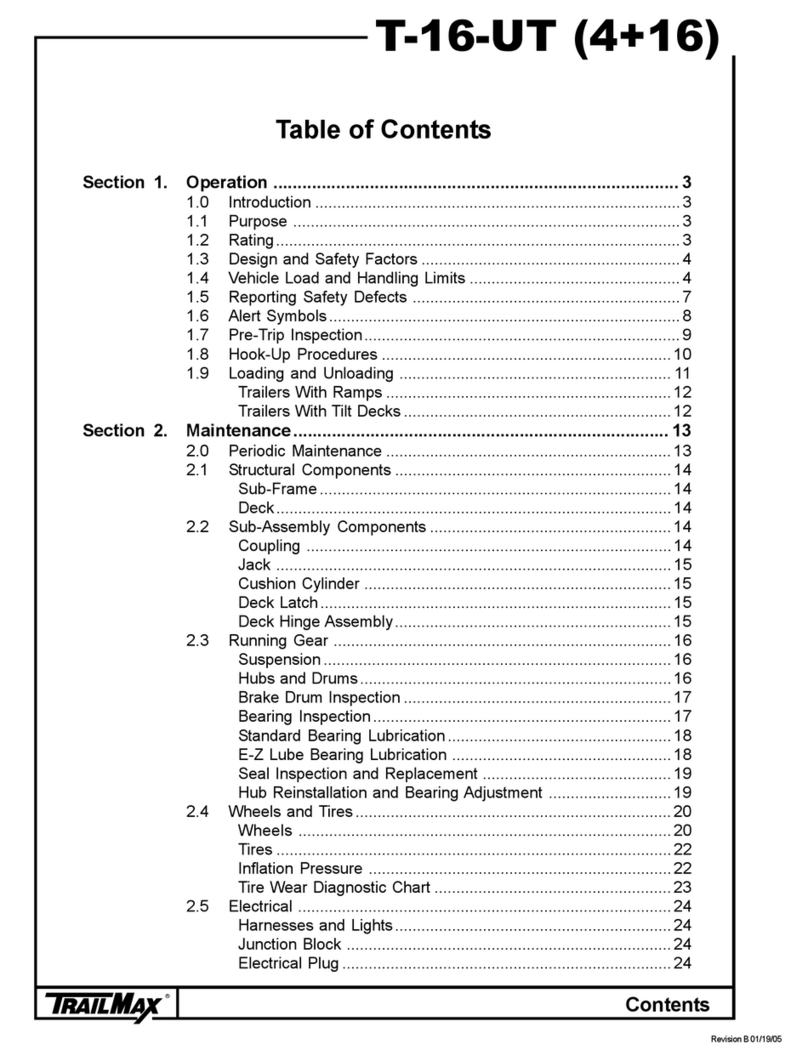

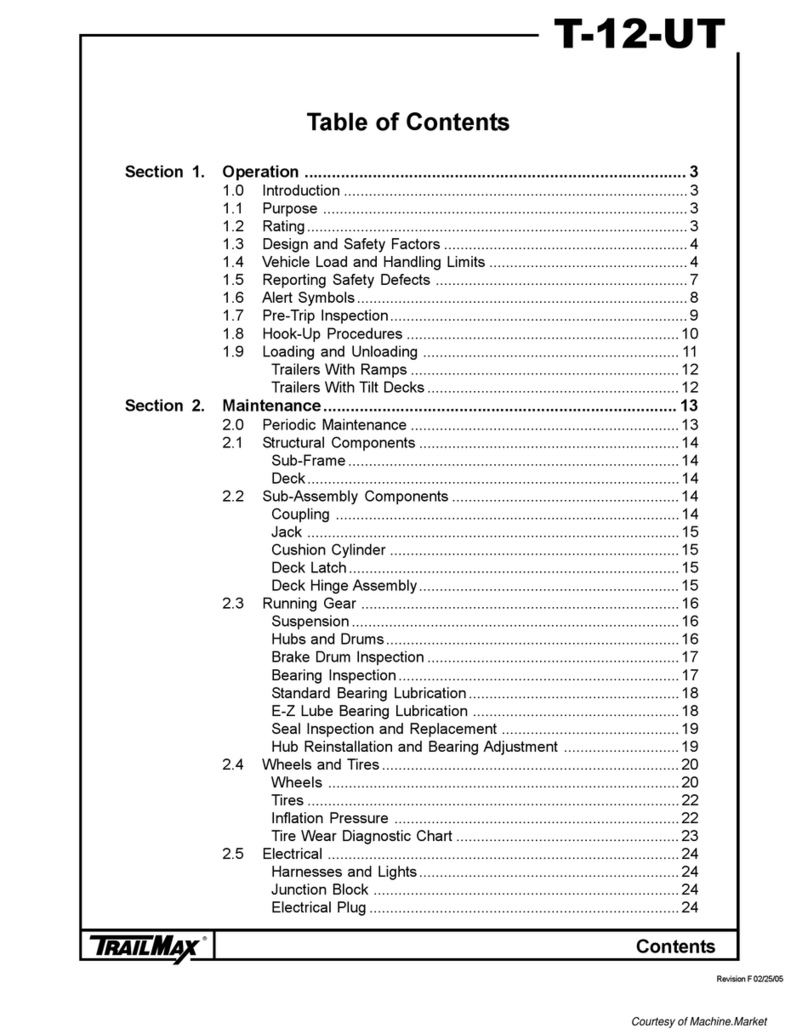

2.6 Brake System (Common to Hydraulic and Electric) ................... 25

Brake Adjustment ..................................................................... 25

Brake Cleaning and Inspection ................................................ 26

Brake Lubrication ..................................................................... 26

2.7 Hydraulic Brake System ............................................................. 27

Operation .................................................................................. 27

Surge Actuator Maintenance .................................................... 27

Corrosive Environment Warning .............................................. 28

Hydraulic Lines ......................................................................... 28

Hydraulic Brakes ...................................................................... 28

Brake System Bleeding ............................................................ 29

Hydraulic Brake System Troubleshooting Chart ...................... 31

2.8 Electric Brake System................................................................. 31

Operation .................................................................................. 31

Using your Brakes Properly...................................................... 32

Synchronization ........................................................................ 33

Controllers ................................................................................ 33

Magnets .................................................................................... 34

Electric Brake System Troubleshooting ................................... 35

Measuring Voltage .................................................................... 35

Measuring Amperage ............................................................... 37

Electric Brake System Troubleshooting Chart ......................... 38

2.9 Pre-Storage Maintenance ........................................................... 40

2.10 Pre-Season Maintenance ........................................................... 41

Section 3. Parts .......................................................................................... 38

3.1 Structural Components ............................................................... 38

Sub Frame ................................................................................ 38

Deck Surface ............................................................................ 39

3.2 Major Sub-Assemblies ................................................................ 40

Hammerblow Drop Leg Jack .................................................... 40

Couplers ................................................................................... 41

Deck Latch Assembly ............................................................... 43

Cushion Cylinder....................................................................... 44

3.3 Running Gear .............................................................................. 45

Suspension, 7K......................................................................... 45

Electric Brake Components, 7K ............................................... 46

Axle End Components .............................................................. 48

3.4 Wheels and Tires ........................................................................ 49

3.5 Electrical ..................................................................................... 50

Harnesses and Lights ............................................................... 50

Electrical Plug ........................................................................... 52

Electric Brake Wiring ................................................................ 53

Electric Breakaway System ...................................................... 53

Section 4. Warranty Claim Procedure ....................................................... 54

Contents