Trakm8 T8 User manual

T8 Mini Installation Manual

T8-Mini & Derivatives

For Cars, Car Derived Vans,

Light Commercial Vehicles

Heavy Goods Vehicles and Trailers

T8-Mini Installation otes v1.0

Generic T8-Mini Installation otes v1.0.doc

Page 2

1 Table of Contents

1

Table of Contents 2

2

Contact Information 3

3

Document Revision History 4

4

Preface 5

4.1

Safety Information 5

4.2

pproval Information 6

4.2.1

Production Test 6

Installation Information 6

4.3

Important Notes! 6

5

Installation 7

5.1

Recommended Installation Sequence Summary 8

5.2

SIM Card 8

5.2.1

Before fitting the SIM card 8

5.2.2

Fitting the SIM card 9

5.3

Mounting the T8-Mini 10

5.4

T8 Wiring and Connections 10

5.4.1

Cable and ccessory Wiring Options 11

5.4.2

Internal GSM/GPS Antenna 11

5.4.3

Power Ground and Ignition Installation 12

5.4.4

Driver Interface Button (Optional) 13

5.4.5

Driver ID Dallas Interface (Optional) 13

5.4.6

Digital Inputs/ nalog Inputs/Digital Outputs 13

5.4.7

T8-Mini Immobiliser Feature. 15

6

Testing 16

6.1

Engineering Mode 16

6.2

Server data 18

7

Appendix A –T8-Mini Wiring iagram 19

8

Appendix B –T8-Mini Connections & Ratings 20

9

Appendix C –T8-Mini-GPRS Records 21

T8-Mini Installation otes v1.0

Generic T8-Mini Installation otes v1.0.doc

Page 3

2 Contact Information

All initial communication or enquiries should be made to:

Trakm8 Limited

Lydden House

Wincombe Business Park

Shaftesbury

Dorset

SP7 9QJ

UK

International Tel: +44 (0) 1747 858444

International Fax: +44 (0) 1747 858222

Orders Order @trakm8.com

T8-Mini Installation otes v1.0

Generic T8-Mini Installation otes v1.0.doc

Page 4

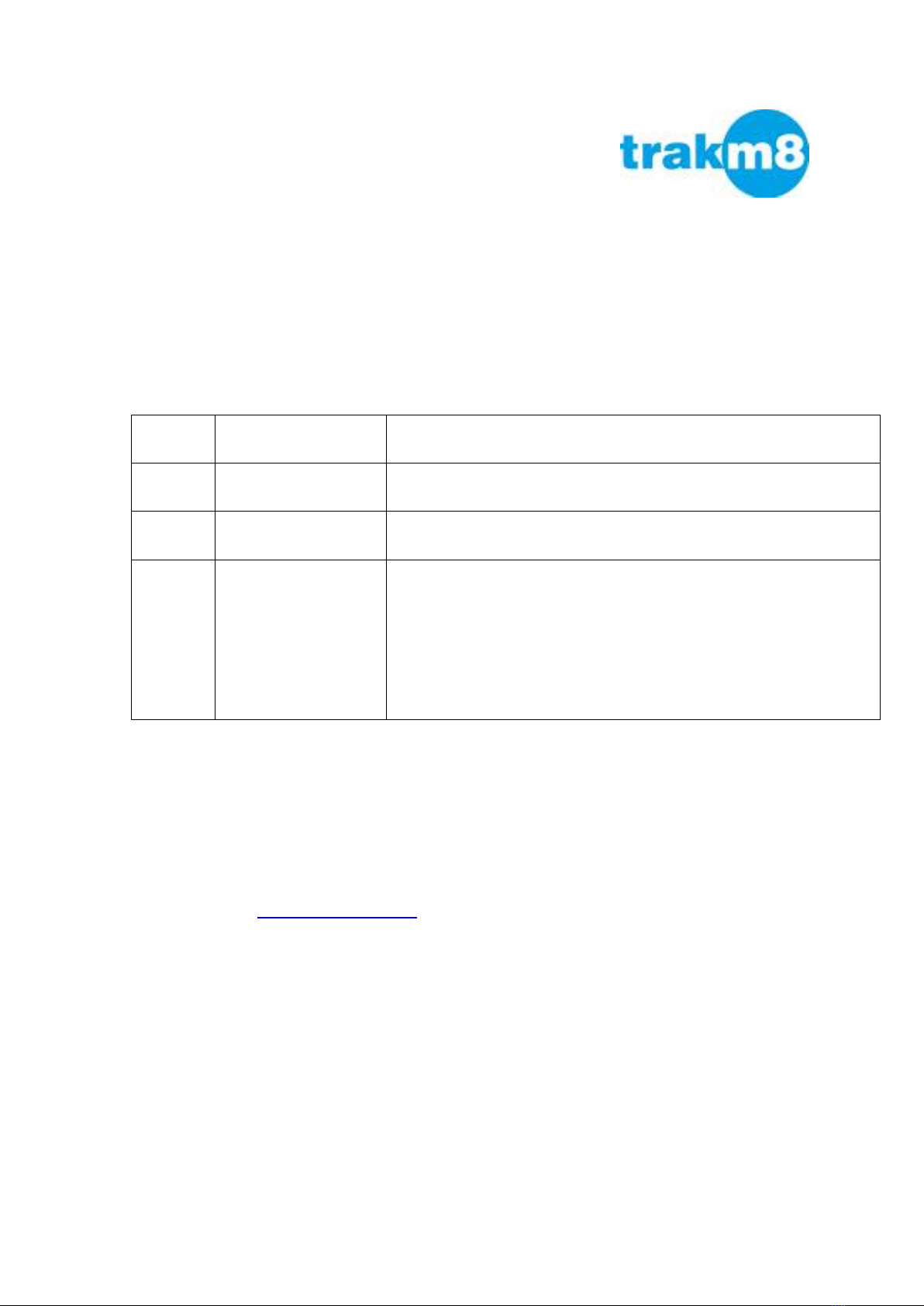

3 Document Revision History

Document Issue Date of Issue Reason/Description of change

1.0 Draft 25-03-11 Fir t Draft

1.0 20-02-12 Fir t relea e

T8-Mini Installation otes v1.0

Generic T8-Mini Installation otes v1.0.doc

Page 5

4 Preface

Failure to comply with the following Warnings, pproval and Safety

information may invalidate warranty, certification or type approval of this

product.

1. ever operate the T8-Mini Platform in close proximity to the human body.

W RNING!

Current FCC regulations limit the EIRP of mobile devices to 2 W.

20 cm (7.87 inch) separation distance between the unit and all

persons must be maintained at all times.

2. Unauthorised modification to this equipment or associated accessories is

forbidden without the express permission and agreement from the product

manufacturer.

3. This equipment should not be operated in hazardous environments i.e. areas

that contain explosive materials or flammable vapours.

4. This equipment should not be operated within aircraft or in close proximity to

medical equipment.

5. Internal components containing beryllium oxide may be used in this

equipment. Dust from this material is a health hazard if inhaled or allowed to

come into contact with the skin. Great care must be taken when handling

these components.

4.1 Safety Information

Please adhere to the following Safety and Installation information at all times.

Supply Voltage: +8V minimum to +32V maximum

Current consumption at: 12V <= 45mA – fit a 2A inline fuse.

24V <= 25mA – fit a 2A inline fuse.

Battery charging peak < 500mA at 12V.

ote: Fuses should be placed in all power lines as close as possible to the

vehicle supply source. (Supply fuse: 2A, Ignition Fuse: 1A)

THE RATINGS OF THESE FUSES SHOUL NOT BE EXCEE E AT ANY TIME

WARNING!

This equipment may only be located in a position where it cannot interfere

with the normal operation of the vehicle or present a hazard to the driver or

passengers. Care must also be taken in the routing of all cables so that the

insulation does not become worn or damaged.

T8-Mini Installation otes v1.0

Generic T8-Mini Installation otes v1.0.doc

Page 6

4.2 pproval Information

The product can be marketed worldwide. Therefore the following certifications

and approvals are provided.

CE –marking

“e” –marking

R&TTE 1999/5/EC (EN3014891) and EN60950-1:2001

FCC

PTCRB registration

The product conforms to CE-marking and e- marking. It is certified with tests

according to R&TTE 1999/5/EC, E 301489-1 and E 60950-1: 2001 for CE

conformity and according to EMV 2004/104/EG for e conformity, respectively.

4.2.1 Production Test

Each module is 100% tested prior to packing and shipping.

Installation Information

All installation and service work must be carried out in accordance with MPT

1362, MPT 1372, RQAS, and VSIB, 95/54/EC, ISO 21609 and / or any other

statutory guidelines or Directives currently in force.

Therefore it is strongly recommended that the T8-Mini platform is installed and

commissioned by suitably trained and qualified Installation Personnel i.e. in the

UK those who are accredited and registered by the Vehicle Systems Installation

Board (www.vsib.co.uk). This is essential in order to maximise any Insurance

discounts that may apply.

4.3 Important Notes!

1. Unauthorised changes or alterations to the equipment or the installation will

invalidate certification issued by the Approved Accreditation Bodies and may

also affect the vehicle manufacturers warranty.

2. Under no circumstances may any part of the T8-Mini system be installed

inside the engine compartment area.

3. The T8-Mini platform contains devices that are susceptible to static damage.

It is necessary to use a proprietary anti-static (ESD) workstation prior to, and

whenever the cover is removed from the unit for service & commissioning

purposes.

4. Where the T8-Mini platform is to be installed into a company vehicle, all

employees or other individuals who are authorized to drive that vehicle

should be advised that a tracking unit is installed, in order to limit any

potential risk of privacy and employment law issues. It is strongly

recommended that evidential proof of this advice be sought and retained.

T8-Mini Installation otes v1.0

Generic T8-Mini Installation otes v1.0.doc

Page 7

5 Installation

Before you begin installing and commissioning the system please ensure that

you have read this manual thoroughly referring to any supplementary information

provided for the T8-Mini as required.

This document covers the T8-Mini and its connections through the following

process:

1. Recommended Sequence

2. Fitting the SIM

3. Mounting the Unit

4. Wiring and connections

i. Power, Ground and Ignition

ii. Internal GSM/GPS Antenna’s

iii. Driver Interface Button/LED

iv. Dallas i-Button/LED

v. Inputs

vi. Outputs

Some of the items above are optional and you may ignore sections describing

features that your T8-Mini does not have.

Important Notes!

When using the T8-Mini you should remember the following:

1. In order for GPS to function correctly, the unit must have a clear view of

the sky in order to receive data from the satellites. Should this view be

obscured, e.g. the vehicle is parked in a metal-clad building then the

performance of the T8-Mini platform may be impeded. Wherever possible

it is preferable to park the vehicle in a location where the antenna will have

a clear all round view of the sky.

2. Whenever you disconnect the T8-Mini from the power supply it may lose

its stored data and so may take a while to obtain a GPS fix when you plug

it back in. The T8-Mini may also lose certain other information from its

memory particularly if the optional backup battery is not fitted. Please

ensure that you take this into consideration when having the vehicle

serviced, as the vehicle battery connections are often removed during

some service procedures. Tell the service technician that you have a T8-

Mini fitted and request that if possible they use a “vehicle memory saver”

plugged into the cigarette lighter socket – this type of device will support

T8-Mini Installation otes v1.0

Generic T8-Mini Installation otes v1.0.doc

Page 8

both the T8-Mini and your vehicle radio system whilst the vehicle battery

is removed.

WARNINGS

1. Do not smoke or use open flames when working near the vehicle.

2.

Ensure that the vehicle’s electrical cables, hydraulic lines, fuel lines, and

safety equipment are not damaged during the installation

.

3.

Ensure that normal control and operation of the vehicle is not impaired by

the installation, particularly the brakes and steering. Ensure that the

airbag operation is not obstructed

.

5.1 Recommended Installation Sequence Summary

The following installation sequence is recommended. Please refer to the detailed

instructions elsewhere in this document for further details.

1. Plan the whole installation and determine suitable locations, mounting

arrangements and cable routes for all hardware items.

2. Fit SIM card (if not supplied pre-installed). Please note that the SIM must be

inserted correctly and the SIM PI code removed where necessary using a

mobile phone.

3. Connect internal back-up battery if fitted to the T8-Mini.

4. Temporarily mount the main T8-Mini and wire the Power and Ignition Sense

feeds leaving the in-line fuses out.

5. Check for optimum location of the GPS unit for GPS signal detection using

the engineering modes. The unit will need to be powered up by temporarily

fitting the fuses.

6. Permanently mount the main T8-Mini in its optimum location.

7. Fit the fuses for the T8-Mini.

8. Commission and test the system.

5.2 SIM Card

5.2.1 Before fitting the SIM card

1. If you have not already registered your SIM card with the mobile network, you

should do this before proceeding. Please refer to the appropriate mobile

network operator instructions on how you do this.

2. Make a note of the number on the SIM card (ES ) as well as a note of your

Voice & Data telephone numbers. There is a convenient space in ppendix

B – T8-Mini Records where you can record this information.

3.

Ensure that a PI number does not protect the SIM card. If this is the case, it

must be removed before inserting it into the T8-Mini – this can be done by

T8-Mini Installation otes v1.0

Generic T8-Mini Installation otes v1.0.doc

Page 9

inserting the SIM into a suitable mobile telephone and then following your

mobile telephone instruction booklet

.

5.2.2 Fitting the SIM card

Important Note!

When inserting or removing the SIM card from the T8-Mini it is necessary to take

the necessary anti-static (ESD) precautions in order to prevent damage to the

unit, these precautions should also be employed prior to removing the cover from

the unit at any time for service and commissioning purposes.

1. Remove the base of the T8 Mini by flexing the latching lugs on each side in

an outward manner to release it from the main body assembly. This is best

achieved using the leverage tool provided or two medium size flat blade

screw drivers in tandem.

2. Relea e the SIM cradle by liding the ilver locking bar toward the GSM

Antenna and allow it to tilt away from the circuit board. Slide the SIM card

into the lot of the tilting ection, o that the gold contact on the SIM card

are facing downward toward the circuit board and that the traight edge of

the SIM card i in erted fir t toward the hinge.

SIM card

holder

Battery

connector

Internal GSM

Antenna

Main M12

connector

T8-Mini Installation otes v1.0

Generic T8-Mini Installation otes v1.0.doc

Page 10

3. Ensure that the SIM card and cradle are pressed gently towards the circuit

board so that it sits flat and slide the silver latching bar away from the GSM

Antenna to lock it in place.

4. Replace the base of the unit by compressing the two halves firmly together

against the seal until the latching lugs click into place.

5.3 Mounting the T8-Mini

You may choose to mount the T8-mini somewhere covertly e.g. in the boot,

under the parcel-shelf or under the dashboard. Suitable mechanical fixings must

be used (not supplied). If the on-board Accelerometer is to be used then it is

extremely important that the unit is rigidly mounted such that it cannot move.

WARNINGS:

1. Your T8-Mini must be securely mounted in a location where it cannot

interfere with the normal operation of the vehicle. It must OT be located in a

position where the cables or the Unit become a hazard to the driver or

passengers.

2. The T8-Mini has been designed with an IP rating of IP67 and as such can be

located in splash areas within the vehicle. Having said this it is recommended

that the unit is not installed inside the engine compartment or areas where it

may come into regular contact with fluids and corrosive substances.

5.4 T8 Wiring and Connections

Important Notes!

1. Unauthorised changes or alterations to the equipment or the installation will

invalidate certification issued by the Approved Accreditation Body and could

also affect the vehicle manufacturer’s warranty.

2. The notes below should be read in conjunction with fig.1 –T8 Mini Wiring

Diagrams.

3. All wiring should be professionally connected to the vehicle electrics via

soldered connections using automotive grade fuse holders and fuses. In

situations where the soldered connections are prohibited by the vehicle

manufacturer and or the customer then AD-Link fuses may be used to pick up

the appropriate Power and Ignition supplies.

4. All wiring should be safely secured to avoid damage from, or chaffing by, any

hot or moving parts.

5. Position the wiring carefully to avoid the possibility of snagging or impact

damage during the normal use of the vehicle.

T8-Mini Installation otes v1.0

Generic T8-Mini Installation otes v1.0.doc

Page 11

6. Before any holes are drilled, check that no parts, wires, pipes or tanks could

be damaged at the exit point of the hole. Suitable grommets must be used

where wires are routed through body panels to prevent chaffing and short

circuits to the chassis.

7. Leave the fuses out of their holders until the installation is complete.

5.4.1 Cable and ccessory Wiring Options

The T8-Mini platform i provided with a ingle cable and doe not have any plug

and play acce orie at thi tage.

However the following ection will include pecific reference a to how to wire

up variou acce orie to deliver the functionality of the firmware.

The electrical connection for the current functionality can be found in the wiring

diagram in Appendix A.

5.4.2 Internal GSM/GPS Antenna

The T8 Mini contains an internal GSM antenna and an internal GPS antenna and

therefore the location of the unit is important to optimise the performance. The

unit should be positioned horizontally and located in a position where it will have

an unobstructed view of the sky. The ideal location in most cars is in the centre

top of the dashboard or behind the instrument cluster as far forward in the vehicle

as possible with the top of the unit facing skywards.

OTE

The GSM antenna is now internal to the unit so care must be taken as to where

the unit is mounted.

Important ote!

The performance of the equipment may be impeded if the unit is mounted

beneath or in very close proximity to electrically conductive materials,

such as metal, certain types of plastic, metalized film or laminate

windscreens. If this applies to your vehicle please install the antenna and

unit elsewhere.

20 cm (7.87 inch) separation distance between the unit and all persons

must be maintained at all times.

When you commission the T8-Mini you will be able to carry out tests to

determine whether suitable GSM and GPS signals are being received. If in doubt

about the suitability of your planned location, it is recommended that you only

temporarily install the unit until you are able to carry out the appropriate

engineering tests. (See Section 5 – Engineering Mode)

T8-Mini Installation otes v1.0

Generic T8-Mini Installation otes v1.0.doc

Page 12

5.4.3 Power Ground and Ignition Installation

Below i a wiring block diagram of the T8 Mini y tem which will be covered in

detail within the following ection .

There i ONLY a ingle cable a embly upplied with the T8-Mini unit and

con i t of a traight 8 pin M-12 connector with un-terminated end (CAB050).

This cable consists of an 8 pin M-12 connector and determines the functionality

that is available to the user. Regardless of which cable is used the Power,

Ground and Ignition connections are identical and should be wired as follows.

Wire

Colour

Description Notes

Red Vehicle Supply

Positive (+ve)

Connect to a permanent Positive supply (8 to 32V) via a 2

amp in-line fuse.

Brown Vehicle Supply

egative (-ve)

Connect to permanent egative supply.

Blue Ignition Sense

Positive (+ve)

switched (active

high)

Connect to a switched ignition line via a 1 amp in-line

fuse. This ignition line should be a true engine running

signal to ensure that journeys are detected correctly. This

must be a primary or “D circuit” connection. An auxiliary

ignition connection is NOT acceptable as this will result in

incorrect operation of the product.

It is highly desirable that these connections are soldered to ensure a good

permanent connection to the vehicle supply and ignition points. It is not the

intention of this manual to cover all electrical connection points for all vehicle

types and therefore the experience of qualified fitting staff is essential to ensure

that suitable location points are found for the vehicle in question. Alternatively

Ad-Link connections connected to the fuse board of the vehicle can be used if a

on Invasive installation is required. For further information on Ad-Link fuses

please E-mail [email protected] for further information.

It is strongly recommended that power pick up points are chosen that DO OT

form part of an auxiliary supply such as cigar lighter or auxiliary power sockets as

these can be compromised by the connectivity of third party devices such as

power chargers, invertors, tools etc.

T8-Mini Installation otes v1.0

Generic T8-Mini Installation otes v1.0.doc

Page 13

5.4.4 Driver Interface Button (Optional)

The T8-mini provides a single wire interface that can be used for the driver

interface button and/ this is also multiplexed as a bidirectional Dallas 1-wire

interface. (See section below)

In order to use this pin as driver button simply connect a switch between this pin

and ground as shown in the wiring diagram in Appendix A. If the Driver button is

fitted with an LED for use as business/Private indication then the LED will also

need to be wired as shown in the diagram.

5.4.5 Driver ID Dallas Interface (Optional)

The T8-mini also implements the required driving circuitry to use this pin as a

Dallas 1-wire interface. This allows an easier implementation of the 1-wire

protocol.

5.4.6 Digital Inputs/ nalog Inputs/Digital Outputs

The T8-Mini O LY has two I/O pins available on the M12 connector. These two

pins (3, Pink = I/O 0) (7,Green = I/O 1) can be used for digital inputs/ analog

inputs or as outputs. If the user is operating the product with the Trakm8

application then both of these I/O have been defined as Outputs to operate the

Red LED and Immobilizer functions.

5.4.6.1 Digital Inputs

All of the T8 Mini inputs (including the ignition) have the same specification and

are capable of detecting a signal from 0v to +32v. The input is deemed to have

“GONE HIGH” when the voltage is greater than 5v and “GONE LOW” when the

voltage is less than 2v (including the open circuit state see below).

Therefore the connection of an input wire into a vehicle circuit varies depending

on the voltage of the circuit being monitored and the direction of state change

you are monitoring for.

In the open circuit state all T8 Mini input circuits are in the low state and therefore

careful consideration must be given when wiring up the input to ensure the

change of state produces the required trigger you are after especially if you want

to detect both the “GOES HIGH” and “GOES LOW” state change.

T8-Mini Installation otes v1.0

Generic T8-Mini Installation otes v1.0.doc

Page 14

Below are some examples of monitoring circuit state changes.

Signal Transition from 0V to +12v/+24v

If the input monitoring is a signal or switch circuit that is producing the actual

voltage transition then the input wire can be connected directly to the circuit and

it should be possible to detect both state transitions.

Signal Transition from open circuit to +12v/+24v

If the input monitoring requires the detection of a switch closing to supply

(+12v/+24v) then the input is simply wired to the normally open side the switch.

Signal Transition from >5v to +12v/+24v

If the input monitoring requires the detection of a voltage change that does not

transition below 2v then a potential divider is required to drop the lower voltage

state into the triggering region. To keep the current drain to a minimum the

combined resistance value should be greater than 10K to keep the current below

1mA.

Signal Transition from open circuit to 0V

If the input monitoring requires the detection of both state transitions of a switch

switching from open circuit to ground, then a pull up resistor is required to

generate the “GOES HIGH” state when the switch becomes open circuit. Again

the resistor value should be greater than 10K to keep the current drain to a

minimum when the circuit is closed.

5.4.6.2 nalogue Inputs

The T8 Mini input are capable of being configured a Analogue input with a 12

bit re olution. Thi i currently not implemented in the Trakm8 application.

5.4.6.3 Digital Outputs

The T8-Mini I/O is capable of being configured as outputs. The outputs are

automotive grade open collector FET devices that drive the output to ground

when active. The FET is capable of sinking up to 500mA and is therefore suitable

for driving lamps, buzzers and relays as required.

The Trakm8 application is currently using these to drive the Red Led and the

immobiliser functions implemented in the T8.

T8-Mini Installation otes v1.0

Generic T8-Mini Installation otes v1.0.doc

Page 15

5.4.7 T8-Mini Immobiliser Feature.

Important Notes!

1. Unless local law permits the T8-Mini Immobiliser MUST NOT be connected

in such a way that it would be possible to disable the vehicle whilst it is under

way. The immobiliser must be wired in such a way that it is only breaking a

cranking circuit of the vehicle. Careful consideration must be observed when

choosing this circuit as modern vehicles usually have these types of circuit

monitored by the ECU of the vehicle. This could lead to a malfunction of the

vehicle’s own monitoring system and may invalidate the manufacturer’s

warranty if the correct circuit is not chosen. (If in doubt then please contact

the vehicle manufacturer for advice).

2. When the Immobiliser is driven in all modes other than “OTA” the T8 Mini is

enabling the relay and utilising the normally open contacts of the relay to un-

immobilise the vehicle. Therefore if the main power and internal battery

backup are removed, then the T8-Mini Immobiliser will default secure so as

to render the vehicle immobilised

3. When the immobiliser is driven in In “OTA” mode of operation the T8 Mini is

enabling the relay and utilising the normally closed contacts of the relay to

immobilise the vehicle. Therefore when it is in the unpowered state the T8-

Mini Immobiliser is inactive and the vehicle will always start.

(See the wiring diagram in Appendix A).

The output of the T8-Mini consists of an Open collector FET capable of sinking

up to 500mA.

This is more than adequate to drive an automotive grade relay. The diagram in

Appendix A shows a normally open relay being driven being driven by output 0

(m12 pin 3).

If modes other than “OTA” are used then the normally open set of contacts

(30/87) are used.

If “OTA” mode is being used then the normally closed set of contacts (30/87a)

are used.

T8-Mini Installation otes v1.0

Generic T8-Mini Installation otes v1.0.doc

Page 16

6 Testing

Once installed the equipment should be tested to ensure that it is operating

satisfactorily and that the positions of the installed items do not impair the driver’s

ability to control and operate the vehicle in any way.

The T8 Mini does not contain any visual indicators on the case such that it does

OT impact on its IP67 rating. Therefore the only means a fitter has of testing

the T8 Mini is to use the engineering screens in the firmware and liaise with the

commissioning team as to the integrity of the data being sent to the server. The

fitter will need to make up a test lead, following the information given in Appendix

A such that the driver button and LED can be used for engineering Mode” testing.

If this is OT done then the only means for testing is through the commissioning

team and the server data integrity.

6.1

6.16.1

6.1 Engineering Mode

Engineering ModeEngineering Mode

Engineering Mode

The T8 has an engineering mode to assist installation and test engineers out in

the field. Engineering Mode is entered by pressing the driver id button >10

times or by issuing the SETE G command. The led will come on solid for a

short period indicating that it is in engineering mode. It will then flash once

indicating that it is in screen one. Subsequent single presses of the button will

advance the engineering mode through the other engineering screens. Upon

entering each engineering screen the led will flash the appropriate number of

times indicative of the screen number you have just entered.

Pressing the button >10 times (but less than 20) will exit the engineering mode.

Engineering screen 1 (GSM/GPRS/GPS indication)

0 trill = no network coverage

1 trill = GSM ok

2 trill = GSM & GPRS ok

3 trill = GSM, GPRS & Jabber connection connected ok

And

0 flash = o GPS coverage

1 flash = 1 satellite, time fix possible

2 flash = 2D GPS fix

3 flash = 3D GPS fix

Engineering screen 2 (Ignition detection)

Led On Ignition On

Led Off Ignition Off

T8-Mini Installation otes v1.0

Generic T8-Mini Installation otes v1.0.doc

Page 17

Engineering screen 3 (External power detection)

You must have the internal Battery connected for this screen to operate

correctly

Led On Ext Power present

Led Off Ext power absent

Engineering screen 4 (Internal Battery detection)

You must have the internal Battery connected with external power and have

had the ignition on at least once for this screen to function correctly

Led On Internal Battery

Led Off Internal Battery not connected

Engineering screen 5 (Tremble Device detection)

Led Pulses when vehicle/device is shaken indicates trembler operational

Led does OT pulse when the vehicle is shaken indicates trembler non

operational

Engineering screen 6 (Normal Tag Detection)

This screen is mutually exclusive with screen 7 so as to O LY detect the

presence of normal tags. These are Tags that have not been entered into the

unit as authorized Tags using the ADDTAG command

Led Pulses upon detection of a normal tag

Engineering screen 7 ( uthorized Tag Detection)

This screen is mutually exclusive with screen 6 so as to O LY detect

Authorized tags. These are tags that have been entered into the unit using the

ADDTAG command.

Led Pulses upon detection of an Authorized Tag.

Engineering screen 8 (GPS Satellite Quality)

This screen provides a visual indication as to the quality of the GPS fix. The led

is flashed once for each satellite that the receiver can see where the signal

strength (RSSI) is > 35dbm.

The unit is deemed to have a good quality fix if the number of satellites visible

above 35 is greater than 4.

T8-Mini Installation otes v1.0

Generic T8-Mini Installation otes v1.0.doc

Page 18

Engineering screen 9 (C N RPM Detection)

This screen is I ACTIVE in the T8 Mini as the product does not contain CA .

Engineering screen 10 (Serial Port 0 RX ctivity)

This screen displays whether the T8 is detecting any RX activity on serial port

0.

Led Pulses when the T8 detects received activity on the serial port.

Engineering screen 11 (Serial Port 1 RX ctivity)

This screen is “I ACTIVE” in the T8 Mini as the product O LY contains one

serial port.

Engineering screen 12 (Dallas Button ctivity)

This screen displays whether the T8 is detecting a Dallas button on the

Receiver.

Led Pulses when the T8 reads the presence of a Dallas button.

Engineering screen 13 (Driver Behavior Dual LED)

This screen alternates the colour of the Driver behaviour module so that the bi-

colour LED can be tested for correct connectivity.

The correct sequence of LED colours is a single flash of each as follows:

Bright Red, Bright Orange, Bright Green, Dim Red, Dim Orange, Dim Green.

The level of the dim flashing is the same as it would be during the hours of

dusk and simulates the functionality of the AUTO dimming function in the

firmware.

6.2

6.26.2

6.2 Server data

Server dataServer data

Server data

Follow the vendor specific commissioning procedure to ensure that your T8-

Mini is communicating all the implemented functional data to the host server.

Pay particular attention if the driver interface button is fitted that both Business

and private journeys are tested along with the Panic function if implemented. If

the Dallas receiver is fitted then test the presence of a driver by presenting a

Dallas tag and then check that the ID is detected in the server data.

T8-Mini Installation otes v1.0

Generic T8-Mini Installation otes v1.0.doc

Page 19

7

77

7 Appendix A

Appendix A Appendix A

Appendix A –

––

– 8

88

8-

--

-Mini

MiniMini

Mini

Wiring Diagram

Wiring DiagramWiring Diagram

Wiring Diagram

The T8-Mini is provided with a very simple Un-terminated cable. Therefore this

wiring diagram has been produced as a guideline to aid fitters in the connectivity

of the basic functionality around driver button/Led, Dallas/Led, Buzzer and

immobilisation.

It is the responsibility of the fitter to ensure that these guidelines are met.

T8-Mini Installation otes v1.0

Generic T8-Mini Installation otes v1.0.doc

Page 20

8

88

8 Appendix

Appendix Appendix

Appendix B

BB

B

–

––

– 8

88

8-

--

-Mini

MiniMini

Mini

Connections & Ratings

Connections & RatingsConnections & Ratings

Connections & Ratings

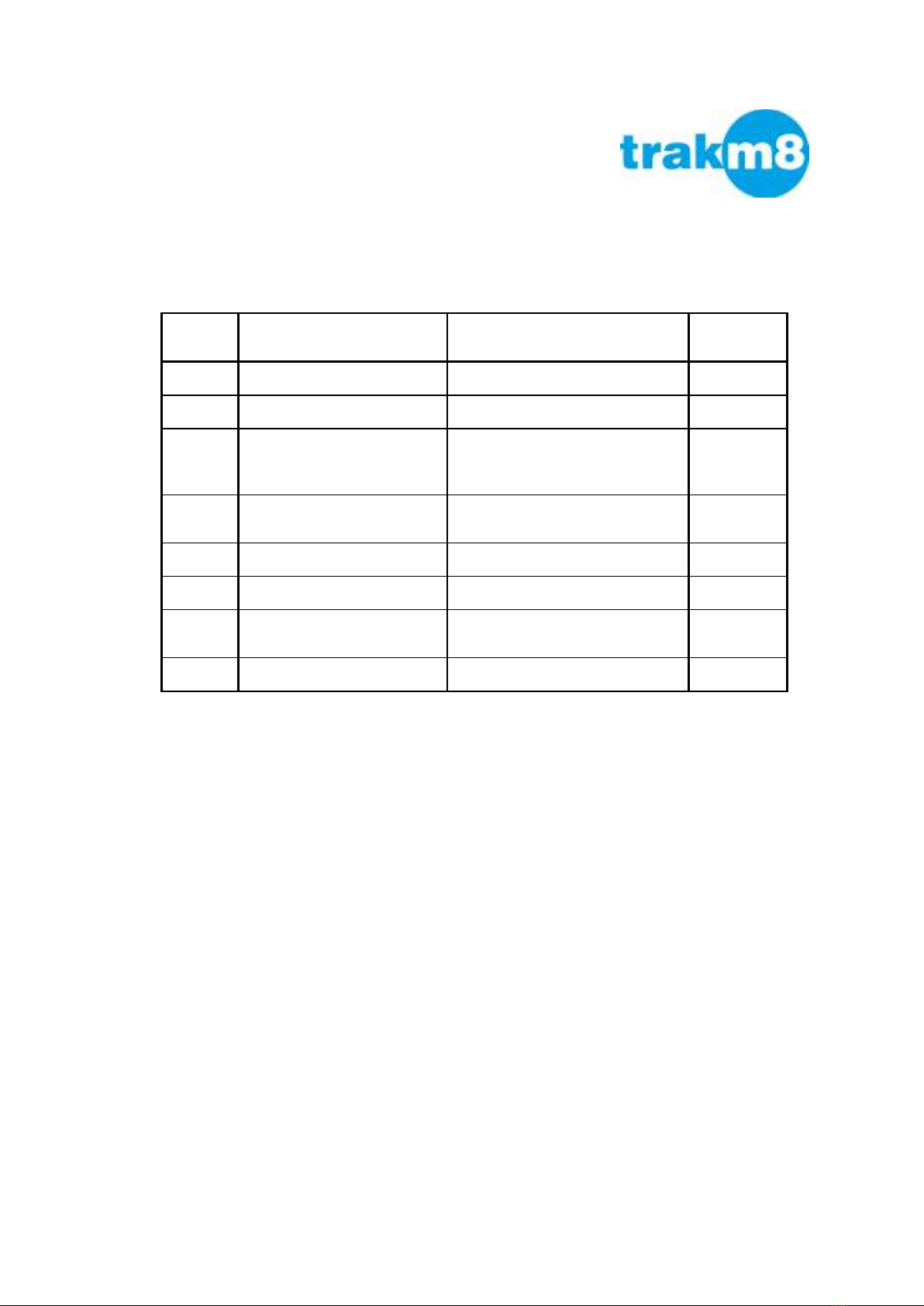

Pin T8-MINI-Signal

esignation

Function Wire

Colour

1

Digital Input 2 Ignition Blue

2

RS232-Rx Serial In White

3

I/O/AIN 0

(Dig or Analog Input 1 or

Op 1.

Immobili er Pink

4

RS232-Tx Serial Out

Yellow

5

Button / Dalla Bu ine /Private/Panic/Driver ID Grey

6

Vin (Supply) Red

7

I/AIN 1

Digital Or Analog Input 2

Red LED/Buzzer Green

8

GND Ground Brown

Table 1 – Signal Description

Other manuals for T8

1

Table of contents

Other Trakm8 Automobile Accessories manuals