CG-PRC026C-GB

10

Unit Placement

Setting The Unit

A base or foundation is not required if the selected unit

location is level and strong enough to support the unit’s

operating weight (see “Weights” section of this catalog).

For a detailed discussion of base and foundation

construction, refer to the sound engineering bulletin or

the unit IOM. Manuals are available through the local

Trane office.

HVAC equipment must be located to minimize sound

and vibration transmission to the occupied spaces of

the building structure it serves. If the equipment must

be located in close proximity to a building, it should be

placed next to an unoccupied space such as a storage

room, mechanical room, etc. It is not recommended to

locate the equipment near occupied, sound sensitive

areas of the building or near windows. Locating the

equipment away from structures will also prevent sound

reflection, which can increase sound levels at property

lines or other sensitive points.

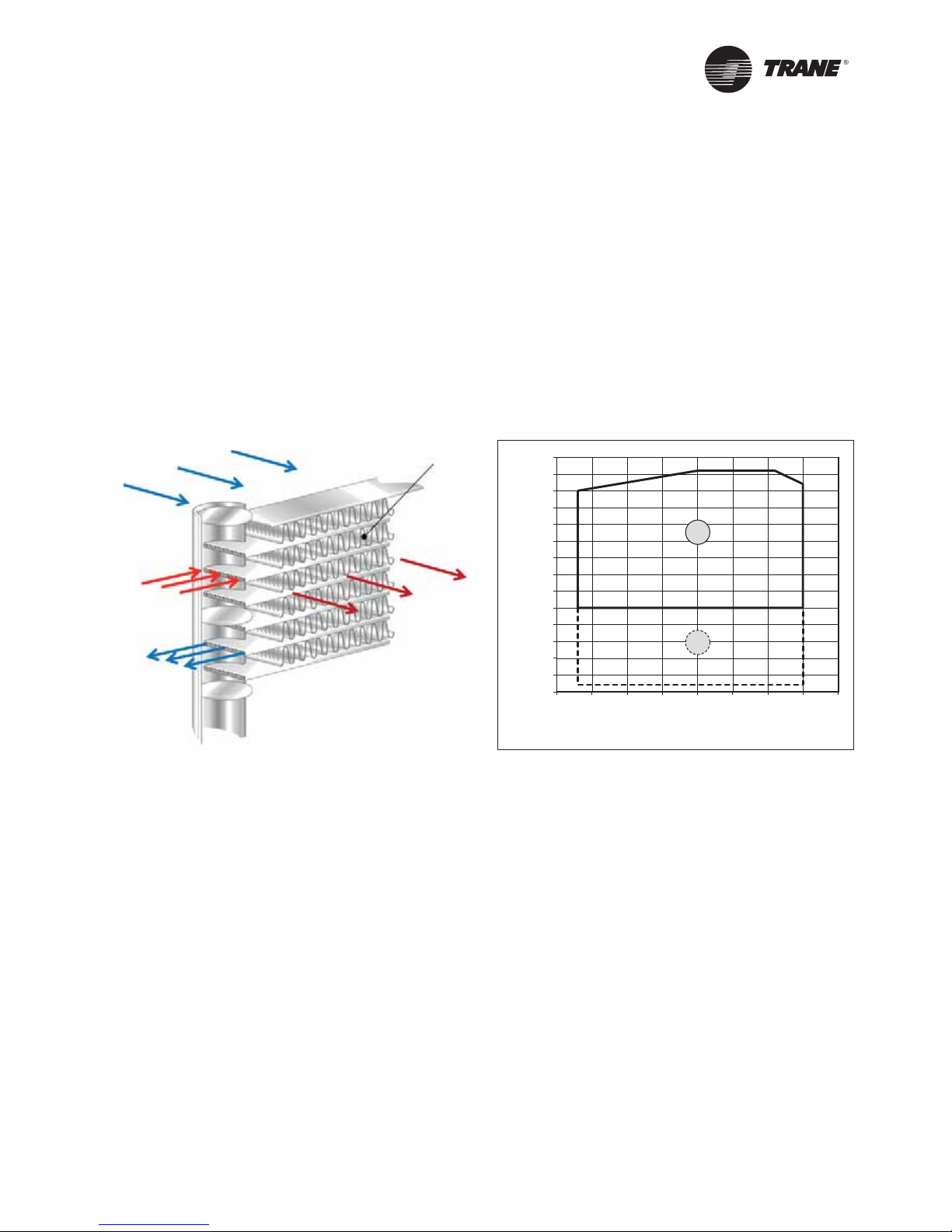

Isolation and Sound Emission

Structurally transmitted sound can be reduced

by elastomeric vibration eliminators. Elastomeric

isolators are generally effective in reducing vibratory

noise generated by compressors, and therefore, are

recommended for sound sensitive installations. An

acoustical engineer should always be consulted in

critical situations.

Figure 9 - Installation example

For maximum isolation effect, water lines and electrical

conduit should also be isolated. Wall sleeves and rubber

isolated piping hangers can be used to reduce the sound

transmitted through water piping. To reduce the sound

transmitted through electrical conduit, use flexible

electrical conduit.

Local codes on sound emissions should always be

considered. Since the environment in which a sound

source is located affects sound pressure, unit placement

must be carefully evaluated. Sound power levels for

chillers are available on request.

Servicing

Adequate clearance for evaporator and compressor

servicing should be provided. Recommended minimum

space envelopes for servicing are located in the

dimensional data section and can serve as a guideline

for providing adequate clearance.The minimum space

envelopes also allow for control panel door swing

and routine maintenance requirements. Local code

requirements may take precedence.

Unit Location

General

Unobstructed flow of condenser air is essential to

maintain chiller capacity and operating efficiency. When

determining unit placement, careful consideration

must be given to assure a sufficient flow of air across

the condenser heat transfer surface.Two detrimental

conditions are possible and must be avoided: warm air

recirculation and coil starvation. Air recirculation occurs

when discharge air from the condenser fans is recycled

back to the condenser coil inlet. Coil starvation occurs

when free airflow to the condenser is restricted.

Condenser coils and fan discharge must be kept free of

snow or other obstructions to permit adequate airflow

for satisfactory unit operation. Debris, trash, supplies,

etc., should not be allowed to accumulate in the vicinity

of the air-cooled chiller. Supply air movement may draw

debris into the condenser coil, blocking spaces between

coil fins and causing coil starvation.

Both warm air recirculation and coil starvation cause

reductions in unit efficiency and capacity because of

the higher head pressures associated with them.The

air-cooled Conquest chiller offers an advantage over

competitive equipment in these situations. Operation is

minimally affected in many restricted air flow situations

due to its advanced chiller controller.

Microprocessor which has the ability to understand the

operating environment of the chiller and adapt to it by

first optimizing its performance and then staying on

line through abnormal conditions. For example, high

ambient temperatures combined with a restricted air

flow situation will generally not cause the air-cooled

model CGAX chiller to shut down. Other chillers would

typically shut down on a high pressure nuisance cut-out

in these conditions.

Cross winds, those perpendicular to the condenser, tend

to aid efficient operation in warmer ambient conditions.

However, they tend to be detrimental to operation

in lower ambients due to the accompanying loss of

adequate head pressure. Special consideration should

be given to low ambient units. As a result, it is advisable

to protect air-cooled chillers from continuous direct

winds exceeding 4.5 m/s in low ambient conditions.

Chiled water piping

should be supported.

Isolators

Flexible electrical

conduit

Concrete base

Isolators

Piping isolation