Transcell Technology TI-1500VC Manual instruction

Transcell Technology, Inc.

Add: 975 Deerfield Parkway Buffalo Grove, IL U.S.A.

Zip: 60089

Tel: 01-800-503-9180 01-847-419-9180

Fax: 01-847-419-1515

Web Site: www.transcell.net

TI-1500VC

Weighing Transmitter

Setup / Operation Manual

Ver 3.5C

2018-05

Transcell Technology, Inc.

R

TABLE OF CONTENTS

1. TI-1500VC Specifications…………………………………………..1

2. Dimension & Installation……………………………………………2

2.1 TI-1500VC Dimension…………………………………………2

2.2 Installation………………………………………………………2

3. TI-1500VC Setup Menu…………………………………………….4

3.1 System menu (F Menu) ………………………………………4

3.2 User menu………………………………………………………8

4. Operation …………………………………………………………...9

4.1 keyboard……………………………………………………….9

4.2 Display and Annunciator……………………………………..10

4.3 TI-1500VC Calibration……………………………………….11

4.3.1 Calibration …….……………………………………………..11

4.3.2 Adjust the Zero Track Band (F3) …………………………..12

4.3.3 Adjust the Manual Zero Range (F4) …………………………13

4.3.4 Adjust the Auto Zero Range (F15)……………………………13

4.3.5 Adjust DA (F25) ………………………………………………..13

5. RS485 Communication Port………………………………………15

5.1 Connecting the RS485 output……………………………….15

5.2 Communication Mode of RS485 ……………………………15

5.3 Data Format (TI-1500VC Vision: V3.5C) ………………….16

5.4 Command Format ……………………………………………17

Hardware Vision Explain……………………………………………..18

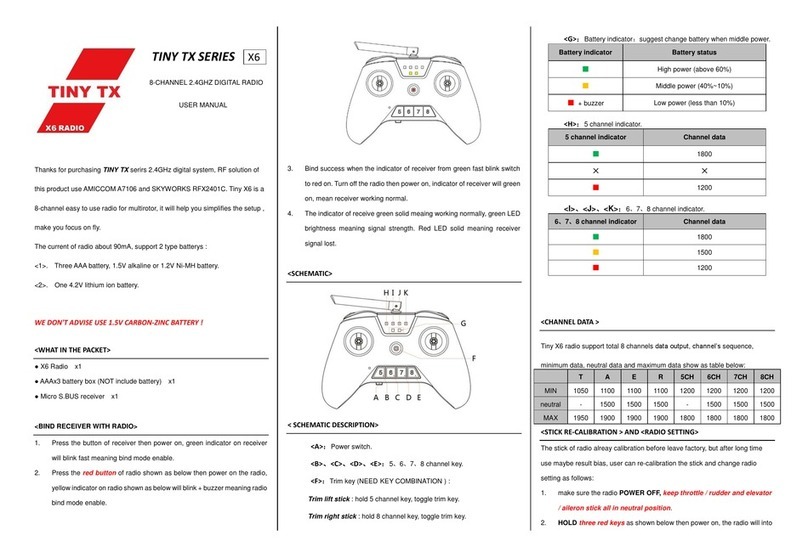

1. TI-1500VC Specifications

(1) Analog Signal Input:

The transmitter can drive 4 x 350Ωload cell. The signals input

every channel can be adjusted. The excitation voltage is +5V.

(2) Interface:

a. 4—20mA analog output (with digital adjust)

b. 0—10V analog output (with digital adjust)

These two output channels can not use in the same time, you

should choose one output channel to operate.

c. Communication port: RS485

(3) Weighing Resolution: III

Except 4-20mA & 0-10V output

(4) Display / Keyboard

7-segment, LCD;

1 LED annunciator

5 keyboards

(5) Function:

Auto zero track, Digital Filter, Digital Calibration, Keep Peak

Value

(6) Sampling Rate: 100Hz

(7) Rated Voltage: DC 15V±10%, 500mA

(8) Power: <=4W

(9) Operating Temperature: -10℃--+55℃

(10) Enclosure: Stainless steel & water proof

-1-

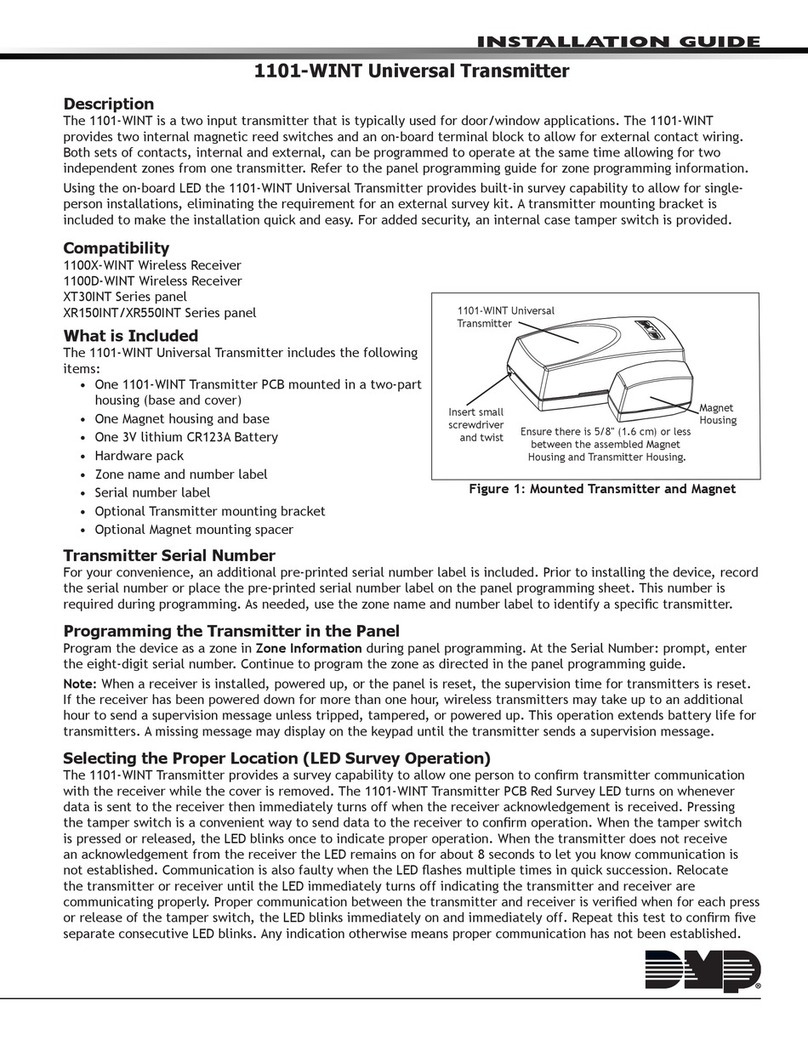

2. Dimensions & Installation

2.1 TI-1500VC Dimension:

Unit: mm

2.2 Installation:

TI-1500VC Connection Assignment

P+ P- +24 0 Io Vo AA BB

-2-

Φ

The power terminal, Analog Signals output and Communication

port locate the upper of the display, mark J2. Total 8 connect

terminals. Use slotted screwdriver clockwise tension.

Follow is the definitions of the connect terminals:

Maker Definition Description

P+ Positive for DC Power

P- Negative for DC Power DC 15V±10%, 500mA

Note: Please connect

Power +/- correct.

+24 Analog Single

( 0-10V/4-20mA) drive

power+ ( Exterior power)

Power standard: DC 15~24V

If using this power supply

to analog single current,

please open J3.

0 Common port a. Analog single drive power-

b. With Ioor Vocompose

signal loop.

Io4-20mA output Single With Common port compose

signal loop.

Output range: 0~24mA

Vo0-10V output Single With Common port compose

signal loop.

Min. load resistance: 10KΩ

AA RS485 in-phase

input/output

BB RS485 re-phase

input/output

When several TI-1500VC

are in one network, the last

TI-1500VC’s J4 should be in

short circuit, RS-485

terminal resistance is

enable.

-3-

3. TI-1500VC Setup Menu

3.1 System menu (F menu)

The section provides more detailed descriptions of the selections

found in the system menu chart (F menu).

Factory-set (F21) defaults are shown in bold with a checkmark (√).

F menu

Name/Code Description Code/Value

F1

Graduation Specifies number of full-scale

graduations. Value should be

consistent with legal require-

ments and environmental limits

on the useful system resolution.

500 1000

1500 2000

2500 3000

4000 5000√

6000 8000

10000 12000

20000 30000

40000 50000

F2

Span Gain Span Gain is related to A/D

integration time. The larger the

span gain, the higher the internal

resolution, but the slower the

update speed. Note that the scale

must be re-calibrated whenever

this parameter is altered. See

Appendix C for more information.

25 50

75 100

150√200

F3

Zero Track

Band

Selects the range within which

the scale will automatically zero.

Note that the scale must be in

standstill to automatically zero.

Selections are in Display

Divisions.

OFF√

0.5d 1d 3d

4d 5d 6d

7d 8d 9d

-4-

F4

Zero Range Selects the range within which

the scale may be zeroed. Note

that the indicator must be in

standstill to zero the scale.

1.9 2√

100

F5

Motion Band Sets the level at which motion is

detected by comparing the

present display update with the

previous one.

1d√ 3d

5d 10d

F6

Digital Filter AUTO: Auto Digital Filter

FAST: Fast Filter

8: More Stability

16: Most Stability

AUTO FAST

8 16√

F6A

Digital Filter Average Value Filter 16 32√ 48

64

F7

Overload

Limit

Selects the desired formula which

determines the point at which the

indicator shows overload. All

selections are based on the

primary unit selected in F8.

“FS”=Full scale in primary units

Overload display “□□□□□□”

FS FS+2%√

FS+1d

FS+9d

F8

Calib. Unit Selects the primary base unit to

be used in the calibration

process. Also the default unit for

normal operation.

1-lb

2-kg√

F9

Display

Divisions

Determines the desired weigh

increments. Value should be

consistent with legal

requirements.

div-1√

div-2

div-5

-5-

F10

Decimal Pt. Determines location of the

decimal point. 0√0.0

0.00 0.000

0.0000 00

F14

Disable the

lb/kg key

Allows the lb/kg key to be

disabled so that an operator

cannot accidentally press the key

and change the displayed units.

Cr-DIS√

Cr-EnA

F15

Zero Range

when Power

on

Selects the zero range when the

system power on. OFF√

(±)10%

100%

F16

Zero

Calibration

Places the system into the zero

calibration routine. Press ZERO

key to begin

sequence

F17

Span

Calibration

Places the system into the span

calibration routine. Press ZERO

key to begin

sequence

F18

View

Calibration

Actuates the function that allows

you to view both the zero and

span calibration value. The

values displayed in this function

are valid only after Calibration

(F16 & F17) has been

successfully completed.

Press ZERO

key to show

zero value;

Press ”→” key

to show span

value.

-6-

F19

Key-in Zero Allows you to key-in known zero

calibration value in case of

memory loss in the field.

Press ZERO

key to begin

sequence

F20

Key-in Span Allows you to key-in a known

span calibration value in case of

memory loss in the field.

Press ZERO

key to begin

sequence

F21

Factory

Reset

This sub-menu will reset all

parameters to the default

settings.

USE WITH CAUTION.

Press the

ZERO key

twice to

execute.

F23

DA Output

Type

Selects theAnalog Output type:

4-20mA or 0-10V Aout-C√

Aout-V

F24

DA Output

Enable

Allow/Forbid analog output

(4-20mA or 0-10V) DA-dIS

DA-EnA√

F25

DA Digital

Adjust

Adjusts the analog output value. Press ZERO

key to begin

sequence

-7-

3.2 User menu

Changing communication mode and formula is in this menu.

A menu

Name/Code Description Code/Value

A1

Baud Rate Selects the baud rate for data

transmission through the serial

port.

1200 2400

4800 9600

19200√

A2

Data Bits and

Parity

Selects the number of data bits

and parity of serial transmission.

8n√

7O

7E

7n

A3

Mode of

Serial

Transmission

Selects when data will be sent

out of the serial port to a printer

or computer:

“C”=Continuous mode

“d”= Demand mode

d√

C

A4

Display

Check

Actuates the function that

illuminates all digit segments,

decimal points, and LCD

annunciators in a test sequence.

Press ZERO

key to begin

sequence

A5

ID No. Entry Settings the Signal resource,

when more than one device in

one net.

[01-32] 01√

A20

Enable

ZERO key in

unstable

Allow/Forbid use ZERO key to

clear zero when the system is in

unstable state.

rZ-dIS√

rZ-EnA

-8-

4. Operation

4.1 Keyboard

TI-1500VC is utilized SMD mini-keyboard, easy to use. In different

mode, the keyboards have different function:

Function Keys Layout

Definitions of keys function

Keyboard Setting Mode Weigh Mode

(Press) Weigh Mode

(Keep Press)

SW1 ↑

Back to Main menu

or increase value

Kg/lb

Change units

---------

SW2 ↓

Enter Sub-menu or

decrease value

>0<

Set the indicator

display zero.

---------

SW3 SET

Save the setting

value

---------

---------

-9-

SW4 ←

Display the next

sub-menu or move

left

---------

---------

SW5 →

Display the next

sub-menu or move

right

PRINT

Print information

Enter HOLD

Mode

* 1. Press and Hold “SET” key while system power on, until the

display show [F1], enter setting mode. Turn off the system, then

turn it on again, the system back to normal weigh mode.

2. In F or A menu mode, press and hold “↑” key, back to normal

weigh mode.

4.2 Display and Annunciator

TI-1500VC is utilized a blue 7-segments LCD display. Follow is the

display detail:

TI-1500VC LCD display

Zero →

No meaning →

Stabile →

-10-

RedLED

↑

In normal weigh mode, the LED is flickering: the flicker frequency is

almost 2Hz in zero, the flicker frequency is almost 1Hz in other

weight; in setting mode, the LED lighten or black out.

4.3 TI-1500VC Calibration

Note: Every TI-1500VC has Factory Reset (F21) when it out of

the factory. The 4-20mA and 0-10V has been adjusted, so the

user shouldn’t repeat F21, otherwise the analog output should

been adjusted again.

4.3.1 Calibration

Example: The system result: 3000 x 0.1kg=300kg

(1) Graduations: Enter setting mode, the display show [F1].

Press “↓” key enter, the display show [xxxxx], if now the value

is [3000], press “↑”, back to the main menu. Otherwise, press

“→” or “←” key, until the display show [3000], press “SET” to

save the change. Then press “↑”, back to the main menu, the

display show [F1] again.

(2) Display Divisions: Press “→” key, until the display show [F9].

Press “↓” key enter, the display show [div x], if now the value is

[div 1], press “↑”, back to the main menu. Otherwise, press

“→” or “←” key, until the display show [div 1], press “SET” to

-11-

save the change. Then press “↑”, back to the main menu, the

display show [F9] again.

(3) Decimal Point: Press “→” key, until the display show [F10].

Press “↓” key enter, the display show [xxx], if now the value is

[0.0], press “↑”, back to the main menu. Otherwise, press “→”

or “←” key, until the display show [0.0], press “SET” to save the

change. Then press “↑”, back to the main menu, the display

show [F10] again.

(4) Zero Calibration: Press “→” key, until the display show [F16].

Make sure there are no test weights on the platform, press “↓”

key enter, the display show the present zero A/D count. When

the stabile annunciator turns on, press “↓” key to set zero point,

then press “SET” key to save the zero value.

(5) Span Calibration: Press “→” key, until the display show [F17].

Place the full capacity test weight on the platform, press “↓”

key enter, the display show flash [ 0], press “←” key 3 times,

the display show [ 0000], press “↑” input [3], now the display

show [3000], it’s equal to the test weight. When the stabile

annunciator turns on, press “SET” key to save the span value.

Now finishing the calibration, turn off the system. Then turn it on

again, the system back to the normal weigh mode.

4.3.2 Adjust the Zero Track Band (F3)

Zero Track Band means in stabile state the system will

automatically zero within the setting zero track range. The system’s

default zero track value is 1d. If the system use in large wind

environment or there will be some residues leave on the platform

every weight, the zero track parameter should be

-12-

increased according the fact.

Note:

Zero Track Range will effect the manual zero range. The larger

zero track range, the smaller the manual zero range. After run

zero track several times, it will lead to manual zero disable.

4.3.3 Adjust the Manual Zero Range (F4)

The function is being operated the deriver by manual zero clear.

The manual zero range is according to F4 value.

4.3.4 Adjust the Auto Zero Range (F15)

The function is made deriver to zero, when the system power on.

Note: If using in bucket scale system, the F15 value should be set

[OFF], its means when the system power off or restart, the system

will not be to zero automation.

4.3.5 Adjust DA (F25)

The analog output 4-20mA and 0-10V has been adjusted, when the

TI-1500VC out of the factory. The parameter should not be

adjusted again generally. If necessary, please follow the step:

(1) Enter F23 to select the type of analog output.

(2) Install the test circuit. (Command: connect to the device

directly.)

(3) Enter F25, press “↓”, the display show the present DA value

(0V or 4mA) [xxxxx].Adjust way:

[↑] key: Rough adjust. Press once, the value increase 50;

[↓] key: Rough adjust. Press once, the value decrease 50;

[SET] key: Save the value. Or when the present value is not

-13-

adjusted, press [SET] Key into next vale sub-menu.

[←] key: Fine adjust. Press once, the value increase 1;

[→] key: Fine adjust. Press once, the value decrease 1.

Note:

When F23=Aout-C, F25 can adjust follow item:

DA0 → 4mA adjust

DA1 → 20mA adjust

DA_ _ _ _ → 2mA adjust ( Lowest weight mark port current )

DA□□□□ → 22mA adjust (Highest weight mark port current )

When F23=Aout-V, F25 can adjust follow item:

DA0 → 0V adjust

DA1 → 10V adjust

DA_ _ _ _ → -0.04V adjust ( Lowest weight mark port current )

DA□□□□ → 10.8V adjust (Highest weight mark port current )

-14-

5. RS485 communication port

5.1 Connecting the RS485 output

a. Point to Point

b. Point to Multi-point

5.2 Communication Mode for RS485

(a) Continuous mode: send data continuously

STX NULL Device Add. Operate Command CR LF

-15-

(b) Demand mode: send data when a PRINT command is issued

from the peripheral equipment.

STX Add. I/O Weight

Data Weight

Units State Parity

bit CR LF

5.3 Data Format ( TI-1500VC Vision:V3.5c)

Start Transmission (1 bit): STX;

Device Address (2 bits): Address information;

I/O port state (3 bits): I/O port state information;

Weight Data (8 bits): Symbol (1 bit) + Decimal Point (1 bit) + xxxxxx

(6 bits, integer type);

Weight Units (1 bit): K-kg, L-lb

State (1 bit): 0-Overload, M-Motion, H-Hold, S-Stability;

Parity bit (1 bit): The low-byte of the sum of Device address, I/O

port state, Weight Data, Weight Units and State;

End symbol (2 bits): CR+LF

Note:

Weight Data, the definition of the decimal point:

0 ----- No decimal point (Integer)

1 ----- Number with one decimal place

2 ----- Number with two decimal place

3 ----- Number with three decimal place

4 ----- Number with four decimal place

8 ----- No decimal point (Integer)

-16-

PC

TI-1500VC

TI-1500VC

adr:03

TI-1500VC

adr:01

adr:02

TI-1500VC

adr:xx

adr:00

TI-1500VC

PC

5.4 Command Format

Device Address (2 bits): When the device address is less than 10

bits, please add 0 in front of the address.

Operational command (2 bits):

GD: Get weight data;

GC: Get calibration information;

GP: Get equipment address information;

GV: Get software vision;

GS: Get TI-1500VC factory series No;

CC: Transmit Units;

CH: Enter/Exit Hold Mode;

CZ: set the system to display zero.

-17-

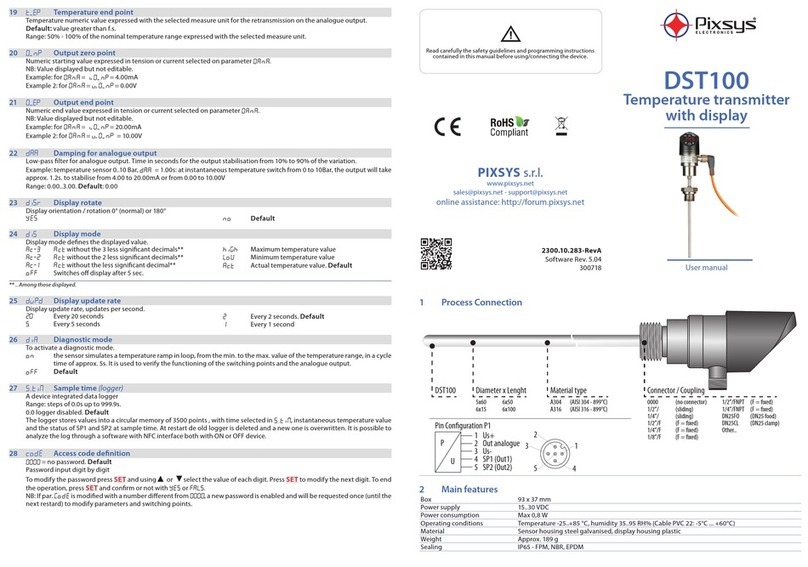

Hardware Vision Explain:

Show as follow figure. There is a hardware’s mark label paste near

the power terminal. So the different PCB board which marks

different sign can not be changed. Otherwise the TI-1500VC will be

destroyed. If the transmitter out of operate because of the

hardware error, please take it back to the factory, don’t repair it by

yourself.

-18-

Hardware Vision Label

Table of contents

Popular Transmitter manuals by other brands

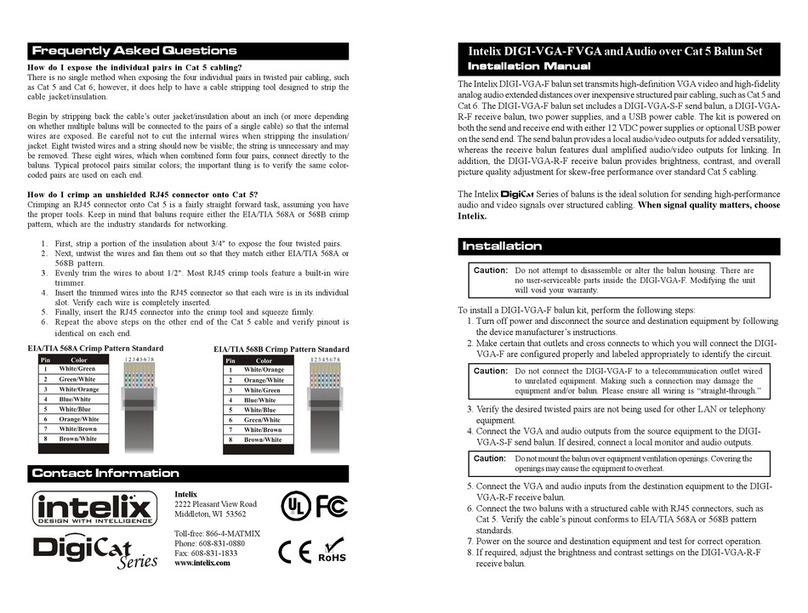

Intelix

Intelix DigiCat Series installation manual

YOKOGAWA

YOKOGAWA Dpharp vigilantplant EJA210A user manual

Honeywell Home

Honeywell Home 5800MINI Installation & setup guide

Yamamoto Electric Works

Yamamoto Electric Works Manostar EMT1 instruction manual

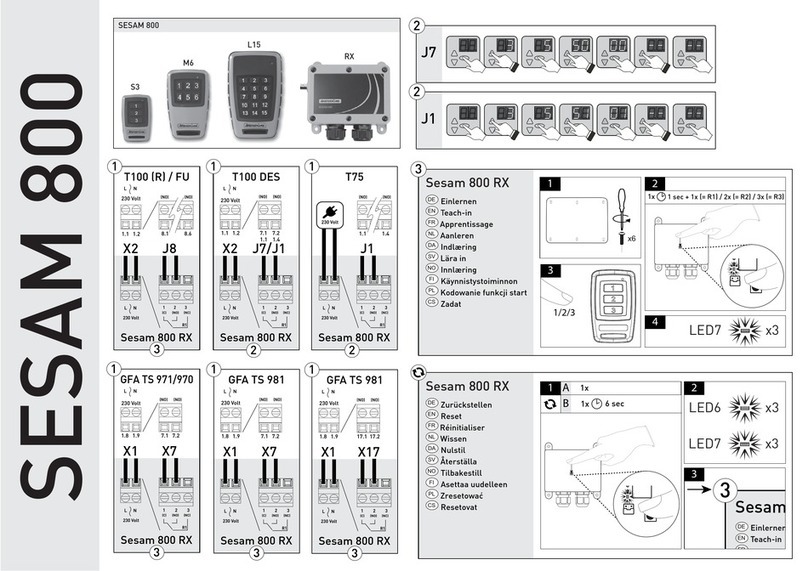

Akerstroms

Akerstroms SESAM 800 S3 quick start guide

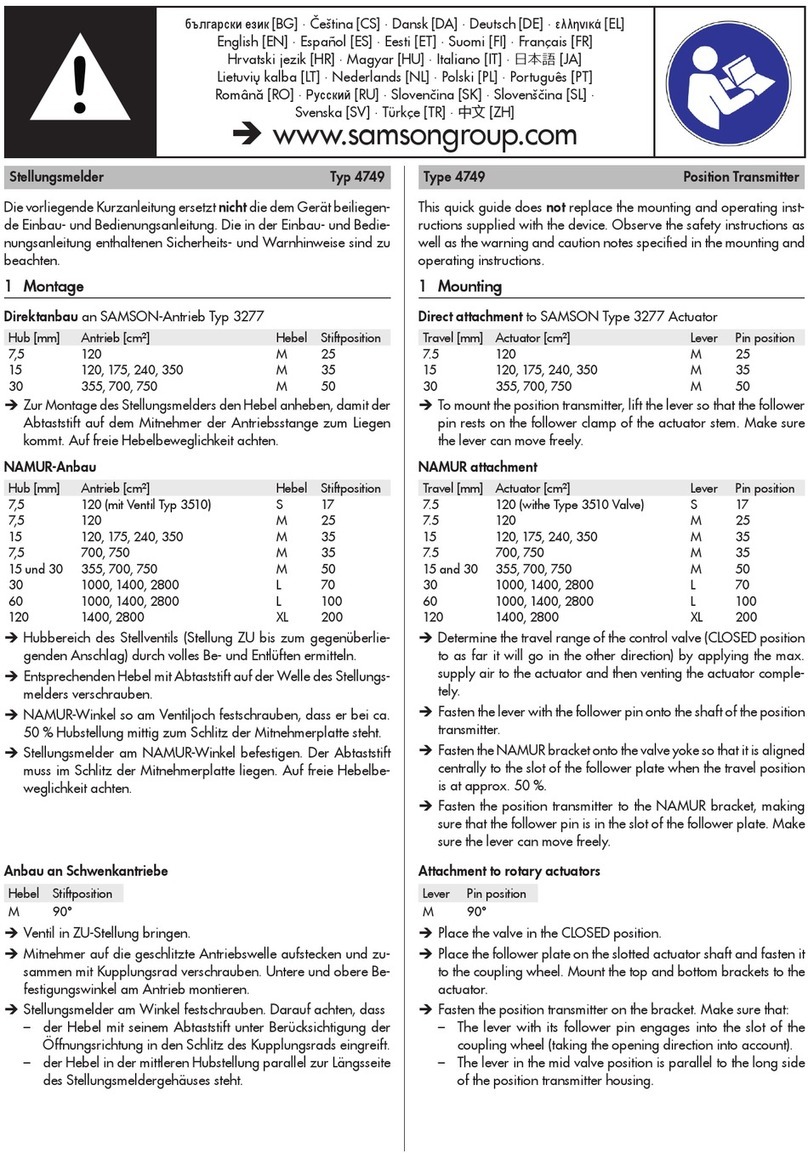

Samson

Samson 4749 manual

Michell Instruments

Michell Instruments Easidew user manual

Nice

Nice MYGO2BD Instructions and warnings for installation and use

DigitaLinx

DigitaLinx DL-1H1V1U-WP-W owner's manual

Altinex

Altinex SIGNAL MANAGEMENT SOLUTIONS UT260-105 user guide

MikroTik

MikroTik D2352AC quick guide

JUMO

JUMO SIRAS P21 AR operating manual