JENCO 692 User manual

OPERATION MANUAL

THE JENCO MODEL 692

PH TRANSMITTER

JENCO

ELECTRONICS, LTD.

MANUFACTURER OF PRECISION INSTRUMENTS

1

INTENDED USE AND GENERAL INTRODUCTION

The models 3672, 3673 and 3675 are precise instruments for the measurement and control

of pH and mV (ORP).

Two output relays are provided in the model 3675 for ON/OFF control. The isolated 4-20

mA output current of the model 3675 covers the input control range of 0 to 14 pH and 0 to

1400 mV.

A front panel programmable HIGH/LOW ALARM relay is provided in the models 3672

and 3673.

The isolated 4-20 mA output of the model 3672 can be set for a input control span of any

2 to 14 pH (200 to 1400 mV), via the front panel CONTROL SET POINT and SPAN ADJ

controls. The output 4-20 mA current can be selected for increasing or decreasing values

for increasing pH and mV (ORP) inputs. The isolated 4-20 mA output current of the

model 3672 covers the input control range of 0 to 14.00 pH and ±1999 mV.

The output pulse frequency of the model 3673 is proportional to the ion concentration,

over a preset proportional band of 2 pH and 200 mV. The pulse frequency output can be

selected for increasing or decreasing pulse rate for increasing pH and mV (ORP) inputs.

The maximum pulse frequency can be adjusted by the front panel PULSE RATE

ADJUST control. The pulse frequency output of the model 3673 covers the input control

range of 0 to 14.00 pH and ±1999 mV.

2

A large LCD display is used for readability under bright ambient conditions.

The models 3672, 3673 and 3675 are housed in a rugged 1/4 DIN plastic case, allowing it

to fit into standard panel cut-outs as well as the most commonly available industrial

weatherproof and environmental housings.

INITIAL INSPECTION

Carefully unpack the instrument and accessories. Inspect for damage in shipment. If any

damage is found, NOTIFY YOUR JENCO DISTRIBUTOR IMMEDIATELY. All

packing materials should be saved until satisfactory operation is confirmed.

3

FRONT PANEL FORMAT FOR THE MODEL 3672

1. LCD display

2. CONTROL SET POINT switch

3. CONTROL SET POINT LED

4. CONTROL SET POINT control

5. OUTPUT CURRENT SELECT switch

6. pH STANDARDIZATION control

7. pH SLOPE control

8. 4-20 mA SPAN ADJUST control

9. ALARM SET POINT switch

10. ALARM SET POINT LED

11. ALARM SET POINT control

12. ALARM SET POINT HIGH /LOW

SELECT switch

FIGURE 1A

4

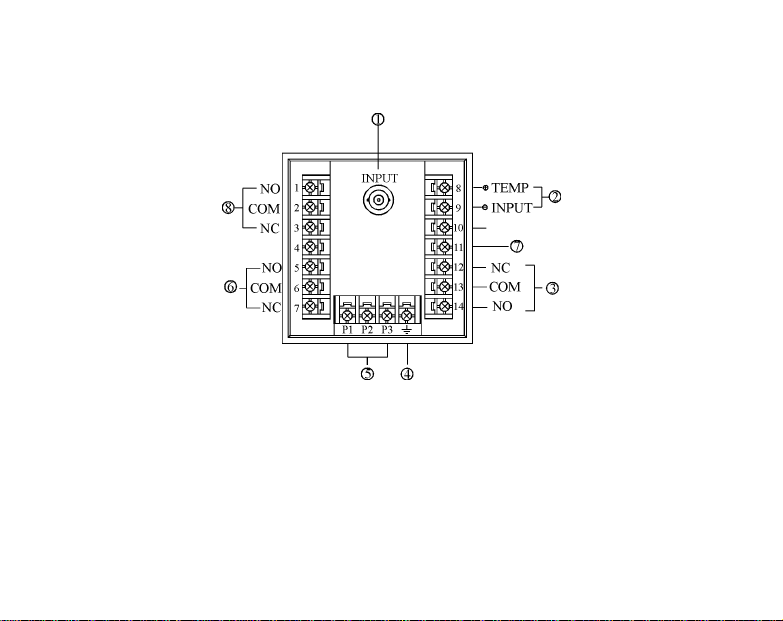

REAR PANEL FORMAT FOR THE MODELS 3672

1. pH/mV electrode BNC input

2. ATC probe input

3. Isolated 4-20 mA output

4. Reference electrode input

5. EARTH ground

6. AC power input

7. ALARM output relay

8. CONTROL output relay

FIGURE 2A

5

FRONT PANEL FORMAT FOR THE MODEL 3673

1. LCD display

2. PULSE RATE ADJUST control

3. CONTROL SET POINT switch

4. CONTROL SET POINT LED

5. CONTROL SET POINT control

6. PULSE FREQUENCY HIGH/LOW

SELECT switch

7. pH STANDARDIZATION control

8. pH SLOPE control

9. DEAD AND ADJUST control

10. ALARM SET POINT switch

11. ALARM SET POINT LED

12. ALARM SET POINT control

13. ALARM SET POINT HIGH/LOW

SELECT switch

FIGURE 1B

6

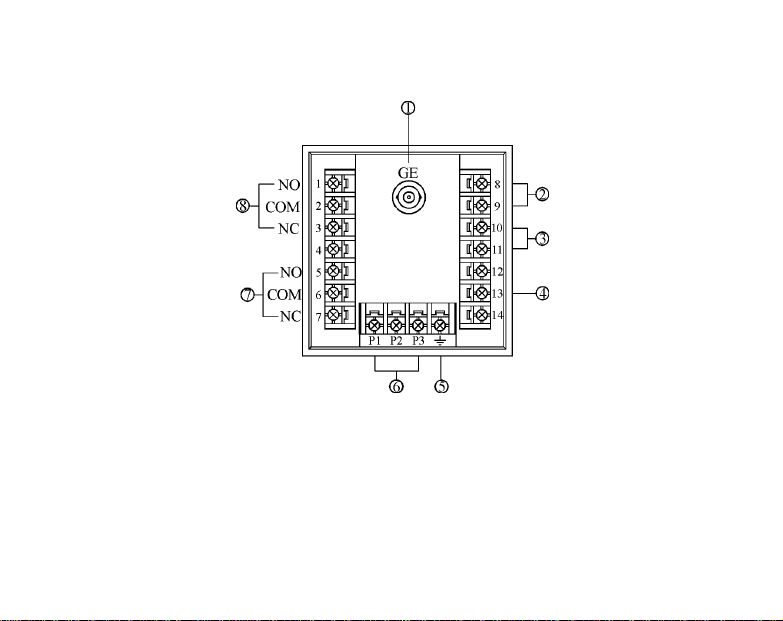

REAR PANEL FORMAT FOR THE MODELS 3673

1. pH/mV electrode BNC input

2. ATC probe input

3. Pulse frequency output

4. EARTH ground

5. AC power input

6. ALARM output relay

7. Reference electrode input

8. CONTROL output relay

FIGURE 2B

7

FRONT PANEL FORMAT FOR THE MODELS 3675

1. LCD display

2. HIGH ALARM SET POINT switch

3. HIGH ALARM SET POINT LED

4. HIGH ALARM SET POINT control

5. pH STANDARDIZATION control

6. pH SLOPE control

7. LOW ALARM SET POINT switch

8. LOW ALARM SET POINT LED

9. LOW ALARM SET POINT control

FIGURE 1C

8

REAR PANEL FORMAT FOR THE MODELS 3675

1. pH/mV. electrode BNC input

2. ATC probe input

3. Isolated 4-20 mA output

4. Reference electrode input

5. EARTH ground

6. AC power input

7. HIGH ALARM output relay

8. LOW ALARM output relay

FIGURE 2C

9

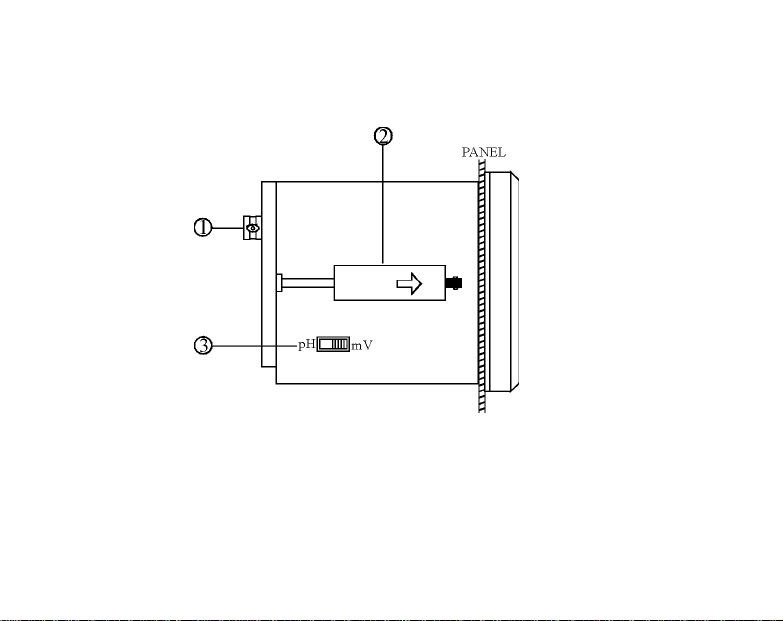

SIDE VIEW

1. pH/mV input BNC connector

2. Mounting bracket 3.pH/mV SELECT switch

FIGURE 3

10

TEMPERATURE COMPENSATION

The models 3672, 3673 and 3675 are designed to be used with a PT-100 RTD temperature

probe for automatic temperature compensation, ATC, operations. The alpha value of the

PT-100 element is 0.00385.

A precision 0.1% resistor can be connected across the ATC input terminals to simulate a

fixed process temperature.

11

Temperature in ℃Resistor value in Ohms

0 100.00

10 103.90

20 107.79

25 109.73

30 111.67

40 115.54

50 119.40

60 123.24

70 127.07

80 130.89

90 134.78

100 138.50

TABLE 1

12

REAR PANEL CONNECTION SCHEME

(Refer to FIGURE 1A/1B/1C and FIGURE 2A/2B/2C)

1. Connect the AC line to the rear terminals of the instrument. The instrument can be

powered by 115 VAC or 230 VAC, 50/60 Hz. Make sure that the Earth terminal is

connected to the earth lead of the AC power line.

2. Connect the proper load to the output relays. Be sure that the load does not exceed the

relay rating, 5 Amp at 115 VAC and 2.5 Amp at 230 VAC for RESISTIVE load only.

3. Set the pH/mV switch to the position for pH or mV operations. (Refer to FIGURE 3)

4. Load connections

Models 3672/3675

Connect the proper load to the 4-20 mA output terminals. Make common mode

voltage does not exceed 500 VDC.

Model 3673

Connect the pulse pump input leads to the output terminals of the pulse frequency

output. The common mode voltage is not to exceed 1500 VDC.

5. Increasing/decreasing outputs for increasing pH (mV) inputs

Model 3672 Refer to pages 10, 11, 12.

Set the OUTPUT CURRENT SELECT switch to the desired postion.

Model 3673 Refer to pages 10, 11, 12, 13.

Set the PULSE FREQUENCY SELECT switch to the desired position.

6. Electrode connections

13

6.1 Combination pH (mV) electrodes

Connect the pH (mV) electrode cable to the pH/mV electrode BNC input

connector.

6.2 Separate pH (mV) electrodes

Connect the working electrode to the pH/mV electrode BNC input connector.

Connect the reference electrode to the Reference input terminal.

7. Temperature compensation input connections

7.1 ATC mode

Connect the automatic temperature compensation, ATC, probe to the ATC input

terminals.

7.2 A percision 0.1% resistor can be connected across the ATC terminals to simulate

a fixed process temperature. (Refer to TABLE 1)

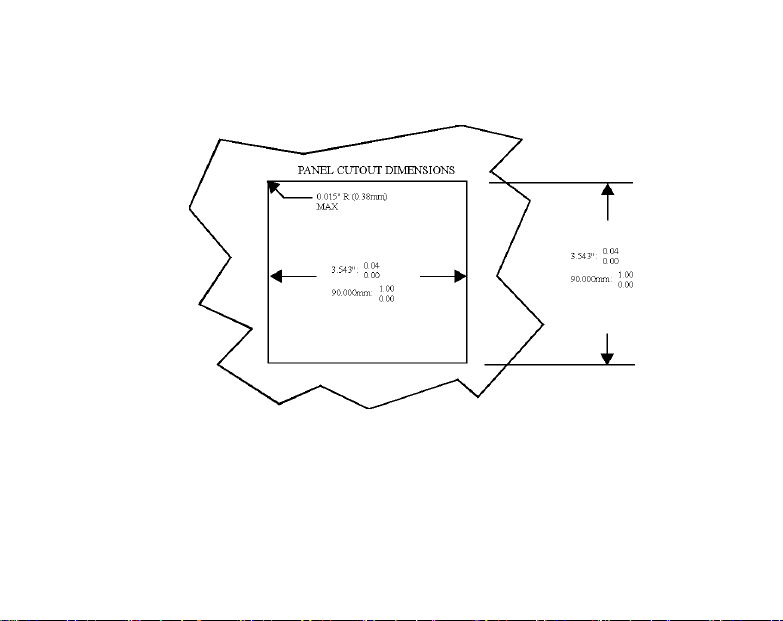

MOUNTING PROCEDURE

1. Make a cutout on any panel, with a thickness of 1/16 in. (1.5 mm) to 3/8 in. (9.5 mm).

(Refer to FIGURE 4)

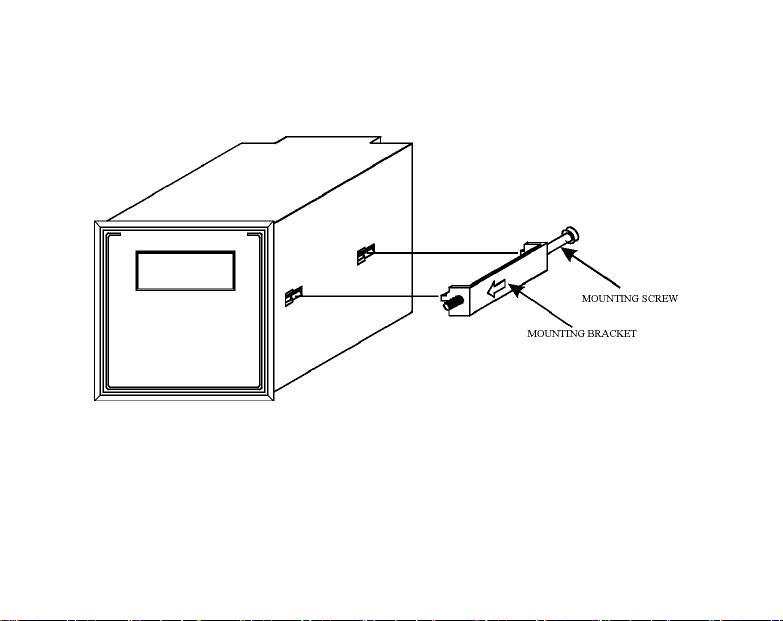

2. Remove the mounting brackets assembly from the panel meter and insert the panel

meter into the cutout. (Refer to Figure 5)

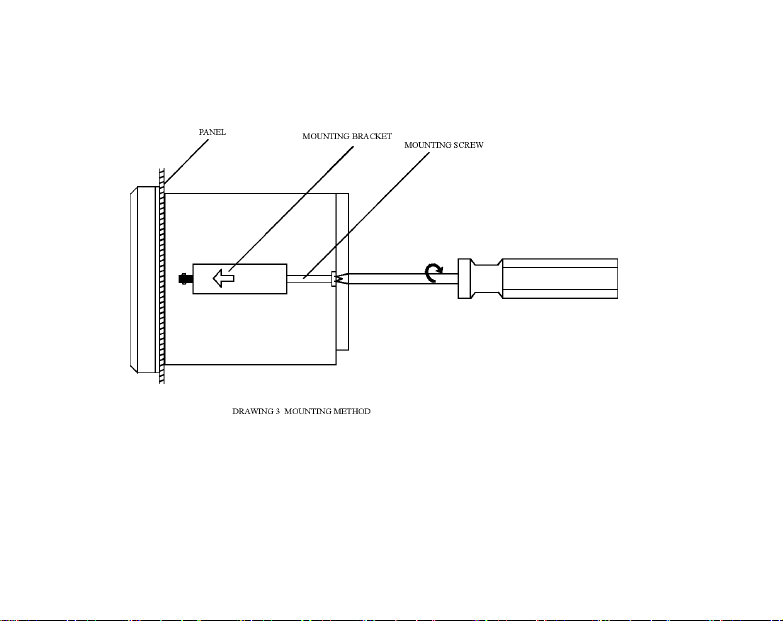

3. Replace the mounting brackets assembly onto the panel meter and fasten the

mounting screws to secure the panel meter to the mounting panel. (Refer to Figure 6)

14

Panel Cutout

FIGURE 4

15

Panel Meter With Mounting Bracket And Screw

FIGURE 5

16

Mounting Method

FIGURE 6

17

pH CALIBRATION

Refer to REAR PANEL CONNECTION SCHEME, pages 11, 12.

Refer to TEMPERATURE COMPENSATION, page 10.

1. Rinse the pH electrode and ATC probe with distilled water.

2. Measure the temperature of the buffer 7 solution with a precision thermometer.

3. Immerse the pH electrode and ATC/TEMP probe in buffer 7. Allow sufficient time

for the pH electrode and ATC probe to reach temperature equilibrium with the buffer

7.

4. Adjust the STAND control for the instrument to display the buffer value

corresponding to the temperature measured in 2. Refer to TABLE 2.

5. Remove the pH electrode and ATC probe from buffer 7 and rinse with distilled water.

6. Measure the temperature of a second buffer with a precision thermometer.

7. Immerse the pH electrode and ATC probe in the second buffer .For accurate pH

measurements, the second buffer should be close in pH and temperature values to

process under test. In practice, pH buffers 4 and 10 are commonly used.

8. Adjust the SLOPE control for the instrument to display the buffer value

corresponding to the temperature measured in 6. Refer to TABLE 2.

9. Remove the pH electrode and ATC probe from the second buffer and rinse with

distilled water. The instrument is dual point calibrated and ready for measurements.

18

TEMPERATURE COEFFICIENT OF THE pH BUFFERS

BUFFERS

℃10.01 7.00 4.01

0 10

.

32

7.

11 4

.

00

5 10

.

25

7.

08 4

.

00

10 10

.

18

7.

06 4

.

00

15 10

.

12

7.

03 4

.

00

20 10

.

06

7.

01 4

.

00

25 10

.

01

7.

00 4

.

01

30

9.97

6

.9

84

.

02

35

9.9

36

.9

84

.

02

40

9.

8

9

6

.97

4

.

03

45

9.

86 6

.97

4

.

04

50

9.

83 6

.97

4

.

06

55

9.

80 6

.97

4

.

0

7

60

9.7

86

.9

84

.

10

TABLE 2

19

ISOLATION VOLTAGE

The differential voltage between the outputs and the load should not exceed the maximum

values. Exceeding the maximum values may cause permanent damage to the instrument

and load.

1. Relay output

The maximum isolation voltage of the relay output contacts is 1500 VDC. The

voltage differential between the relay output contacts and the load should not exceed

1500 VDC.

2. Current output

The maximum isolation voltage of the 4-20 mA output is 500 VDC. The voltage

differential between the 4-20 mA output and the load should not exceed 500 VDC.

OUTPUT LOAD

1. Relay output

The current through the relay output contacts should not exceed 5 Amp at 115 VAC

and 2.5 Amp at 230 VAC in order hot to cause permanent damage the relay contacts.

This rating is specified for RESISTIVE loads only.

2. Current output

The maximum load is 550 ohms. Output current inaccuracies may occur for load

impedance in excess of 550 ohms.

Table of contents

Other JENCO Transmitter manuals