Transmate TapMate XL-424 User manual

08/30/2018

Before you operate this equipment,

read carefully and understand this operating manual.

If you need assistance or find parts missing or damaged,

call: 1.800.426.9341

ROMAC INDUSTRIES, INC. • 1.800.426.9341 • www.romac.com

TapMate™XL-424

Pipe Drilling Machine

OPERATING MANUAL

Waterworks Tools By Romac

Transmate

2

TAPMATE™ XL-424 Operating Manual

TABLE OF CONTENTS

Specication.................................................................................................................................................... page 3

Machine Overview........................................................................................................................................ page 4

ASSEMBLY

Open the Shipping Crate............................................................................................................................ page 5

Cutter and Pilot Identication .................................................................................................................. page 6

About Adapter Hub Sizes ........................................................................................................................... page 7

Adapter Hub Installation and Removal................................................................................................. page 8

TapMate XL-424 Set-Up for 4"-12" Taps...............................................................................................page 10

TapMate XL-424 Set-Up for 14"-24" Taps .............................................................................................page 14

Attaching the TapMate XL-424 to the Valve........................................................................................page 19

OPERATION

Performing the Tap .....................................................................................................................................page 22

Disassembly and Removal of the Coupon .........................................................................................page 27

Care and Maintenance ..............................................................................................................................page 28

PARTS IDENTIFICATION DRAWINGS

TapMate XL-424 (included items)...........................................................................................................page 29

TapMate XL-424 (base machine).............................................................................................................page 30

Adapter Bells (4" - 12")................................................................................................................................page 31

Adapter Bell (14" - 24") ...............................................................................................................................page 32

Small Shaft Head Assembly......................................................................................................................page 33

Large Shaft Head Assembly......................................................................................................................page 33

Jam Nut............................................................................................................................................................page 33

TM-XL, PVC Pilot............................................................................................................................................page 34

TM, PVC Pilot..................................................................................................................................................page 34

TM-XL, Shaft Nose ........................................................................................................................................page 35

TM, Shaft Nose...............................................................................................................................................page 35

Hydraulic Motor Assembly........................................................................................................................page 36

Shipping Crate / Workstation...................................................................................................................page 36

TRAVEL CHARTS..........................................................................................................................................page 37

Cast Iron Pipe...............................................................................................................................................pages 38

Ductile Iron Pipe ................................................................................................................................ pages 39 - 40

C900 PVC Pipe ...............................................................................................................................................page 41

C905 Pipe ............................................................................................................................................. pages 42 - 43

ASTM D2241 - IPS PVC Pipe ........................................................................................................... pages 44 - 45

Asbestos Cement (A/C) Pipe.....................................................................................................................page 46

ASTM D1785 PVC (Sch. 40, 80 &120) Pipe ...........................................................................................page 47

HDPE Pipe ............................................................................................................................................pages 48 - 50

3

TAPMATE™ XL-424 Operating Manual

• Heavydutysteelconstruction.

• Hydraulicmotorintegratedtoshaftandmachine.

• Weightofthedrillingmachineis285lbs.(lesstheadapterbell,pilotdrillandcutters).

• Lengthofthedrillingmachineonlyis87”(lesstheadapterbell,pilotdrillandcutters).

• Cuttertraveldistanceis39".

• Forusewith4"-24"cutters.

• SuitableforuseonCastIron,DuctileIron,Asbestos/Cement,Steel,PVCandHDPEpipe.

• 300psipressurerating.

• CompatiblewithTapMateandorQuikValveAdapters,CuttersandShaftNosesandPVCPilots.

• ExternalcomponentsoftheTapMateXL-424areQPQheattreatedforprotectionfrom

wearandcorrosion.

• Manualfeedprovidescontrolandfeedbackduringthecut.

• rustTubeisa#2StubAcmereadforrapidandcontrolledtravelthrough

thevalveandtappingsleeveneck.

• rustTubefeaturesascaletoindicatetheamountoftravel.

• IndicatorscaleontheLeadTubeshowstheexactcutterdepthandprogressofthecut.

• Inputtorquelimit:Continuous=3,604in-lbs.,Intermittent=4,283in-lbs.

• InputRPM:33.

TAPMATE™ XL-424 MACHINE SPECIFICATION

4

TAPMATE™ XL-424 Operating Manual

MACHINE OVERVIEW

WhileyoumaybefamiliarwiththeTapmatedrillingmachine,thismachineislargerandhasdierent

operatingrequirements.eseinclude:

• eTapMateXL-424hasnoslidingtubesorbrakes.

• Fewerturnsarerequiredtocompletethetap(inmostcases).

• TwojamnutsinsteadofonehavebeenusedtolockthecutterinplaceontheTapMateXL-424

(14"-24").

• TapMateXL-424feedratesareslowerbecauseofthenewthreads.

eTapMateXL424drillingmachineconsistsoffourdistinctsections.esesectionsaretheShaft,Lead

Tube,rustTubeandtheBrakeTube.

ethreadedrustTubeislocatedinthecenterofthemachineandtheBrakeTubeispositionedtoward

thebackofthemachine.Together,theycontroltraveloftheHolesawandpilotdrill.Priortothecut,the

HolesawandPilotDrillareextendedthroughthevalveandtappingsleevenecktothepipewallusingthe

BrakeTubeHandles.Afterthecutiscomplete,theHolesawandPilotDrillretractbackoutofthewaytoallow

thevalvetobeoperated.

AfterthetapiscompletedandyouaredrawingtheCutterawayfromthepipe,thethreadpitchprevents

waterpressurefromturningthebraketube.

eLeadTubeandLeadNut,arelocatedinsidethefrontendoftherustTube.Together,theyprovide

theforwardpressurenecessaryforthePilotDrillandShellCutterduringthecutting

operation.

eShaftisasinglepiecerunningthroughthecenterofthemachine.Itisthreadedonthefrontendto

acceptthePilotDrillandShellCutter.eotherendoftheShaftmateswiththehydraulicdriveunit.

Lead Tube

Thrust Tube

Brake Tube

Shaft

Lead Nut

w/Handles

Brake Locking

Bolt

Rear Lifting Ring

Locking

Collar

Integrated

Hydraulic

Drive

5

TAPMATE™ XL-424 Operating Manual

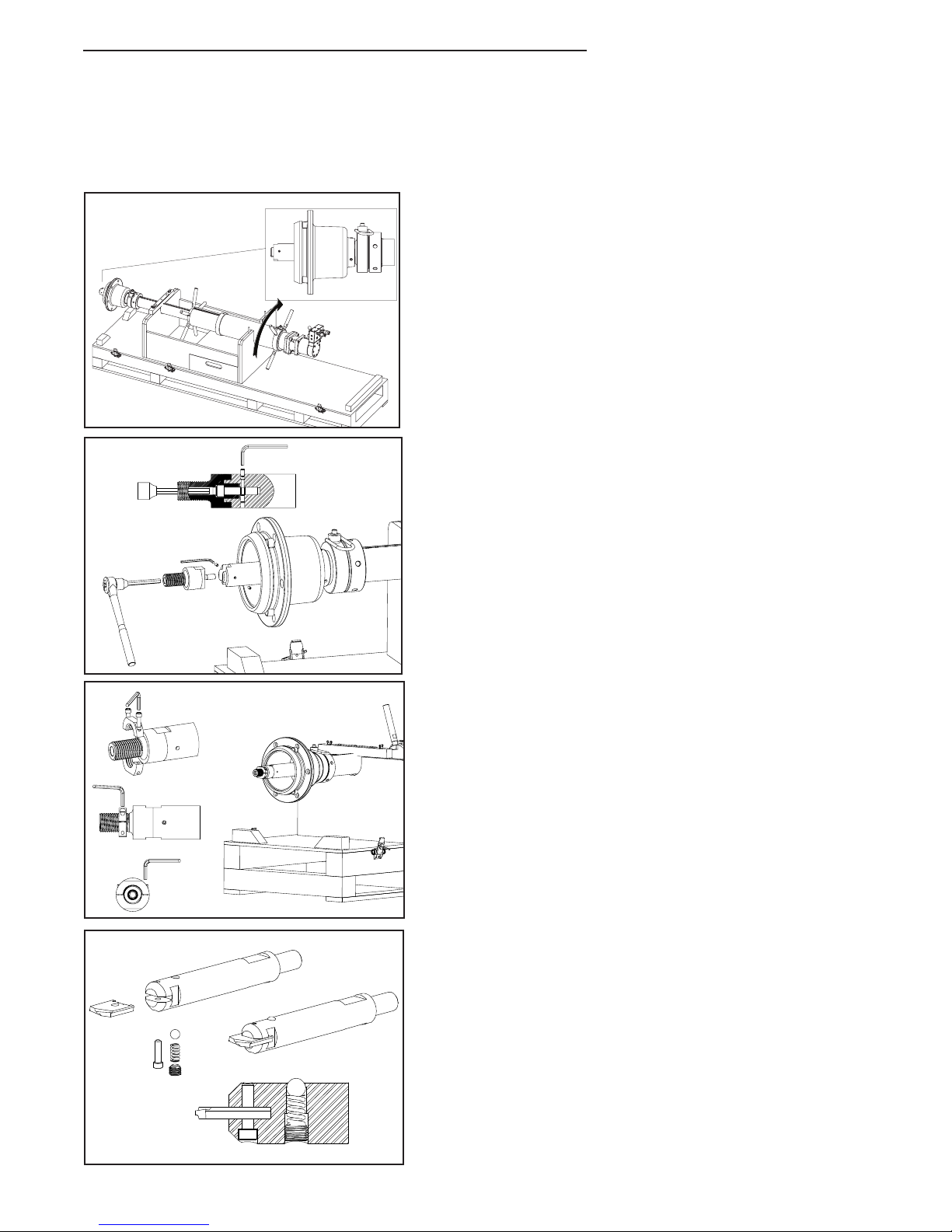

OPEN THE SHIPPING CRATE/WORKSTATION

1. Openall(six)ofthelatchesaroundbottomofthe

crate.

2. Swingopentheend(seedrawingatleft).

3. Liftandremovecover(seedrawingatleft).

6

TAPMATE™ XL-424 Operating Manual

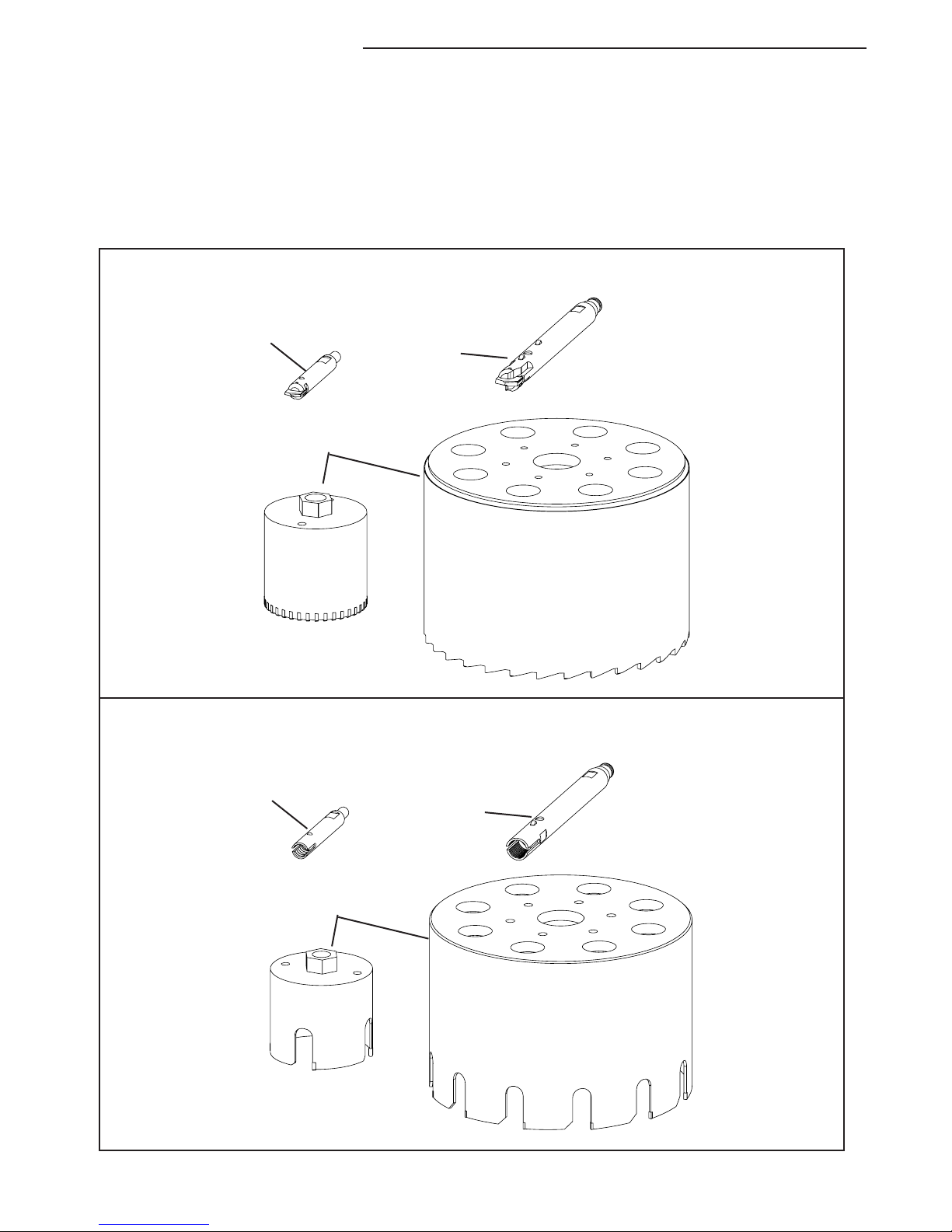

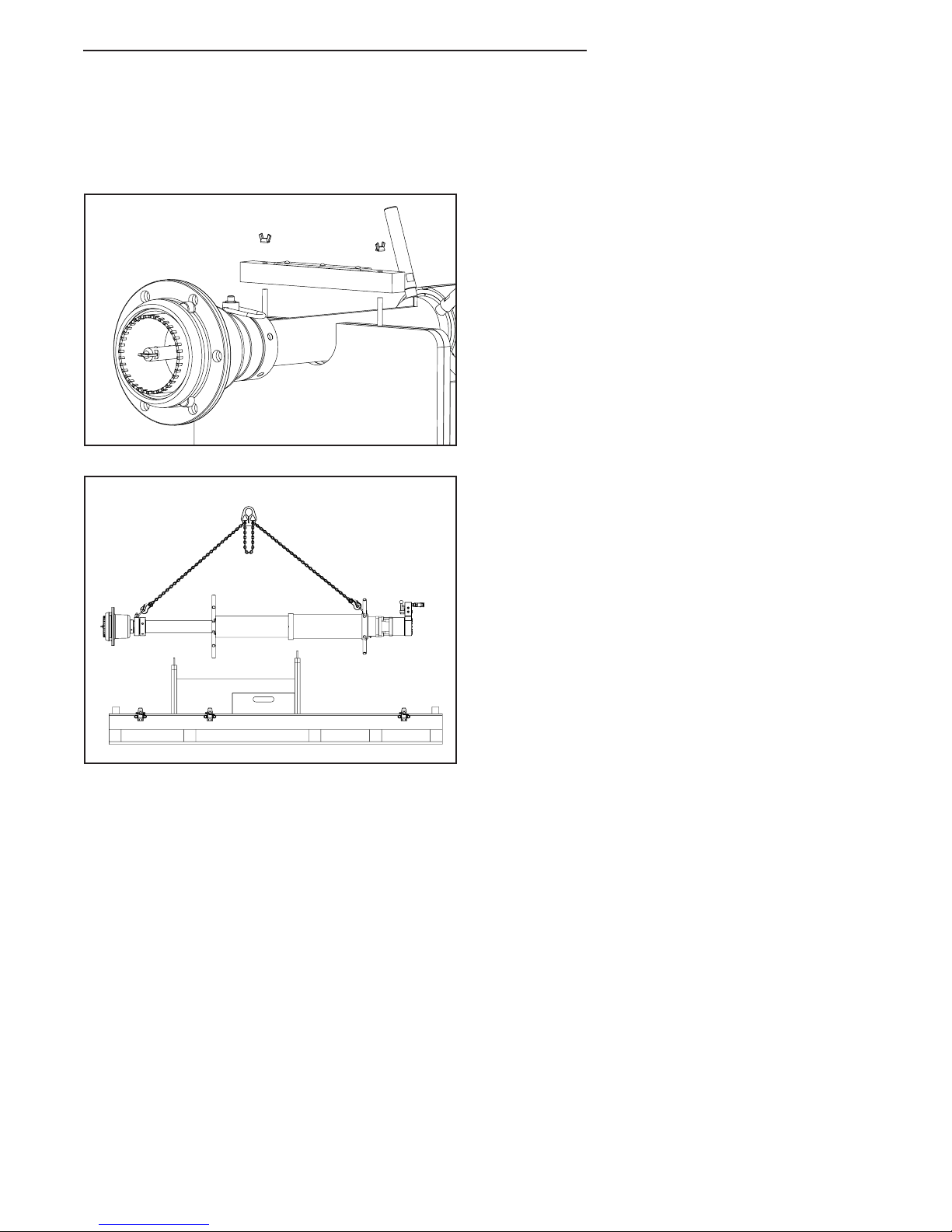

CUTTER AND PILOT IDENTIFICATION

1.Selectthepropercutterandpilotforthepipeyou'llbetapping.Seethedrawingsbelow.

TM, Shaft Nose

(4" - 12" taps)

Cutter and Pilots shown below are for use on Ductile Iron, Cast Iron and

Asbestos / Cement pipe.

TM, Shaft Nose

(4" - 12" taps)

Cutter and Pilots shown here are for use on PVC pipe.

TM, Shaft Nose

(14" - 24" taps)

Carbide Cutters

TM, Shaft Nose

(14" - 24" taps)

Carbide Cutters

7

TAPMATE™ XL-424 Operating Manual

ABOUT ADAPTER HUB SIZES

1.EnsurethatthecorrectAdapterHubissecurelyattachedtotheLeadTube.

TodeterminewhichAdapterHubyou'llneed,seethedrawingsbelow.

Note: The TapMate XL-424 is shipped from the factory without an Adapter Hub installed.

Small Adapter Hub

for use with

4" - 12" TapMate Adapter Bells.

Large Adapter Hub

for use with

14" - 24" TapMate XL-424 Adapter Bells.

8

TAPMATE™ XL-424 Operating Manual

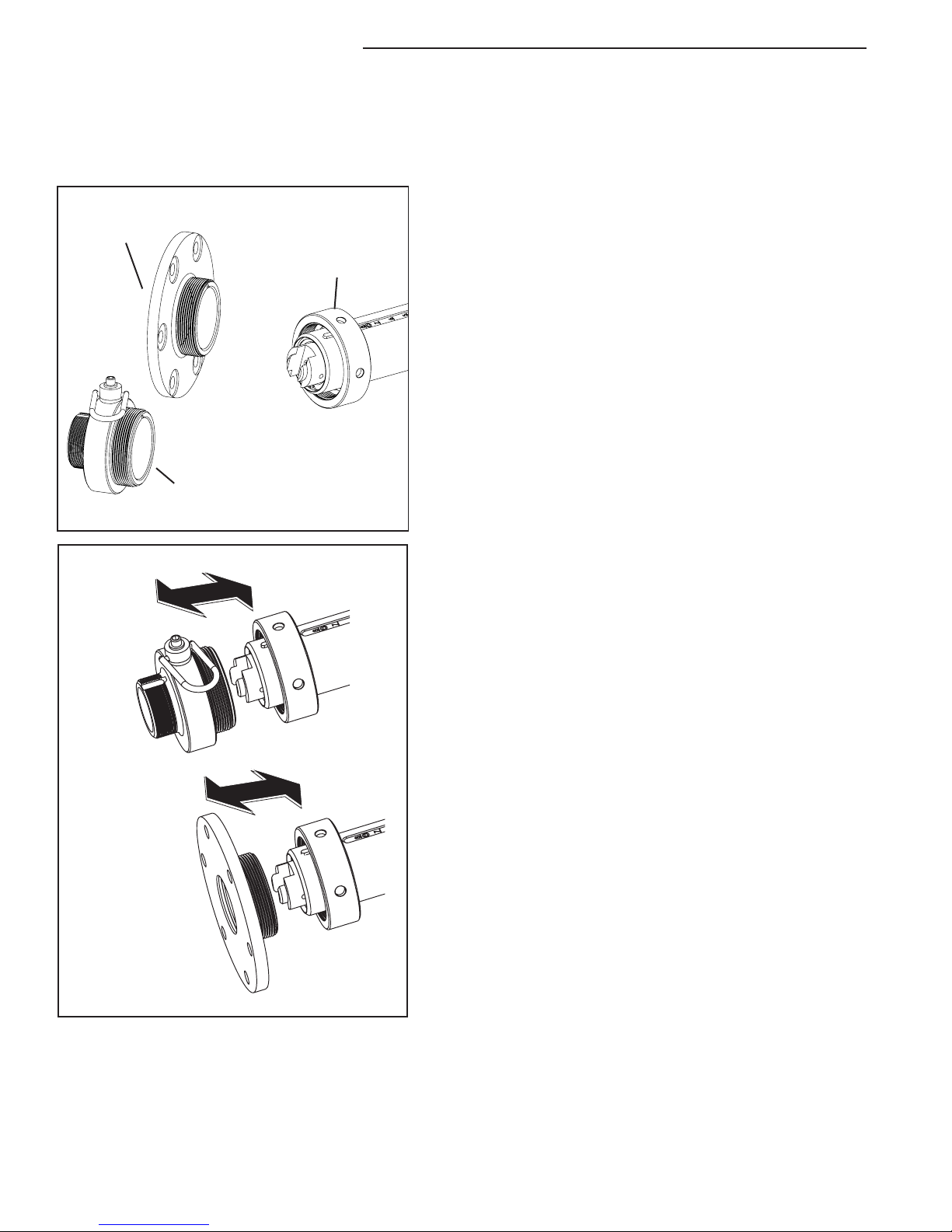

ADAPTER HUB INSTALLATION AND REMOVAL

Large Adapter

Hub

Lead Tube

Locking Collar

Small Adapter

Hub

Installation:

1. SelecttheappropriateAdapterHubforthesizeofAdapter

Belltobeused(SmallAdapterHubfor4"-12"andLarge

AdapterHubfor14"-24").

2. AlignthekeywayintheAdapterHubwiththekeyinthe

topoftheLeadTube(seedrawingatleft).

3. SlideAdapterHubovertheendoftheLeadTubeand

engagethethreadsoftheLeadTubeLockingHubCollar

(seedrawingatleft).

Large Adapter

Hub

Small Adapter

Hub

9

TAPMATE™ XL-424 Operating Manual

ADAPTER HUB INSTALLATION AND REMOVAL (cont.)

4. Tightenwithaspannerwrench.

Removal:

1. UnscrewtheAdapterHubfromtheLeadTube

LockingCollarwiththeSpannerWrench.

2. SlidetheAdapterHubotheLeadTubeand

storeinShippingCrate/WorkStation.

Large Adapter HubSmall Adapter Hub

Large Adapter HubSmall Adapter Hub

10

TAPMATE™ XL-424 Operating Manual

TAPMATE XL424 SETUP FOR 4" 12" taps:

For instructions on attaching the Large Adapter Bell (for 14" - 24" taps), turn to page 14.

1. AftertheSmallAdapterHubhasbeensecurelyattachedtothe

LeadTube,checktheTapMateAdapterBelltobesurethatthe

o-ringisinneckoftheadapter.

2. ScrewtheappropriatesizeandstyleAdapterBellontotheendof

theAdapterHub.Youshouldfeeltheo-ringcompressasyou

nishthreadingitontotheAdapterHub(seedrawingatleft).

3. erearefoursetscrewholesaroundtheneckoftheadapterbell.

Continuetothreadtheadapteronuntilthenextholeisoverthe

atslotonthetopofthehub.

4. Insertonesetscrewintotheholelocatedabovetheatandusea

3/16”allenwrenchtotightenthesetscrew(seedrawingatleft).

Note: The set screw must bear ENTIRELY on the at of the Small

Adapter Hub. Otherwise, damage to the threads of the Hub under

the set screw may occur, which in turn will make the Adapter very

dicult to remove. Further damage to the threads of the Adapter Bell

may also occur as you unscrew it from the Hub.

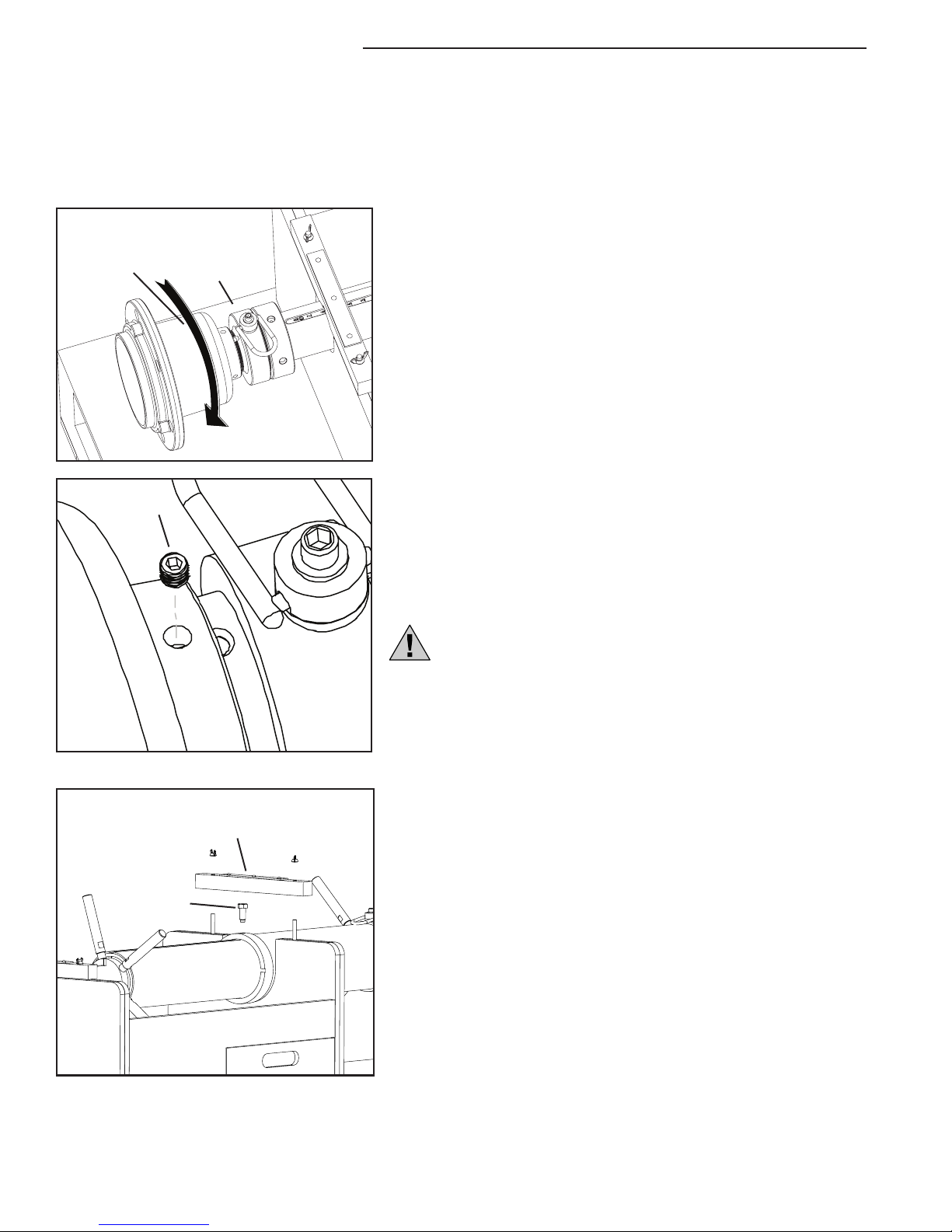

5. RemovetheBrakeTubeLockingBoltfromtheBrakeTube

(seedrawingatleft).iswillallowtheBrakeTube

torotateseperatefromtheentiremachine.Removetheback

workstationbrace.Leavethefrontworkstationbraceinplace.

Small

Adapter

Hub

Adapter Bell

(4" - 12")

Set

Screw

Brake Tube

Locking Bolt

Workstation

Rear Brace

11

TAPMATE™ XL-424 Operating Manual

TAPMATE XL424 SETUP FOR 4" 12" taps:

(cont.)

6. readtheBrakeTubedowntherustTubeby

rotatingitinaclockwisedirection,asviewedfromthe

backofthemachine(seedrawingatleft).Dothisuntil

theShaftextendsoutoftheAdapterBell.edistance

willvarydependingonthetypeandsizeofAdapter

Bellbeingused.

7. Applytheanti-gallinglubricanttotheSmallShaft

HeadBoltandstarttothreaditintotheendofthe

Shaftwiththe3/8"Allenwrench.Alighthekeyup

withthekeywayandnishscrewingtheSmallShaft

Headintoplace.Applytheanti-gallinglubricanttoboth

setscrewsandthreadthemintotheShaftusingthe1/8"

Allenwrench.eylocktheSmallShaftHeadBoltinplace,

preventingitfromlooseningduringthecuttingoperations.

8. eJamNutfacilitateseasyremovaltheShellCutters.

readtheJamNutontotheShaft.Runittothe

endofthethreads,andthenbackoonecomplete

revolution.Witha3/16"allenwrench,tightenJamNut

halvessothatthegapbetweenthemiseven

(seedrawingatleft).SecuretheJamNuthalvesby

torquingscrewstoapproximately50in-lbs.

9. TaketheTMShaftNose(orTMPVCPilot)and

examinetheretentionballsystem.Itshouldrequire

rm-to-hardpressuretodepresstheball.eball

shouldsnapbackintoplacesmoothly.Iftheballis

sticking,disassemble,andcleanthehole,balland

spring.Reassemble,andre-examinetoensuretheballis

functioning properly.

ChecktoseethattheSpadeBitintheTMShaftNose

is sharp and that it is held securely in the slot. If the

SpadeBitischippedordamaged,itshouldbereplaced.

TM Shaft Nose

12

TAPMATE™ XL-424 Operating Manual

TAPMATE XL424 SETUP FOR 4" 12" taps:

(cont.)

10. readtheTMShaftNoseorTMPVCPilot(dependingonthematerialofpipeyouaretapping)into

theendoftheShaftandtightenuntiltheshankoftheTMShaftNoseortheTMPVCPilotisushagainsttheface

oftheShaft.Duetothelongerbodylengthofthe10and12inchshellcutters,aPilotDrillExtensionmust

beattachedbetweentheShaftandtheShaftNose(orPVCPilot)andtightenedintoplaceforthesesizetaps.

Seedrawings(below)forShaftNosecongurations.

11. NowsliptheshellcutterovertheTMShaftNoseorTMPVCPilotandthreaditontotheShaftuntilitissnug

againsttheJamNut.

12. RetracttheShellcutterintotheAdapterBellbyrotatingtheBrakeTubeinacounter-clockwisedirection.eBrake

Tubewillstoprotatingwhenitshows“zero”(oralittlebeyond)ontherustTube.Locatethesetscrewholein

theBrakeTubebackoverthescaleintherustTubeandre-attachtheBrakeTubeLockingHandle.eBrake

TubeLockingHandlemaydamagetherustTubethreadsifitisn'tlocatedoverthescale.

13. CheckthattheLeadNutissittingat"zero"ontheLeadTube.

SHAFT NOSE CONFIGURATION FOR 10" 12" CUTS

TM Shaft Nose

XL Shaft TM Jam Nut

TM Pilot Drill

Extension

SHAFT NOSE CONFIGURATION FOR 4" 8" CUTS

TM Shaft Nose

XL Shaft TM Jam Nut

13

TAPMATE™ XL-424 Operating Manual

TAPMATE XL424 SETUP FOR 4" 12" taps:

(cont.)

13. Removethefronttie-downbracefromthecrate.

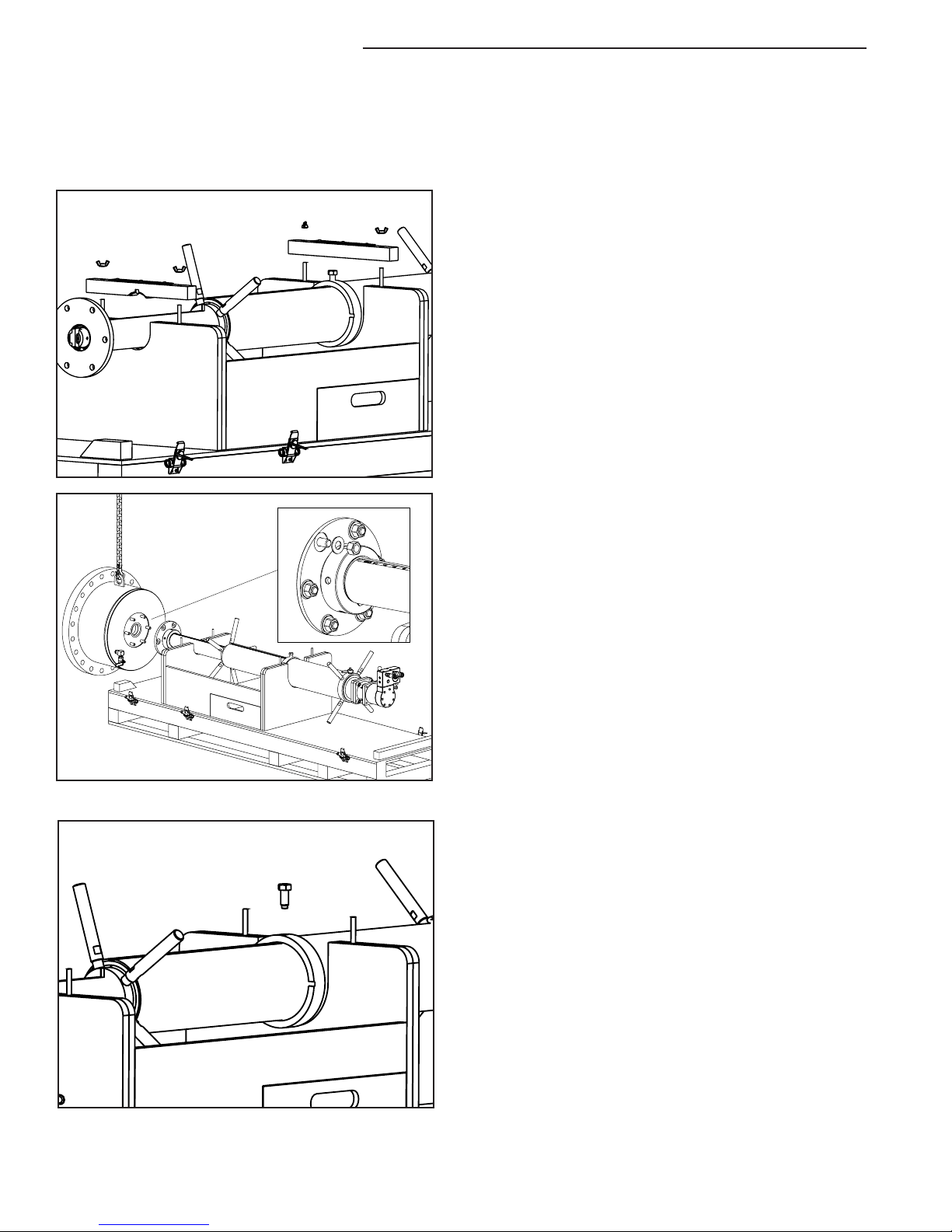

14. eTapMateXL424isnowreadytobeliftedand

attachedtothegatevalve.Whenliftingthemachine,

usetheLiftingRingsattherearofthemachineandat

theSmallAdapterHubasyourliftpoints.Adjustthe

ChainChokersothatthemachineaslevelas

possible.

14

TAPMATE™ XL-424 Operating Manual

TAPMATE XL424 SETUP FOR 14" 24" taps:

For instructions on attaching the Small Adapter Bell (for 4" - 12" taps), go to page 8.

1. Removefrontandrearbracesfromworkstation.

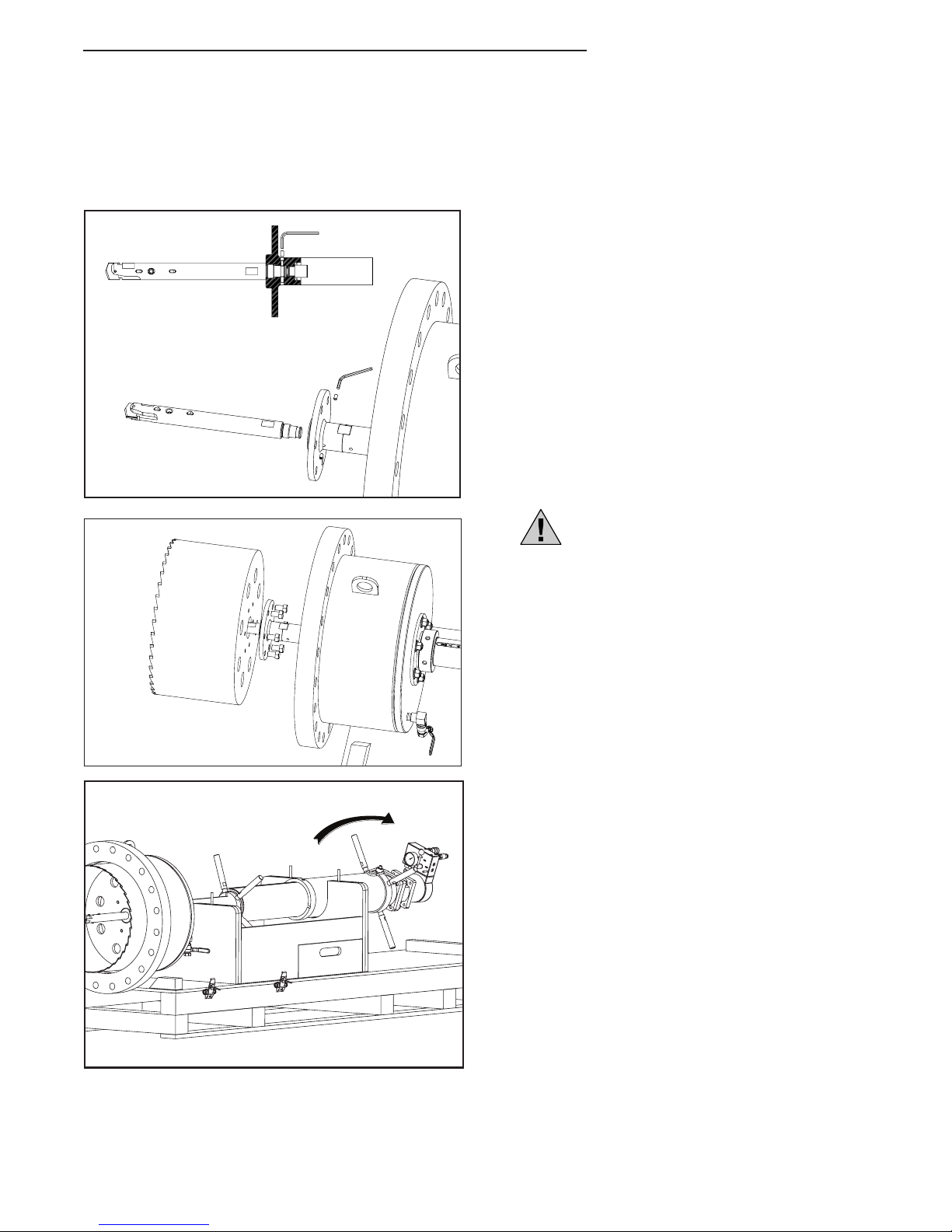

2. WiththeLargeAdapterHubproperlyinstalledonthe

LeadTube(seestepsonpage6),liftandmovethe

appropriatesizeandstyleTapMateXL-424Adapterbell

intoplace(seedrawingatleft).

3. Removethesixnutsandwashersfromtheoutsideof

theadapter.Alsomakesurethatthegasketisinplace.

4. LifttheAdapterBellbytheliftingeye,andmove

itintoplace.eShaftgoesthroughthecenterhole

intheadapter.Carefullyslidetheadapterbolts

throughthematingholesintheLargeAdapterHub.

5. Replacethenutsandwasherbackontotheadapter

and tighten.

6. RemovetheBrakeTubeLockingBoltfromtheBrake

Tube(seedrawingatleft).iswillallowtheBrakeTube

to rotate.

15

TAPMATE™ XL-424 Operating Manual

TAPMATE XL424 SETUP FOR 14" 24" taps:

(cont.)

7. readtheBrakeTubedowntherustTubebyrotating

itinaclockwisedirection,asviewedfromthebackof

themachine(seedrawingatleft).DothisuntiltheShaft

extendsoutoftheAdapterBell.edistancewillvary

dependingonthetypeandsizeofAdapterBellbeing

used.

8. Applytheanti-gallinglubricanttotheLargeShaftHead

BoltandstarttothreaditintotheendoftheShaftwith

the3/8"Allenwrench.Alignthekeywiththekeyway

andnishscrewingtheLargeShaftHeadintoplace.

Appytheanti-gallinglubricanttobothsetscrewsand

threadthemintotheShaftusingthe1/8"Allenwrench.

eylocktheLargeShaftHeadBoltinplacepreventing

it from loosening during the cutting operation.

16

TAPMATE™ XL-424 Operating Manual

TAPMATE XL424 SETUP FOR 14" 24" taps:

(cont.)

9. TaketheTMXL-ShaftNose(orTMXL-PVCPilot)and

examinetheretentionpinsystem.Itshouldrequire

firm pressure to depress the pin, and the pin should

snapbackintoplacesmoothly.Ifthepinissticking,

disassemble,andcleanthehole,pinandspring.

Reassemble,andre-examinetoensurethepinis

functioning properly.

ChecktoseethattheSpadeBitissharpandthatitis

heldsecurelyintheslot.IftheSpadeBitischippedor

damaged,itshouldbereplaced.

TM XL Shaft Nose

17

TAPMATE™ XL-424 Operating Manual

TAPMATE XL424 SETUP FOR 14" 24" taps:

(cont.)

10. NoticethatthethreadedendsontheTM-XLShaftNose

(andtheTM-XLPVCPilot)areinterruptedbyasmooth

area.WhentheTM-ShaftNose(orTM-XLPVCPilot)

isthreadedallthewayontotheLargeShaftHead,this

smoothareawilllineupwiththetwosetscrewholes

locatedintheLargeShaftHead.readSetScrewinto

placeandtightenwithan1/8"allenwrench(seedrawing

atleft)lockingtheShaftNoseorPVCPilotintoplace.

' 11.

MovetheappropriatesizeShellCutterovertheShaft

Nose(orPVCPilot)andontothefrontbossofthe

LargeShaftHead.AlignthethroughholesoftheLarge

ShaftHeadwiththetappedholesintheCutter.Secure

withthesixCutterboltsprovided.Tightentoa

minimumof30-40ft-lbs.

12. RetracttheShellCutterintotheAdapterBellby

rotatingtheBrakeTubeinacounter-clockwisedirection.

eBrakeTubewillstoprotatingwhenitshows"zero"

ontherustTube.

CheckthattheLeadNutissittingat"zero"onthe

LeadTube.

Note: Due to the weight of some Shell Cutters,

use a suitable strap and lifting mechanism

when lifting and installing the Shell Cutter.

18

TAPMATE™ XL-424 Operating Manual

TAPMATE XL424 SETUP FOR 14" 24" taps:

(cont.)

13. eTapMateTM-XL424isnowreadytobeliftedand

attachedtothegatevalve.Whenliftingthemachine,

using the lifting loop at the end of the machine and the

loopontheadapterbell.

Note: Adjust the Chain Choker so that the machine is

lifted as level as possible.

19

TAPMATE™ XL-424 Operating Manual

ATTACHING THE TAPMATE XL424 TO THE VALVE:

eillustrationsinthissectiondepicta6”size-on-sizetapusingaRomacFTS420FabricatedSteelTappingSleeve,anMJ

byFlangegatevalveandtheTapMateXL-424machinewithanMJadapterbell.Regardlessofthesizetapyou're

performing, the steps are the same.

1. Installandassembletappingsleeveandgatevalveperthe

manufacturer'sinstructions.Pressuretestthetapping

sleeveandgatevalveassemblybeforebeginningthetap.

NOTE: At this point, you'll take some measurments to

determine the necessary depth of your tap. Record

these measurements, as you'll use these values in

subsequent steps.

2. Withthevalvegatestillclosedfromthepressuretest,

measurethedistancefromthevalveangefacetothe

gate(seedrawingatleft).

3. WiththeShellCutterfullyretracted,takethefollowing

measurements(seedrawingsatleft)

• MeasurethedistancetheShaftNose/PVCPilot

extendsbeyondtheAdapterBellange.

• MeasurethedistancethattheShellCutterextends

beyondtheAdapterBellange.

• esedistanceareoftendierentdependingonthe

tapsizeandtheAdapterBell.

4. CarefullycomparethemeasurementstakeninSteps2

and3,toensurethattherewillbenointerference

betweentheShaftNose/PVCPilotorShellCutter,

andthegatevalvewhenthetapiscompleted.

Clearance Distance

Pilot Drill

C

L

Valve Body

Centerline of the

Waterway

Valve Gate

Distance

Cutter Clearance

Valve

Flange

Face

Tapping Sleeve Neck

Pipe

Extension Distance

Shaft Nose/PVC Pilot

Extension Distance

Shaft Nose/PVC Pilot

MJ Adapter

(without Gasket)

Distance

Cutter's Extension

Flange Adapter

Distance

Cutter's Extension

20

TAPMATE™ XL-424 Operating Manual

Distance to Pipe

Centerline of

the Waterway

Valve Gate

C

L

Pipe OD

Valve

Flange

5. Carefullyreleasethepressureinthesleeveandvalve.

OPENthevalvegatecompletely.

6. Measure,andnotethedistancefromthevalveangeto

thepipe(throughthevalve,sleeveneckandany

extensions).Recordthismeasurment,asthisvalueis

necessaryinsubsequentsteps.

Pipe

Distance to Distance of Cut

Travel Chart's

<

=

39 Inches Total Machine

Bar Travel Distance

C

L

-

+Cutter's Extension

out of Adapter

and into Valve Body

or

BORING BAR TRAVEL & DISTANCE OF CUT

7.eTapMateXL-424boringbarcantravel39inches,whichismorethanadequateformosttaps.

Beforeyoubeginyourtap,makesurethetotaldistancetocutisnotmorethan39inches.

Todeterminethedistancenecessaryforyourtap,seethedrawingbelow.

ATTACHING THE TAPMATE XL-424 TO THE VALVE:

(cont.)

Note: Conrm that the ID of the pipe is greater than the Cutter's OD.

Table of contents