Transporter PLUS 11 MK 2 Release note

Issue : - Man/P11,02 1 Last rev: 26.08.2010

FOR THE ULTIMATE IN QUALITY AND SERVICE

PLEASE CONTACT US AT:-

The Old Airfield, Gosfield, Halstead, Essex C09 1SA

(01787) 478490 Fax :( 01787) 476047

www.transporter-engineering.com

E-mail: [email protected]

PLUS 11 MK 2 CAR TRANSPORTER

DRIVERS MANUAL

Issue : - Man/P11,02 2 Last rev: 26.08.2010

CONTENTS

DECK MAXIMUM LOADS AND LOAD SECURITY……………………………..3

OPERATION AND SAFETY SIGNS ................................................................4

CARE OF BODY PAINT WORK ......................................................................4

GENERAL SAFETY.........................................................................................4

GENERAL VEHICLE LAYOUT ........................................................................5

TYRE PRESSURES AND TORGUE SETTINGS.............................................6

MAXIMUM DECK LIFTING CAPACITIES........................................................7

DAILY SAFETY CHECKS................................................................................8

OPERATION OF THE POWER TAKE OFF UNIT (PTO).................................8

LOADING RAMPS ...........................................................................................8

OPERATING DECKS ......................................................................................9

HAND RAILS .................................................................................................10

TRAILER SUSPENSION VALVE OPERATION.............................................10

LOADING LIGHTS.........................................................................................10

COUPLING AND UNCOUPLING THE RIGID................................................ 11

UNLOADING IN THE EVENT OF A MECHANICAL FAILURE ......................12

VEHICLE SECURING SYSTEMS..................................................................13

VEHICLES ON THE TRANSPORTER...........................................................14

LOADING SEQUENCE DIAGRAMS..............................................................15

TYPICAL LOADING DIAGRAMS................................................................... 31

SERVICE FACILITIES (Listings) SUPPLIMENT SHEET

SERVICE FACILITIES (Locations) SUPPLIMENT SHEET

This manual is an important document and as such should remain with the

vehicle. It is a Health and Safety requirement that the driver can refer to the

document to establish SWL.

Before operating this transporter you must be trained in its operation and be

fully conversant with the controls. Misuse could cause injury to operator and

serious damage to the vehicle.

Issue : - Man/P11,02 3 Last rev: 26.08.2010

DECK MAXIMUM LOADS AND LOAD SECURITY

The following sets out the maximum applied load for each deck and loading

angles, subject to the following criteria being established at all times.

•Each vehicle deck maximum imposed load limit of 2,500 kgs which

must not be exceeded.

•The trailer top deck and the rigid top deck each have a combined

maximum imposed load limit of 7,500 kgs and 5,000 kgs respectively

which must not be exceeded.

•The trailer front scissor arm mechanism maximum imposed load limit of

2,500 kgs which must not be exceeded, although the hydraulic

pressure relief system is not designed to lift an imposed load in excess

of 750 kgs.

•All imposed loads should be uniformly distributed.

•All loads carried must be fully and properly secured prior to moving

decks or the vehicles carried, in accordance with your company loading

instructions. Never move the transporter unless every vehicle loaded

on it is fully and properly secured.

•The above criteria apply subject to the transporter and all its equipment

being properly maintained.

•If you are in any doubt never operate a deck or move a transporter

without contacting your manager.

OPERATION AND SAFETY SIGNS

1. Operation signs are located next to all controls.

2. Warning signs are a reminder to be alert to potential dangers in the area

shown with a risk of injury or death.

3. Caution signs are a reminder to be alert to potential dangers in the area

shown which may cause product or surrounding damage.

4. Always replace signs that have been lost or defaced.

Issue : - Man/P11,02 4 Last rev: 26.08.2010

CARE OF BODY AND PAINTWORK

The use of cold water at normal tap pressure is recommended for the first three

months, after which steam cleaning at temperatures below 60 degrees centigrade

and spraying no closer than 300 mm from the surface is permissible, with care.

Any damage to the painted surfaces, eg dents, scratches, should be treated and

repainted as soon as possible to prevent any further degradation of the bodywork.

ALWAYS ensure lubrication points, slides etc are adequately greased after the use

of high pressure or steam cleaners. Never pressure wash lifting chains.

GENERAL SAFETY

WARNING: These safety precautions are important. You must also refer to the

chassis/cab manufacturers operating and maintenance instructions together with

the Transporter recommendations. You must always abide by the laws and

regulations of the country in which you operate.

•You must fully understand all controls for operating this vehicle before use.

•You must obey all warning/cautionary and safety labels on this vehicle and

replace any that are missing or damaged.

•Carry out routine servicing as specified by Transporter and the manufacturer of

the chassis/cab.

•Always know the height of your transporter by measuring the load before

departure; adjust the height indicator accordingly.

•Transporter recommends four straps per vehicle: 2 forwards and 2 rearwards.

•Beware of overhead obstructions: bridges, trees, cables etc.

•Make sure all loose equipment is secured safely.

•Stand the vehicle on firm level ground when operating, lifting or jacking. Apply

the parking brake and chock the wheels.

•Do not exceed the lifting capacities of the decks.

•It is important that the vehicle is operated within the C & U regulations and axle,

GVW and GTW are not exceeded.

•Do not make adjustments that you do not understand.

•Do not move the decks whilst on the transporter. Never go under an

unsupported deck.

•Other persons must be kept at a safe distance while the vehicle or its equipment

is in operation.

•Check that the decks are not contaminated with oil or grease and that the straps

are stored in a manner that will not interfere with the safety of personnel working

on the deck.

•All movements on the Plus 11 MK 2 are hydraulic with the exception of the

manual loading ramps. Loosen the lock and slide the ramp out fully using the

strap; always lock the ramp in the “out position” by straddling it, keeping your

back straight then lift the ramp into the locked position. It is recommended that

the ramp is lifted off the lock by straddling the ramp and lifting it out of the

locked position before driving on the last car. After positioning the car, slide the

ramp in with the strap and lock in place.

Issue : - Man/P11,02 5 Last rev: 26.08.2010

1. Over cab platform. 13. Towing eye

2. Peak ramp. 14. Drawbar lifting pillars

3. Peak ramp flap support pin. 15. Van loading bridging plate.

4. Rigid lifting pillars. 16. Top deck front sliding ramp.

5. Main top deck. 17. Top deck rear sliding ramp.

6. Top deck kick up ramp. 18. Main top deck

7. Top deck rear extension ramp. 19. Rear pillar ladder

8. Front bumper ladder. 20. Scissor ramp inner section.

9. Hand pump valve. 21. Scissor ramp outer frame.

10. PTO/hand pump control valve. 22. Front section of kickup ramp.

11. Hydraulic/air control valves. 23. Kick up ramp

12. Towing coupling. 24. Well deck ramps

25. Hydraulic/air control valves.

26. Park and Shunt valve

(offside).

27. EBS diagnostics socket.

28. Bogie decking

29. Fold down step for rear ladder.

30. Rear end section.

31. Manual loading ramps and

stowage.

1

2

3 4

5 6

4

7 15 16

14

17

18 19

14

21

24

22

23

8

9 10

11

12

13

2

0

28

25 26

27

29

30

31

GENERAL VEHICLE LAYOUT

RIGID

DRAWBAR

Issue : - Man/P11,02 6 Last rev: 26.08.2010

130 PS1 90 PSI Trailer tyres all 124 PSI

315/70 R22.5 315/60 R22.5 295/60 R22.5 (150/147 L Rated)

TORQUE SETTINGS

Wheels Torque M22x1.5 @ 570-630 Nm (445 lb ft)

Tow Hitch Bolt Torque M20 (8.8) @ 410 Nm (330 lb ft)

Tow Hitch Castellated Nut @ 500 Nm (360 lb ft)

Tow Eye Bolts Torque M20 (10.9) @ 610 Nm (450 lb ft)

TYRE PRESSURES AND TORQUE SETTINGS

Issue : - Man/P11,02 7 Last rev: 26.08.2010

The weights indicated are the maximum amounts that can be lifted by individual

decks and are not a guide to the legal capacity of the transporter. Gross vehicle

weights vary depending upon the axle configuration of the rigid.

Five axle road trains gross train weight 38000KG

Six axle road trains gross train weight 41000KG

Trailer gross 22100KG

MAXIMUM DECK LIFTING CAPACITIES

PEAK RAMP

2500 KG

KICKUP RAMP

2500 KG

TOP DECK (total)

5000 KG

FRONT RAMP

2500 KG

SLIDING RAMP

2500 KG

TOP DECK (total)

7500 KG

MAXIMUM DOWN FORCE

ON COUPLING

1000 KG

SCISSOR RAMP FRONT

USE AS LOADING AID

(LIFTING CAPACITY 750 KG)

SCISSOR RAMP

REAR

1750 KG

KICKUP FRONT

RAMP

2500 KG

KICK UP REAR

5000 KG

Issue : - Man/P11,02 8 Last rev: 26.08.2010

DAILY SAFETY CHECKS

A visual inspection should be conducted daily on the following items:

1. All routine driver checks as set out in the Guide to Maintaining

Roadworthiness should be performed to the rigid unit and trailer. In addition

the following items must be checked.

2. Security of the front ladder.

3. Safety hand rails are all secure and complete with no visual damage (see the

hand rails section).

4. Securing straps and bollards are working correctly, with no cuts to straps or

defects to bollards.

5. Make sure that all straps are stowed securely, clear of all moving parts.

6. Visually inspect the rigid coupling, connecting pipes and suzie cables for

defects.

ENGAGING OPERATING AND DISENGAGING THE POWER TAKE OFF (PTO)

Both trailer hydraulic pipes must be coupled before attempting to perform the

following procedure. A link pipe must be used if not trailer is coupled.

1. Make sure that the air is at full pressure.

2. Press the clutch pedal down keeping it disengaged.

3. Engage the PTO using the switch in the cab.

4. Slowly re-engage the clutch.

5. It may be necessary to increase the engine RPM to a maximum of 800 RPM.

This will be achieved by either a hand throttle or the cruise control.

6. To disengage the PTO, press down the clutch pedal keeping it disengaged.

7. Switch off the PTO.

8. Re-engage the clutch gently.

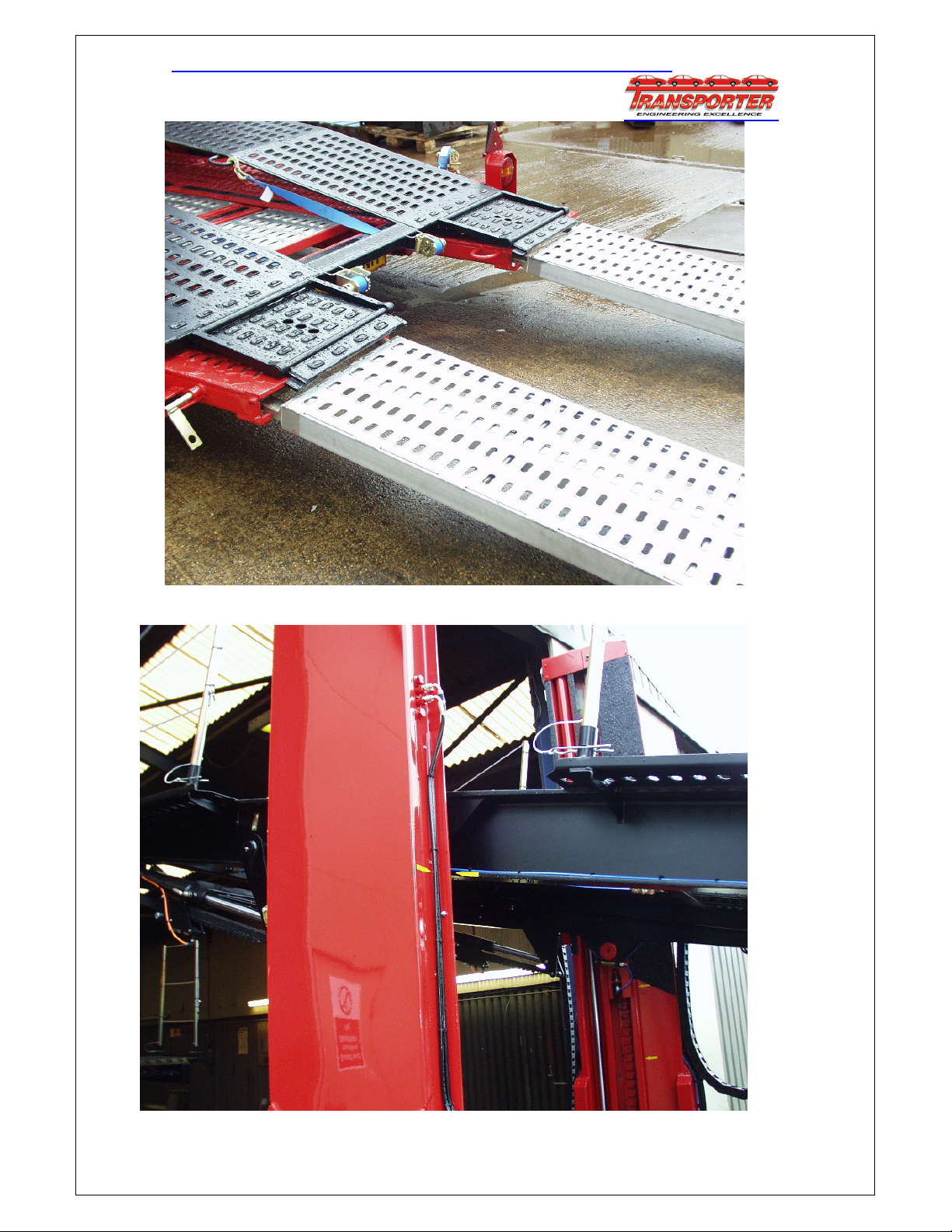

REMOVING LOADING RAMPS

Always bend your knees and not your back when moving ramps. When tipping a

loaded vehicle with a car in position 11, slide the ramps out to maximum and lift into

locating lugs after this first car has been removed.

1. Make sure the transporter is on level ground.

2. Release the loading ramp’s stowage pin.

3. Use the straps to draw out the loading ramp lifting initially.

4. Stand with a leg either side of the ramp and pull out to full extent.

5. Lift ramp onto the locating lugs. The ramps are now secure and ready for loading.

REPLACING LOADING RAMPS

Always bend your knees and not your back when moving ramps. It is good practice

to lift the ramps off the locating lugs before driving the last car into position 11.

1. Stand with a leg either side of the loading ramp and lift it off the locating lugs.

2. Using the webbing strap to draw the ramp back to its stowed location.

3. Use the locking pin to secure the ramp in place, making sure the ramp straps

are retained behind the catch.

Issue : - Man/P11,02 9 Last rev: 26.08.2010

Control handles

Lock release air buttons

OPERATING DECKS

Important! All personnel must be clear of the vehicle before operating any

controls.

LIFTING DECKS

1. Pull the relevant control handle towards you from its neutral position. The

deck should now raise as the handle is held in this position.

2. When the deck is at the required height, return the lever to the neutral position

then lower the deck onto the locking rack.

The deck must be supported by the locking rack, not by the chain or

hydraulic cylinders.

LOWERING DECKS

1. Pull the relevant control handle towards you from its neutral position, so that

the deck lifts enough to release the locking pawls on both sides.

2. Press in and hold the relevant locking release air button.

3. Push the control handle away from you whilst keeping the air button de-

pressed, the deck should now lower. Always check the deck is lowering

evenly.

4. When the deck has reached its required level, return the lever to the neutral

position.

5. Release the air button to re-engage the deck locks.

6. Further lower the deck so that the pawl is supported by the locking rack.

The locking rack blocks are spaced at 50mm intervals.

Issue : - Man/P11,02 10 Last rev: 26.08.2010

Most decks and ramps are operated using the above method, but some slide

ramps have a double pilot check valve as a locking mechanism instead of a locking

pawl. Always check that the control levers return to neutral when released.

HAND RAILS

The transporter has been fitted with a hand rail system that meets Health and

Safety regulations at time of manufacture. Any retrospective change in the

legislation after the vehicle has entered service is the responsibility of the operator.

The system must be maintained and defected if:

Posts are missing.

Posts have been damaged, distorted or corroded.

Ropes are not tensioned or defective.

TRAILER SUSPENSION RAISE/LOWERVALVE (Optional fitting)

The suspension valve can be used to raise or lower the trailer suspension height, to

aid ground clearance when loading and unloading certain vehicles. This valve

must be returned to the main ride height position as shown before setting off. The

vehicle may be driven with the valve in the high position to aid loading the

transporter on and off ferries.

LOADING LIGHTS

Loading lights are a standard fitting on the Transporter car transporters. These are

operated from inside the cab using the trailer coupling light switch. Extra care

should be taken when working in the dark – if possible position the vehicle in a well

lit area.

Issue : - Man/P11,02 11 Last rev: 26.08.2010

Coupling in open position Coupling in locked position

UNCOUPLING THE RIGID UNIT

Before carrying out the following procedure, ensure that the transporter is on

firm level ground, with a suitable block to support the trailer front cross

member, ideally in the centre.

1. Apply the trailer parking brake.

2. Raise the rigid suspension.

3. Put the suitable supporting block under the trailer front cross member in the

centre.

4. Lower the suspension on to the supporting block, so that the towing eye is in

the centre of the coupling (ie there should be a gap at the top and bottom).

5. Disconnect all suzies and hydraulic pipe connections.

6. Lift the coupling pin release lever (you may have to rock the truck to get the

pin to release).

7. Carefully drive the rigid away from the drawbar slowly.

8. Caution Do not put you hand in the open coupling jaws, it may snap shut. To

close the coupling, push the lever with your hand in the opening direction.

The pin will locate in the locked position.

RE-COUPLING THE RIGID UNIT

1. Make sure that the coupling pin release handle is in the raised position.

2. Reverse the rigid unit to the trailer checking that the coupling is central to the

towing eye; if so reverse onto the eye (you may have to rock the unit

backwards and forwards to fully engage). Make sure that the coupling has

fully locked shut and the lock control pin is home. Apply the truck parking

brake.

3. Raise the rigid unit suspension and connect all the ‘suzies’ and hydraulic

pipes.

4. Remove the block from under the trailer and reset the suspension of the rigid

unit to its normal ride height position.

Issue : - Man/P11,02 12 Last rev: 26.08.2010

5. Release the trailer parking brake.

UNLOADING IN THE EVENT OF A MECHANICAL FAILURE

You will require adequate air pressure to enable the locking pawl air valves to

operate.

Should power be lost to the PTO pump, follow the procedure listed below.

1. Switch the change over control valve (located behind the main rigid control

handles) from the PTO pump to the hand pump position, turning the lever 90

degrees. (See photos above).

2. Place the supplied handle into the hand pump valve. This valve is situated

next to the main rigid control levers.

3. The control handle for the deck you want to move will have to be pulled

towards you and held open, whilst at the same time the hand pump is

manually pumped up and down, lifting the deck so that the locking pawls can

be released.

4. When the locking pawl has been released, de-press the air button whilst

lowering the deck with the control handle. (This operation may be slower than

usual).

Issue : - Man/P11,02 13 Last rev: 26.08.2010

VEHICLE SECURING SYSTEMS

The load restraint system used on the transporter can either be bollards and straps,

mobile straps, or wheel chocks, or you may have a mixture of all three systems.

Pulling directions must be considered when securing vehicles on the transporter, as

a guideline two straps pulling in either direction (ie forwards and backwards), with

chocks on each wheel should be adequate. Your company should be able to

advise you on the system and number of restraints required for particular loads

being carried.

Bollard

Swivel T hook and strap

Over wheel Strap Assembly

Tommy Bar

A typical wheel chock

Hand Ratchet

Issue : - Man/P11,02 14 Last rev: 26.08.2010

CAUTION

BEFORE TILTING CAB

1. Remove or hinge the front ladder forward. Failure to carry out this procedure

will damage the cab.

2. You must ensure the peak ramp is DOWN to the stops before raising it

over the cab platform.

3. Failure to carry out this procedure will severely damage the lifting mechanism.

LOADING VEHICLES ONTO THE TRANSPORTER

1. Before loading ensure that all the decks are set in their correct position for

loading, with all the straps and wheel chocks stowed safely out of the way.

2. Check that visibility is good, with frost etc cleared from vehicle windows.

3. Check that the ground clearance is adequate.

4. When the vehicle is loaded into position, apply the hand brake fully and leave

the vehicle in first gear (or in park position on automatics).

LOADING THE TRANSPORTER PLUS 11

Before carrying out the following procedure, make sure you have had sufficient

training and are fully conversant with all the controls and operation of the

transporter. You should also be wearing suitable safety equipment, eg high visibility

jacket, boots and gloves. Remove all sharp objects such as rings and watches that

could damage the vehicles during loading.

The following pages will guide you through the method of loading the Plus 11

Transporter.

(The procedure for unloading the transporter is generally as for loading it, but in

reverse).

PLUS 11 MK 2 RIGID AND DRAWBAR LOADING SEQUENCE

Issue : - Man/P11,02 15 Last rev: 26.08.2010

Remove loading ramp stowage pins, pull out loading ramps and lift into locked position.

Set trailer top deck front to align arrows and fully lower rear to loading angle.

PLUS 11 MK 2 RIGID AND DRAWBAR LOADING SEQUENCE

Issue : - Man/P11,02 16 Last rev: 26.08.2010

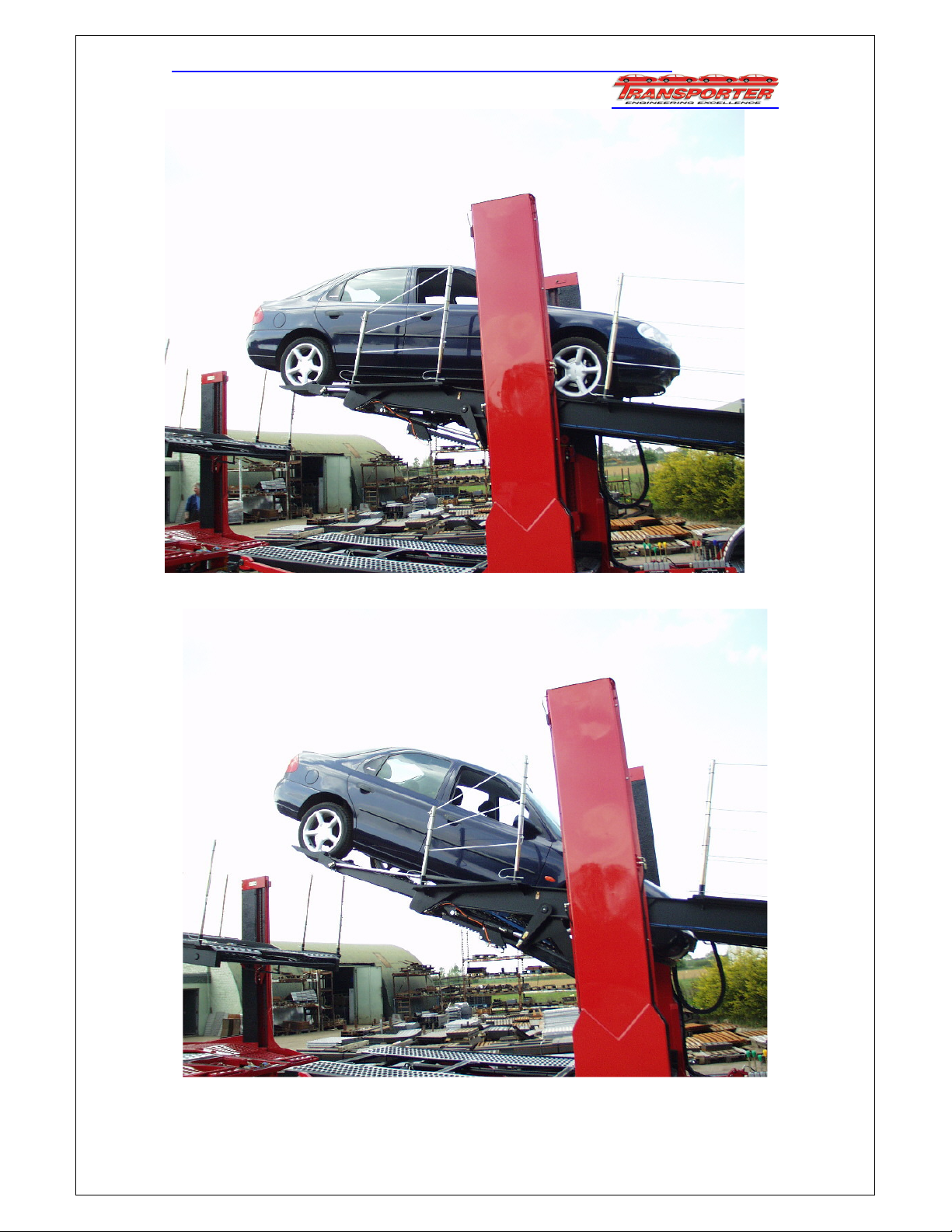

Car 1: Reverse car onto front drop ramp.

Secure car to ramp, fully extend ramp and lower to desired height.

PLUS 11 MK 2 RIGID AND DRAWBAR LOADING SEQUENCE

Issue : - Man/P11,02 17 Last rev: 26.08.2010

Car 2: Fold over front wheel stops, drive car onto ramp up to stops.

Secure car to ramp, extend and lower to desired position.

PLUS 11 MK 2 RIGID AND DRAWBAR LOADING SEQUENCE

Issue : - Man/P11,02 18 Last rev: 26.08.2010

Car 3: Drive car onto rear of deck, lift up wheel stop and secure.

Adjust clearance between cars and raise top deck to maximum height.

PLUS 11 MK 2 RIGID AND DRAWBAR LOADING SEQUENCE

Issue : - Man/P11,02 19 Last rev: 26.08.2010

Adjust well deck rear to align with upper arrows on pillar and lower onto locks.

Raise front of well deck scissor and front of kickup

ramp to maximum, lowering ramps onto their locks.

PLUS 11 MK 2 RIGID AND DRAWBAR LOADING SEQUENCE

Issue : - Man/P11,02 20 Last rev: 26.08.2010

Raise over cab platform slightly, and adjust top deck to bridge between peak ramp and trailer.

Car 4: Reverse car onto peak ramp.

Table of contents

Other Transporter Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Neogen Corporation

Neogen Corporation Electro Jac 6 Operator's manual

AGCO

AGCO Challenger RoGator 600C Workshop service manual

Vaderstad

Vaderstad TopDown TD 300 Series quick start

Farm King

Farm King 1684 Operator and parts manual

HEK

HEK GTP Dual T 1500 user manual

Montag

Montag Fortifier 2212 Operator's manual