HEK GTP Dual T 1500 User manual

HEK GTP Dual T 1500

8095-304

Issue: 11-2005

This manual is assigned to:

USER'S MANUAL

TRANSPORT PLATFORM / MATERIAL HOIST

II HEK GTP Dual T 1500 • 8095-304

©2005,HEK ManufacturingB.V.,Middelbeers,TheNetherlands

Noinformationfrom this publication may be copied and/or published in print, microfilm or

anyother form, withoutpriorwritten permission fromHEKManufacturing B.V.

Figuresandillustrationsarefor illustrational purposeonly and donot necessarily haveto meet thedesign of

the product on the market at any time.

IIIHEK GTP Dual T 1500 • 8095-304

HEK Manufacturing B.V.

Westelbeersedijk 18 P.O.box2

5091 SM Middelbeers 5090 AA Middelbeers

TheNetherlands TheNetherlands

Tel. : +31 13 51 48 653

Fax : +31 13 51 48 630

www.HEK.com

FOREWORD

TheHEK GTP Dual T 1500 is a very

compacttransport platform whichcanalso

beused as a material hoist (optional).

Thebasicversion of the machine can be

usedfor the verticaltransportationof both

personneland materials.Byinstalling the

conversionkit (optional) themachinecan

also be used as a material hoist.

Thismanual describestheinstallation,

controland maintenanceofthe machine.

Theheight of themast,which consists of

separateelements, can easily be adjusted

tosuit the working level.Themastcan be

easilyand safely assembled from thehoist.

Read this manual carefully before using the machine.

Take all safety precautions mentioned in chapter 3 into account!

Themachine can onlybeused if anchored.

Considerableattention has been given to

thesafety aspects intheconstruction of the

HEKGTPDualT 1500, e.g. the rack-and-

piniondrive unit is equipped witha motor

brake and a fail safe brake, acting on both

racksviaa shaft.

Thesolidconstructionensuresthatonly

minimummaintenance is required.

Thisinstruction manualdescribes onlythe

basicmachineand the additional options

in which it is supplied by HEK

ManufacturingB.V..

FOREWORD

IV HEK GTP Dual T 1500 • 8095-304

TABLEOF CONTENTS

TABLE OF CONTENTS

FOREWORD ...................................................... III

TABLEOFCONTENTS..................................... IV

MEANINGOF THE SYMBOLSUSED .............. VI

HEKGTPDUALT1500APPLICATIONS........... VI

1. TECHNICALDATA ..................................1-1

1.1 General ...................................................1-1

1.2 Mast element..........................................1-2

1.3 Dimensions.............................................1-2

1.4 Electrical installation...............................1-3

1.5 Load ofthe machine................................1-4

1.6 Load during useas transportplatform .....1-4

1.7 Load during use as material hoist............1-4

1.8 Anchoringforces .....................................1-5

1.8.1 Anchoring ...............................................1-6

1.8.2 Anchoringforces .....................................1-6

2. COMPONENTS ......................................2-1

2.1 General ...................................................2-1

2.2 HEK GTPDual T1500 conversion kitfor

use as a material hoist (optional) ............2-2

2.3 Landingsafeguards .................................2-2

3. SAFETY .................................................3-1

3.1 General ...................................................3-1

3.2 Safety beforeuse ....................................3-1

3.3 Safety duringuse ....................................3-1

3.3.1 Safety during use of the machine as ...........

transportplatform ....................................3-2

3.3.2 Safety during use of the machine as material

hoist(optional) ........................................3-2

3.4 Safety afteruse.......................................3-3

3.5 Built-inandattached protectivedevices...3-3

3.6 Personnel ...............................................3-4

4. TRANSPORT ..........................................4-1

4.1 Transport onthe buildingsite ..................4-2

5. CONTROLUNITS ...................................5-1

5.1 Connector andmain switchon cable

drum .......................................................5-1

5.2 Ground stationswitchbox........................5-1

5.3 Using the machine as a material hoist ........

(optional - only with the ground station ........

switchboxinstalled) ................................5-2

5.4 Selectionof identificationplate transport .....

platform/ material hoist...........................5-2

5.5 Selector switch .......................................5-2

transportplatform /material hoist............5-2

5.6 Control boxonplatform ...........................5-3

6. ASSEMBLYANDANCHORING ..............6-1

6.1 Preparation forassembly ........................6-2

6.2 Groundsupport .......................................6-3

6.3 Distanceto building ................................6-4

6.4 Assembling thetransport platform...........6-5

6.5 Assembling the mast ..............................6-6

6.6 Anchoring the masts ............................. 6-11

6.7 Lightningprotection............................... 6-13

6.8 Landingbarriers .................................... 6-14

7. OPERATION ...........................................7-1

7.1 General ...................................................7-1

7.2 Preparationfordaily use..........................7-2

7.3 Periodic check ........................................7-3

7.4 Convertingthemachine ...........................7-4

7.5 Operatingthemachine fromtheplatform .....

(transportplatform- GTPmode) ..............7-5

7.6 Operatingtheloading platform.....................

(materialhoist - GTLmode).....................7-7

7.7 Transferringtoscaffoldor platform...........7-9

7.8 Slidingdoor........................................... 7-10

7.9 Transferplateoperation ......................... 7-11

7.10 Operationin an emergency situation ..... 7-12

7.11 Fail safebrake ...................................... 7-13

7.12 Overloadprotection ...............................7-13

7.12 Raisingthe transport platformfrom the........

buffers ...................................................7-13

8. DISASSEMBLYANDTRANSPORT........8-1

9. MAINTENANCE ......................................9-1

9.1 General ...................................................9-1

9.2 Maintenanceintervals..............................9-2

9.3 Motorbrake.............................................9-4

9.3.1 General ...................................................9-4

9.3.2 Operation ................................................9-4

9.3.3 Maintenance ...........................................9-5

9.4 Failsafe brake ........................................9-7

9.4.1 Droptest.................................................9-8

9.4.2 Returning the fail safe brake to its

originalposition .......................................9-9

9.5 Fail safebrake activated- platform

raised....................................................9-10

9.6 Testingthe overload protection .............. 9-11

10. MALFUNCTIONTABLE.........................10-1

11. ENVIRONMENTALLYFRIENDLY .................

DISPOSAL............................................ 11-1

12. INDEX ................................................... 12-1

APPENDIX1.REGULAR CHECKS... APPENDIX1

VHEK GTP Dual T 1500 • 8095-304

EC DECLARATION OF CONFORMITY

We, HEKMANUFACTURINGB.V.

Westelbeersedijk 18

5091 SM Middelbeers

TheNetherlands

herebydeclare that, on thebasisofits design and construction,thetransport platform

namedbelow as well asthemodel brought into circulationbyusconform to theTechnische

UberwachungsvereinHannover certificateissued withthenumber below.

Changesmade to themachinewithoutour consent invalidatethisdeclaration.

Designation: Transportplatform

Machinetype: HEK GTP Dual T 1500

Inaccordancewith: EN 12158-1

EN 1495

BGI825

Numbercertificate: 78/220GS/YMA313909

Certifiedby: TUVHANNOVER/SACHSEN-ANHALTE.V.

Date / place: Middelbeers,The Netherlands,July9th 2004

Authorisedsignature: E.M.A. vanHek

ChairmanoftheBoard

HEKMANUFACTURING B.V.

EC declaration of conformity - copy

ECDECLARATIONOFCONFORMITY

VI HEK GTP Dual T 1500 • 8095-304

WARNING

Failingto (exactly)complywith

theworking or operating

instructionsmay lead to serious

injury,fatalaccident, severe

mechanicaldamageoroperating

losses.

Duringuse, no personmaystand

underthe machine.

MEANING OF THE SYMBOLS USED

HEK GTP DUAL T 1500 APPLICATIONS

SYMBOLS,APPLICATIONS

Danger:high voltage.

Dangerof falling objects.

* Thebasic version of the machine canbeusedforthe vertical transportation of both

personneland materials. Byinstallingthe conversion kit(optional)themachine can

also be used as a material hoist.

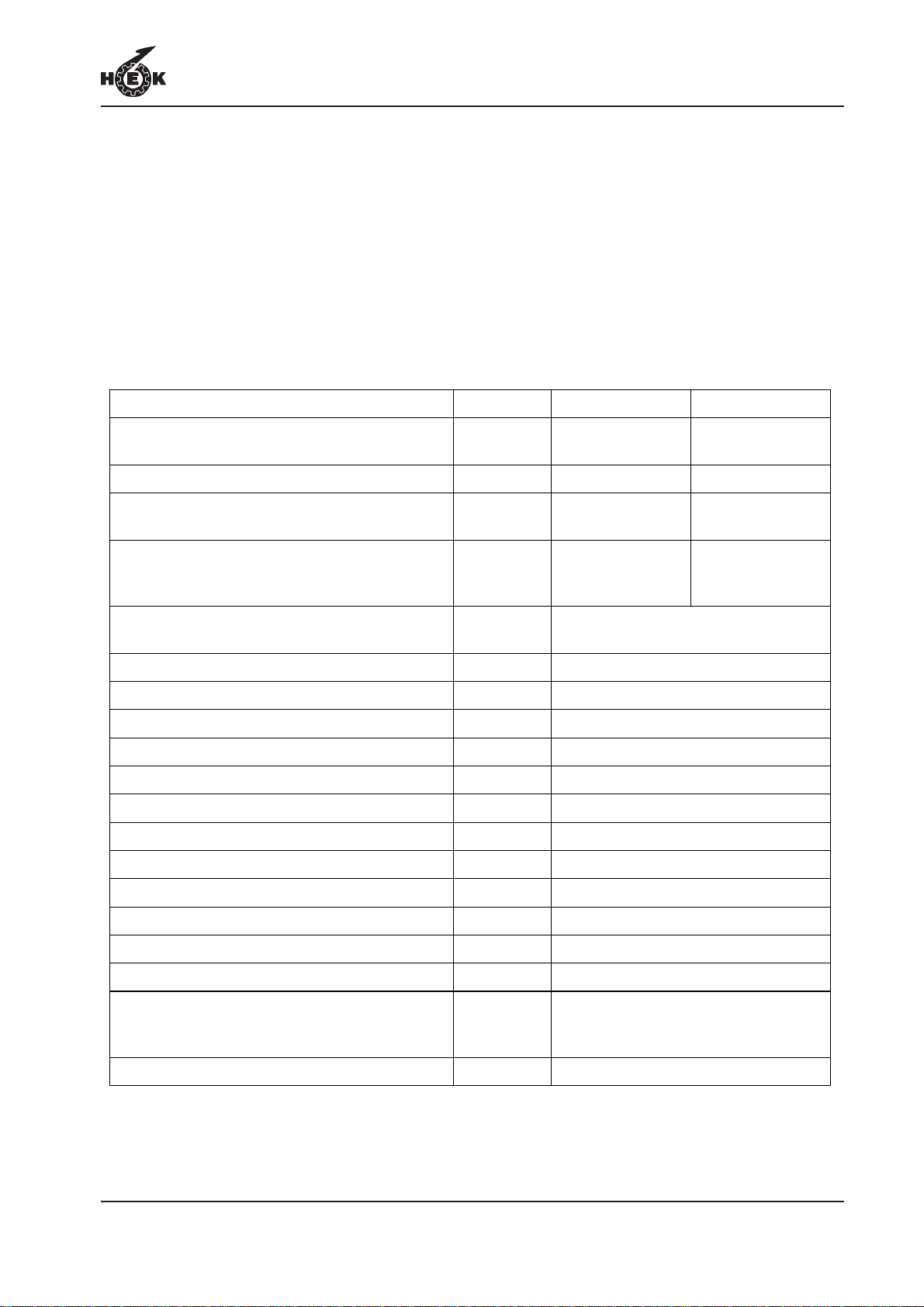

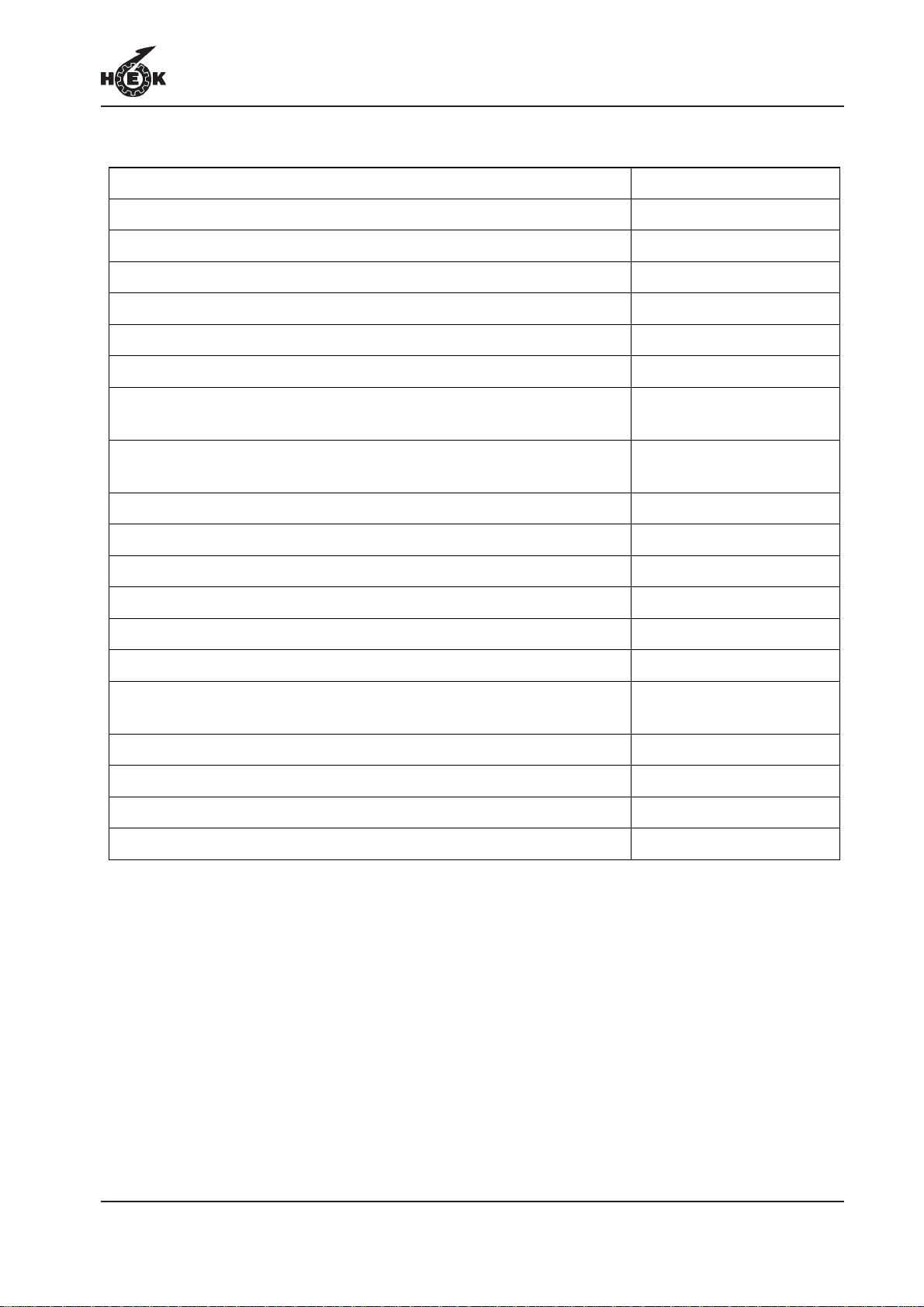

Machine used as Transport platform Material hoist (optional)*

Position selector switch in

control box on platform 12 m/min - 3.2 Ft/min 12 m/min – 3.2 Ft/min

Position identification plate

on platform Transport platform Material hoist

Transport of passengers permitted as

accompaniment of the load forbidden

Transport of goods permitted in combination

with at least 2 passengers permitted

Operation from platform

from ground station via

remote control

Control dead man's control automatic control

Landing barrier mechanical interlocking+

electrically monitored mechanical interlocking +

electrically monitored

Max. wind force during use 7 Beaufort (15.6 m/s – 35

Mph ) 8 Beaufort (20.2 m/s – 45

Mph)

VIIHEK GTP Dual T 1500 • 8095-304

TECHNICALDATA

Fig.1-01 Dimensions HEK GTP Dual T 1500

VIII HEK GTP Dual T 1500 • 8095-304

leftblank on purpose

TECHNICALDATA

1-1HEK GTP Dual T 1500 • 8095-304

1. TECHNICAL DATA

Note:

Thespecifications below are based onstandard applications of the HEKGTP Dual T

1500.Under certain circumstances, the actual specifications maybeamended.

Insuch cases writtenpermissionof themanufacturerisobligatory.

1.1 General

* Themachineisprovidedwitha2.5m(98inch)stopafterwhichtheloweringspeed

becomes12m/min(32Ft/min)

Description Fig. 1-01

Machine set as Transport

platform Material hoist

(optional)

Min. / max. number of passengers 2 - 7 0

Lifting and lowering speed 12 m/min (32

Ft/min) 12 m/min (32

Ft/min)*

Max. wind force during use 15.6 m/s (35

Mph)

(7 Beaufort)

20.2 m/s (45

Mph)

(8 Beaufort)

Loading capacity 1,500 kg (3,306 Lb) (see section

1.5)

Platform length 3,300 mm (30 inch)

Platform width 1,400 mm (55 inch)

Min. height platform fencing 1.1 m (43.3 inch)

Anchoring distance C2 6 – 8 m (236 – 315 inch)

Max. mast height, free-standing B Not allowed

Max. mast height, anchored B 120 m (394 Ft)

Max. mast height above last anchor C3 3 m (118 inch)

Mast type DRK400 (see section 1.2)

Distance between cable guides 6 m (236 inch)

Height first anchor at ground frame B 3 – 4 m (118 – 157 inch)

Min. platform height 0.6 – 0,7 m (23 – 28 inch)

Noise level < 70 dB

Basic machine weight (including 2 mast

elements and 2 uppermost mast

elements) 1,980 kg (4,365 Lb)

Max. wind force during assembly 12.8 m/s (6 Beaufort)

TECHNICALDATA

1-2 HEK GTP T Dual 1500 • 8095-304

1.2 Mast element

1.3 Dimensions

Fig.1-02 Dimensionstop

Fig.1-02, Dimensions [mm]

MM Inch

A 3270 93.3

B 3130 123

C 2200 86.6

D 2900 114

E 1690 66.5

F 1400 55

G 1570 61.8

H 3580 141

TECHNICALDATA

1-3HEK GTP Dual T 1500 • 8095-304

1.4 Electrical installation

HEK GTP Dual T 1500 230 VAC/60Hz

Number of motors 2

Nominal supply voltage 240 VAC

Supply voltage range 220 - 260 VAC

Supply voltage frequency 60 Hz

Power consumption based at S3-40%

Connector on cable drum CEE 5p - 32 A - 6h

Cable between building site cabinet and machine < 15 m (50

Ft) 5x0.015 inch2

Cable between building site cabinet and machine 15 to 50 m

(50 to 165 Ft) 5x0.023 inch2

Machine cable in cable drum 0 to 120 m (0 to 395 Ft) 5x0.015 inch2

Control voltage Landing barrier 48 VAC

Control cabinet 24 VAC

Motor brakes 105 VDC

Used as GTP (basic version) & GTL (option)

Speed 39 Ft/min

Control Control box on

platform

Nominal / starting current 27 A / 80 A

Building site fuse (slow) 32 A

Nominal power consumption 8 kVa

Recommended min. power generator capacity 35 kVa

TECHNICALDATA

1-4 HEK GTP T Dual 1500 • 8095-304

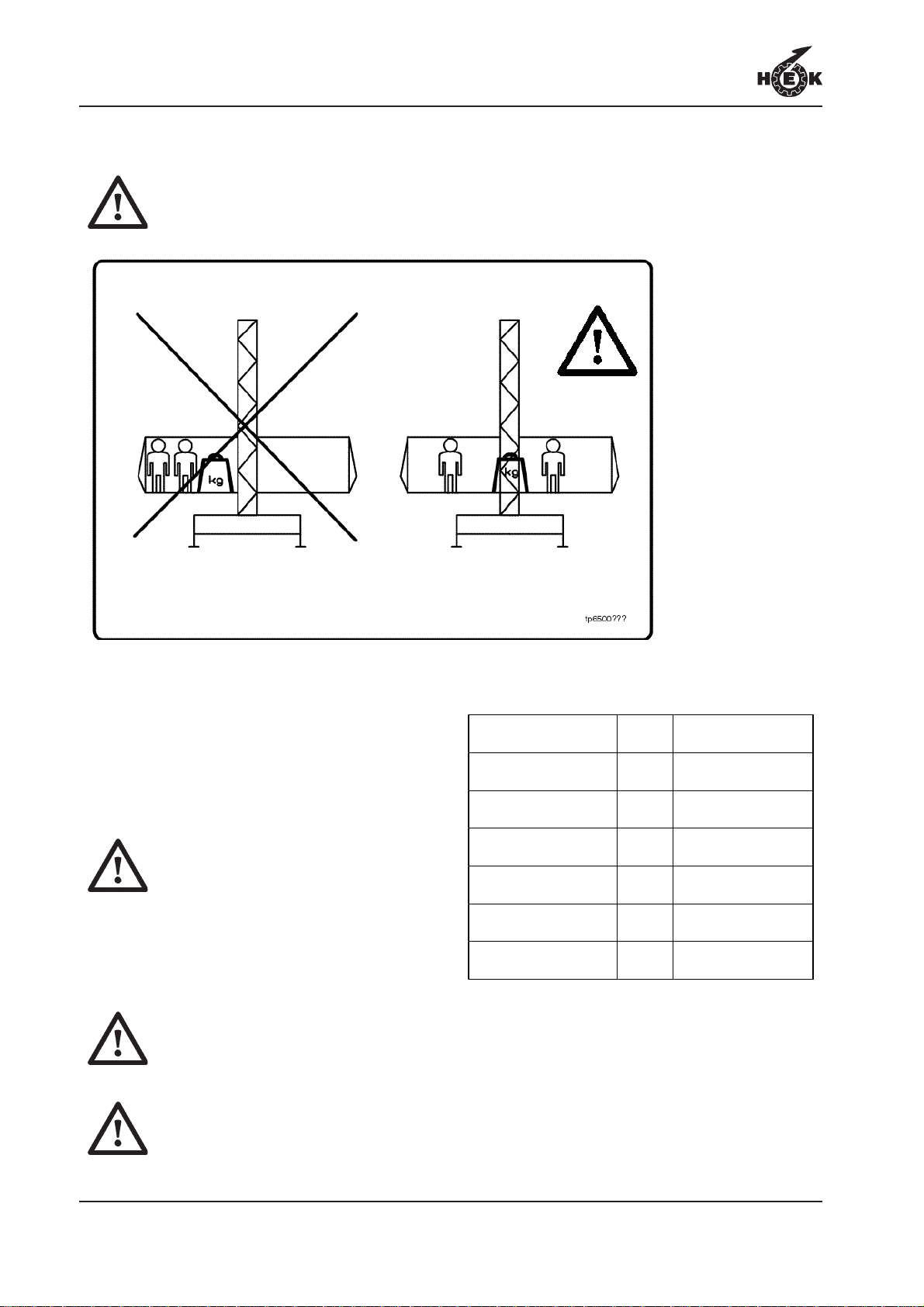

1.5 Load of the machine

Theloadmustbe evenly

distributedover thefullplatfom

area.(fig.1-03).

Fig.1-03 Distribution of load

1.6 Load during use as transport

platform

Seethetable for maximum load and

maximumnumberofpersons.

Inthe case thataroof(optional)

ismounted, the maximum loadis

reduced with 150 kg.

1.7 Load during use as material hoist

Max.load1,500kg.

Inthe case thataroof(optional)

ismounted, the maximum loadis

reduced with 150 kg.

Transportofpassengers

forbidden.

LADING GELIJKMATIG VERDELEN!

Passengers + Load (kg)

2 (min.) + 1300

3 + 1200

4 + 1100

5 + 1000

6 + 900

7 (max.) + 800

DISTRIBUTE LOAD EVENLY

TECHNICALDATA

1-5HEK GTP Dual T 1500 • 8095-304

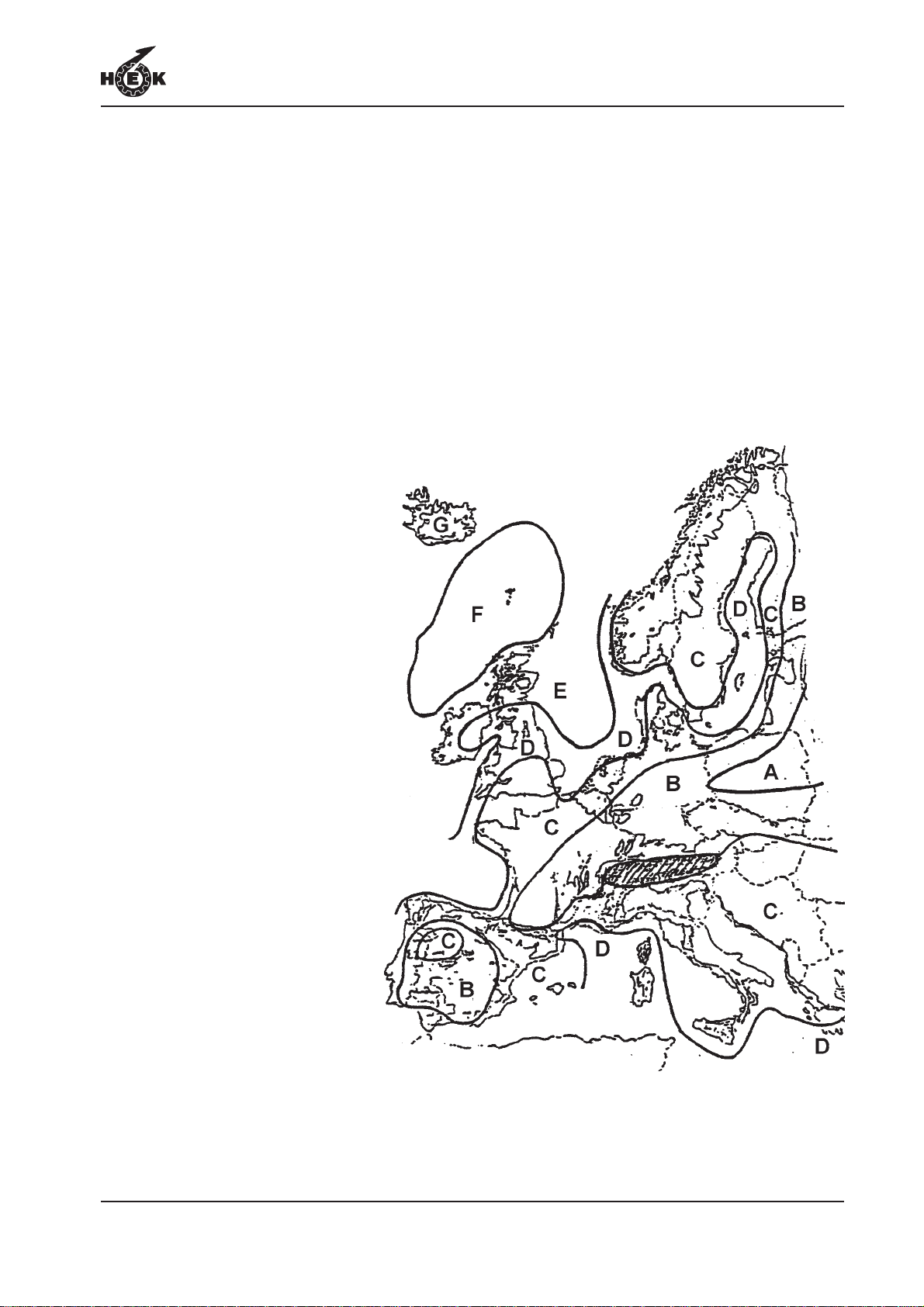

Fig. 1-04 Wind map of Europe

1.8 Anchoring forces

Torquescaffoldcouplings:50 Nm - 36.9

Lbf-Ft

Theanchoring forces depend on thearea

inwhich the machineisused.The

anchoringforces for thedifferentwind

areas in Europe are described in the

section1.8.1 and 1.8.2. In figure1-04the

windareas in Europe are shown.

TECHNICALDATA

1-6 HEK GTP T Dual 1500 • 8095-304

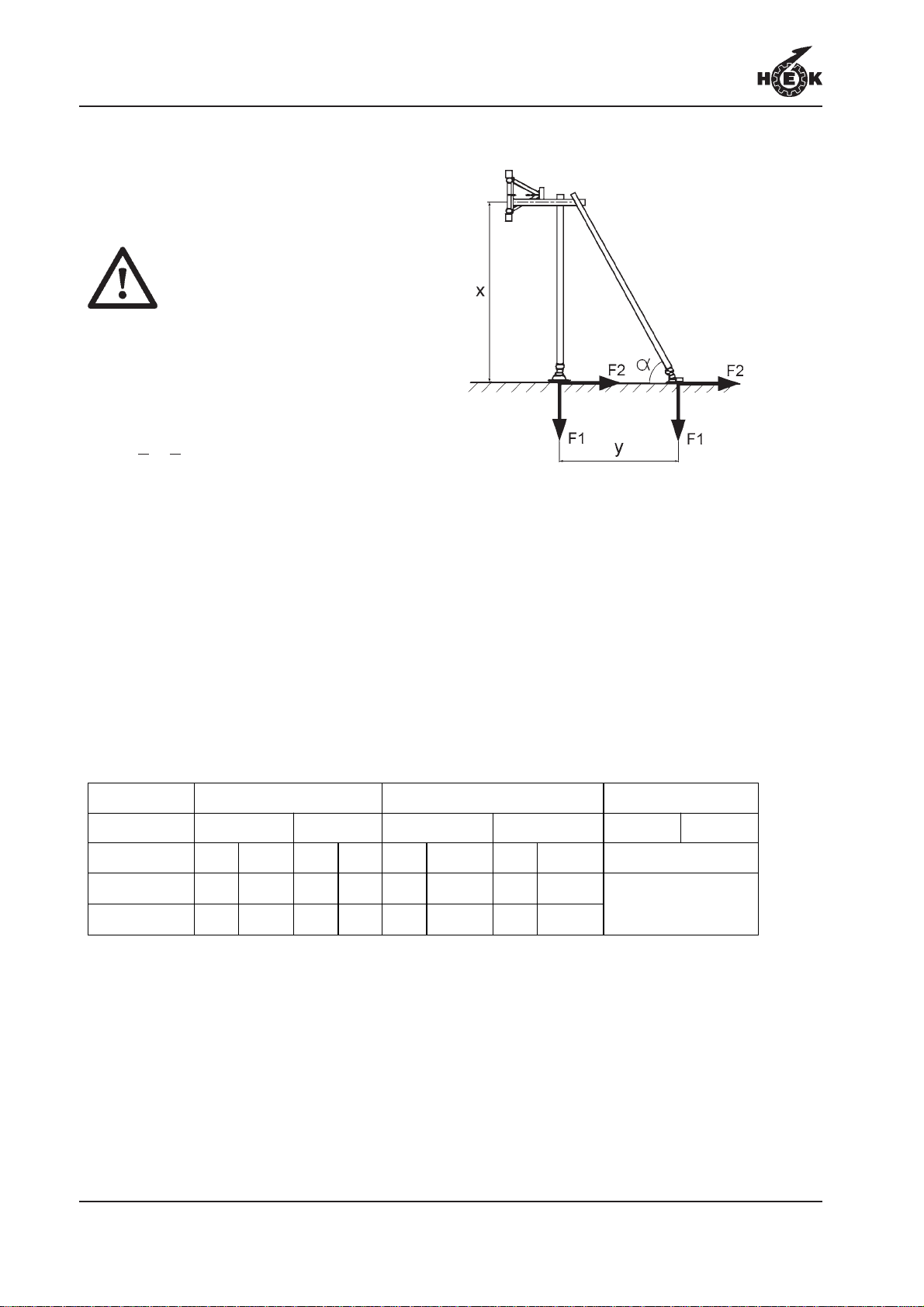

Fig.1-05 Anchoring

1.8.1Anchoring

Theanchoring forces should be adsorbed

bythefacadeaccordingto static rules.

Ifthe machine is placedinfront

ofa scaffold, theanchoring

forcesshouldbeabsorbedby

thescaffold according to the

staticrules.

Theanchoringforces in table 1 are

applicableunder the followingconditions:

- 45°< α < 60°

- x=2.3m(90.5 inch) up to and including

3 m (118 inch)

- x/y=1 m (39Inch) upto and including

1.75m(69inch)

Example:

- x=2.5m(98inch)

- y=2.5m(98inch)

- wind region C

See table: - F1 = 5.2 kN (1,169 Lbf)

- F2 = 3.6 kN (809 Lbf)

1.8.2Anchoring forces

Table 1 Area A-C Area D Area E-G

F1 F2 F1 F2 F1 F2

(kN) (Lbf) (kN) (Lbf) (kN) (Lbf) (kN) (Lbf) (kN) - (Lbs)

α= 45° 5.2 1,169 3.6 809 6.8 1,528 4.6 1,034

46° < α< 60° 7.8 1,753 3.6 809 10.1 2,270 4.6 1,034

Consult your dealer

COMPONENTS

2-1HEK GTP Dual T 1500 • 8095-304

2. COMPONENTS

2.1 General

Thebasic rack-and-pinion transport

platformconsists ofthefollowing elements

(fig.2-01):

* 2drive units (1)

* masts(two off) (2)

* platformwith fence, loadingrampand

landingbarrier(3)

* groundframe (4)

* controlsystem, consisting ofacontrol

boxon the platform (5)andaground

stationcontrol box(optional)

* roof(optional)

* assemblyplatform (optional)

Thedrive unit,whichis driven bytwo

electric motors, is guided along a rack on

themastbymeans of two pinions per

mast.

Oneshaft,runningunderneaththeplatform,

attachestoboth mast racks and

guaranteesthat bothdriveunits (1)run

synchronously.Furthermore,theshaftis

equippedwithafailsafebrake.Ifthe

maximumspeedofdescent is exceeded,

thefailsafe brake will stop the machine.

Theplatform(3)canbeequippedwith a

roof(optional) to protect the passengers

andthe material presentonthe platform

againstfalling materials andtheweather.

Thegroundframe (4) is equipped with

admissionpointsfor loading the machine

ontoa truck or unloading itfromavan by

meansof a forklift.

Fig.2-01 Basic machine HEK GTP Dual 1500

2

35

4

1

1

COMPONENTS

2-2 HEK GTP Dual T 1500 • 8095-304

Theplatform is equipped with four

shacklesfor lifting with acrane.

Duringthe assembly and useofthe

machinethe platformcanonly be

controllediftheloading ramp is closed and

secured.

Thebasic control unit (machine used as a

transportplatform) canbefound on the

platformitself. When themachineisused

asamaterial hoist, it is controlled via the

thecontrol boxonthe groundstation

(optional).

Allelectrical connections,whichmust be

disconnectedfor transport purposes, are

beingmade by means of connectors.

Thesimple designensuresthat only

minimummaintenance is required.

Themast elements,the wheelset,the

transportplatform, the cable guidesand

variousother componentshavebeen

galvanisedandthoroughlytreated withan

anti-corrosionmaterial.

2.2 HEK GTP Dual T 1500 conversion

kit for use as a material hoist

(optional)

Usethe optional conversion kittoconvert

thebasicmachine with dead man‘s control

forthe transportationofpersonnel and

materialsintoamaterialhoist for the

transportationofmaterials only.

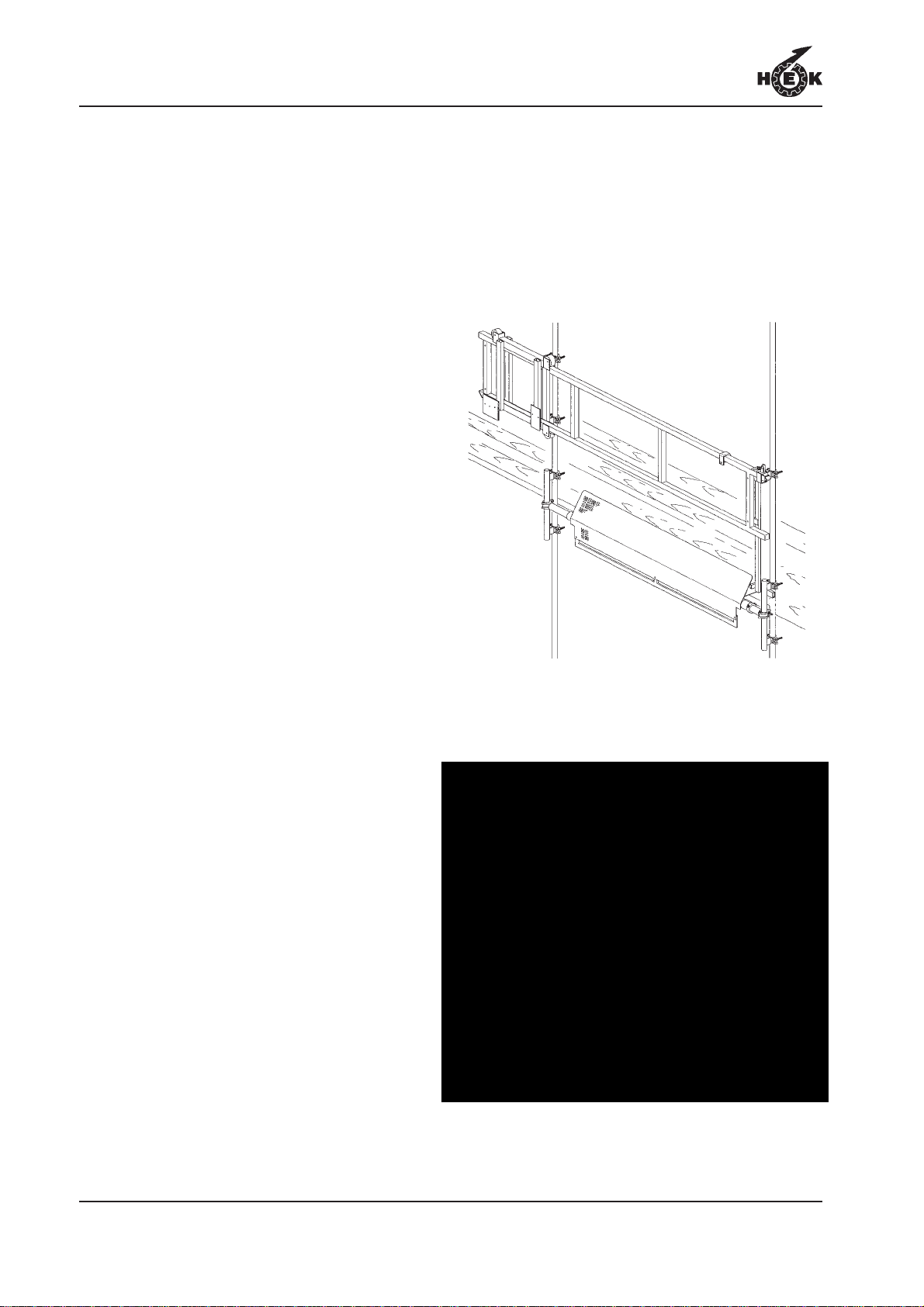

Fig.2-03 Landingsafeguards

2.3 Landing safeguards

Theloading and unloading placesnearthe

scaffold or facade are equipped with

landingsafeguards to preventpersons

and/ormaterials from falling (fig. 2-02 and

fig.2-03).

Fig.2-02 Landingsafeguards

SAFETY

3-1HEK GTP Dual T 1500 • 8095-304

3. SAFETY

3.1 General

Themachine maynotbe

modified or adapted.

Thesurfaceonwhichthe

machinestands must be stable

enoughto supporttheweight of

themachine, themastsand the

load.

Themast mustALWAYS be

properlyanchored.

Incase the fencingprovides

insufficientprotection, suitable

climbingmaterialmust be used

during(dis)assembly at height

above2metres.

Itisprohibitedtoclimbtheroof.

3.2 Safety before use

- Themachine mustnotbeused

withoutbeing adequatelysupported.

- Theground framemustbe

adequatelysupported.

- Theworking area aroundthehoist

mustbefreeof obstacles.

- Theswitchbox doors must be closed

beforeuse.

- Donot(dis)assemble the machine

duringwindsof12.5m/s(28Mph)or

more(6 on the Beaufort scale).

The'Emergencyoff'-button must

beusedbeforetheassemblyof

amast element or an anchor or

duringmaintenance.

3.3 Safety during use

Transport platform: During

windsabove15.6m/s(35Mph)

(7on the Beaufortscale),the

hoistmustbeplaced in the

lowestposition and must not be

used.

Material hoist: Duringwinds

above20.2 m/s (45 Mph) (8 on

theBeaufort scale), thehoist

mustbe placed in the lowest

positionand must not be used.

Theremust be no objects inthe

pathof the cabin.

Whilstthe hoist is in use, no one

may be in the area under the

cabin.

Itisprohibitedtoclimbthemast.

Materialand / or toolsmustnever

extendbeyond the edgesofthe

platform.Material whichcanroll

mustbe properlysecured.The

loadmust not leanagainstthe

fencing.

Thedistance betweenthe

machineand high-voltage cables

must be at least 10 metres (32

Ft).

Whenhaving totransport large

materials and / or tools, please

firstcontact yoursupplier

becauseof the windsensitivity.

SAFETY

3-2 HEK GTP Dual T 1500 • 8095-304

Incase ofanimminent

thunderstorm,themachinemust

beswitchedoff in time due to the

riskof a lightning strike. The

powermust be switched off and

thepower plug must beremoved

fromthe socket.

- Ifthe material hoist is not used in

daylightconditions, the appropriate

areamust be lit adequately so that

theoperatorhasgoodvisioninall

conditions. Theluminositynearthe

controlcabinetmust beatleast50lux.

- Themachinemayonlybeusedforthe

purposeforwhichitwasdesigned,

thatis,fortheverticaltransportation

ofmaterialsupervisedbypersons,not

exceedingthemaximumpermitted

weight of 1,500kg (3,309 Lb).

- Placetheload(material,personnel,

etc.)evenlyonthemachine.

- Assembly,disassembly,operation of

themachineshouldonlybecarriedout

bypersonswhoarefullyconversant

withthecontentsofthisinstruction

manual.

- Inspectionandmaintenancemustbe

carried out as specified in this user's

manual.

- Duringassemblyandservicing,the

hoistmaynot beusedforanyother

purpose.

- Locallyapplicableworkingandsafety

regulationsmustalwaysbeadheredto.

- Duringnormaluse,thefencingmust

neverberemoved.

- Theworkingareamustbefreeof

obstacles(buildingwaste,dirt,snow,

etc.).

3.3.1Safety during use of the machine

as transport platform

Duringwindsabove15.7 m/s (35

Mph)(7 on theBeaufortscale),

theplatform must be placed in

thelowest position andmustnot

beused.

- Theload (material,personnel,etc.)

mustbe evenlydistributedon the

hoist.

- Thehoist may onlybeused for the

purposeforwhichitwas designed,

thatis, forthevertical transportation

ofmaterial supervised by persons,

notexceeding themaximum

permitted weight of 1,500 kg (3,309

Lb).

- See the diagram on page VII for a list

ofoptionaland/orrequiredsafety

devices.

3.3.2Safety during use of the machine

as material hoist (optional)

No passengers allowed!

Duringwindsabove20,2 m/s (45

Mph)(8 on theBeaufortscale),

thehoistmust be placed in the

lowestposition and must not be

used.

- Theload (material, etc.) mustbe

evenlydistributed onthehoist.

- Thehoistmayonlybeusedforthe

purposeforwhichitwasdesigned,

thatis,fortheverticaltransportationof

materialnotexceedingthemaximum

permitted weight of 1,500 kg (3,309

Lb).

- See the diagram on page VII for a list

ofoptionaland/orrequiredsafety

devices.

SAFETY

3-3HEK GTP Dual T 1500 • 8095-304

3.4 Safety after use

- Transportoverpublic roadsmustonly

beundertaken usingthe transport

vehicleintended for thispurpose.

- Thehoistmust be placed at the

lowestlevel andthemain switchmust

besecurelylocked against

unauthoriseduse.

3.5 Built-in and attached protective

devices

Thismachine was constructedtooffer the

highestpossible safetylevel,bothduring

assemblyand during use. Therefore, itis

fittedwith thefollowingbuilt-in and

attachedprotective devices:

- Electricallyprotected mast guard:

wheneverthe mast guardisopen, the

platformwill be locked.

- 'Emergencyoff'-buttononthecontrol

box.If this buttonispressed,the hoist

willbeblocked.

- Mechanicalprotection of thesafety

barrieron the platform.

- Bufferswhich catchthe platformin

thecase that the limit switches do not

function.

- Inthe eventofa powerfailure,the

motorbrakes will be automatically

activated.

- Electricallyprotected mast lifting aid:

wheneverthe lifting aid is raised, the

platformwill be locked.

- Inthe event of a powerfailure,itis

possibletolowerthehoist by

releasingthe motor brake.

- Ifthespeedofdescentisexceeded,

thefailsafebrakewillbe activated.

- Ifthe end stop switch 'UP' does not

functionand the hoistkeepson

ascending,the upper emergencylimit

switch'UP' will be activated.

- Ifthe end stop switch'UP'and the

proximityswitch donotfunction and

thetopmast is missing, allowing the

hoistto continue operating,thedrive

unitwill remain attached byhooksto

theuppermost mastelement.

- Ifthe end stop switch 'DOWN' does

notfunction and thehoistkeeps on

descending,the loweremergency

limitswitch'DOWN' will be activated

andthe machine willstopworking.

- 2.5metre (98 inch) stop:

Whendescending the lift will stop at a

heightof 2.5 metres (98 inch),

followingwhichthelowering

pushbuttonhas to be pressedfor

furtheroperation.Awarning signalwill

begiven and the indication light will

beflashing during 3 seconds.After

these3 seconds, theplatformwill

descendand theindicationlightand

thewarning signal will keepworking

untilthe platformis down.

- Electricalprotection of the loading

ramp:whenever the loading rampis

open,the platform will be locked.

- Overloadprotection: if the machine is

overloaded,further usewillbe

blocked.

SAFETY

3-4 HEK GTP Dual T 1500 • 8095-304

3.6 Personnel

Assembly, disassembly andoperationof

thehoist should onlybecarriedout by

personswho:

- are older than 18 years of age

- havebeen instructedon the

assembly,disassembly and

operationof the machine

- havebeen appointed by the

employerexclusivelyforassembly,

disassembly, operation and/or

maintenanceofthemachine. The

authorityto operatethemachine

shouldbe confirmed in writing.

- areawareoftheapplicablesafety

regulationsandwhoarefully

conversantwiththecontentsofthis

instructionmanual.

- Technicalstaffshouldbeable to

solveall problems occurringduring

assemblyand disassembly of the

machine.

- Operatingstaffshouldbe fully

conversantwiththesituations

occurringduring operation.

- Ifoperating ortechnicalstaff

observes defects or danger or does

notagree with the applicable safety

regulations,the ownerand/orperson

incharge should be notified

immediately.

- Repairson the electrical systems

mustbecarriedoutbyqualified

electriciansonly.

- Allconstruction workersmustwear

protectiveclothing, like a safety

helmet,safety shoesandsuitable

clothing.

- Ifthe machine is handed over toa

thirdparty,the fullnameof the

person(s)obtaining the machine

mustberecorded.

Table of contents

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions