Mandam MBS User manual

Other Mandam Farm Equipment manuals

Mandam

Mandam SUPER User manual

Mandam

Mandam MGP Series User manual

Mandam

Mandam Hybro 3,0 User manual

Mandam

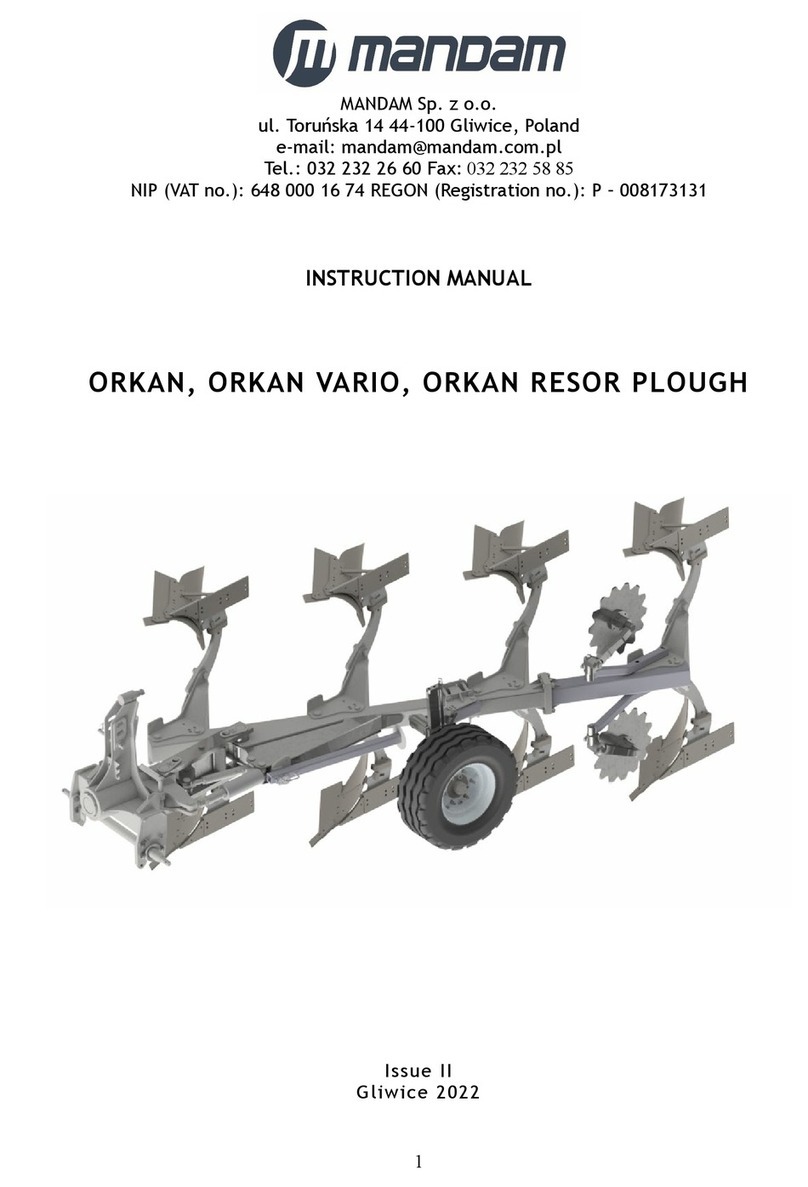

Mandam ORKAN 3+ User manual

Mandam

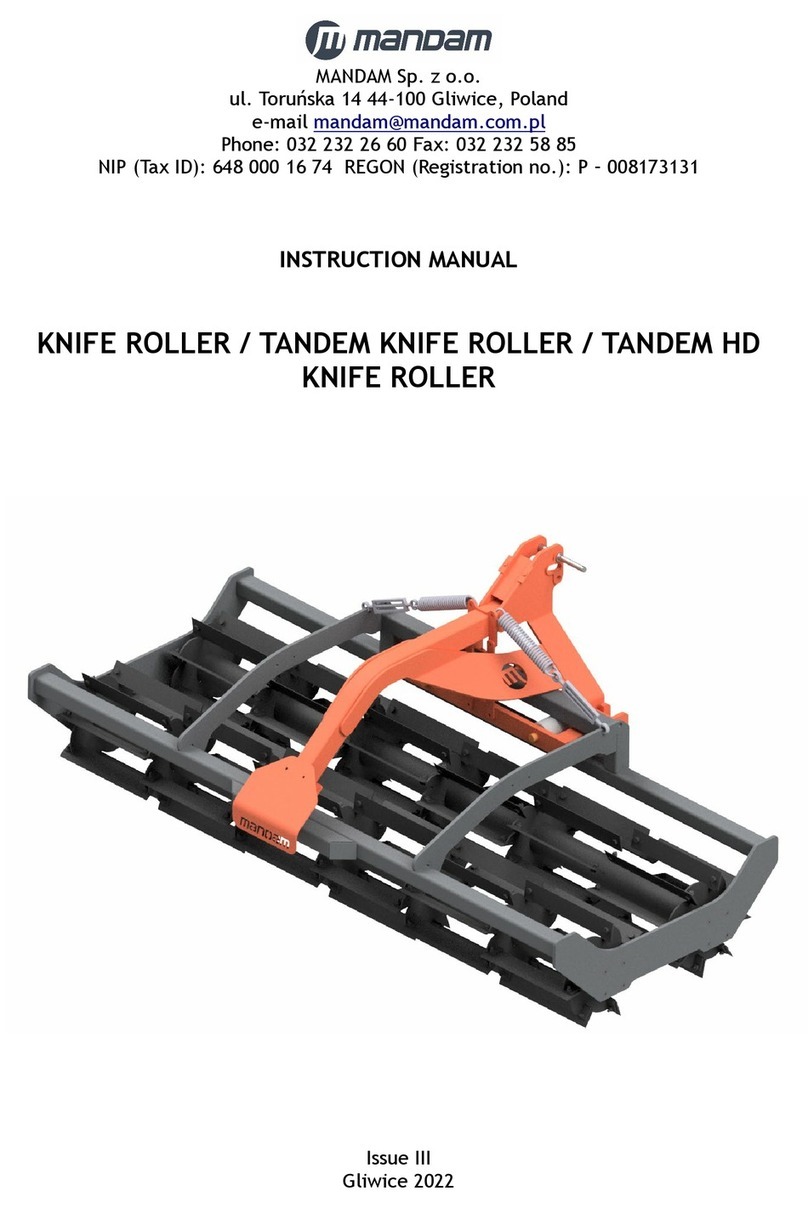

Mandam KNIFE ROLLER 3.0 User manual

Mandam

Mandam GAL-K User manual

Mandam

Mandam GAL-C User manual

Mandam

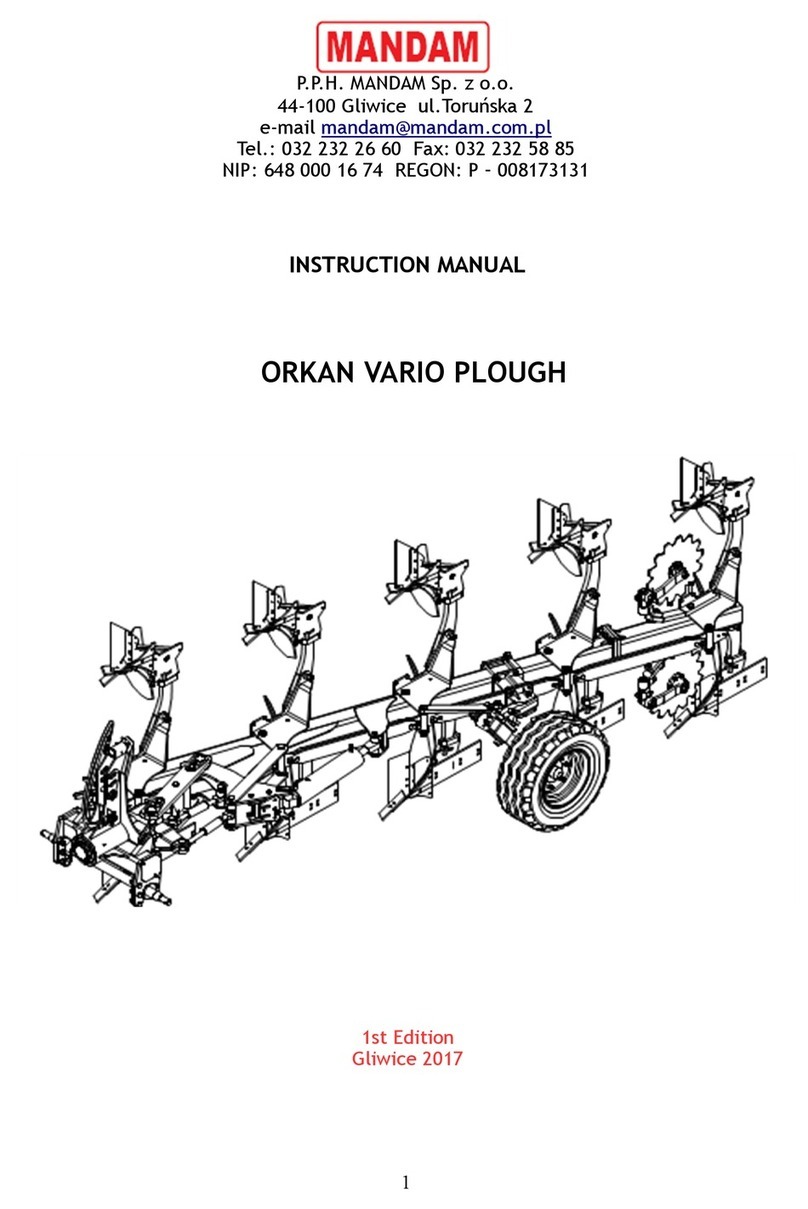

Mandam ORKAN VARIO Series User manual

Mandam

Mandam MCH Series User manual

Mandam

Mandam RHINO User manual

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions