1800 816 277www.tti.com.au

3

Product HandBook

DieselSergeant™

Disclaimer

All information, illustrations, and specifications contained in this manual are based on the latest product

information available at the time of this publication’s printing. TransTank International (TTi) reserves the right

to alter and substitute specifications and methods at any time, in line with our commitment to continuous

improvement.

No patent liability is assumed with respect to the use of information contained within this manual. While

every precaution has been taken in the preparation of this manual, TTi assumes no responsibility for errors or

omissions.

Thank you for purchasing a DieselSergeant™ Diesel Refueling Unit

(DieselSergeant), which will provide many years of reliable service when

operated and maintained in accordance with this manual.

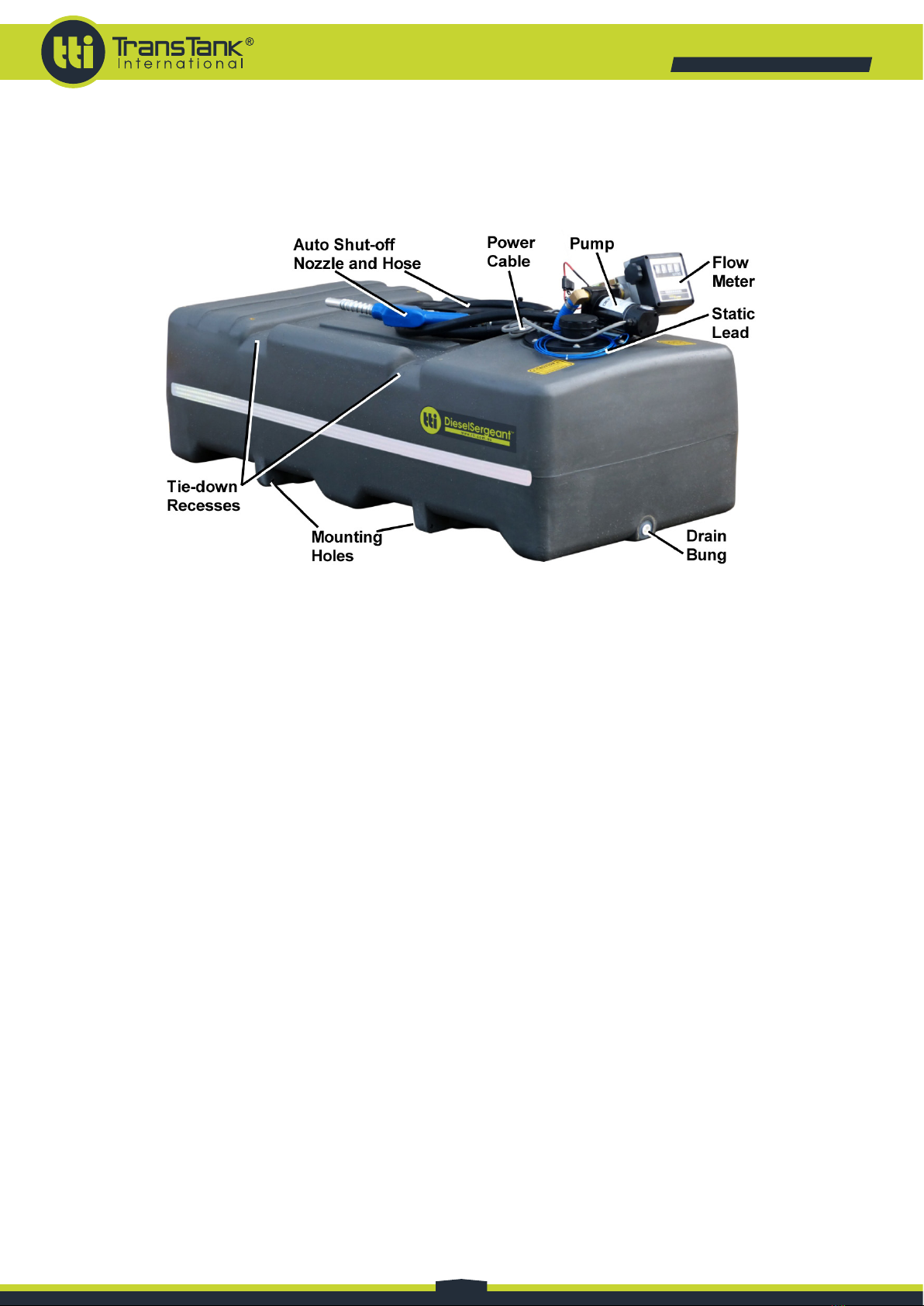

TTi manufacture two DieselSergeant units, 220 and 400 litre tanks, supplied with an electric pump as

standardandmountingframeoptions. Thismanualdescribes theoperation,drivingstabilityandmaintenance

procedures applicable to all units, noting additional requirements to options where necessary.

All TTi DieselSergeant tanks are rotationally moulded from quality polyethylene, purpose designed

and manufactured to high standards, and complying with AS1940-2004 and AS2809.2-2008. The

DieselSergeant is designed as a trailer or tray-mounted tank diesel fuel dispensing system, to deliver and

refuel your equipment in the field.

The DieselSergeant unit is supplied complete, tested and ready to go. TTi recommends that only diesel be

used in the DieselSergeant unit. TTi warrants that the DieselSergeant has been designed and built for its

intended purpose for transporting and dispensing diesel fuel.

The owner is responsible to ensure that the equipment is operated in accordance with this manual, with

Australian WorkSafe requirements, applicable road rules and local council regulations. TTi is not liable for

any loss, injury or death resulting from the failure to observe all safe working regulations as required by law.

Included with your DieselSergeant unit is the following documents:

• Operator’s Handbook (this manual, which includes the Warranty Registration Card)

• Dieselflo electric pump manufacturer’s handbook

• Optional four-digit mechanical flow meter or 5-digit electronic flow meter manuals

• Tank Quality Check Form. This is your verification that the unit has been quality checked, and verifies the

serial number affixed to the unit.