TransTank FireBoss Service manual

Operator’s HandBook

FireBoss™

www.tti.com.au

Manufacturer of “The Safest Tanks in Motion”

1800 816 277www.tti.com.au

2

FireBoss™

Product HandBook

Table of Contents

Safety 4

General Safety Instructions 5

General Information 6

Specications 6

Description 6

Machine Limitations 8

Driving Stability 8

Operating Instructions 8

Beforerstuse 8

Pump Operation 9

Filling the Tank 10

FireBoss Operation 11

Risk Assessment 12

Maintenance 13

Periodic Checks 13

Maintenance Schedule 13

Trouble Shooting 16

Warranty 17

Warranty Policy 17

What this Warranty Does Not Cover? 17

How to Obtain Service Under this Warranty? 17

Warranty Limitations 17

1800 816 277www.tti.com.au

3

FireBoss™

Product HandBook

Disclaimer

All information, illustrations, and specifications contained in this manual are based on the latest

product information available at the time of this publication’s printing. TransTank International

(TTi) reserves the right to alter and substitute specifications and methods at any time, in line

with our commitment to continuous improvement.

No patent liability is assumed with respect to the use of information contained within this

manual. While every precaution has been taken in the preparation of this manual, TTi assumes

no responsibility for errors or omissions.

Thank you for purchasing a FireBoss Low Profile UTV Fire Fighting Unit (FireBoss),

which will provide many years of reliable service when operated and maintained in

accordance with this manual.

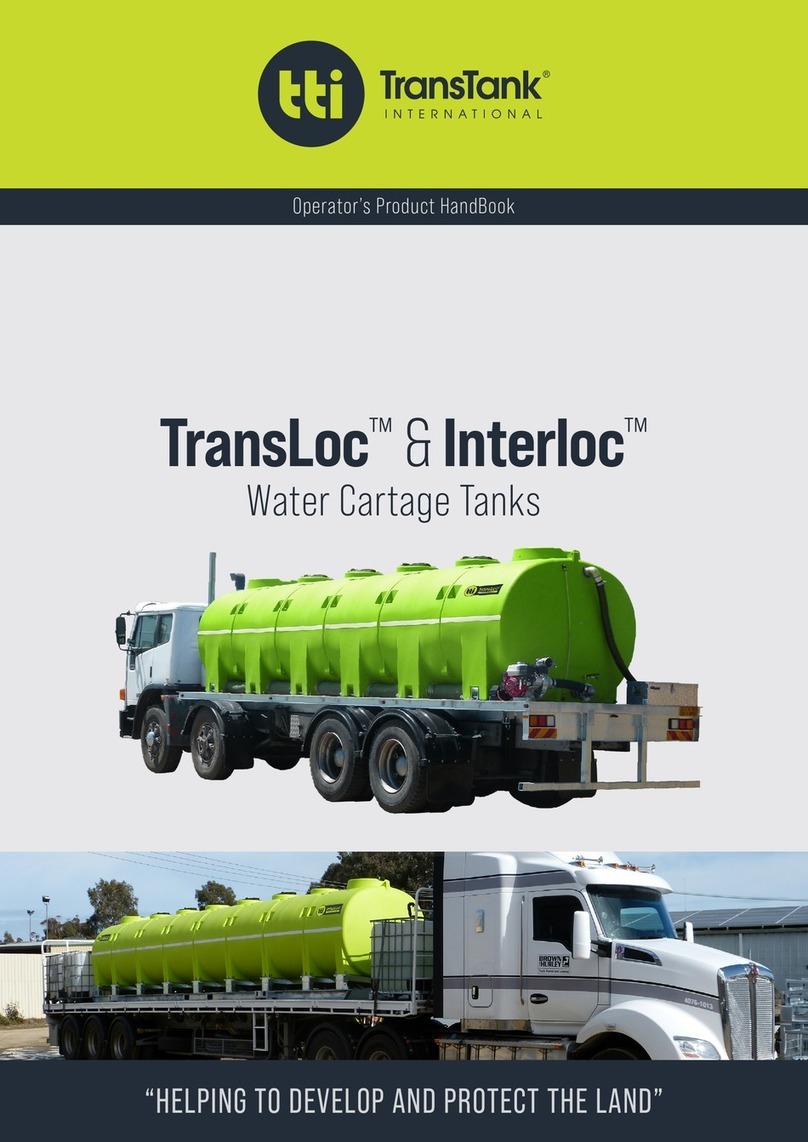

TTi manufacture two FireBoss units, both with 300 litre tanks, supplied with a petrol-powered pump. This

manual describes the operation, driving stability and maintenance procedures applicable to all FireBoss

units, noting additional requirements to options where necessary.

All TTi FireBoss tanks are rotationally moulded from quality polyethylene, purpose designed and

manufactured to high standards. The FireBoss is a Utility Terrain Vehicle (UTV) tub-mounted unit designed

for firefighting, tree watering or washdown activities. The FireBoss can also be mounted on the back of a

utility or trailer.

The FireBoss unit is supplied complete, tested and ready to go. TTi recommends that only water be used in

the FireBoss unit. TTi warrants that the FireBoss has been designed and built for its intended purpose for

firefighting and dispensing water, such as tree watering.

The owner is responsible to ensure that the equipment is operated in accordance with this manual, with

Australian WorkSafe requirements, applicable road rules and local council regulations. TTi is not liable for

any loss, injury or death resulting from the failure to observe all safe working regulations as required by law.

Included with your FireBoss unit is the following documents:

• Operator’s Handbook (this manual, which includes the Warranty Registration Card)

• Honda petrol engine manufacturer’s handbook

• Aussie Pumps manufacturer’s handbook

• Tank Quality Check Form. This is your verification that the unit has been quality checked, and verifies

the serial number affixed to the unit.

1800 816 277www.tti.com.au

4

FireBoss™

Product HandBook

Safety

This manual is intended for use by personnel experienced in the use of this and similar equipment. Read and

understand this manual before attempting to operate or perform routine maintenance on this equipment.

Your safety is of prime priority.

A WARNING highlights an essential operating or maintenance procedure, practice,

condition or statement, which, if not strictly observed, could result in injury or

death of personnel, or long-term health hazards.

A CAUTION highlights an essential operating or maintenance procedure,

practice, condition or statement, which, if not observed, could result in damage or

destruction of equipment.

A NOTE highlights or clarifies an essential systems description, operating or

maintenance procedure, condition or statement.

1800 816 277www.tti.com.au

5

FireBoss™

Product HandBook

General Safety Instructions

1. This unit is designed and manufactured solely for the purpose of carrying and pumping water for

firefighting, washdown and tree watering activities. Under no circumstances should it be used for any

other purpose. It must never be used for transporting fuel or chemicals.

2. Only authorised and trained personnel are to operate this equipment. Operators must have read and

fully understood this manual before operating the FireBoss unit.

3. Do not operate this equipment while under the influence of alcohol or any drugs that could impair your

capabilities in any way.

4. Personal Protection Equipment (PPE) must be worn when refuelling or operating the pump on the

FireBoss. Exposure to excessive noise over an extended period can cause impairment or loss of

hearing.

5. Avoid unleaded petrol contact with skin and eyes, and avoid breathing vapours or mists. Refer to the

relevant Safety Data Sheet (SDS).

6. Any spillage of fuel while refilling the pump engine’s tank should be immediately cleaned up and the

materials used in the clean-up disposed of safely and in accordance with relevant regulations applying

to the safe use, storage and disposal of fuel.

7. Ensure the capacity of the vehicle is suitable for the loaded mass of the FireBoss. Refer to the vehicle’s

operator manual for safe working loads and relevant safety instructions. Do not exceed the carrying

and braking capacity as specified by the vehicle manufacturer. As a guide, one litre of water weights

one kilogram (kg), therefore a full 300 litre FireBoss unit will weigh in excess of 350kg.

8. The FireBoss must never be left unattended while being filled with water.

9. Do not operate the pump when there is no water in the tank.

10. Do not disconnect any hoses, nozzles or filters while the equipment is operating. Disconnecting any

components while under pressure may result in uncontrolled water discharge which may be hazardous.

11. At completion of operation, switch the pump off and relieve any residual pressure by squeezing the

spray gun trigger.

12. Care should be taken at all times, particularly when operating on rough or steep terrain. Drivers should

be aware of fluid surge affecting the centre of gravity.

13. The FireBoss has safety labels affixed to various locations on the unit. These labels should be kept

clean and legible, and replaced if damaged.

14. Any unauthorised modifications to this equipment may affect its function and create a serious safety

risk. Any unauthorised modifications will void any warranty on the unit.

1800 816 277www.tti.com.au

6

FireBoss™

Product HandBook

General Information

Specifications

Tank UV resistant polyethylene tank (300 litre capacity), Standard Compact and

configurations

Standard Equipment Honda GX50 petrol driven pump with 210 L/min capacity

Aussie Pumps QP154SX single impeller pump

18m 19mm fire hose reel with adjustable nozzle

Fabricated galvanised steel frame

Auxiliary freshwater tank with tap for handwashing

Description

The TTi FireBoss is designed to carry and distribute water using a self-contained pump and hose reel

dispensing system, refer to Figure 2, which shows the Standard unit. The FireBoss is configured in two

different styles, both designed to fit into the trays of UTVs:

• Standard – 300 litre tank, 1,000mm long, 1,250mm wide and 600mm high

• Compact – 300 litre tank, 870mm long, 1,100mm wide and 850mm high

Either configuration of the FireBoss is suitable for fitting to a conventional utility tray or trailer

Figure 1 – VersatileBoom mounted on UTV

Figure 1 – FireBoss Low Profile UTV Fire Fighting Unit

1800 816 277www.tti.com.au

7

FireBoss™

Product HandBook

The FireBoss has the following features, refer to Figure 2.

Figure 2 – Component Identification (Compact FireBoss)

Tank

All TTi tanks are constructed from UV resistant, virgin material polyethylene. The tank is fully drainable

and has a twist locking filling cap.

Incorporated into the top of the tank is a small freshwater tank with tap for handwashing.

Hose Reel

Each FireBoss is fitted with an 18m 19mm diameter fire hose mounted on a manually operated hose reel.

The hose is fitted with an adjustable nozzle which locates against the integral fairlead when the hose is

fully retracted. The nozzle adjusts from closed through to jet and mist sprays, depending on requirement.

Pump

The FireBoss is fitted with an Aussie Pumps QP154SX single impeller pump firefighting pump coupled to a

Honda GX50 4-stroke recoil (pull) start engine.

Frame

The chassis frame of the FireBoss unit is an all steel, fully welded construction and hot dip galvanised for

corrosion resistance. The Standard FireBoss is mounted to the frame via metal straps, while the Compact

FireBoss is bolted to the frame. Both units have incorporated forklift pockets.

1800 816 277www.tti.com.au

8

FireBoss™

Product HandBook

Machine Limitations

The FireBoss unit is subject to operating limitations. It is the operators’ responsibility to ensure that this

equipment is being operated safely and within these limitations.

Driving Stability

The FireBoss unit is heavy when filled with water. To maintain stability while operating this unit:

• Ensure the trailer tyres are inflated to their correct pressure at all times. Underinflated tyres can cause

excessive lateral motion of the tyre, which may cause a rollover.

• Allow extra room for braking and turning when the tank is full.

• Ensure any side gradient (slope) is accounted for, especially when the FireBoss tank is full, as the unit

will have a higher centre of gravity.

Operating Instructions

Before first use

Your FireBoss Low Profile UTV Fire Fighting Unit is delivered fully assembled. Before use, it needs to be set

up using the following instructions:

• Complete the warranty registration online at www.tti.com.au/warranty-registration, or use the Warranty

Registration Card at the back of this handbook.

• Store this handbook, along with the Tank Quality Check Form and pump unit’s manual in the provided

leather pouch, in a safe and easily accessible place for future reference.

WARNING: The operator must fully understand all aspects of this handbook. Do not

operate the FireBoss if you are unfamiliar with its operation until you have read this

handbook.

• Read and thoroughly understand this handbook, paying particular attention to all safety requirements,

before using the FireBoss for the first time.

• Check that all fittings, valves, hoses and electrical leads are secure following transit, and are not

damaged in any way.

• Inspect the tank for any damage or abrasions that may have occurred during transit.

1800 816 277www.tti.com.au

9

FireBoss™

Product HandBook

• Position your FireBoss onto the vehicle and mount securely, either using tie-down straps located into

the tie-down recesses or lugs on both sides of the tank, depending on configuration, refer to Figure 2

and Figure 3 for locations. The tie-down straps must be rated to at least the total mass of the unit when

filled with fluid. Alternatively, the integrated tank frame may be bolted to the vehicle.

• Prepare the pump engine in accordance with the Honda engine’s manual supplied with your FireBoss

unit.

Pump Operation

The FireBoss’s petrol pump engine is started as follows, refer to Figure 3:

• Turn the fuel lever to ON.

• If the engine is cold, turn the choke lever to ON.

• Set the throttle lever to idle for cold starting. If restarting a warm engine, the throttle can be left at

normal engine operating speed.

• Turn the power switch to ON. Pull the recoil starter handle until the engine starts, then back off the

choke lever to OFF.

• Once the engine is warmed up, adjust the throttle to increase the engine speed to normal operating

revs.

• When the engine needs to be stopped, turn the power switch to the OFF position.

CAUTION: The FireBoss must be securely mounted to the vehicle. Failure to do

so may result in the unit moving or falling off the moving vehicle. Warranty is

conditional on the unit being correctly mounted.

CAUTION: The engine must be inspected and prepared in accordance with the

manufacturer’s instructions. Failure to fulfil this requirement may void the engine’s

warranty.

CAUTION: Ensure the engine’s throttle is set to idle if the engine is cold. Do not

adjust the throttle to maximum speed until the engine has warmed up.

1800 816 277www.tti.com.au

10

FireBoss™

Product HandBook

If the FireBoss is not going to be used within the next few hours, shut the system down by turning the fuel

tap to OFF.

Figure 3 – Engine Start-up

Filling the Tank

The FireBoss tank is filled as follows:

Open the tank’s filler cap by twisting and lifting the cap.

• Insert the hose from the water supply into the top of the FireBoss tank and turn ON the supply.

• Observe the water level directly in the tank. When the tank is filled, turn the water supply OFF.

• Replace the tank’s filler cap and twist to lock.

CAUTION: The FireBoss unit is designed for water use only. It must not be used for

chemicals or fuel.

CAUTION: To prevent overflow, do not leave the filling operation unattended.

1800 816 277www.tti.com.au

11

FireBoss™

Product HandBook

FireBoss Operation

Initial Operation Set Up

The FireBoss Low Profile UTV Fire Fighting Unit is operated as follows:

• Fill the tank from an appropriate water source, refer to the Filling the Tank procedure above.

• Unlock the hose reel then pull out the required length of hose off the reel. Check that the hose nozzle

is closed.

Note: The pump is self-priming due to the direct coupling to the FireBoss tank.

• Start the pump (referring to the procedure above) and adjust engine speed.

CAUTION: To prevent damage, do not operate the pump for more than five minutes

with the hose nozzle closed.

• Open the fire hose’s nozzle by rotating it to achieve the desired spray pattern. If necessary, adjust the

engine speed to obtain the optimal water pressure.

• Upon completion of the task, close the fire hose nozzle and turn the pump engine to OFF.

• Open the fire hose nozzle again to release the residual pressure.

• Rewind the hose onto the reel by manually winding the handle on the side of the reel. Close the nozzle

once the hose is fully retracted and the nozzle is located near the hose’s fairlead.

1800 816 277www.tti.com.au

12

FireBoss™

Product HandBook

Task Hazard Risk Control Measure/Mitigation

Partially fill the tank

with water, start the

pump engine & test

the hose spray

Manual handling;

slips, trips or falls;

petrol fumes; fingers

jammed

Medium

Concentrate on task; follow safe

manual handling techniques:

• Don’t lift on your own if > 20kg,

bend knees & keep back straight;

Keep fingers clear;

• Keep unit at least 8m away from

overhead powerlines;

• Fire extinguisher nearby;

• Follow warning stickers on tanks;

Wear PPE for petrol fumes - mask

& gloves.

Check weather

conditions

Manual handling;

slips, trips or falls

Low

• Follow safe manual handling

techniques: don’t lift on your own

if >20kg, bend knees & keep back

straight.

Use spray or fire

fighter units.

As above; loss of

load; heat & cold;

noise; exceed load

limit of vehicle;

hose entanglement;

exhaust fumes;

terrain & slopes; run

over by unit

High

As above:

• Wear clothes to suit heat & cold;

• Wear hearing protection if noise >85

dBa;

• Follow the manufacturer ’s safe

operation instruction for the vehicle

and the spray unit

• Don’t overload - water weighs 1kg

for every 1 litre

• Secure unit to tow vehicle;

• Keep hose tidy;

• Put unit brakes on (if fitted).

Clean up, maintenance

& storage

As above

Low

As above;

• Wear PPE for clean up;

• Store unit in a dry, well ventilated

area.

Burn risk Hot exhaust/muffler

Med

• Do not reach over hot exhaust

• Do not service engine while hot

• Wear appropriate PPE

Risk Assessment

1800 816 277www.tti.com.au

13

FireBoss™

Product HandBook

Maintenance

Your FireBoss Low Profile UTV Fire Fighting Unit requires minimal maintenance but regular cleaning and

checks will ensure safe and reliable service over its lifetime. Periodic checks and inspections will identify

any potential issues, enabling timely rectification and minimising downtime.

For the petrol engine driven pump, refer to the supplied Honda manual, drain and replace the engine oil in

accordance with the manufacturer’s recommendations.

Periodic Checks

The following checks and cleaning operations should be undertaken on a regular basis. The frequency

of these activities will depend on the nature of the operating environment and the operational hours of

the FireBoss unit. Refer to the maintenance schedule tables below for details of maintenance intervals.

• Clean the unit and inspect it for any signs of damage or wear. Replace any safety labels if they are

damaged or illegible.

• Check all hoses, fasteners and fittings are firmly secured, tighten if necessary.

• Unwind the hose fully to check that hose is in good order. Pressurise the line and check operation of

spray nozzle. Rewind the hose onto the reel, ensuring it retracts all the way.

• Check the engine’s oil level weekly. Top up as required.

• Check for any signs of fuel or oil leaks. If detected, investigate and rectify immediately.

• If the FireBoss is to be stored for an extended period, ensure the tank and all pipelines are empty and

are not pressurised. Store the unit is a clean, dry and well-ventilated area.

Maintenance Schedule

The following tasks are be conducted in accordance with each of the schedules. All scheduled tasks are

to be undertaken concurrently. For example, at the three month maintenance interval, all task listed are

to be undertaken, in addition to the daily, weekly and monthly tasks.

CAUTION: In dusty, dirty or smoky environments, cleaning, inspection and

servicing of the unit on a regular basis is essential. The cleaning, inspection and

servicing must be undertaken more frequently in harsh conditions to avoid damage

or destruction of equipment.

NOTE: Maintenance is important. Keep a record of all maintenance tasks

conducted on the FireBoss unit.

1800 816 277www.tti.com.au

14

FireBoss™

Product HandBook

TTi recommends photocopying these schedules in order to keep a detailed log of all maintenance

tasks. A copy of these schedules will be required to support any warranty claim.

Daily tasks

The following tasks are to be undertaken daily, or prior to each use, of the FireBoss unit.

Weekly tasks

The following tasks are to be undertaken each week or 10 operating hours, whichever occurs first.

Monthly tasks

The following tasks are to be undertaken each month or 20 operating hours, whichever occurs first.

#Task Date Signed

1All Daily tasks

2Remove and clean the engine’s air filter

3Check engine oil level, top up as required

#Task Date Signed

1All Daily and Weekly tasks

2Check hose and hose reel by unwinding fully

3

* Change engine oil (first change, thereafter every

six months or 100 operating hours), refer Honda

manual

#Task Notes

1Inspect the FireBoss for any signs of damage or wear Clean, repair or replace

2Check the engine’s electrical connections Test function of engine

3Check fuel Top up as required

4Inspect engine’s air filter and housing for dust Clean, replace as necessary

1800 816 277www.tti.com.au

15

FireBoss™

Product HandBook

Three Monthly tasks

The following tasks are to be undertaken every three months or 50 operating hours, whichever occurs

first.

Six Monthly tasks

The following tasks are to be undertaken every six months or 100 operating hours, whichever occurs

first.

Twelve Monthly tasks

The following tasks are to be undertaken every twelve months or 200 operating hours, whichever occurs

first.

#Task Date Signed

1All Daily, Weekly, Monthly and 3-Monthly tasks

2Change engine oil

3Inspect spark plug

#Task Date Signed

1All Daily, Weekly, Monthly, 3-Monthly & 6-Monthly

tasks

2Replace the engine’s air filter

3Drain and flush the fuel tank

4Replace the engine’s fuel filter

5Replace the spark plug

#Task Date Signed

1All Daily, Weekly and Monthly tasks

2Inspect the air filter, replace if clogged or damaged

3Check engine oil level, top up as required

1800 816 277www.tti.com.au

16

FireBoss™

Product HandBook

Two Years tasks

The following tasks are to be undertaken every 24 months or 500 operating hours, whichever occurs

first.

Trouble Shooting

If a fault develops with the FireBoss, the following trouble shooting table provides guidance to identify

and rectify the problem.

#Task Date Signed

1All Daily, Weekly, Monthly, 3-Monthly, 6-Monthly and

12-Monthly tasks

Problem Possible

cause Remedy

Pump will not feed water Hose nozzle

closed

Open hose nozzle

Engine will not crank Loose

Connections

Clean and tighten

connections

Faulty ON/OFF

switch

Check switch operation,

replace as needed

Mechanical

problem in

engine

Check Engine

1800 816 277www.tti.com.au

17

FireBoss™

Product HandBook

Warranty

Warranty Policy

TTI will, at its option, repair or replace without charge any part covered by this warranty which is found

to be defective in material and/or workmanship within one (1) year after date of sale to the original retail

purchaser. If the product is used for rental purposes, this warranty is limited to ninety (90) days.

Upon request, the customer will make the defective part available for inspection and/or return the defective

part to TTi, transportation charges prepaid. All parts and components are covered by this warranty except

the following, which are warranted separately by their respective manufacturers:

• engines

• gearboxes

• pumps

• regulators.

TTi does not assume any warranty obligation, liability or modification for these items, which are covered

exclusively by the stated warranty of the respective manufacturers.

What this Warranty Does Not Cover?

This warranty does not cover:

1. defects caused by depreciation or damage caused by incorrect mounting, normal wear, accidents,

improper maintenance, improper use or abuse of the product, alterations or failure to follow the

instructions and warnings provided.

2. Any charges for making service calls, clean up time and transport charges.

3. The use of non-genuine parts on equipment supplied by TTi. This will automatically negate any warranty.

How to Obtain Service Under this Warranty?

Warranty service can be arranged by contacting your dealer, or by contacting TTi directly on 1800 816 277.

Proof of warranty registration and date of purchase may be required to verify warranty coverage. Any

defective parts returned to TTI must be accompanied by a Return Goods Note. This form can be obtained

by contacting Product Support on 1800 816 277 or emailing ProductSupport@tti.com.au.

Warranty Limitations

Warranty limitations are as follows:

1. There is no other express warranty. Any warranty that may be implied from this purchase including

merchantability and fitness for purpose is hereby limited to the duration of this warranty and to the

extent permitted by law. Any and all implied warranties are excluded.

2. TTI will not be liable for any incidental, consequential or special damages and/or expenses in connection

with the purchase or use of this equipment, to the extent permitted by law.

3. Only the warranty expressed in this limited warranty shall apply and no dealer, distributor or individual

is authorised to amend, modify, or extend this warranty in any way. Accordingly, additional statements,

whether oral or written, do not constitute warranties by TTi, and should not be relied upon.

www.tti.com.au

1800 816 277

PO Box 137, Nathalia, VIC, 3638

Murray Valley Hwy, Nathalia, VIC 3638

Proudly Built By:

Signature Date Signature Date

Quality Checked By:

Scan to view our PDF

Handbook online

Table of contents

Other TransTank Tank Equipment manuals

TransTank

TransTank FirePatrol14 Service manual

TransTank

TransTank TransLoc User manual

TransTank

TransTank AquaTrans Service manual

TransTank

TransTank TopCrop Service manual

TransTank

TransTank DieselSergeant Service manual

TransTank

TransTank DieselCadet Service manual

TransTank

TransTank SuperReel Service manual

TransTank

TransTank FloodRite Service manual

TransTank

TransTank DieselPatrol Service manual

TransTank

TransTank SilageMaster User manual