TransTank TrailPro Deluxe Service manual

Manufacturer of The Safest Tanks in Motion

www.tti.com.au

TrailPro™ Deluxe

HANDBOOK

OPERATOR’S

with 6m boom and 30m Hose Reel

TTi’s TrailPro™ Deluxe HandBook

2Call 1800 816 277www.tti.com.au 2

Table of Contents

Introduction 3

Risk Assesment 4

Operating Instructions 5

Mixing and Filling 6

Calibration 6

Calibration Procedures 7

Spraying Guide 8

Spraying Consideration 9

After Season Care 10

STT Models 11

Spray Lance 12

Spare Parts List 13

Spare Parts List 14

Warranty 15

Warranty Limitations 16

Warranty Registration Card 17

TTi’s TrailPro™ Deluxe HandBook

3Call 1800 816 277www.tti.com.au 3

Introduction

Please read your operators handbook carefully before mounting and using your

SpotPro Deluxe sprayer. Keep your handbook in a safe place.

Congratulations on your purchase of a TTi SpotPro Sprayer which is complete and

ready to attach to an ATV. Ideally suited to farmers or spray contractors for weed

spraying, fence line spraying, spraying of drainage channels and around buildings

etc.

Your Safety

• When mounting to any vehicle ensure that you have read the Vehicle Owner’s

Manual and that you comply with all the weight restrictions as specified by the

vehicle manufacturer, as overloading can cause injury or death.

• To ensure your own safety and that of your employees if applicable you must

comply with all relevant environmental, work place health and safety legislation

and codes of practice.

• Select and wear appropriate Personal Protection Equipment in accordance with

the label of the product you intend using and your own safe work practices.

• Once the spraying operation has been completed, decontaminate the tank

and spray accessories. Dispose of tank rinsings in compliance with current

environmental, work place health and safety regulations.

• Personal Protection Equipment must still be worn while decontaminating your

sprayer as per warning at 3 above.

• Improper or careless use of this sprayer can cause serious injury. Minors should

never be allowed to use this sprayer. This sprayer should not be used when

bystanders or animals are in the area. This sprayer should never be used while

children are in the area.

• Never leave the sprayer unattended without turning off the engine and relieving

the line pressure, and flushing the sprayer of any harmful chemicals.

• You must be in good mental health to operate this sprayer and not be under the

influence of alcohol or any drugs that could impair your vision, physical strength,

dexterity, judgment, or other mental capacity

TTi’s TrailPro™ Deluxe HandBook

4Call 1800 816 277www.tti.com.au 4

Risk Assesment

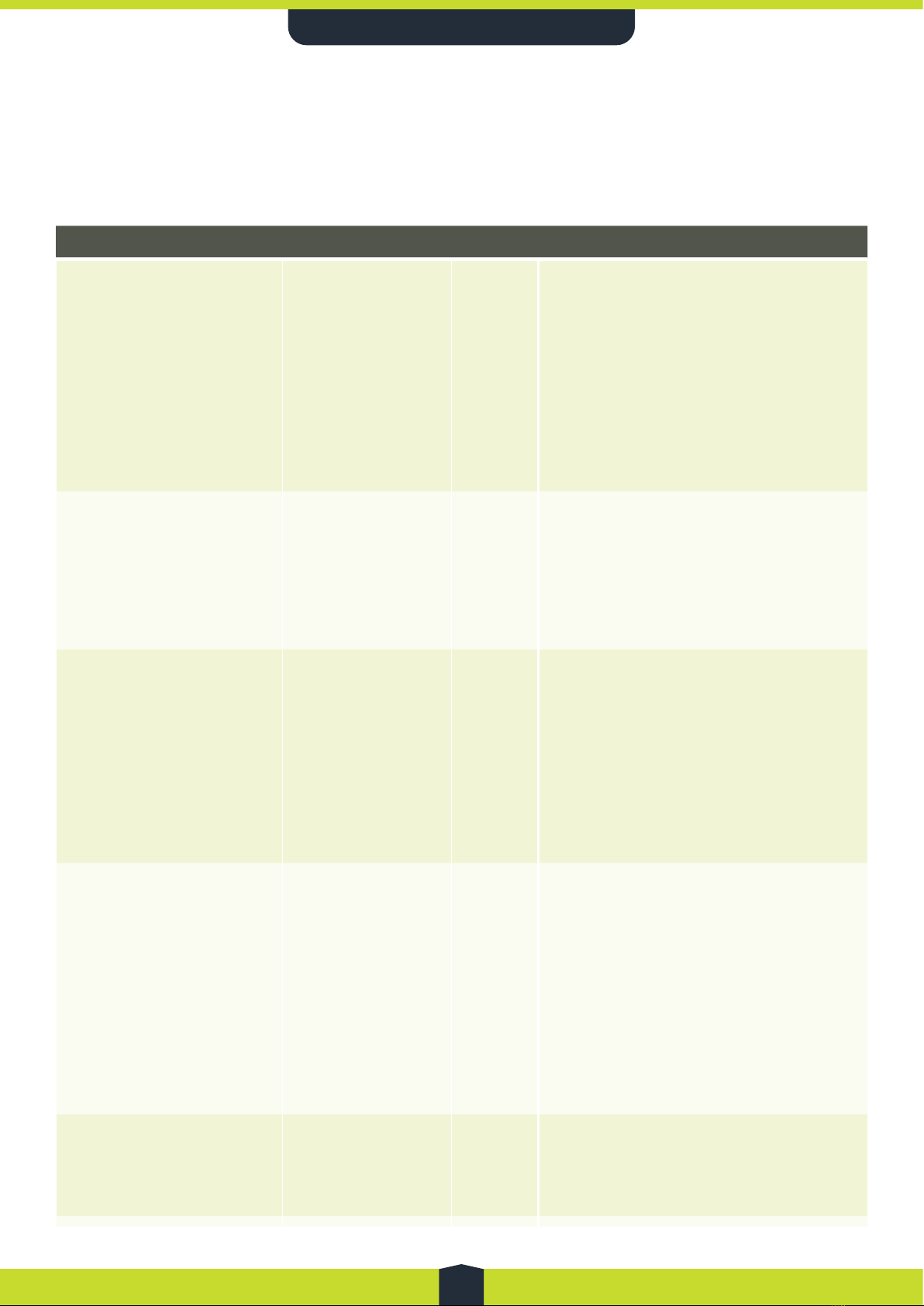

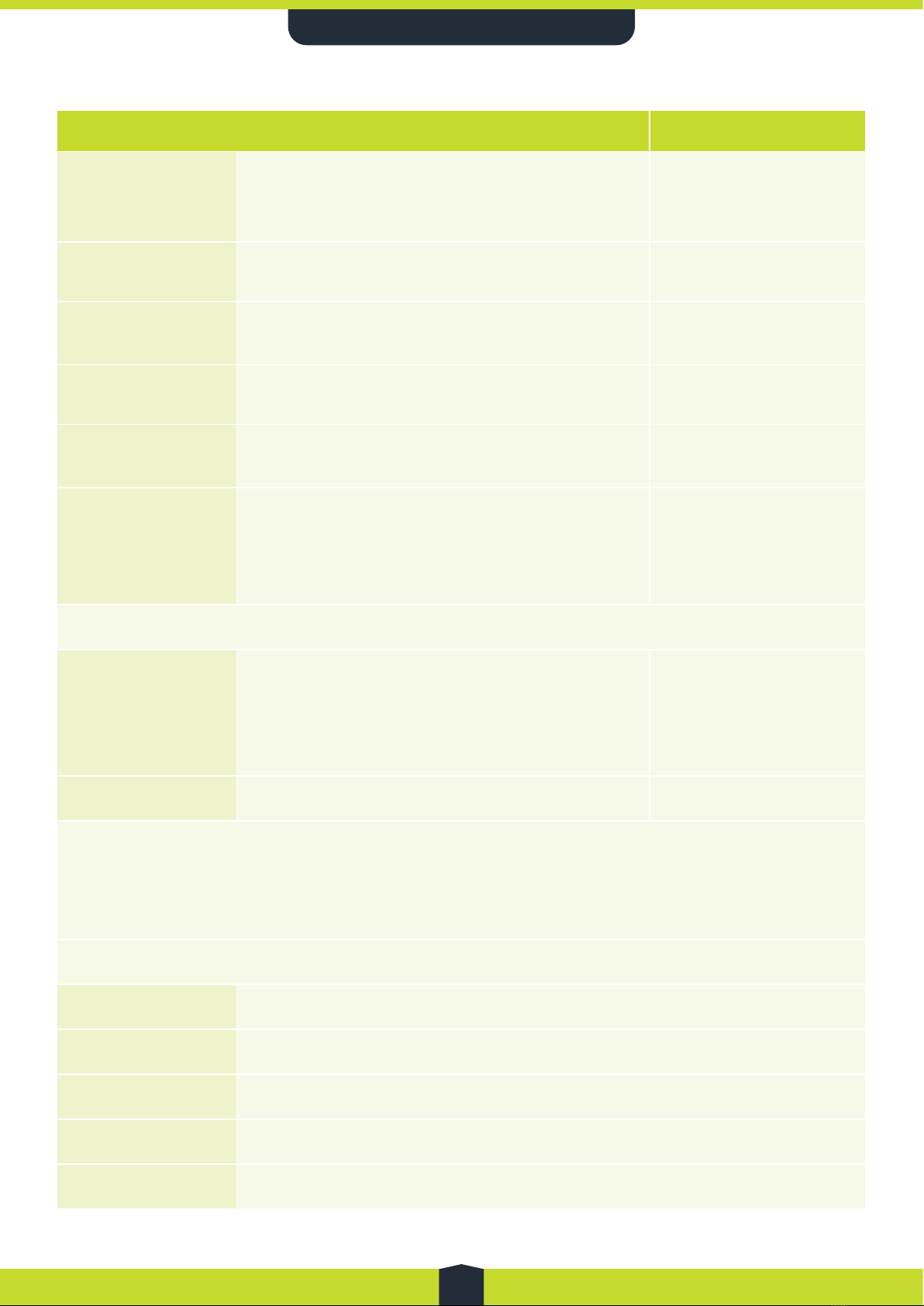

Product Information Risk Assessment Sheet

TTi - TrailPro Sprayer

TASK HAZARDS RISK CONTROL MEASURES

Partially fill the tank

with water, start the

motor & test the spray

unit

Manual

handling; slips,

trips or falls;

petrol; fumes;

fingers jammed

Medium

Concentrate on task; follow safe

manual handling techniques:

• Don’t lift on your own if > 20kg;

• Bend knees & keep back

straight;

• Keep fingers clear;

• Keep unit at least 8m away

from overhead powerlines;

• Fire extinguisher nearby;

• Follow warning stickers on tanks;

• Wear PPE for petrol & fumes-

mask & gloves.

Check weather

conditions & select the

appropriate PPE to suit

the chemicals to be

used

Manual

handling; slips,

trips or falls

Low

• Put on PPE as per the chemical

requirements in the Material Safety

Data Sheet-coveralls, gloves, safety

footwear, glasses & respirator;

• Follow safe manual handling

techniques:-

• Don’t lift on your own if >20kg,

• Bend knees & keep back straight.

Mix chemicals

(if applicable)

&

fill spray tank

As above; spray

drift, chemical

spillage,

emission

of vapors or

flammability;

weather;

untrained

visitors

Medium

• As above;

• User trained in the state’s

chemical mixing &

administration course eg Chem.

Cert;

• Follow the relevant Environment

Protection Authority

requirements;

• Fire extinguisher present;

• Keep visitors away from the job

unless wearing full PPE.

Using spray unit

As above;

loss of load;

heat & cold;

noise; exceed

load limit of

vehicle; hose

entanglement;

exhaust fumes;

terrain & slopes;

run over by unit

High

• As above;

• Wear clothes to suit heat &

cold;

• Wear hearing protection if noise

> 85 dBa;

• follow the manufacturer’s safe

operation instruction for the

vehicle and the spray unit;

• Don’t overload - water weighs

1kg for every 1 litre;

• Secure load to vehicle;

• Keep hose tidy; put unit brakes

on.

Clean up,

maintenance &

storage

As above

Low

• As above;

• Continue to wear PPE for clean

up;

• Store unit in a dry, well

ventilated area.

TTi’s TrailPro™ Deluxe HandBook

5Call 1800 816 277www.tti.com.au 5

Operating Instructions

Check all hoses, connections and hose clamps to ensure that the unit has been

delivered to you without transportation loss or damage.

Before attempting any spraying with your new unit, operate it with water only to

familiarize yourself with its features and capabilities and to ensure that your sprayer

has arrived in a safe working condition. Please contact your dealer immediately

should anything appear to have been damaged.

Prepare the engine for use as per the engine manual supplies with your sprayer.

Ensure that the correct quantity and type of oil is used when filling the engine.

Start Up Procedure

• Prepare the engine for start as per the engine manual and pump manual.

• Add the spray solution to the tank (See “Mixing and Filling”).

• Ensure that the pressure regulator lever is in the BYPASS position and the pressure

adjusting knob is screwed out (anti-clockwise). Failure to do so will invalidate

pump warranty.

• Start the engine and allow it to warm up. Run the pump with the regulator lever

in the BYPASS position in order to discharge entrapped air from the system for at

least two minutes before changing the regulator lever to the PRESSURE position.

(Rotate clockwise)

• To set the correct spraying pressure, open the flow through the hand gun

(discharge solution back to tank) and turn the pressure regulator knob in a

clockwise direction until the required pressure is achieved. Spray nozzle pressure

will vary according to hose length, nozzle size, etc. When the hand gun is

released the increased pressure in the system will be automatically adjusted by

the pressure regulator valve and excess flow will be returned to the spray tank.

TTi’s TrailPro™ Deluxe HandBook

6Call 1800 816 277www.tti.com.au 6

Mixing and Filling

Sites for mixing and filling the sprayer should be carefully chosen to be away from any

risk of spillages draining into water courses or into environmentally sensitive areas.

Children and animals must always be kept way from mixing and filling operations.

The following steps are given as a guide for mixing and filling the sprayer.

• Read the product label and follow all directions carefully, taking special care

with regard to the order in which the products are added to the tank.

• Calibrate the sprayer according to recognized calibration method using water

only. Calibration must be done with the nozzle tip that has been selected for the

spraying task.

• Measure out the correct quantities of pesticides, using clean measuring jugs

used only for this purpose.

• Half fill the sprayer with clean water and then add the measured pesticide/

herbicide.

• Rinse out the measuring jug and empty container and pout all rinsings into the

spray tank. Agitate by stirring with a suitable round edged paddle.

• Top up the tank with water to the required level, ensure that the tank is not over-

filled and the outside is clean and dry before handling.

• Safely dispose of empty containers in compliance with current regulations

• Mixing sites must be well away from watercourses and other environmental

sensitive areas. Children and animals must be kept away.

Calibration

Accurate calibration is an essential of any spraying function as it ensures that

the chemical is applied at the rate intended on the product label. Application in

excess of the recommended rate is prohibited, can damage plants/foliage and is

uneconomical.

Calibration must always be carried out:

• When spraying for the first time with new spray equipment

• At the beginning of each season

• After changes of nozzle tips, spraying pressures or speed

• After every 100 hectares of spraying

When calibrating a sprayer, a minimum of coverall, gloves and boots must be worn.

A face shield and PVC apron may be included depending on the task and the

cleanliness of the sprayer.

TTi’s TrailPro™ Deluxe HandBook

7Call 1800 816 277www.tti.com.au 7

Calibration Procedures

Boom Sprayers Hydraulic Nozzles Example

Read the label

Spray VOLUME

Product Dose

Spray QUALITY

200 litres/hectare

50 litres/hectare

Medium

Measure TIME per

100 Metres

Measure time in seconds over land similar to

that to be sprayed 41.9 seconds

Calcute SPEED SPEED(km/h) = 360 divided by TIME (sec) 360/41.9 = 8.6km/h

Measure nozzle

SPACING Normally 0.5 metres (50cm) 0.5 metres

Measure TIME per

100 Metres

OUTPUT = VOLUME x SPEED x SPACE / 600

(L/min) (L/hec) (km/hr) (metre) 200 x 8.6 x 0.5 ÷600

Select NOZZLE

Refer to nozzle manufacturer data charts or

other sources and select the size and type

of nozzle that will produce the calculated

OUTPUT and required spray QUALITY

Now, check the calibration on the sprayer

Check nozzle

OUTPUT

With water, check outputs of 4 or more

nozzles using a calibrated jug or flow meter.

Check all nozzles are aligned correctly and

spray patterns are good

Average output = 41.9

litres/minute

Calibrate SPRAYER SPEED (km/h) = 360 divided by TIME (sec) 1.40 x 600 ÷0.5 ÷8.6

As the nozzle output and therefore the spray volume are less than target figures,

increase the pressure to, say 2.5 bar and repeat the calibration to achieve 200 litres

per hectare

Now, check the calibration on the sprayer

Nozzle Fitted 11004 - RED

Spray Volume 200 litres/hectare

Spray Pressure 2.5 bar

Spray Quality Medium

Forward Speed 8.6 km/h

TTi’s TrailPro™ Deluxe HandBook

8Call 1800 816 277www.tti.com.au 8

Spraying Guide

The following steps are given as a guide for spraying with your trailer unit.

• Before commencing spraying, plan the work effectively to reduce potential

contamination to a minimum.

• Wind Direction and speed must be taken into account. Avoid spraying on hot

and sunny days or when wind speed exceeds 6.5km/h

• Do not spray if the operator, bystanders, watercourses or any not targeted

vegetation appears to be in danger from spray drift contamination.

• Drift can be reduced by lower nozzle height, lower pressures or by fitting larger

nozzles.

• To commence spraying, squeeze trigger. Release the trigger to stop the spray –

the regulator will automatically allow spray solution to bypass through the return

line and back to the tank.

• Spray at a constant speed (as used during calibration) and shut off the hand

lance trigger or boom at the end of each swath or before changing direction.

• Work in parallel lines at the correct spacing when spraying large area – this is

better than moving the hand lance from side to side in a swinging movement

which causes damage by overdosing.

TTi’s TrailPro™ Deluxe HandBook

9Call 1800 816 277www.tti.com.au 9

Spraying Consideration

For effective spraying ensure you have taken the following factors into account.

1. Work Rates

• Speed of operation

• Water points or nurse tanks

• Rate of travel

• Swath width

• Spray volume applied

2. Wind and Drift

• Wind Speed

• Wind Direction

• Airspeed at boom height

• Avoid spraying on still warm days as convection currents may cause drift

in unpredictable directions.

• Optimum wind speeds are between 3km/h to 7km/h

• Wind direction and drift is controlled by;

• Reducing nozzle height

• Reducing pressure and using larger nozzle

• Fit low-drift nozzles producing larger droplets

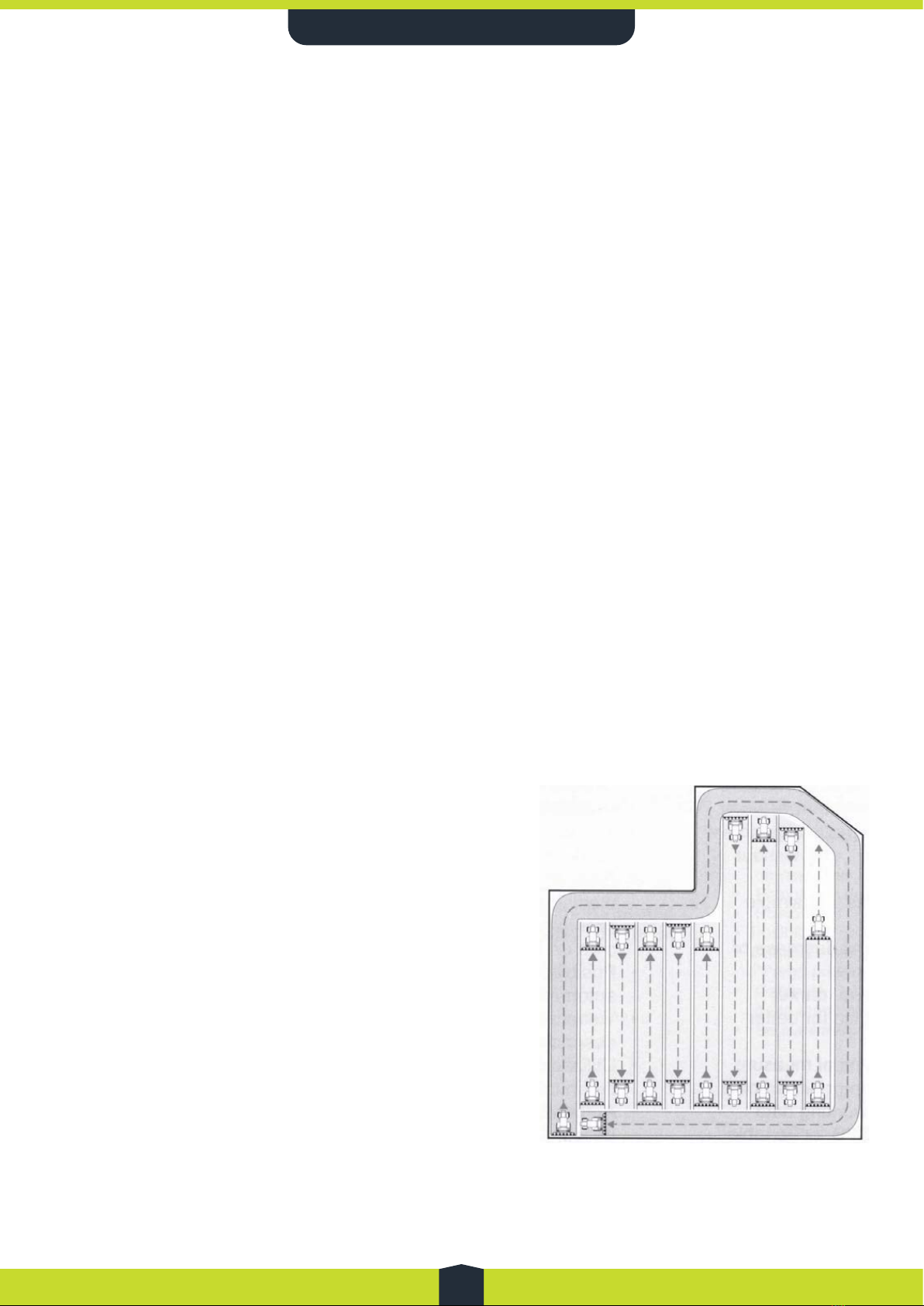

3. Field Work (see diagram)

Swath marking and spraying

• Mark out to ensure proper pass matching

– use flags foam markers or tramlines

• Where large obstructions exist in the

middle of an area to be sprayed, mark

out and spray the area like a separate

headland

• The perimeter of the eld should be

sprayed rst. The width of two swaths will

give adequate turning space at the ends

of spray runs

• Never spray while turning

4. Speed

• Maintain a constant speed when spraying. Should you need to increase

your spraying speed, larger delivery nozzles must be fitted. Re-calibrate as

required

S G S D

OPERATORS HANDBOOK 9

SPRAYING CONSIDERATION

For effective spraying ensure you have taken the following factors into account

1. Work Rates

• Speed of operation

• Water points or nurse tanks

• Rate of travel

• Swath width

• Spray volume applied

2. Wind and drift

• Wind Speed

• Wind Direction

• Airspeed at boom height

Avoid spraying on still warm days as convection currents may cause drift in unpredictable

directions.

Optimum wind speeds are between 3km/h to 7 km/h

• Wind direction and drift is controlled by;:

• Reducing nozzle height

• Reducing pressure and using larger nozzles

• Fit low-drift nozzles producing larger droplets

3. Field Work (See diagram below)

Swath marking and spraying

• Mark out to ensure proper pass matching – use ags foam markers or tramlines

• Where large obstructions exist in the middle of an area to be sprayed, mark out and spray

the area like a separate headland.

• The perimeter of the eld should be sprayed rst. The width of two swaths will give

adequate turning space at the ends of spray runs.

• Never spray while turning.

4. Speed

Maintain a constant speed when spraying. Should you need

to increase your spraying speed, larger delivery nozzles

must be tted. Re-calibrate as required

OPERATOR HANDBOOK 8

CONSIDERATIONS WHEN SPRAYING

For effective spraying ensure you have taken the following factors into account

1. Work Rates

• Speed of operation

• Water points or nurse tanks

• Rate of travel

• Swath width

• Spray volume applied

2. Wind and drift

• Wind Speed

• Wind Direction

• Airspeed at boom height

Avoid spraying on still warm days as convection currents may cause drift in unpredictable

directions.

Optimum wind speeds are between 3km/h to 7 km/h

• Wind direction and drift is controlled by;:

• Reducing nozzle height

• Reducing pressure and using larger nozzles

• Fit low-drift nozzles producing larger droplets

3. Field Work (See diagram below)

Swath marking and spraying

• Mark out to ensure proper pass matching – use flags foam markers or tramlines

• Where large obstructions exist in the middle of an area to be sprayed, mark out and spray

the area like a separate headland.

• The perimeter of the field should be sprayed first. The width of two swaths will give

adequate turning space at the ends of spray runs.

• Never spray while turning.

4. Speed

Maintain a constant speed when spraying. Should you need to increase your spraying speed, larger

delivery nozzles must be fitted. Re-calibrate as required

www.tti.com.au

Call 1800 816 277

• After use, the sprayer must be thoroughly decontaminated including tank,

pump, hoses, boom and hand lance to avoid damage to crops from harmful

spray residue and to the sprayer from corrosion or abrasion.

• After spraying, flush the tank, hose, boom, and hand lance by running it with

clean water plus recommended cleaning fluid. It is best to clean sprayers in

the field or area just treated.

• The suction strainer attached to the pump suction line should be cleaned

periodically. Lift the strainer from the base of the tank and brush off with a soft

brush.

• Nozzle filters (if fitted), nozzle tips, nozzle caps and gaskets should be cleaned

by soaking in water, brushing with a nozzle brush and allowed to dry. Never blow

through nozzles with your mouth, not use wire or pins to clear any blockages.

• Unscrew the hand lance grip and remove the filter screen and clean in the

same way as described for the suction strainer. Ensure that the o-rings do not

become displaced during cleaning. Re-assemble the hand lance correctly.

• Aligning the filter screen in the handle body before the hand lance grip is

screwed back.

• Check tyre pressure.

• When storing your sprayer ensure that it is clean and dry and kept in a well

ventilated place.

9www.tti.com.au | Call 1800 816 277

TTi - Operators Handbook

TTi’s TrailPro™ Deluxe HandBook

10 Call 1800 816 277www.tti.com.au 10

After Season Care

NOTE: It is important that when cleaning the sprayer one wears proper safety

equipment. See your chemical or fertilizer package for this information.

• After spraying chemicals run water through the tank, pump, and all hose hookups.

If wettable powder dries out in the system it is very difficult to put back into

suspension and can cause malfunction, damage or injury.

• Disassemble the tips and rinse with water or cleaning solution (ie one appropriate

for the chemical sprayed).

• Clean the tip opening with a wooden toothpick. Never use wire or a hard object

that could distort the opening.

• Water rinse and dry the tips before storing.

Be sure to dispose of all unused chemicals or solutions in a proper and ecologically

sound manner.

TTi’s TrailPro™ Deluxe HandBook

11 Call 1800 816 277www.tti.com.au 11

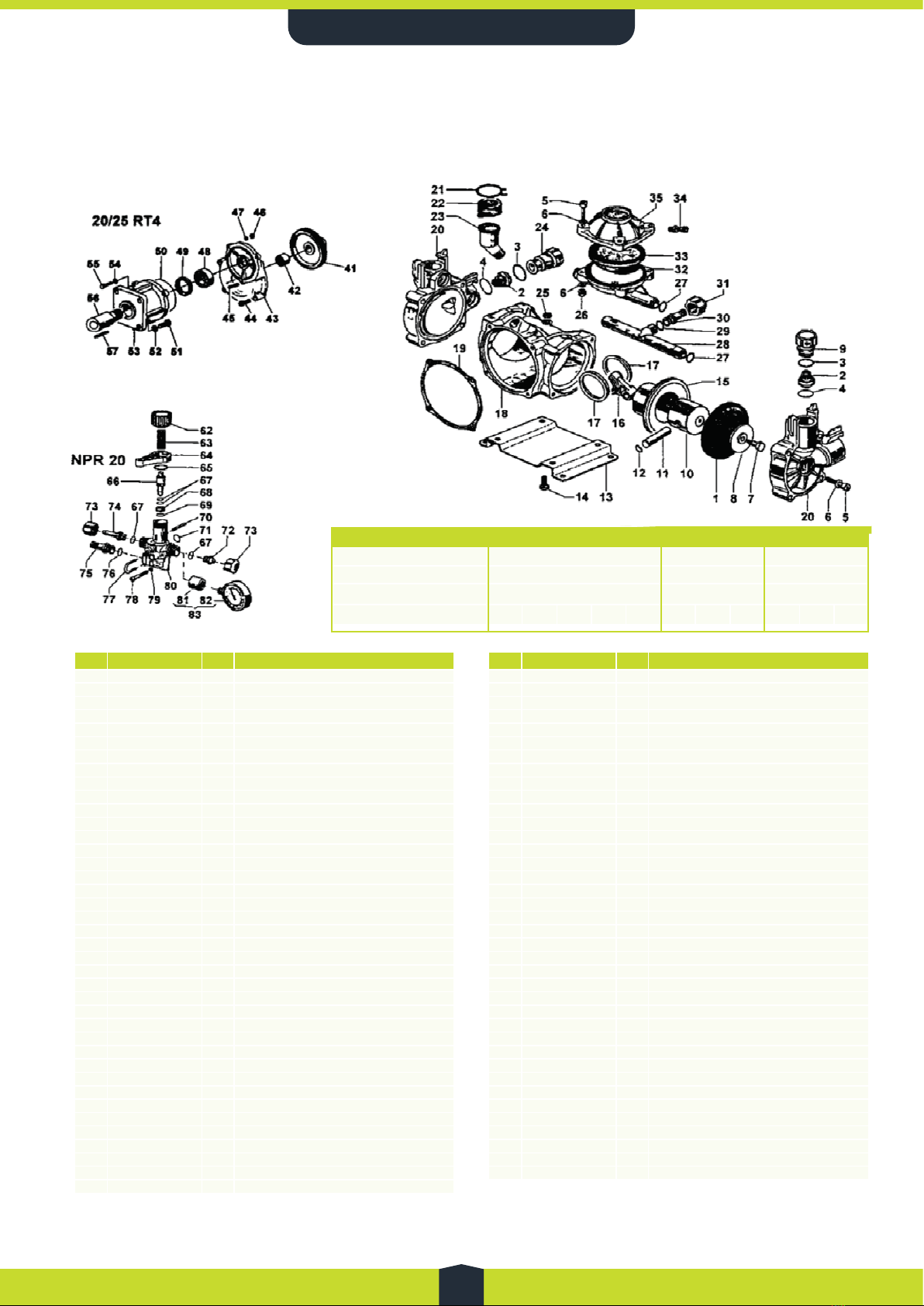

STT Models

22 L/min Pump

Item Code Description

11 STA31 1 ¼” MBSP Poly Tank Fitting with Gasket

12 STAHS25 25mm Suction Hose

13 STAB031 1 ¼” Suction Filter Complete

14 4HP Honda Motor GC135

15 STAP31 Bertonini Pump & Gearbox 22l/m, 20Bar, - 20RT4

16 i) BE 80.3060.00.2 O’Ring 1.78 x 12.42mm

ii) BE 84.0521.00.2 90° Elbow Connector 19mm

iii) BE 82.0042.10.2 ¾” Flynut

17 STAHS19 19mm Suction Hose

18 aAR2452045 1 ¼” FBSP to 1” MBSP Reducer

18 bi) AR116420 1” X 20mm Elbow

ii) AR2002040 1” Flynut

iii) ARG10041 1” O’Ring

19 AIBFP30606 3/8” MBSP x 10mm Hose Barb - Brass

20 STAH10 10mm Spray Hose

21 STAP76 NPR20 Regulator - 20Ba

26 i) AR106525 1¼” x 25mm Straight

ii) ARG10051 1¼” O’Ring

iii) AR2002050 1¼” Flynut

34 L/min Pump

Item Code Description

11 STA31 1 ¼” MBSP Poly Tank Fitting with Gasket

12 STAHS25 25mm Suction Hose

13 STAB031 1 ¼” Suction Filter Complete

14 6.5HP Honda Motor GX160

15 STAP37 Bertonini Pump & Gearbox 34L/m, 40bAR,-PA330

16 i) BE 80.3200.00.2 O’Ring 2.62 x 22.22mm

ii) BE 84.0542.00.2 90° Elbow Connector 19mm

iii) BE 82.0049.10.2 Nut M34

17 STAHS25 25mm Suction Hose

18 i) AR2002050 1 ¼” Fly Nut

ii) ARG10051 1¼” O’Ring

iii) AR116525 1¼” x 25mm Elbow

19 AIBFP30606 3/8” MBSP x 10mm Hose Barb - Brass

20 STAH10 10mm Spray Hose

21 STAP78 NPR20 Regulator - 20Ba

26 i) AR106525 1¼” x 25mm Straight

ii) ARG10051 1¼” O’Ring

iii) AR2002050 1¼” Flynut

TTi’s TrailPro™ Deluxe HandBook

12 Call 1800 816 277www.tti.com.au 12

Spray Lance

S Lance

30.1903.8

29.17.02.26

23.602.34

23.602.29

29.507.10

29.1607.3

29.902.8

29.1003.24

23.1310.8

23.1603.14

23.1304.29

23.601.25

30.208.130

23.1003.16

29.801.40

29.1101.1

23.602.34

12 www.tti.com.au | Call 1800 816 277

TTi - Operators Handbook

TTi’s TrailPro™ Deluxe HandBook

13 Call 1800 816 277www.tti.com.au 13

Spare Parts List

(Pump Series VF - STAP30) 22L/min

(PA 330 VF - STAP36) 34L/min

Pos Code Qty Description

194.0040.31.2 2Piston Diaphragm

194.0040.33.2 2Viton Piston Diaphragm (non stock)

294.9828.97.3 4Valve Assy

380.3219.00.2 4O-Ring 3.0 x 25

482.4154.00.2 4Gasket Dia. 30 x 24 x 1

586.2796.00.2 12 Screw M8 x 40 UNI5931

684.3685.00.2 16 Washer Dia. 8.4 x 15 x 1.5

794.0048.43.2 2Diaphragm Locking Bolt

894.0036.32.2 2Disk

994.0091.98.2 2Outlet Valve Cap

10 94.0017.08.2 2Piston Dia. 42 (20 series)

10 94.0016.08.2 2Piston Dia. 48 (25 series)

11 85.2004.00.2 2Piston Pin

12 80.0003.00.2 4Ring Dia. 10

13 94.0022.61.2 1Mounting Rail

14 86.2059.00.2 4Screw M6 x 14 UNI5739

15 94.0007.01.2 2Piston Sleeve Dia. 42 (20 series)

15 94.0005.01.2 Piston Sleeve Dia. 48 (25 series)

16 94.0008.09.2 2Conrod

17 94.0047.76.2 2Conrod Ring

18 94.0001.09.2 1Crankcase

19 94.0080.72.2 1Crankcase Cover Gasket

20 94.0002.09.2 2Pump Head

21 81.7537.00.2 1Clamp

22 94.0044.31.2 1Oil Filter Cap

23 94.0043.32.2 1Oil Filter

24 94.0090.98.2 2Inlet Valve Cap

25 94.0075.66.2 1Cap

26 81.4575.00.2 4Nut MB UNI5588

27 80.3181.00.2 4O-Ring 2.62 x 15.54

28 94.0014.32.2 1Inlet Manifold

29 80.3060.00.2 1O-Ring 1.78 x 12.42

30 84.0521.00.2 190° Elbow Connector Dia. 20

31 82.0042.10.2 1Wing Nut G. 3/4

32 94.0004.09.2 1Damper Body

33 94.0041.31.2 1Damper Diaphragm

33 94.0041.33.2 1Viton Damper Diaphragm

34 86.1605.00.2 1Air Valve

35 94.0003.09.2 1Damper Cover

Pos Code Qty Description

41 81.2837.00.2 1Ball Bearing Dia. 35 x 62 x 14

42 80.2178.10.2 1Oi Seal Dia. 40 x 52 x 7

43 94.0216.09.2 1Bearing Housing (VF)

44 86.2168.00.2 4Screw M6 x 22 UNI5931

45 94.0029.26.2 1Crankshaft VF

46 81.4525.00.2 3Dado M5 Uni5588

47 84.3542.00.2 2Rosetta D.5, 3 x 10 x 1

48 81.2631.00.2 1Cuscinetto Stere

49 80.2117.00.2 1Anello Radiale

50 80.3210.64.2 1Anello Or 2,62 x 75, 87

51 86.2566.00.2 4Vite Te 5/16” - 24 unf L=3/4”

51 86.2622.00.2 4Vite Te M8 x 22 Uni5739 (Honda G100)

52 84.3685.00.2 4Rosetta D.8, 2 x 15 x 1,5

53 94.0210.09.2 1Flangia Motori Termici (Rt4”)

54 84.3560.00.2 3Rosetta D.5, 5 x 15 x 1,6

55 86.1935.10.2 2Vite Te M5 x 25 Uni 5737

56 94.0211.42.2 1Pignone Z=10 (Sae 3/4”)

56 94.0228.42.2 1Pignone Z=10 (Honda G100-s)

56 94.0218.42.2 1Pignone Z=10 (Honda G100-q)

57 80.6436.00.2 1Linguetta 4, 75 x 5 x 30

57 80.6445.00.2 1Linguetta 5 x 5 x 30 (Honda G100-s)

62 94.0203.32.2 1Knob

63 94.0073.48.2 1Spring

64 94.0202.32.2 1Lever

65 80.3199.00.2 1O-Ring 2.62 x 21.89

66 94.0204.32.2 1Poppet

67 80.3174.00.2 4O-Ring 2.62 x 9.92

68 05.0068.51.2 1Seat

69 80.3056.00.2 1O-Ring 1.78 x 8.73

70 85.1045.00.2 1Pin Dia, 3 x 30

71 80.3217.00.2 1O-Ring 3.0 x 14

72 94.0201.32.2 1Pressure Regulator Plug

73 82.0015.00.2 2Wing Nut G. 1/2

74 84.1528.00.2 1Outlet Conenctor Dia. 10

75 84.1551.00.2 1Return Connector Dia. 13

76 80.3178.00.2 1O-Ring 2.62 x 13.1

77 94.0206.49.2 1Quick Release Pin

78 86.1743.90.2 2Screw M5 x 45 UNI5931

Spare Kits

TTi Part No. STAP101 STAP102 STAP103

Kit Part No. 94.9881.97.3 94.9870.97.3 94.9871.97.3

Kit Description Pump

Seals Kit VF

Valves

Assy

BUNA-N

Diaphragms

Position No. 42 27 3 4 19 234127 4

S L

(Pump Series VF - STAP30) 22L/min

(PA 330 VF - STAP36) 34L/min

S P L

Pos Code Qty Description

194.0040.31.2 2Piston Diaphragm

194.0040.33.2 2Viton Piston Diaphragm (non stock)

294.9828.97.3 4Valve Assy

380.3219.00.2 4O-Ring 3.0 x 25

482.4154.00.2 4Gasket Dia. 30 x 24 x 1

586.2796.00.2 12 Screw M8 x 40 UNI5931

684.3685.00.2 16 Washer Dia. 8.4 x 15 x 1.5

794.0048.43.2 2Diaphragm Locking Bolt

894.0036.32.2 2Disk

994.0091.98.2 2Outlet Valve Cap

10 94.0017.08.2 2Piston Dia. 42 (20 series)

10 94.0016.08.2 2Piston Dia. 48 (25 series)

11 85.2004.00.2 2Piston Pin

12 80.0003.00.2 4Ring Dia. 10

13 94.0022.61.2 1Mounting Rail

14 86.2059.00.2 4Screw M6 x 14 UNI5739

15 94.0007.01.2 2Piston Sleeve Dia. 42 (20 series)

15 94.0005.01.2 Piston Sleeve Dia. 48 (25 series)

16 94.0008.09.2 2Conrod

17 94.0047.76.2 2Conrod Ring

18 94.0001.09.2 1Crankcase

19 94.0080.72.2 1Crankcase Cover Gasket

20 94.0002.09.2 2Pump Head

21 81.7537.00.2 1Clamp

22 94.0044.31.2 1Oil Filter Cap

23 94.0043.32.2 1Oil Filter

24 94.0090.98.2 2Inlet Valve Cap

25 94.0075.66.2 1Cap

26 81.4575.00.2 4Nut MB UNI5588

27 80.3181.00.2 4O-Ring 2.62 x 15.54

28 94.0014.32.2 1Inlet Manifold

29 80.3060.00.2 1O-Ring 1.78 x 12.42

30 84.0521.00.2 190° Elbow Connector Dia. 20

31 82.0042.10.2 1Wing Nut G. 3/4

32 94.0004.09.2 1Damper Body

33 94.0041.31.2 1Damper Diaphragm

33 94.0041.33.2 1Viton Damper Diaphragm

34 86.1605.00.2 1Air Valve

35 94.0003.09.2 1Damper Cover

36 81.2531.00.2 1Needle Bearing DHK 1312

37 94.0026.32.2 1Crankshaft Spacer

38 81.2688.00.2 1Needle Bearing DHK 2520

39 94.0027.32.2 1Spacer

40 80.1264.00.2 1Ring Dia. 35

Pos Code Qty Description

41 81.2837.00.2 1Ball Bearing Dia. 35 x 62 x 14

42 80.2178.10.2 1Oi Seal Dia. 40 x 52 x 7

43 94.0216.09.2 1Bearing Housing (VF)

44 86.2168.00.2 4Screw M6 x 22 UNI5931

45 94.0029.26.2 1Crankshaft VF

46 81.4525.00.2 3Dado M5 Uni5588

47 84.3542.00.2 2Rosetta D.5, 3 x 10 x 1

48 81.2631.00.2 1Cuscinetto Stere

49 80.2117.00.2 1Anello Radiale

50 80.3210.64.2 1Anello Or 2,62 x 75, 87

51 86.2566.00.2 4Vite Te 5/16” - 24 unf L=3/4”

51 86.2622.00.2 4Vite Te M8 x 22 Uni5739 (Honda G100)

52 84.3685.00.2 4Rosetta D.8, 2 x 15 x 1,5

53 94.0210.09.2 1Flangia Motori Termici (Rt4”)

54 84.3560.00.2 3Rosetta D.5, 5 x 15 x 1,6

55 86.1935.10.2 2Vite Te M5 x 25 Uni 5737

56 94.0211.42.2 1Pignone Z=10 (Sae 3/4”)

56 94.0228.42.2 1Pignone Z=10 (Honda G100-s)

56 94.0218.42.2 1Pignone Z=10 (Honda G100-q)

57 80.6436.00.2 1Linguetta 4, 75 x 5 x 30

57 80.6445.00.2 1Linguetta 5 x 5 x 30 (Honda G100-s)

62 94.0203.32.2 1Knob

63 94.0073.48.2 1Spring

64 94.0202.32.2 1Lever

65 80.3199.00.2 1O-Ring 2.62 x 21.89

66 94.0204.32.2 1Poppet

67 80.3174.00.2 4O-Ring 2.62 x 9.92

68 05.0068.51.2 1Seat

69 80.3056.00.2 1O-Ring 1.78 x 8.73

70 85.1045.00.2 1Pin Dia, 3 x 30

71 80.3217.00.2 1O-Ring 3.0 x 14

72 94.0201.32.2 1Pressure Regulator Plug

73 82.0015.00.2 2Wing Nut G. 1/2

74 84.1528.00.2 1Outlet Conenctor Dia. 10

75 84.1551.00.2 1Return Connector Dia. 13

76 80.3178.00.2 1O-Ring 2.62 x 13.1

77 94.0206.49.2 1Quick Release Pin

78 86.1743.90.2 2Screw M5 x 45 UNI5931

79 84.3542.00.2 2Washer Dia. 5.3 x 10 x 1

80 94.0200.32.2 1Pressure Regulator Body

81 94.0207.32.2 1Nipples G. 1/2 - G. 1/4

82 83.0010.002 1Pressure Gauge

83 94.9849.97.3 1Pressure Gauge Kit

Spare Kits

TTi Part No. STAP101 STAP102 STAP103

Kit Part No. 94.9881.97.3 94.9870.97.3 94.9871.97.3

Kit Description Pump

Seals Kit VF

Valves

Assy

BUNA-N

Diaphragms

Position No. 42 27 3 4 19 234127 4

Quantity Incl. 14441444241

13www.tti.com.au | Call 1800 816 277

TTi - Operators Handbook

TTi’s TrailPro™ Deluxe HandBook

14 Call 1800 816 277www.tti.com.au 14

Spare Parts List

Karin STAP77 (15bar) + STAP78 (40bar)

Karin STAP77 (15bar) + STAP78 (40bar)

STING - STAP79 (15bar) + STAP80 (40bar)

S P L

Pos Code Qty Description

124.0310.32.2 1Valve Housing

283.0080.00.2 1Pressure Gauge 0-100 Bar

283.0010.00.2 1Pressure Gauge 0-24 Bar

380.3060.00.2 1O-Ring 1.78 x 12.42

454.0521.00.2 190° Elbow Connector Dia. 20

582.0042.10.2 1Wing Nut G. 3/4

684.5544.10.2 1Left Tap G.3/8 - G. 1/2

784.1544.00.2 2Outlet Straight Port D. 10

882.0010.00.2 2Wing Nut G. 1/2

984.5544.00.2 1Right Tap G. 3/8 - G. 1/2

10 85.2585.00.2 1Cap G. 3/8

11 84.3585.00.2 2Washer Dia. 6.4 x 12.5 x 1.6

12 86.2426.00.2 2Screw M6 x 60 UNI5737

13 84.4525.00.2 4Nut M5 UNI5588

14 80.3218.00.2 1O-Ring 3.0 x 22

15 80.3059.00.2 1O-Ring D. 1.78 x 11.11

16 24.0320.51.2 1Valve Seat

17 86.1841.50.2 1Screw M4 x 12

18 24.0319.51.2 1Poppet

19 24.0313.36.2 1HPS Diaphragm

20 84.3539.00.2 4Washer Dia. 5.3 x 10 x 1

21 86.1944.20.2 4Screw M5 x 50

22 24.0311.32.2 1Flange

23 80.3075.00.2 1O-Ring

24 80.3175.00.2 1O-Ring 2.62 x 10.78

25 85.1148.00.2 1Pin

26 24.0314.53.2 1Guiding Piston

27 24.0312.32.2 1Lever

28 24.0316.48.2 1Spring 40 Bar

28 24.0550.18.2 1Spring 15 Bar

29 24.0321.32.2 1Knob

Pos Code Qty Description

124.0310.32.2 1Valve Housing

283.0080.00.2 1Pressure Gauge 0-100 Bar

283.0010.00.2 1Pressure Gauge 0-24 Bar

380.3060.00.2 1O-Ring 1.78 x 12.42

454.0521.00.2 190° Elbow Connector Dia. 20

582.0042.10.2 1Wing Nut G. 3/4

684.5544.10.2 1Left Tap G.3/8 - G. 1/2

784.1544.00.2 2,3 Outlet Straight Port D. 10

882.0010.00.2 2,3 Wing Nut G. 1/2

984.5544.00.2 1,2 Right Tap G. 3/8 - G. 1/2

10 85.2585.00.2 1,2 Cap G. 3/8

11 80.3213.00.2 1C-Ring 3.0 x 22

12 80.3182.00.2 1C-Ring 2.62 x 17.13

13 26.0220.18.2 1Valve Seat

14 86.1934.80.2 1Screw M5 x 16 UNI5933 Inox

15 26.0201.18.2 1Ceramic Poppet

16 26.0189.36.2 1HPS Diaphragm

17 26.0203.32.2 1Diaphragm Holder Piston

18 24.0301.32.2 1Flange

19 80.3208.20.2 1O-Ring 2.62 x 34.6

20 80.3181.20.2 4O-Ring 2.62 x 15.88

21 24.0302.53.2 4Guiding Piston

22 24.0303.32.2 1Lever

23 85.1161.00.2 1Pin Dia. 4 x 45.5

24 26.0217.48.2 1Spring (15 Bar)

24 26.0212.48.2 1Spring (40 Bar)

25 24.0304.61.2 1Shim

26 24.0304.32.2 1Knob

27 24.0306.49.2 1Spring

28 86.2428.00.2 1Screw T.C.E.I. M6 x 65 UNI5931

29 24.0307.32.2 1Cap

30 81.4542.00.2 4Nut M6 UNI5588

31 84.3585.00.2 6Washer Dia. 6.4 x 12.5 x 1.6

32 86.2426.00.2 6Screw M6 x 60 UNI5737

Spare Kits

TTi Part No. STAP133

Kit Part No. 25.9963.97.3

Kit Description Karin Kit

Position No. 314 15 16 18 19 23 24

Quantity Incl. 1 1 1 1 1 1 1 1

Spare Kits

TTi Part No. STAP134

Kit Part No. 25.9964.97.3

Kit Description Sting Kit

Position No. 311 12 13 15 16 19 20

Quantity Incl. 1 1 1 1 1 1 1 1

14

www.tti.com.au |

Call 1800 816 277

TTi - Operators Handbook

Pos Code Qty Description

124.0310.32.2 1Valve Housing

283.0080.00.2 1Pressure Gauge 0-100 Bar

283.0010.00.2 1Pressure Gauge 0-24 Bar

380.3060.00.2 1O-Ring 1.78 x 12.42

454.0521.00.2 190° Elbow Connector Dia. 20

582.0042.10.2 1Wing Nut G. 3/4

684.5544.10.2 1Left Tap G.3/8 - G. 1/2

784.1544.00.2 2Outlet Straight Port D. 10

882.0010.00.2 2Wing Nut G. 1/2

984.5544.00.2 1Right Tap G. 3/8 - G. 1/2

10 85.2585.00.2 1Cap G. 3/8

11 84.3585.00.2 2Washer Dia. 6.4 x 12.5 x 1.6

12 86.2426.00.2 2Screw M6 x 60 UNI5737

13 84.4525.00.2 4Nut M5 UNI5588

14 80.3218.00.2 1O-Ring 3.0 x 22

15 80.3059.00.2 1O-Ring D. 1.78 x 11.11

16 24.0320.51.2 1Valve Seat

17 86.1841.50.2 1Screw M4 x 12

18 24.0319.51.2 1Poppet

19 24.0313.36.2 1HPS Diaphragm

20 84.3539.00.2 4Washer Dia. 5.3 x 10 x 1

21 86.1944.20.2 4Screw M5 x 50

22 24.0311.32.2 1Flange

23 80.3075.00.2 1O-Ring

24 80.3175.00.2 1O-Ring 2.62 x 10.78

25 85.1148.00.2 1Pin

26 24.0314.53.2 1Guiding Piston

27 24.0312.32.2 1Lever

28 24.0316.48.2 1Spring 40 Bar

28 24.0550.18.2 1Spring 15 Bar

29 24.0321.32.2 1Knob

Spare Kits

TTi Part No. STAP133

Kit Part No. 25.9963.97.3

Kit Description Karin Kit

Position No. 314 15 16 18 19 23 24

Quantity Incl. 1 1 1 1 1 1 1 1

STING - STAP79 (15bar) + STAP80 (40bar)

Karin STAP77 (15bar) + STAP78 (40bar)

STING - STAP79 (15bar) + STAP80 (40bar)

S P L

Pos Code Qty Description

124.0310.32.2 1Valve Housing

283.0080.00.2 1Pressure Gauge 0-100 Bar

283.0010.00.2 1Pressure Gauge 0-24 Bar

380.3060.00.2 1O-Ring 1.78 x 12.42

454.0521.00.2 190° Elbow Connector Dia. 20

582.0042.10.2 1Wing Nut G. 3/4

684.5544.10.2 1Left Tap G.3/8 - G. 1/2

784.1544.00.2 2Outlet Straight Port D. 10

882.0010.00.2 2Wing Nut G. 1/2

984.5544.00.2 1Right Tap G. 3/8 - G. 1/2

10 85.2585.00.2 1Cap G. 3/8

11 84.3585.00.2 2Washer Dia. 6.4 x 12.5 x 1.6

12 86.2426.00.2 2Screw M6 x 60 UNI5737

13 84.4525.00.2 4Nut M5 UNI5588

14 80.3218.00.2 1O-Ring 3.0 x 22

15 80.3059.00.2 1O-Ring D. 1.78 x 11.11

16 24.0320.51.2 1Valve Seat

17 86.1841.50.2 1Screw M4 x 12

18 24.0319.51.2 1Poppet

19 24.0313.36.2 1HPS Diaphragm

20 84.3539.00.2 4Washer Dia. 5.3 x 10 x 1

21 86.1944.20.2 4Screw M5 x 50

22 24.0311.32.2 1Flange

23 80.3075.00.2 1O-Ring

24 80.3175.00.2 1O-Ring 2.62 x 10.78

25 85.1148.00.2 1Pin

26 24.0314.53.2 1Guiding Piston

27 24.0312.32.2 1Lever

28 24.0316.48.2 1Spring 40 Bar

28 24.0550.18.2 1Spring 15 Bar

29 24.0321.32.2 1Knob

Pos Code Qty Description

124.0310.32.2 1Valve Housing

283.0080.00.2 1Pressure Gauge 0-100 Bar

283.0010.00.2 1Pressure Gauge 0-24 Bar

380.3060.00.2 1O-Ring 1.78 x 12.42

454.0521.00.2 190° Elbow Connector Dia. 20

582.0042.10.2 1Wing Nut G. 3/4

684.5544.10.2 1Left Tap G.3/8 - G. 1/2

784.1544.00.2 2,3 Outlet Straight Port D. 10

882.0010.00.2 2,3 Wing Nut G. 1/2

984.5544.00.2 1,2 Right Tap G. 3/8 - G. 1/2

10 85.2585.00.2 1,2 Cap G. 3/8

11 80.3213.00.2 1C-Ring 3.0 x 22

12 80.3182.00.2 1C-Ring 2.62 x 17.13

13 26.0220.18.2 1Valve Seat

14 86.1934.80.2 1Screw M5 x 16 UNI5933 Inox

15 26.0201.18.2 1Ceramic Poppet

16 26.0189.36.2 1HPS Diaphragm

17 26.0203.32.2 1Diaphragm Holder Piston

18 24.0301.32.2 1Flange

19 80.3208.20.2 1O-Ring 2.62 x 34.6

20 80.3181.20.2 4O-Ring 2.62 x 15.88

21 24.0302.53.2 4Guiding Piston

22 24.0303.32.2 1Lever

23 85.1161.00.2 1Pin Dia. 4 x 45.5

24 26.0217.48.2 1Spring (15 Bar)

24 26.0212.48.2 1Spring (40 Bar)

25 24.0304.61.2 1Shim

26 24.0304.32.2 1Knob

27 24.0306.49.2 1Spring

28 86.2428.00.2 1Screw T.C.E.I. M6 x 65 UNI5931

29 24.0307.32.2 1Cap

30 81.4542.00.2 4Nut M6 UNI5588

31 84.3585.00.2 6Washer Dia. 6.4 x 12.5 x 1.6

32 86.2426.00.2 6Screw M6 x 60 UNI5737

Spare Kits

TTi Part No. STAP133

Kit Part No. 25.9963.97.3

Kit Description Karin Kit

Position No. 314 15 16 18 19 23 24

Quantity Incl. 1 1 1 1 1 1 1 1

Spare Kits

TTi Part No. STAP134

Kit Part No. 25.9964.97.3

Kit Description Sting Kit

Position No. 311 12 13 15 16 19 20

Quantity Incl. 1 1 1 1 1 1 1 1

14 www.tti.com.au | Call 1800 816 277

TTi - Operators Handbook

Pos Code Qty Description

124.0310.32.2 1Valve Housing

283.0080.00.2 1Pressure Gauge 0-100 Bar

283.0010.00.2 1Pressure Gauge 0-24 Bar

380.3060.00.2 1O-Ring 1.78 x 12.42

454.0521.00.2 190° Elbow Connector Dia. 20

582.0042.10.2 1Wing Nut G. 3/4

684.5544.10.2 1Left Tap G.3/8 - G. 1/2

784.1544.00.2 2,3 Outlet Straight Port D. 10

882.0010.00.2 2,3 Wing Nut G. 1/2

984.5544.00.2 1,2 Right Tap G. 3/8 - G. 1/2

10 85.2585.00.2 1,2 Cap G. 3/8

11 80.3213.00.2 1C-Ring 3.0 x 22

12 80.3182.00.2 1C-Ring 2.62 x 17.13

13 26.0220.18.2 1Valve Seat

14 86.1934.80.2 1Screw M5 x 16 UNI5933 Inox

15 26.0201.18.2 1Ceramic Poppet

16 26.0189.36.2 1HPS Diaphragm

17 26.0203.32.2 1Diaphragm Holder Piston

18 24.0301.32.2 1Flange

19 80.3208.20.2 1O-Ring 2.62 x 34.6

20 80.3181.20.2 4O-Ring 2.62 x 15.88

21 24.0302.53.2 4Guiding Piston

22 24.0303.32.2 1Lever

23 85.1161.00.2 1Pin Dia. 4 x 45.5

24 26.0217.48.2 1Spring (15 Bar)

24 26.0212.48.2 1Spring (40 Bar)

25 24.0304.61.2 1Shim

26 24.0304.32.2 1Knob

27 24.0306.49.2 1Spring

28 86.2428.00.2 1Screw T.C.E.I. M6 x 65 UNI5931

29 24.0307.32.2 1Cap

30 81.4542.00.2 4Nut M6 UNI5588

31 84.3585.00.2 6Washer Dia. 6.4 x 12.5 x 1.6

32 86.2426.00.2 6Screw M6 x 60 UNI5737

Spare Kits

TTi Part No. STAP134

Kit Part No. 25.9964.97.3

Kit Description Sting Kit

Position No. 311 12 13 15 16 19 20

Quantity Incl. 1 1 1 1 1 1 1 1

TTi’s TrailPro™ Deluxe HandBook

15 Call 1800 816 277www.tti.com.au 15

Warranty

Warranty Policy

Your TrailPro is guaranteed free from defect in materials, workmanship or manufacture

for 12 months from the date of purchase. Any parts which appear to us to be

defective either in material or workmanship will be replaced or repaired at no cost

to the purchaser, subject to the following conditions:

1. The registration card enclosed in this handbook must be returned to us within 7

days of purchase.

2. The guidelines in this handbook have been adhered to in every respect.

3. In the unlikely event of sprayer failure this should be reported to your dealer who

will act on your behalf to resolve the issue to your satisfaction.

4. Any defective parts will be returned by your dealer within 7 days of failure,

together with a report describing the failure and conditions in which the failure

occurred.

5. The following are specifically excluded from the terms of warranty:

• Fair wear and tear to pump moving parts and diaphragms

• Fair wear and tear to nozzles and nozzle bodies

• Damage caused by neglect or lack of lubrication

• Damage caused by misuse or abuse

• Damage caused while the sprayer is in transit

TTi’s TrailPro™ Deluxe HandBook

16 Call 1800 816 277www.tti.com.au 16

Warranty Limitations

a] There is no other express warranty. Any warranty that may be implied from this

purchase including merchantibility and finess for a particular purpose is hereby

limited to the duration of this warranty and to the extent permitted by law. Any and

all implied warranties are excluded.

b] TTI will not be liable for any incidental, consequential or special damages and/

or expenses in connection with the purchase or use of this equipment, to the extent

permitted by law.

c] Only the warranty expressed in this limited warranty shall apply and no dealer,

distributor, or individual is authorized to amend, modify, or extend this warranty

in any way. Accordingly, additional statements, whether oral or written, do not

constitute warranties by TTi, and should not be relied upon.

Whilst every care has been taken in the preparation of these instructions, no liabilities

can be accepted with regard to errors or omissions. Product specifications are

subject to change in line with our commitment to continuous improvement.

TTi’s TrailPro™ Deluxe HandBook

17 Call 1800 816 277www.tti.com.au 17

Warranty Registration Card

To validate your warranty, please complete registration on-line at:

www.tti.com.au/warranty-registration

Alternatively if you are unable to register on-line fill in all the details below, copy

I have read and understood the instructions in this booklet.

[located on side of tank]

Model:

Serial Number:

Date Purchased:

Purchaser’s Name:

Post code:

Purchaser’s Address:

Phone #: Mobile #:

Email Address:

Purchaser’s Signature:

/.

/.

/.

/.

www.tti.com.au

1800 816 277

sales@tti.com.au

PO Box 137, Nathalia, VIC, 3638

Murray Valley Hwy, Nathalia, VIC 3638

Table of contents

Other TransTank Utility Vehicle manuals

Popular Utility Vehicle manuals by other brands

Cub Cadet

Cub Cadet M465 Operator's manual

Polaris

Polaris BRUTUS HD Operator's handbook

Taylor-Dunn

Taylor-Dunn B0-248-48AC Operation, t roubleshooting and replacement parts manual

Craftsman

Craftsman ZTS 7500 Operator's manual

Textron Specialized Vehicles

Textron Specialized Vehicles Cushman Shuttle 4 ELiTE 2020 owner's manual

Polaris

Polaris RANGER XP 900 2013 owner's manual