5.52.707.00.01.02 9

5 Technical data

Pos: 9.2 /1_HADEF/5-- TECHNISCHE DATEN/Krane/EEE/EEE @ 2\ mod_1287490269266_52.doc x @ 16396 @ @ 1

Capacity Span

up to Wheel base Max. wheel load

with hoist

Type 66/04

Max. wheel load

with hoist

Type 29/06

Wheel

Ø Stepless trolley

drive

from….to

Motor power

2x

Weight*

ca.

kg mm mm kg kg mm m/min kW kg

1000

7000 1200 692 705 125

0,5 – 20

or

0,5 - 40

0,37 744

9000 1200 788 801 125 0,37 1077

12000 1600 968 981 160 0,37 1858

15000 2200 1214 1227 200 0,37 2813

17000 2200 1383 1398 200 0,37 3279

18000 2500 1556 1571 250 0,55 4065

20000 2500 1735 1750 250 0,55 4773

2000

7000 1200 1222 1245 125 0,37 903

9000 1200 1314 1337 125 0,37 1184

12000 1600 1553 1576 160 0,37 2059

14000 2200 1717 1740 200 0,37 2681

16000 2200 1921 1945 200 0,37 3474

18000 2500 2204 2229 250 0,55 4588

20000 2500 2316 2341 250 0,55 5163

3200

7000 1200 1805 1907 160 0,37 1005

9000 1200 1970 2072 160 0,37 1510

12000 1600 2188 2290 160 0,37 2248

13000 2200 2307 2409 200 0,37 2694

16000 2200 2585 2687 200 0,37 3732

18000 2500 2807 2705 250 0,55 4588

20000 2500 2988 3090 250 0,55 5288

5000

7000 1600 2777 2795 160 0,37 1283

11000 1600 3116 3134 200 0,37 2236

12000 1600 3173 3191 200 0,37 2405

16000 2200 3596 3614 200 0,37 3940

18000 2500 3833 3851 250 0,55 4831

20000 2500 4025 4043 250 0,55 5548

6300

7000 1600 3390 3408 200 0,37 1353

10000 1600 3671 3689 200 0,37 2064

12000 1600 3845 3863 200 0,37 2602

14000 2200 4060 4078 200 0,37 3345

17000 2500 4405 4423 250 0,37 4603

18000 2500 4530 4548 250 0,55 5074

20000 2500 4747 4765 250 0,55 5891

10000

6000 1600 5126 5228 250 0,55 1704

9000 1600 5500 5488 250 0,55 2361

11000 1600 5714 6016 250 0,55 2915

12000 2200 5841 6143 315 0,75 3311

14000 2200 6077 6379 315 0,75 4079

15000 2500 6186 6488 315 0,75 4437

18000 2500 6632 6934 315 0,75 6058

20000 2500 6944 7246 315 0,75 7221

*Weights without lifting unit and standard profile

Listed data are standards. Intermediate sizes possible.

Pos: 9.3 /1_HADEF/5-- TECHNISCHE DATEN/Allgemei n/E-Motor/400V Motor @ 3\ mod_1378727800377_52.d ocx @ 27382 @ @1

3-phase current motor 400V/50Hz - IP55 – F – max. 1000 m above sea level.

Order-related Special data, refer to the motor nameplate.

Pos: 10.1 /1_HADEF/6- -MONTAGE/*Ü1*/#. Kapi tel - Montage @ 0\mod_1172127 582099_52.doc x@ 255 @ @ 1

6 Installation

Pos: 10.2.1 /1_HADEF/ 6--MONTAGE/Allgemei n/01.Krane - alle (außer 380)@ 2\mod_1287066709326_52.doc x@ 162 13 @ @1

Assembly depends on the local environment. The crane must be assembles stress-free. The runway must

be perfect.

Operating regulations for cranes in accordance with the validated accident prevention regulations.

There must be end stops (provided by the customer) on both ends of the crane runway.

They must be attached so that the rubber buffers or the trolley wheels drive against them in their end

position.

Generally, additional lifting gear (e.g. fork lift, lifting platforms) will be required for the assembly.These must

take the weight of the devices safely.

Pos: 10.3.1 /1_HADEF/6- -MONTAGE/Krane/EEE+EHH+EDD/ 1 Komplettkran @ 2\mod_1287 496814822_52.doc x@ 164 03 @ @1

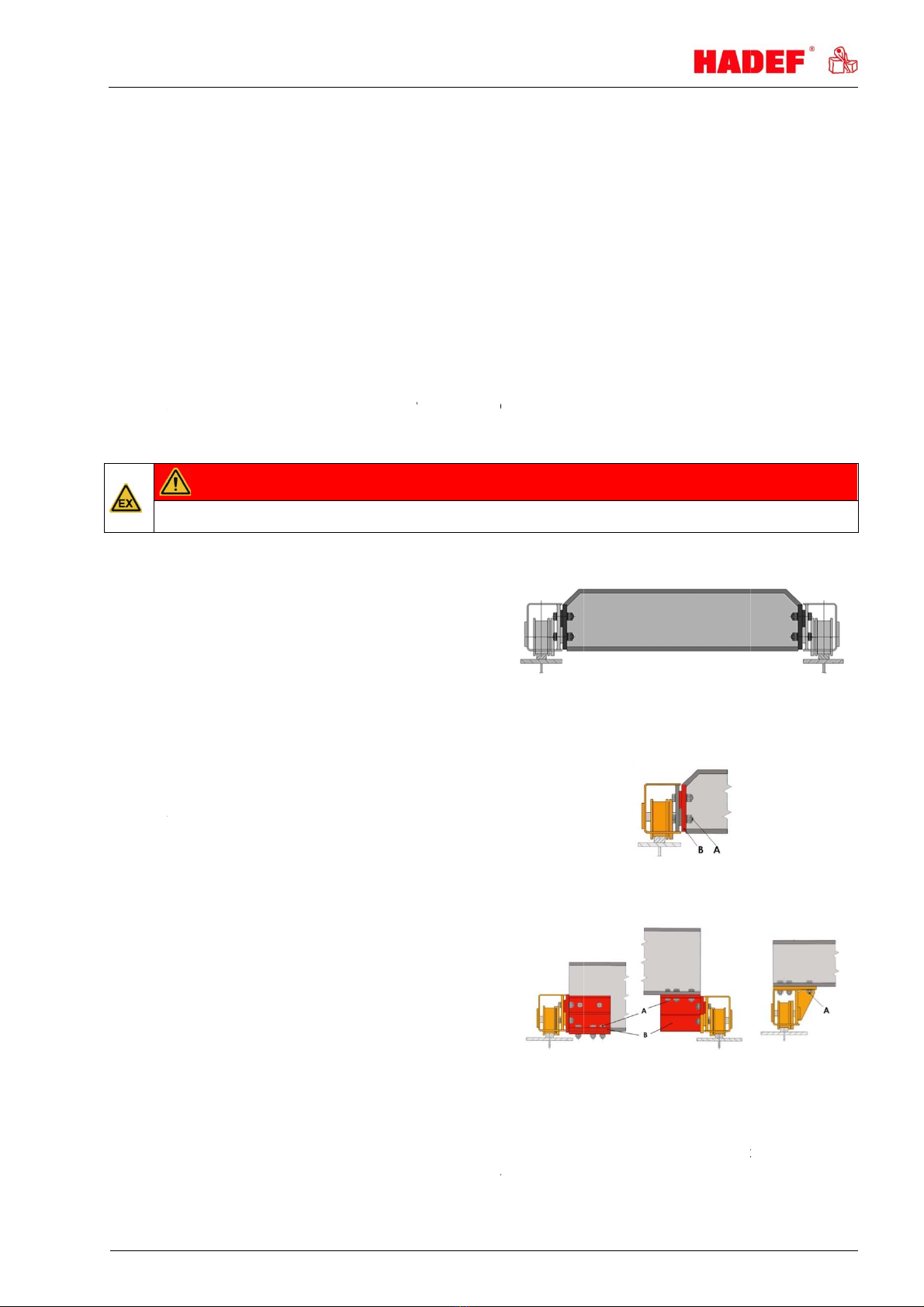

6.1 Assembly - for complete cranes

The crane is fully assembled and installed, including the hoist and power supply for the electric or pneumatic

version.

It only needs to be placed on the crane way with a suitable lorry mounted crane.