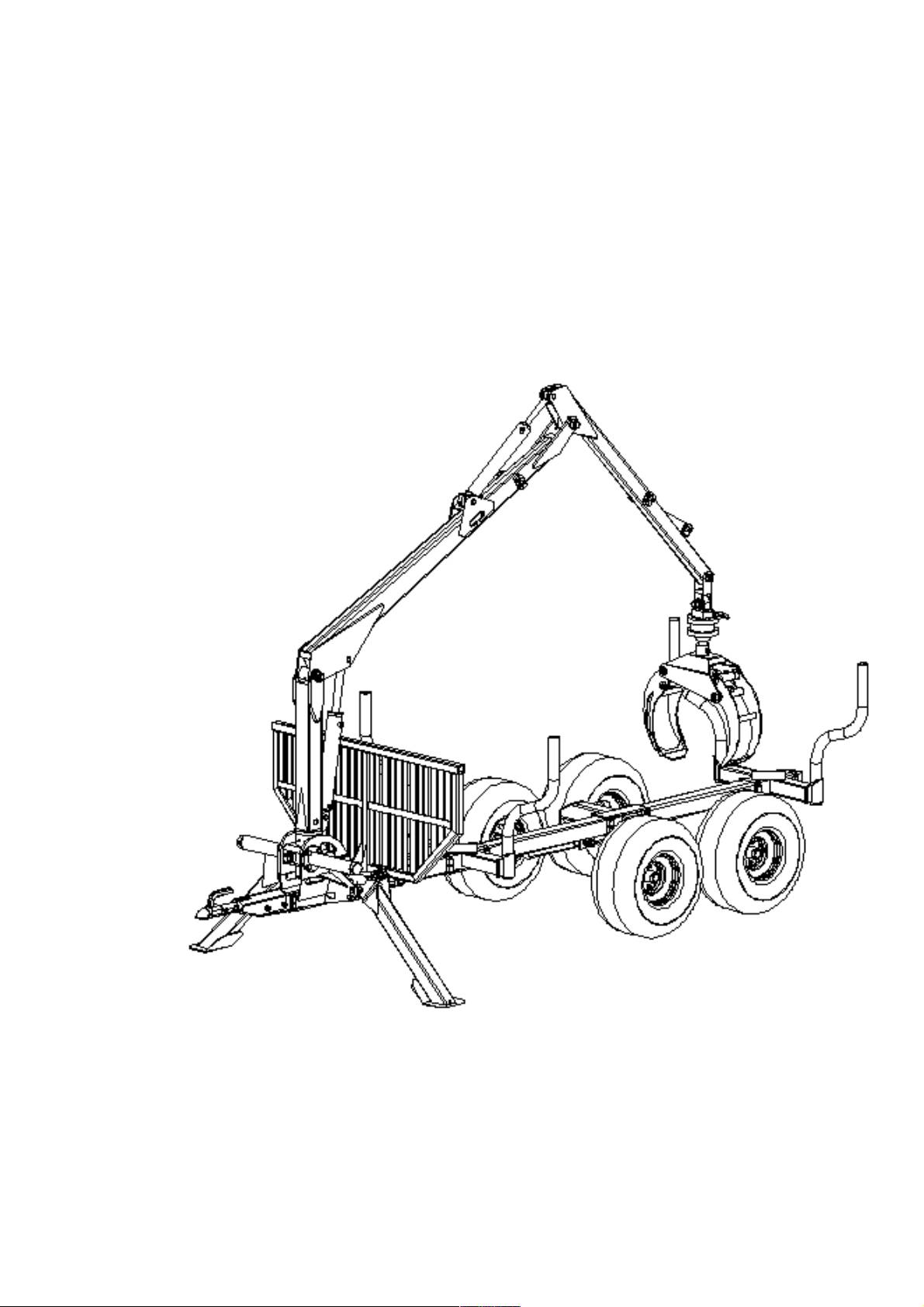

G R A P P L E L O A D E R

V a h v a J u s s i 3 2 0

2011 Kreisi Metall

4

Safety and working methods

For your own and other safety please read carefully the following information.

--DO NOT use the trailer and crane before you are convinced that nobody is near working

area of the crane ( max 10m ).

-When reversing the trailer, driver has to be convinced that nobody is behind the trailer.

-The operator of the crane has to have a clear overview from the working area.

-It is prohibited to go beneath the trailer when operating the crane or trailer.

-Before driving check that no tools or equipment are located on or under the trailer.

-Do not use the trailer for work that it is not intented for.

-The load on trailer of has to be evenly distributed to prevent the trailer from tipping over.

-Check that tire pressure and axel weight are right before towing the trailer( tire pressure

suggested 1kPa).

-Use only original spare parts from manufacturer to prevent damaging the crane or trailer.

-Never put a bigger load on the trailer then is allowed by the manufacturer, otherwise the

warranty of the trailer will expire. ( MAX LOAD 1500 kg)

Assembly of Vahva Jussi 320

1. Attatche the wheels to the axel

2. Move the front bracket to working position.

3. Move the boggyframe to working position.

4. Move the back bracket to working position.

5. When 4WD is installed check every time that bolts are tight.

Installation on hydraulic unit and valve package:

1. Install the hydraulic unit in front of a operating vehicle.

2. Install the valve package to the back of the trailer.

3. Check that the whoses of hydraulic unit are connected correctly

to valve package (in right order shown on the valve package

unit)

Do not pressurize the control valve’s return line first, this could cause the valve to

break!