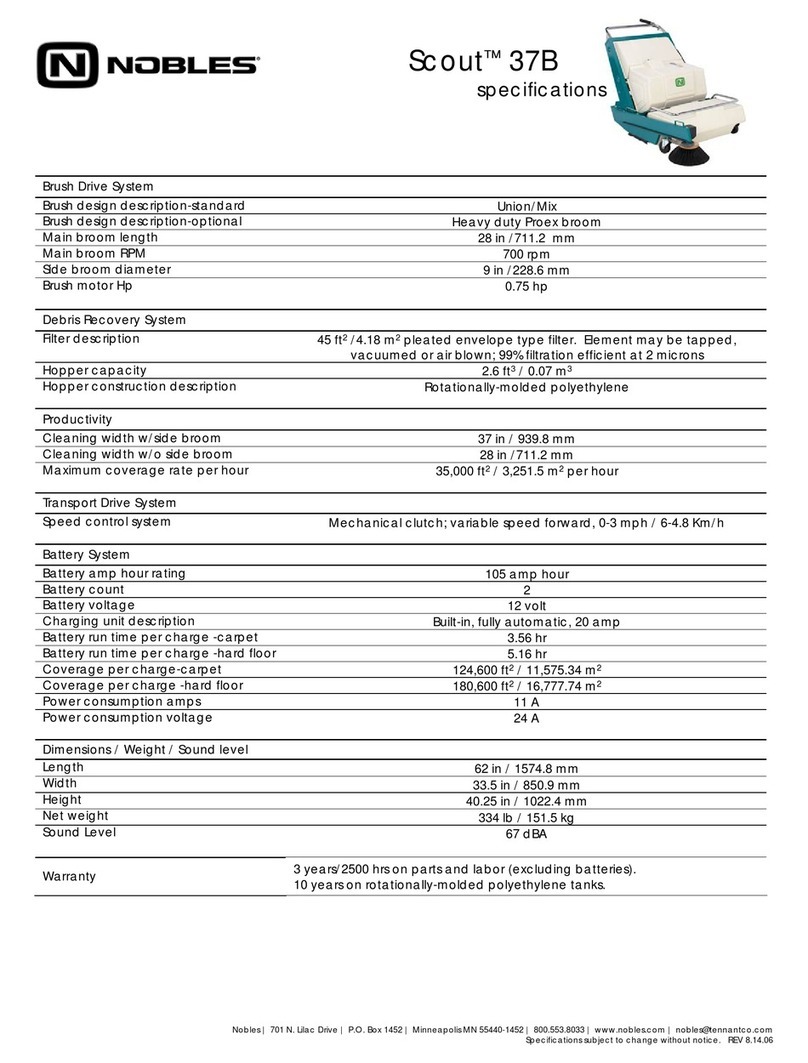

Trelawny TCG 250 User manual

TCG 250 Floor Grinder

Operation and Maintenance Manual

www.trelawnyspt.co.uk

OPERATION

Foreword

Thank you for your purchase of the

TRELAWNY TCG250 Floor Grinder.

This manual contains the necessary

maintenance information for you to

ensure proper operation and care for

this machine.

See also the manual that is

s up p l ie d b y t h e e n g i n e

manufacturer.

It is essential for you to read

t h r o u g h t h e s e m a n u a l s

thoroughly.

In the unlikely event that you

experience problems with your

TCG250, please do not hesitate to

contact your local Trelawny dealer or

a ge nt . W e a lwa ys w el co m e

feedback and comments from our

valued customers.

General Information

Before op erating, perform ing

maintenance or repairing the

TCG250 FLOOR GRINDER this

m a nu a l m u s t be r e ad a n d

understood by the operator, if in any

doubt, ask your supervisor before

using this equipment.

Local safety regulations must be

followed at all times. Failure to follow

these instructions could result in

damage to the TCG250 and/or

personal injury.

Trelawny SPT Limited disclaims all

responsibility for damage to persons

or objects arising as a consequence

of incorrect handling of the machine,

failure to inspect the machine for

damage or other faults that may

influence the operation prior to

starting work, or failure to follow the

safety regulations listed or applicable

to the job site.

This machine is primarily designed

for the smoothing of concrete,

marble and terrazzo surfaces. It can

be used both indoors and out.

Electric models are more suitable for

indoor use because of the toxic

exhaust gases that are produced by

petrol engines.

Safety

WEAR SAFETY BOOTS, FACE

MASK, SHATTERPROOF

GLASSES, HELMET, GLOVES and

any other personal protective

equipment required for the working

conditions. Avoid loose clothing; this

may become trapped in moving

parts and cause serious injury.

TO AVOID NUISANCE DUST,

connect an industrial vacuum

cleaner (minimum 3000watts or

equivalent) to the 50mm (2”) vacuum

port situated at the rear of the

machine.

ENSURE THAT THE WORK PLACE

IS WELL VENTILATED. Avoid

operating engine-powered machines

in an enclosed area, since engine

exhaust gases are poisonous.

BE VERY CAREFUL WITH HOT

COMPONENTS. The exhaust and

other parts of the engine are hot

during operation and can remain hot

for some time after shutdown.

DO NOT REFUEL THE ENGINE

WHILE THE ENGINE IS HOT OR

RUNNING, there is a very real

danger from explosion –always

refuel when the engine is cold, and

in the open air.

During transportation fasten fuel cap

tightly and close fuel tap.

DO NOT OPERATE ELECTRIC

VERSIONS IN WET CONDITIONS.

CAUTION THIS MACHINE IS

HEAVY. I t we ighs b etween

(92kg/202lbs) and (144kg /317 lbs)

dependent on power unit.

Do not lift this machine manually.

Risk of Hand-arm

Vibration injury

These tools may cause Hand-arm

Vibration Syndrome injury if their use

is not adequately managed.

We advise you to carry out a risk

assessment and to implement

measures such as; limiting exposure

time [i.e. actual trigger time, not total

time at work], job rotation, ensuring

the tools are used correctly, ensuring

the tools are maintained according to

our recommendations, and ensuring

that the operators wear personal

p r o t e c t i v e e q u i p m e n t [ P P E ]

particularly gloves and clothing to

keep them warm and dry.

Employers should consider setting

up a programme of health

s u r ve i l l an c e t o e s t a b l is h a

benchmark for each operator and to

detect early symptoms of vibration

injury.

We are not aware of any PPE that

provides protection against vibration

injury by attenuating vibration

emissions.

See „Specifications‟ section for

vibration emission data.

Further advice is available from our

Technical Department.

We strongly advise you to visit the

Health & Safety Executive website

http://www.hse.gov.uk/vibration This

site provides excellent advice and

information on HAV and currently,

includes a Hand-arm Vibration

Exposure Calculator that is easy to

use to work out the daily vibration

exposure for each of your operators.

Media Types &

Applications

Grinding Blocks

All can be used wet or dry

Coarse grinding blocks

These are fitted as standard on

machines fitted with the grinding

block option. These are designed for

the rapid removal of material. They

produce a surface finish suitable for

directly laying floor coverings or for

two part epoxy paint coatings and for

the first grind of terrazzo floor

surfaces.

Medium grinding blocks

These are less aggressive than the

coarse blocks, they should provide a

surface finish suitable for painting or

used as the next stage to the coarse

grinding blocks, when achieving a

polished surface on terrazzo tiles or

other marble type surfaces.

Fine grinding blocks

These are the least aggressive of all

the grinding media. These are

generally only used for final finishing

to provide a surface suitable for final

polishing.

OPERATION

In addition, scarifying blocks and

wire brushes are available which can

be fitted in place of the grinding

blocks.

Diamond Disc machine

The machine is fitted with a 20

segment diamond disc for medium

concrete as standard (see below for

specification). There are also 10

segment discs for very aggressive

grinding and 16 segment discs for

aggressive grinding available. The

20 segment disc are the most

economical and least aggressive.

All discs can be used wet or dry.

Grinding disc 20 segment (Blue)

(Soft bonded diamond)

Premium disc.

For medium to hard material,

granite, cured concrete or terrazzo.

Grinding disc 20 segment (Black)

(Medium bonded diamond)

Premium disc.

For medium or general abrasive

materials - medium strength

concrete or adhesives.

Grinding disc 20 segment (Red)

(Hard bonded diamond)

Premium disc.

For softer or abrasive materials -

green (less than 48hrs old) or

medium strength concrete, or

adhesives.

Pre-Start Check

ALL VERSIONS

Check all bolts and screws for

tightness. Ensure that all fittings are

secure.

Check the drive belts for correct

tightness. There should normally be

approximately 13mm (1/2") of free

play when the belt is depressed in

the middle position between the two

pulleys.

To check and set the belt tension,

refer to the Belt installation &

Adjustment section.

The TCG250 is supplied with a

specially commissioned electric

motors and starter switch assembly.

Each unit is fully tested and the

overload relays have been calibrated

a n d s e t a c c o r d i n g t o t h e

manufactures specifications.

In the event of malfunction on a new

machine, the owner should first

check that the power supply on site

is suitable and adequate.

All cables should be fully uncoiled

and never left wrapped around cable

reels or tied in loops.

The starter box is fitted with a safety

feature to protect the motor and

relays from damage. Should an

overload condition occur which

triggers the thermal overload within

the starter, depress the red stop

button to reset.

Note that the circuitry may have to

cool down for a period before the

overload switch can reset itself upon

depressing the stop button.

The starter boxes are preset and

under no circumstances should they

be tampered with, stripped down or

adjusted, otherwise it will invalidate

the warranty.

.

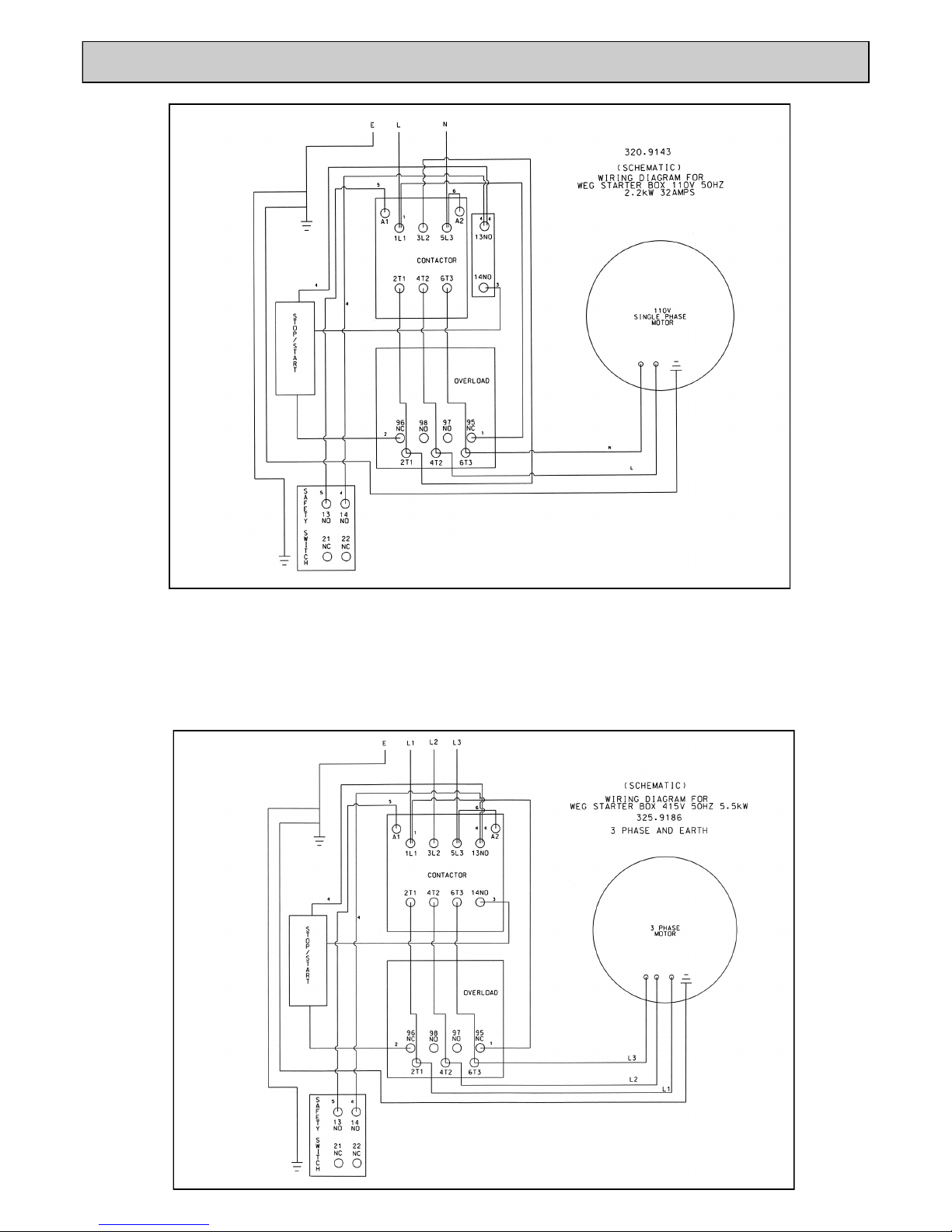

110v Motor

The motor requires the minimum of a

32amp, 110v power supply.

Always use the shortest possible

length of extension cable. To avoid

voltage drop the cable must be a

minimum core wire size of 2.5mm2

but preferably 4.0mm2cross-section.

The maximum length of cable can

then be 15 metres and 30 meters

respectively.

Use a centre tap transformer with a

continuous rated output of at least

3.0KVA. In practice this means that

a 5.0KVA transformer must be used.

Manufacturers have different

methods of rating their equipment.

All transformers and cables should

be fitted with 32amp plugs and

sockets.

The 230v supply to the 110v

transformers ideally should be rated

to at least 20amp if supply problems

are to be avoided.

230v and 415v Motors

Take particular care when using

230v or 415v Machines, ensure that

the electrical supply is earthed and

that breakers and fuses are correct

for the loading.

The 230v motor requires the

minimum of a 13amp, 220v power

supply.

The 415v motor requires the

minimum of a 10amp, 380v power

supply. Always use the shortest

possible length of extension cable.

To avoid voltage drop the cable must

have a minimum core wire size of

2.5mm2cross-section area.

Maximum length of cable 30 meters.

Starting

Machines fitted with petrol

engines

The disc must be raised off the floor

surface before starting the engine

from cold.

The machine is fitted with a pedal

operated stand to allow the disc to

be raised off the ground when

starting the engine.

Tilt the machine back by it‟s handle

bar whilst depressing the pedal,

keeping the pedal depressed, lower

the machine back to the floor. The

weight of the machine keeps the

stand engaged and the head off the

floor.

The engine may now be started.

When starting from cold the throttle

lever must be in the fast position to

allow the automatic choke to

operate. Subsequent starting may

be carried out with the lever in the

idle/slow position.

Once the engine is at operating

temperature you may begin work.

To retract the stand simply tilt the

machine back.

See next section for detailed engine

starting procedure.

ENGINE VERSIONS

CAUTION

Beware of POISONOUS FUMES.

Start and operate only in well-

ventilated areas.

Be careful with

HOT COMPONENTS.

The exhaust and other engine parts are

hot during and for some time after

operation. Do not touch them.

OPERATION

Petrol engine starting procedure

Check that there is sufficient fuel in

the fuel tank. (See manufactures

hand book for type)

Check that the engine oil level is

correct. (See pre-start check)

Ensure that the machine is started

on a level surface.

Open the engine fuel tap.

For cold engine starting, the 5.5hp

engines have an automatic choke,

apply full throttle to operate.

Set the start switch to the "on"

position on Honda supplied engines.

Check that the machine has been

raised on its stand.

Pull the „hold to run‟ lever against the

handle bar.

Pull the recoil starter cord handle.

After the engine starts, move the

throttle lever towards the idle/tick-

over position until the engine runs

smoothly.

After a minute or two reduce to a

quarter open throttle setting and

warm up the engine for a further 2~3

minutes before setting to tick over.

The warm up procedure is

particularly important during cold

weather.

Machines fitted with an

electric motor

IMPORTANT:

Pull back on the handle bars to

retract the machines stand, pull the

„hold to run‟ lever against the handle

bar and press the green start button

on the switch box, then gently lower

the disc onto the surface being

worked.

IMPORTANT

Do not pull the recoil starter cord

to the end of its travel as it may

cause damage to the engine or

injury to the operator.

When the engine starts, recoil the

cord slowly.

Do not allow the cord to snap back

to its start position.

: EMERGENCY SHUTDOWN :

Release the “Hold to run lever” on

the handle bar and/or switch off

the ignition switch on Honda

engine versions.

Machine Operation

(Please refer to manual handling

recommendations when lifting.)

Connect a suitable commercial

vacuum which has been designed

for the collection of concrete dust

and possibly toxic paint particles, or

for use in the pharmaceutical or food

industries, Trelawny can supply

special HEPA filtered vacuums

which are suitable for these

applications.

Or if suitable for the area being

worked, connect a water hose to the

supplied connection at the rear of

the machine.

Shut Down

On electric powered machines,

simply release the “hold to run”

lever.

On engine powered machines, move

the engine‟s throttle lever to the slow

speed position. (This avoids the

engine becoming washed internally

by neat fuel if switched off from high

engine revolutions.)

Release the „hold to run‟ lever and

on Honda engines, switch off the

engine's start switch.

Important:

Close the engine fuel tap.

On both electric and engine powered

machines, use the stand to raise the

disc off the ground to prevent any

built up heat deforming the rubber

coupling if it is left under load whilst

hot and stationary. The machine

can be stored whilst on it‟s stand.

After the engine or motor has

completely cooled, clean off any

concrete dust from external

components and remove any heavy

build up of concrete dust from inside

the front dust skirt, (See start of

“Grinding Block Replacement”

section for safe method of gaining

access to inside of front dust skirt).

Take care when using hoses or

pressure washers and clean within

the dust skirt area only.

Do not to allow water to be directed

at or splashed onto the engine,

electric motor or any electrical

components. Once clean and dry,

cover the machine to protect it and

store the grinder in a dry place.

Machine Storage

Long period storage: over

3months

Clean outside of machine, inspect

the grinding blocks for wear; replace

any worn parts as required.

Remove any build up of material

from inside of grinding disc area

following step in start of “Grinding

Block Replacement” Section .

Cover the machine to protect it.

Store the machine in a dry place.

Be sure to check security of wooden

wedges after any lay up period.

On engine-powered machines,

once the engine has reached

operating temperature and you are

ready to start work, set the throttle

lever to the full throttle position, pull

back on the handle bars to retract

the machines stand and slowly lower

the disc to the surface.

The machine may oscillate slightly

during use, which is normal. Move

the machine slowly backwards and

forwards, slightly swinging the

grinding head right and left; this will

ensure that a uniform finish is

achieved.

Complete a small area noting the

performance; on engine versions

reduce the throttle to tick over and

release the „hold to run‟ lever.

Then on both engine and electric

motor versions release the „hold to

run‟ lever to stop the machine,

inspect the finish produced.

If necessary change the grade of

grinding blocks or diamond discs

and recheck performance and

surface finish.

MAINTENANCE

Belt Installation &

Adjustment

Removal

Remove t he top cover b y

unscrewing the two 8mm bolts either

side of the chassis.

Loosen the engine/motor mounting

plate bolts and slide the engine/

motor forward. Slide the belt off the

drive pulley and then remove it from

the engine/motor pulley.

Installation

Slide the new belt onto the engine/

motor pulley first, locating the belt in

the pulleys teeth. Then slide onto

into the teeth of the drive pulley.

Slide the engine/motor backwards

until the slack in the belt is taken up,

gently nip the four bolts and ensure

the slack in the belt is correct (see

note below). If the tension needs

adjusting move the motor mounting

plate in the desired direction until the

correct tension is achieved.

Tighten all engine/motor mounting

plate bolts fully, refit the top cover

and tighten the 8mm bolts.

IMPORTANT

Normal slack should be

approximately 13mm (1/2") when

the belts are depressed in the

middle position between the

engine pulley and driveshaft

pulley.

Drive system maintenance

The drive system on the TCG250 is

virtually maintenance free and will

give a long service life without

attention providing the belt tension is

set correctly.

The belt may need changing

occasionally, the bearings (29) will

require greasing after any lay up

period and/or every 6 months or

occasionally during heavy use.

Grinding Block

Replacement

Switch off the engine powered

versions and allow the engine to

cool completely, disconnect electric

motor powered versions from its

power supply.

Place the machine on a flat and level

surface.

Raise the front skirt by loosening the

four 10mm guard retaining bolts on

either side of the machine and slide

the guard up to the top of the slots,

tighten the bolts temporarily.

Tilt the machine backwards to rest

on its handle bar.

Place a heavy object (10kg sand

bag, etc.) across the upper part of

the handle bar or tie down for

additional security.

Take note how the grinding blocks

and wedges have been assembled,

using a suitable wooden drift, knock

out the grinding block, not the

wooden wedge.

Dispose of the used grinding blocks

according to local legislation.

Fit each new grinding block squarely

into the grinding plate location corner

at the outer flat face of the grinding

disc.

Secure with a new wooden wedge,

between the block and the inner face

of the grinding block, knock the

wedge into position using a suitable

drift.

Note:

Do not use a mix of old and new

grinding blocks, this will cause rapid

wear of the new blocks and could

cause the machine to become

uncontrollable, unstab le a nd

dangerous in use.

Re-adjust the lower guard and

tighten the bolts.

Diamond Disc/Q.R.

Plate Replacement

Switch off the engine powered

versions and allow the engine to

cool completely, disconnect electric

motor powered versions from its

power supply.

Place the machine on a flat and level

surface.

Raise the front skirt by loosening the

four 10mm guard retaining bolts on

either side of the machine and slide

the guard up to the top of the slots,

tighten the bolts temporarily.

Tilt the machine backwards to rest

on its handle bar.

Place a heavy object (10kg sand

bag, etc.) across the upper part of

the handle bar or rope down for

additional security.

Remove the four countersunk M12

screws from the disc, ensuring that

the disc is supported as the last two

are removed. The disc now will

come away from the drive plate.

Dispose of the used item according

to local legislation.

Offer the new disc up to the drive

plate and align the holes. Loosely fit

the four bolts and then tighten in a

diagonal sequence to 40lb/ft.

Re-adjust the lower guard and

tighten the bolts

Brush Seal

Replacement

The machine is fitted with a flexible

brush seal which will need

replacement from time to time to

maintain the efficiency of the dust

control system. Follow the first five

steps from the above procedure for

changing discs. Drill out rivets and to

remove the brush simply grasp one

end and pull, the brush will come off

the guard.

To fit the new brush, align one end

of the brush with the end of the

guard and use a suitable drift to

knock the brush onto the metal

guard, working along until it is

securely fitted.

TROUBLESHOOTING

FAULT CAUSE ACTION

Engine stops suddenly

or does not run correctly

No fuel in the fuel tank. Refuel fuel tank. (See safety section.)

Spark plug faulty. Replace spark plug.

Fuel blockage. Check fuel line and strainer.

Air filter partially blocked. Replace air cleaner element.

Motor stops suddenly or

does not run correctly

Loose wiring, incorrect voltage, or blown

fuse.

Check connections and power supply or

replace fuse.

Engine/motor runs but

the grinding heads do

not move.

Drive Belts slack or failed. Replace Belt or adjust tension.

Sheared drive key/ loose taperlock bush Replace key and re-torque taperlock bush.

Grinder is slow or erratic No grinding blocks fitted Check grinding discs for any damage, replace

if necessary. Fit new grinding blocks.

Loose or a failed drive belts. Adjust drive belt, or replace.

Surface too rough. Use Trelawny TFP200/250 surface Planer to

produce a smoother surface or to remove bulk

of material prior to grinding. Change grinding

blocks to a coarser grade.

Engine will not start No fuel in the fuel tank Refuel fuel tank, see safety precautions.

Water in fuel Drain fuel tank, float chamber, and refuel.

Incorrect fuel in tank, i.e. diesel in petrol

tank

Clean out fuel tank, all fuel lines and

carburettor float chamber. Refuel with correct

fuel.

Spark plug faulty Replace spark plug.

Motor will not start Power supply is not switched on, blown

fuse, voltage incorrect, loose wiring, or

faulty motor.

Confirm that the power supply is switched on.

Rectify loose wiring, replace blown fuse or

replace motor.

Use above information in conjunction with the Honda / Briggs and Stratton Operation and Maintenance Manual.

If problem has not been cured by any of the above actions, contact your local Trelawny SPT dealership for assistance.

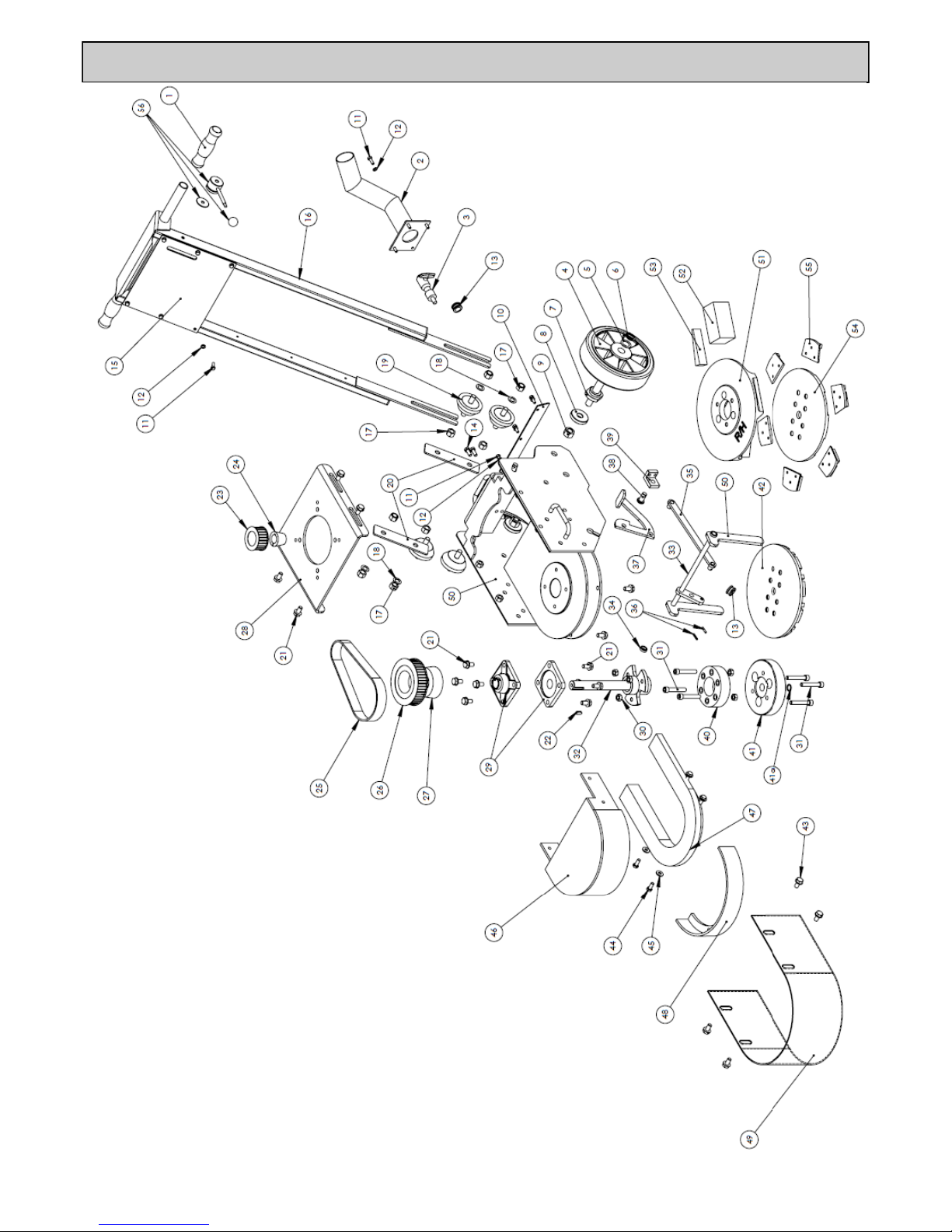

EXPLODED VIEW

Notes

Any items not numerically identified are duplicates of identified

items.

Parts 23-28 are variable dependant on model.

(See additional table on page 12)

Part 42 may be a „Grinding Block Holding Plate‟ (350.00CDR)

dependant on your model, if this is the case your machine will

not have Part 41.

Horse shoe weight, part 47 is an optional extra.

Model specific items are shown in a separate table on page 11.

Not shown:

Motor/engine and associated fasteners, starter box/throttle

lever assembly and safety switch, stand return spring, water

hose and brush seals. (See table for part numbers and details)

PARTS LIST

Item Part No. Description Item Part No. Description

1 822.2000 Rubber grip (x2) 44 831.0820 M8 x 20 hex bolt

2 345.9220 Vacuum takeoff tube 45 811.1008 M8 shake proof washer

3 828.0138/

826.0183/

819.0385

3/8” ball valve/

bulkhead connector/

hose tail

46 345.9223 Belt guard

4 350.9121 Wheel (x2) 47 345.2012 Weight

5 812.1001 20mm plain washer (x2) 48 345.2011 Removable section

6 814.1020 External circlip (x2) 49 345.9221 Dust skirt

7 345.9241 Stub axle (x2) 50 345.2010 Chassis

8 812.1016 M16 washer (x2) 51 350.00CDR R/H Grinding Block Mounting Plate

9 824.1600 M16 Nyloc nut (x2) 52 350.5509 Abrasive Block (Coarse)

10 345.9222 Rear dust skirt 350.5505 Abrasive Block (Fine)

350.5507 Abrasive Block (Medium)

11 831.0620 M6 x 20 hex bolt 350.5519 Wire brush

12 811.1006 M6 shake proof washer 350.5525 Scarifying Block

13 843.0808 Water hose grommet 53 350.5502 Wedge

14 831.0820/

811.1008

M8 x 20 hex bolt

M8 shake proof washer

54 350.5660 6 Segment Quick Fit Plate

15 345.9232 Starter box/throttle mounting plate 55 See Page

13/14

Quick Fit Plate Tooling

16 345.9230 Complete handle assembly 56 350.9180

350.9186

Throttle lever (petrol only)

Ball

17 834.0500 1/2” UNF nyloc nut (x8)

18 812.0500 1/2” plain washer (x4) Items not shown on exploded view

19 830.2000 Rubber mount 1/2” UNF See page 13 Motor/engine

20 345.9231 Handle clamping plate 345.9560A 230v Motor extension

21 831.1030/

811.1010

M10 x 30 hex bolt

M10 shake proof washer (x12)

320.7110 110v starter assembly

22 350.9150 Drive key 8 x 7 x 25 320.7112 230v starter assembly

23 See page 13 Motor pulley 320.7114 415v starter assembly

350.9175 Throttle cable (petrol only)

24 See page 13 Taper lock bush (motor) 719.3000 Water hose (request 0.4M)

25 See page 13 Drive belt 345.9828 Deadmans complete switch assembly

26 See page 13 Drive shaft pulley 345.9826 Deadmans upper switch inc lever

27 See page 13 Taper lock bush (drive shaft) 345.9800 Deadmans switch box (No lever)

28 345.9224

345.9225

Motor mounting plate for all other models

Motor mounting plate for 345.2000, 345.2000D

and 345.2004D

731.3154 Front brush seal

29 350.9116 25mm bearing assembly (x2) 731.3155 Rear brush seal

30 824.1000

824.1200

M10 nyloc nut (x6)

M12 nyloc nut (x6) (for 345.2000D)

713.5060 Stand return spring

31 806.1060

806.1260

M10x60 cap head bolt (x6)

M12x60 cap head bolt (x6) (for 345.2000D)

350.9141 M12 x 25 c/sunk socket screw x4

32 345.9235 Drive shaft

(for 345.2000D)

320.9126D Honda engine pulley for woodruff key type

shaft (N1)

33 345.9207A Pedal operated stand assembly 320.9126E Honda pulley extension for N1 type shaft

34 345.9208 Shaft bush (x2)

35 345.9204 Connecting rod

36 813.0420 4mm roll pin

37 345.9201 Pedal

38 345.9203 Pivot pin

39 345.9202 Pedal bracket

40 350.9146 Rubber coupling

(for 345.2000D)

41 350.9143A Diamond plate adapter

41a 809.3005 O-ring

42 350.5620G 20 Segment diamond disc

43 320.9234

811.1010

M10 x 20 hex bolt

M10 shake proof washer

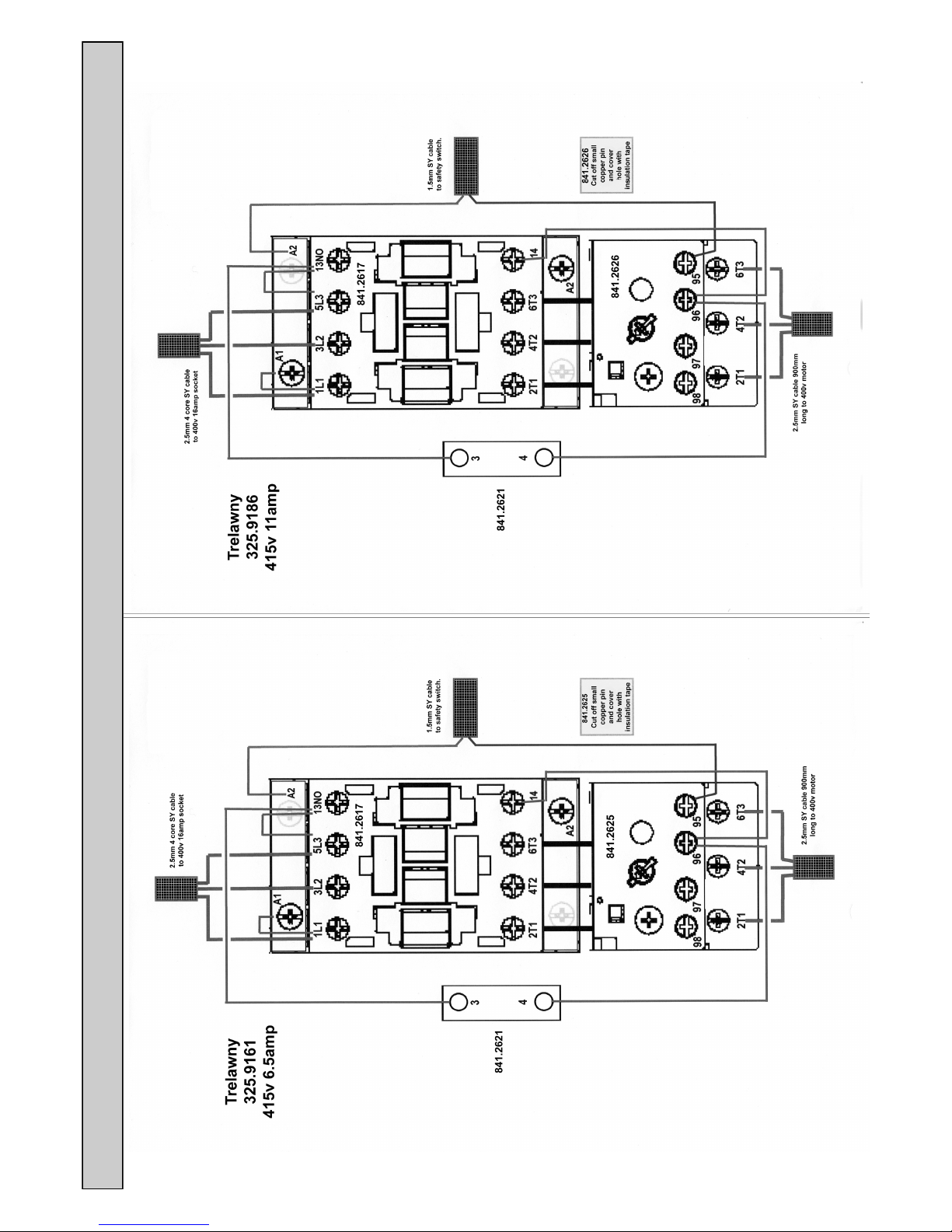

ITEM Part Number DESCRIPTION ITEM Part Number DESCRIPTION

OTHER PARTS NOT SHOWN IN EXPLODED VIEW 230v Lovato Starter Box Components

320.7110 110v starter assembly 841.2616 Contactor (Lovato) 230v

320.7112 230v starter assembly 841.2625 Overload Relay 230v/415v 4-6.5amp

320.7114 415v starter assembly 841.2621 Start Contact (Lovato) all versions

841.2104 230v Panel Mounting Plug (Blue)

841.2102 110v 32amp Lead Plug (Yellow)

841.2104 240v 16amp Lead Plug (Blue) 415v Lovato Starter Box Components

841.2106 415v Lead Plug (Red) 841.2617 Contactor (Lovato) 415v

841.2625 Overload Relay 230v/415v 4-6.5amp

841.2621 Start Contact (Lovato) all versions

110v WEG Starter Box Components 841.2106 415v Panel Mounting Plug (Red)

841.2640 110v Starter Box & Lid inc Buttons

320.7130 110v Panel Mounting Plug (Yellow)

230v WEG Starter Box Components

841.2642 230v/415v Starter Box & Lid inc Buttons

841.2640A Overload Relay 230v only (RW27D17) Lafert Motor Components (see exploded view page 15)

841.2640B Contactor (CWM18.10 230v only) 14 841.2650 Icar or Ducati start capacitor (Black)

320.7132 230v Panel Mounting Plug (Blue) 14 841.2660 Facon or Ducati run capacitor (White)

5 841.2670 SE01 Electronic starter switch

24 841.2680 Fan

415v WEG Starter Box Components 22 841.2690 Fan Cover

841.2642 230v/415v Starter Box & Lid inc Buttons 9/11 841.2694 Terminal box and lid

841.2106 415v Panel Mounting Plug (Red)

Others not show in exploded view

345.9828 Deadmans complete switch assembly

110v Lovato Starter Box Components 345.9826 Deadmans upper switch inc lever

841.2615 Contactor (Lovato) 110v 345.9800 Deadmans switch box (No lever)

841.2620 Start Contactor (Lovato) 110v 320.9300 M5 x 50 Screws for Deadmans Handle x 2

required

841.2624 230/415v Overload Relay 4/6.5amp 320.9305 M5 Nyloc Nuts for Deadmans Handle x 2

required

841.2621 Start Contact (Lovato) all versions 320.9310 M5 Plain Washer x 4 required

841.2102 110v Panel Mounting Plug (Yellow) 320.9150 Spacer Plate (Electric) x 2 required

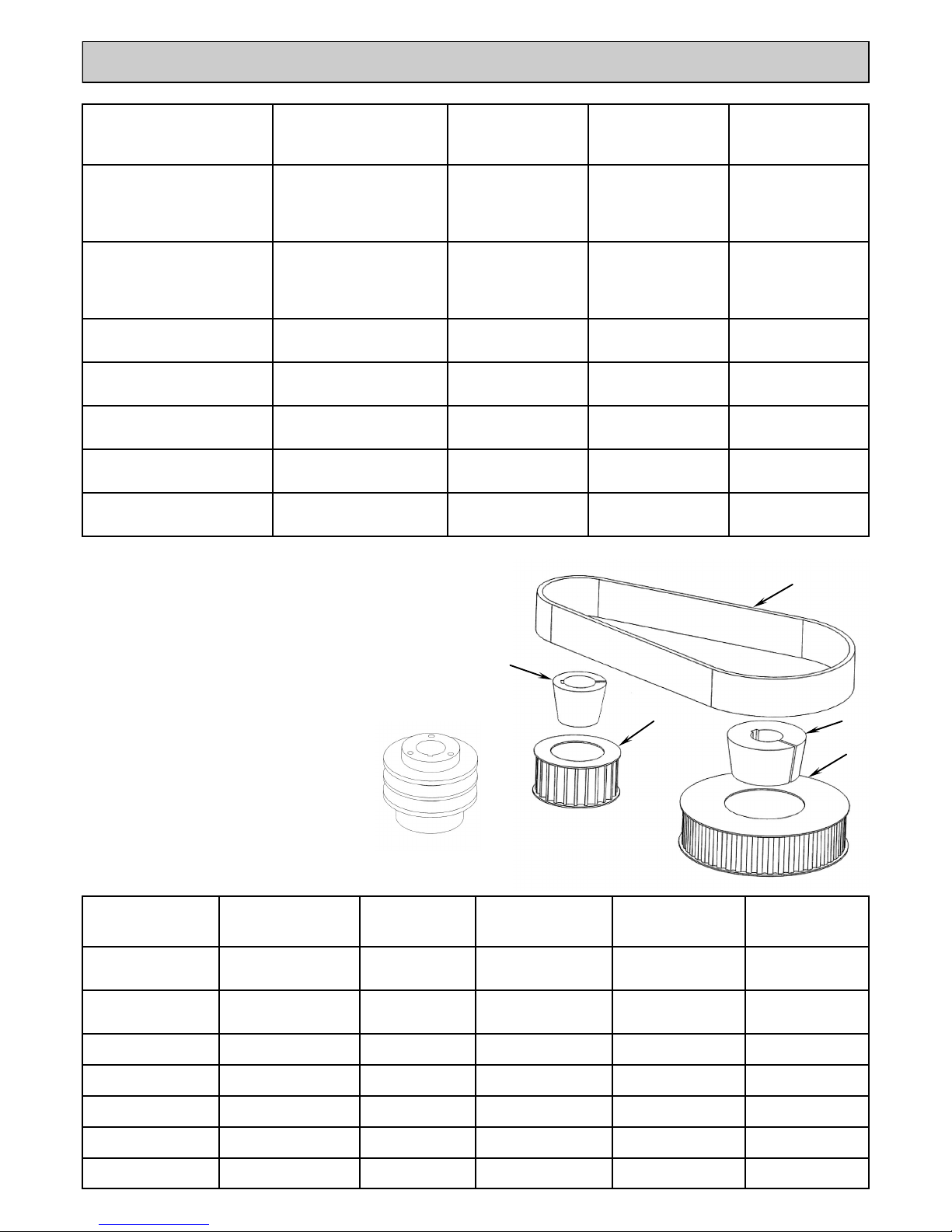

PARTS LIST model specific

Model variant by part

number

(D=Diamond Disc)

Motor/engine/starter

N4 shaft prior to 2014

Motor bolts Motor nuts Motor washers

345.2000

5.5HP petrol

350.9500 Honda N4

shaft

345.9500 Honda N1

shaft

806.5610 (x2) 824.0810 (x2) 811.1008 (x8)

345.2000D

5.5HP petrol

350.9500 Honda N4

shaft

345.9500 Honda N1

shaft

806.5610 (x2) 824.0810 (x2) 811.1008 (x8)

345.2002

110V 1ph 1.8Kw

345.9550 motor

320.9143 starter 831.1240 (x4) 824.1200 (x4) 811.1012 (x8)

345.2002D

110V 1ph 1.8Kw

345.9550 motor

320.9143 starter 831.1240 (x4) 824.1200 (x4) 811.1012 (x8)

345.2004

230V 1ph 2.2kW

345.9565 motor

320.9147 starter 831.1240 (x4) 824.1200 (x4) 811.1012 (x8)

345.2004D

230V 1ph 2.2Kw

350.9560 motor

320.9147 starter 831.1040 (x4) 824.1000 (x4) 811.1010 (x8)

345.2006D

415V 3ph 5.5kW

350.9575 motor

325.9186 starter 831.1240 (x4) 824.1200 (x4) 811.1012 (x8)

Model variant by part

number

(23) PULLEY (MOTOR) (24) TAPER LOCK

BUSH (MOTOR)

(25) BELT (26) PULLEY

(DRIVESHAFT)

(27) TAPER LOCK

BUSH

(DRIVESHAFT)

345.2000 345.9130 Honda N4

345.9126A Honda N1

345.9129A N4

See (23) N1

345.9136 Honda N4

345.9126V Honda N1

345.9134 Honda N4

345.9126D Honda N1 345.9126M Honda

345.2000D 345.9130 Honda N4

345.9126A Honda N1

345.9129A N4

See (23) N1

345.9136 Honda N4

345.9126V Honda N1

345.9134 Honda N4

345.9126D Honda N1 345.9126M Honda

345.2002 345.9130 345.9129A 345.9136 345.9134 345.9126

345.2002D 345.9130 345.9127A 345.9135 345.9123 345.9125

345.2004 345.9133 345.9129B 345.9137 345.9134 345.9126

345.2004D 345.9127A 345.9127A 345.9135 345.9124 345.9124A

345.2006D 345.9127 345.9128 345.9136 345.9124 345.9124B

Taper Lock bushes include new grub

screws (Not illustrated) for fitting

Also supplied with data sheet with torque

setting and method.

Drive components by model 25

24

27

26

23

The TCG250 is available in a range of

configurations.

The appropriate drive components for each

variant are listed in the table below.

Note:

Honda N1 type shaft has a v-belt pulley

arrangement and is not a taper lock pulley,

this item has to be purchased as an

assembly. HONDA N1 PULLEY

Image Part Number Tool Description

365.5495L

PCD Removal Diamond Anti Clock Wise

For removal of coatings, adhesives & toppings

365.5495R

PCD Removal Diamond Clock Wise

For removal of coatings, adhesives & toppings

365.5500

16 Grit Single (Quick Release) Soft Bond

For very course grinding and thin coating removal

365.5500/2

16 Grit Double (Quick Release) Soft Bond

For very course grinding and thin coating removal

365.5501

30 Grit Single (Quick Release) Soft Bond

For Hard Concrete

365.5502 30 Grit Single (Quick Release) Medium Bond

For Medium Hardness concrete

365.5503 30 Grit Single (Quick Release) Hard Bond

For Soft Concrete or for very rough concrete

365.5501/2 30 Grit Double (Quick Release) Soft Bond

For Hard Concrete

365.5502/2 30 Grit Double (Quick Release) Medium Bond

For Medium Hardness concrete

365.5503/2 30 Grit Double (Quick Release) Hard Bond

For Soft Concrete or for very rough concrete

365.5504/2 70 Grit Double (Quick Release) Medium Bond

For Light Grinding and Scratch Removal

365.5506/2 120 Grit Double (Quick Release) Medium Bond

For Light Grinding and Scratch Removal

Media Types - Metal Bond Tools

Image Part Number Tool Description

365.5605

50 Grit Hybrid

365.5610

100 Grit Hybrid

365.5620

200 Grit Hybrid

365.5602A

200 Grit Resin Bond

365.5604A

400 Grit Resin Bond

365.5608A

800 Grit Resin Bond

365.5618A

1500 Grit Resin Bond

365.5635A

3000 Grit Resin Bond

350.5666 Polishing Adapter Plate

Used to attach the “Polishing Tools” to the quick release plate

Media Types - Resin Bond Tools

AmTec 230v 4 pole motor wiring diagram (For use with blocks)

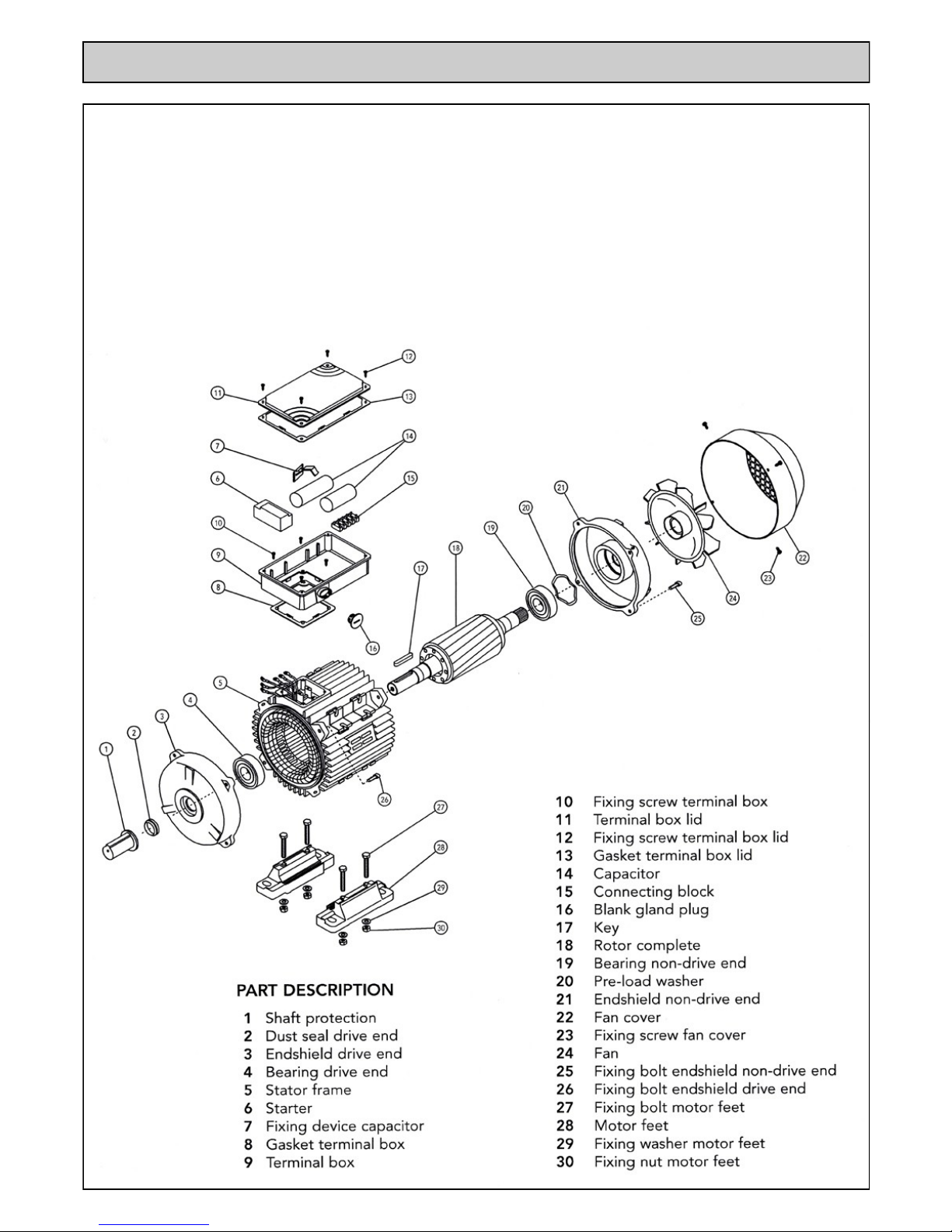

LAFERT ELECTRIC MOTOR EXPLODED VIEW

110v & 230v Motors

Only the most commonly used motor components are carried in stock at

Trelawny SPT Ltd.

These items are listed under the Lafert Motor heading in the parts list on

the previous page.

Note:

Endsheild Drive End Flange not shown in item 3.

Items 27,28,29 & 30 are not used on the Grinder.

WIRING DIAGRAMS

WIRING DIAGRAMS

STARTER BOX WIRING DIAGRAMS (LOVATO)

STARTER BOX WIRING DIAGRAMS (LOVATO)

TECHNICAL SPECIFICATIONS

Machinery Directive Information

This tool has been designed and produced in accordance with the following directives:

2006/42/EC Machinery Directive

If your company has any problem with our products or would like to discuss the possibility of an improvement being made to them, then please do not

hesitate to contact us. Your comments are both important and appreciated.

All rights reserved. Any unauthorised use or copying of the contents or part thereof is prohibited.

This applies to trademarks, model denominations, part numbers and drawings.

Use only genuine Trelawny spares.

The use of non-Trelawny spare parts invalidates the warranty.

Length x Width x Height (inc handle and wheels) 1100mm x 450mm x 980mm 43.3” x 17.7” x 38.6”

Cutting width 254mm 10 inch

Average depth of cut (dependent on concrete) 1 mm 0.040 inch

Electric motors 400v 230v 110v

Power 5.5kW (7.5hp) 2.2kW (3.0hp) 1.8kW

(2.4hp)

Voltage 400v (3ph) 230v (1ph) 110v (1ph)

Supply 11amp 16amp 32amp

Disc speed - rpm approximately 1600 1425 860

Petrol engines: Honda GXV160 Unleaded petrol - disc speed variable dependant on throttle

opening

Weight Electric motor 90kg (198lbs)

5.5hp Petrol engine 87kg (192lbs)

Working distance from wall 25mm side / 20mm front 1.0” side / 3/4” front

Electric motor Noise LwA SWL 86.04dB (A)

Honda Engine 5.5hp 91.5dB (A)

Declared Noise emissions in accordance with EN ISO 15744: 2008

Carborundum Blocks Diamond Disc

Vibration (AEQ) at the Handle Bar (110v Electric) Aeq = 2.36 m/s2 (k) Aeq = 1.25 m/s2 (k)

Vibration (AEQ) at the Handle Bar (230v Electric) Aeq = 1.17 m/s2 (k) Aeq = 0.913m/s2 (k)

Vibration (AEQ) at the Handle Bar (415v Electric) Aeq = 2.75 m/s2 (k) Aeq = 2.34 m/s2 (k)

Vibration (AEQ) at the Handle Bar (Petrol Models) Aeq = 5.61 m/s2 (k) Aeq = 6.35 m/s2 (k)

(K= +40% -0%)

Noise level measured in accordance with EN ISO 15744: 2008

Vibration measured in accordance with EN ISO 28927:2012 & EN ISO 20643:2005

NOTES

NOTES

Other manuals for TCG 250

1

Table of contents

Other Trelawny Floor Machine manuals

Popular Floor Machine manuals by other brands

Duplex

Duplex 280i AC instruction manual

HAKO

HAKO Scrubmaster B 310 R/WZB 960 instruction manual

Tennant

Tennant 96GR Operator's manual

Nilfisk-Advance

Nilfisk-Advance BR755C Instructions for use

Tornado

Tornado PS Series 98220 Operation & maintenance manual

Nilfisk-Advance

Nilfisk-Advance SC4000 Instructions for use