Trelawny TFS230 Troubleshooting guide

OPERATION & MAINTENANCE

TFS230 FLOOR STRIPPER

SAFETY

General Information

Thank you for your purchase of the

Trelawny TFS230 Floor stripper.

Before operating the TFS230 this

manual must be read and understood

by the operator, if in any doubt ask

your supervisor before using this

equipment. Failure to follow these

instructions could result in damage to

the TFS230 and/or personal injury.

Trelawny SPT Ltd disclaims all

responsibility for damage to persons

or objects arising as a consequence

of incorrect handling of the tool,

failure to inspect the tool prior to

starting work for damage or other

faults that may influence the

operation or safe working of the tool,

or failure to follow the safety

regulations listed or applicable to the

job site.

The machine is primarily designed for

the removal of bonded carpet, vinyl,

linoleum, cork and other floor

covering. It can be used for removal

of compacted soil from fork lift truck

areas or solidified printing ink etc.

Operators should be familiar with the

data given in the specification

section.

Please keep these instructions in a

safe and accessible place.

Safety Precautions

Do wear Personal Protective

Equipment including safety goggles,

footwear, ear defenders and gloves.

In some environments it will be

necessary to wear facemasks or

breathing apparatus.

Do ensure that this tool is lubricated

daily.

Do be aware that this tool can create

dust and flying debris.

Do be aware of others working

around you.

Do keep hands and clothing away

from moving parts.

Do store this tool in a secure and dry

environment.

Always observe safe working

practices and local safety regulations

at all times.

Do not allow the tool to run

unattended.

Do not modify this tool in any way, as

this will invalidate the warranty and

could lead to serious injury.

Do not use this tool in potentially

explosive environments.

Do not use petrol (gasoline), thinners

or any other high flash point solvent

to clean the tool.

Ensure that the work place is well

ventilated. Avoid using a fuel

powered generator in an enclosed

area, since engine exhaust gases are

poisonous.

Safety

WEAR SAFETY BOOTS, FACE

MASK, SHATTERPROOF

GLASSES, HELMET, GLOVES and

any other personal protective

equipment required for the working

conditions. Avoid loose clothing; this

may become trapped in moving

parts and cause serious injury.

ENSURE THAT THE WORK PLACE

IS WELL VENTILATED.

BEWARE OF MOVING BLADE,

serious injury could occur if the

stripper blade is brought into contact

with body parts during operation.

DO NOT OPERATE ELECTRIC

VERSIONS IN WET CONDITIONS.

CAUTION THIS MACHINE IS

HEAVY. It weighs 45kg / 99lbs.

Do not lift this machine manually.

Risk of Hand-arm

Vibration injury

These tools may cause Hand-arm

Vibration Syndrome injury if their use

is not adequately managed.

We advise you to carry out a risk

assessment and to implement

measures such as; limiting exposure

time [i.e. actual trigger time, not total

time at work], job rotation, ensuring

the tools are used correctly, ensuring

the tools are maintained according to

our recommendations, and ensuring

that the operators wear personal

p r o t e c t i v e e q u i p m e n t [ P P E ]

particularly gloves and clothing to

keep them warm and dry.

Employers should consider setting

up a pr ogram me of health

s u r ve i l la nc e t o es t a b li s h a

benchmark for each operator and to

detect early symptoms of vibration

injury.

We are not aware of any PPE that

provides protection against vibration

injury by attenuating vibration

emissions.

See ‘Specifications’ section for

vibration emission data.

Further advice is available from our

Technical Department.

We strongly advise you to visit the

Health & Safety Executive website

http://www.hse.gov.uk/vibration This

site provides excellent advice and

information on HAV and currently,

includes a Hand-arm Vibration

Exposure Calculator that is easy to

use to work out the daily vibration

exposure for each of your operators.

ASSEMBLY INSTRUCTIONS

There are three main parts:

1. Main body

2. Lower handle

3. Upper handle

STEP1

Fit lower handle to main body with

4 bolts and washers.

STEP2

Pull the knob on LOWER

HANDLE and slide UPPER

HANDLE into lower handle tube.

Secure by turning knob.

HANDLE ADJUSTMENT

Adjust handle up and down by unscrewing the knob and pulling it out slightly

and sliding the upper handle to the desired height.

Secure it after you set the handle height.

STEP 1:

Loosen the knob

and pull

STEP 2:

Set the handle height

to a desired height

STEP 3:

Secure the knob

after setting height

LOWEST POSITION HIGHEST POSITION

BLADE ANGLE ADJUSTMENT

Step 2:

When you reach the required angle

remove foot from the pedal and the

adjustment mechanism engage.

Step 1:

Place foot on the rear pedal and then

push the handle forward.

MAINTENANCE

LUBRICATION

Turn grease cap clockwise to lubricate the slide mechanism

on a daily basis (See diagram below)

If the cap is fully tightened, refill with grease. Turn anti-

clockwise and remove and replenish. (See diagram

below)

Lightly oil the adjustment mechanism

regularly to ensure smooth operation. (See

diagram below)

MAINTENANCE

BLADE REPLACEMENT

Loosen the three Allen screws on top of the blade holder which clamp the

blade in position, remove blade holder and replace the blade. Replace the

holder, replace and tighten the retaining screws.

EXPLODED VIEW

PARTS LIST

ITEM No DESCRIPTIONPART No

1 Sliding set323.9220

2 Blade holder fixing set323.9225

3 Blade holder set323.9230

3-1 Blade323.3509A

323.3509 Blades (Pack of 5)

4 Switch box, CW/Switch and power lead323.9168

5 Handle set323.9103

5-1 Rubber handle set323.2000

6 323.9167 110v Motor

220v Motor323.9146

7 Bottom cover323.9102

8 Front wheel, 2 x pcs/set323.9120

9 Pedal323.9201

10 Rear wheel, 2 x pcs/set323.9121

11 Spring, 2 x pcs/set323.9118

12 Rear wheel support323.9110

13 Main chassis assembly323.2021

14 Front handle set323.9105

15 Eccentric bearing housing set323.9116

16 8mm Hex Allen key805.0801

16-1 4mm Hex Allen key805.0401

20 323.9236 Grease Cap assembly

WIRING DIAGRAM

1- MOTOR CABLE

EARTH (Yellow/Green)

6 - SUPPLY EARTH

(Yellow/Green)

4 - SUPPLY LIVE + (Brown)

5 - SUPPLY NEUTRAL - (Blue)

3 - MOTOR NEUTRAL - (Blue)

2 - MOTOR LIVE + (Brown)

①

②

③

④

⑤

⑥

230v Motors

Take particular care when

using 230v Machines,

ensure that the electrical

supply is earthed and that

breakers and fuses are

correct for the loading.

The 230v motor requires the

minimum of a 13amp, 220v

power supply.

TECHNICAL SPECIFICATIONS

Trelawny SPT Ltd

Trelawny House, 13 Highdown Road, Sydenham Industrial Estate, Leamington Spa, Warwickshire,

CV31 1XT, United Kingdom

Telephone: +44 (0)1926 883781

Fax: +44 (0)1926 450352

Email: sales@trelawny.co.uk

Website: www.trelawnyspt.com

© TSPT UK 2014 Part No: 735.6230 issue 1

SURFACE PREPARATION TECHNOLOGY

Machinery Directive Information

This tool has been designed and produced in accordance with the following directives:

2006/42/EC Machinery Directive

If your company has any problem with our products or would like to discuss the possibility of an improvement being made to them, then please do not

hesitate to contact us. Your comments are both important and appreciated.

All rights reserved. Any unauthorised use or copying of the contents or part thereof is prohibited.

This applies to trademarks, model denominations, part numbers and drawings.

Use only genuine Trelawny spares.

The use of non-Trelawny spare parts invalidates the warranty.

Length x Width x Height (inc extended handle and wheels) 100mm x 86mm x 35mm 39.5” x 34” x 13.5”

Blade width 230mm 7”

Weight 45kg 99 lbs

Electric motors

Power 1500watts 2hp

RPM 1420

Voltage / Amperage 110V (15amp) 230V (9amp)

Noise emission in accordance with EN ISO 15744: 2008 and ISO 3744:2010

Noise levels:

LpA 82 dba

Vibration emission measured in accordance with EN ISO 20643:2005

Vibration (AEQ) at handle: 11.5m/s2

Other manuals for TFS230

1

Table of contents

Other Trelawny Floor Machine manuals

Popular Floor Machine manuals by other brands

Pioneer Eclipse

Pioneer Eclipse Express Power Glide Operator's manual

Nilfisk-Advance

Nilfisk-Advance SC450 Instructions for use

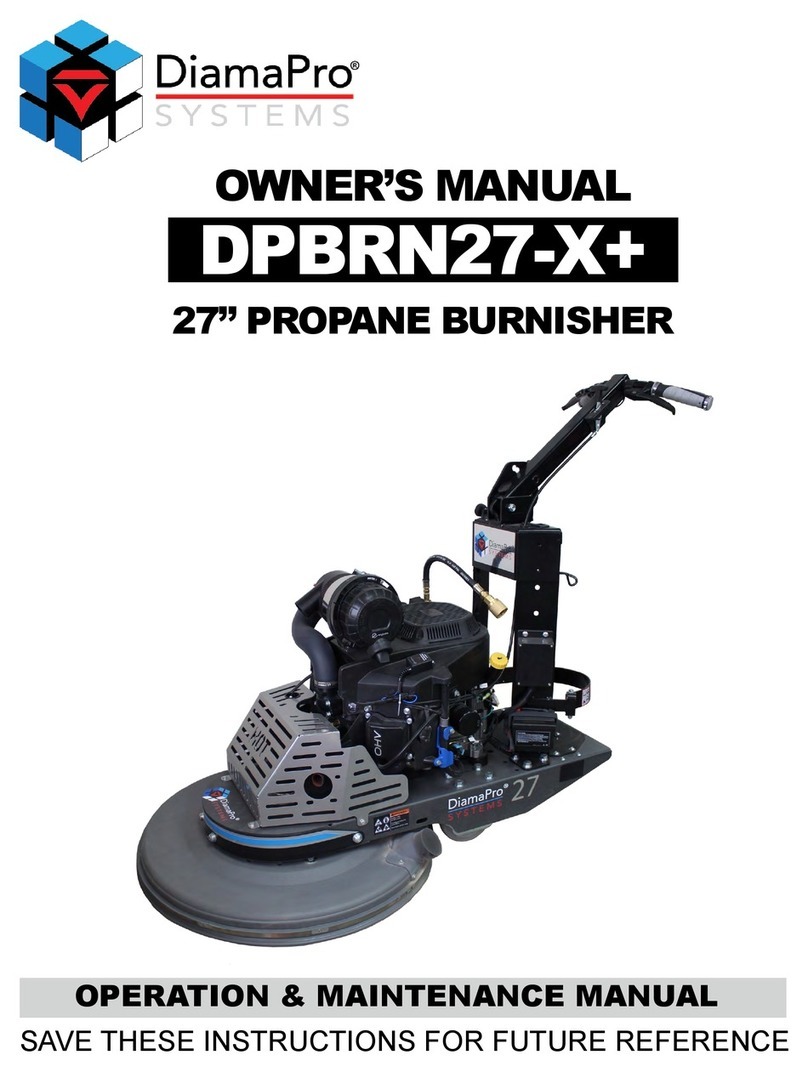

DiamaPro Systems

DiamaPro Systems DPBRN27-X+ owner's manual

Tennant

Tennant 1140 607681 Operator and parts manual

Amano

Amano Pioneer Eclipse PE440ST Operator's manual

Nilfisk-Advance

Nilfisk-Advance Shadow 17 Operator's manual and parts list