Trelawny Hydraflex Hold Cleaner Troubleshooting guide

HYDRAFLEX HOLD CLEANER

OPERATION & MAINTENANCE

OPERATION

Foreword

Thank you for purchasing the

Hydraflex Hold Cleaner.

This manual contains the necessary

maintenance information for you to

ensure proper operation and care for

your machine.

It is essential for yo to read

thro gh these man als

thoro ghly.

In the unlikely event that you

experience problems with your

Hydraflex, please do not hesitate to

contact your local dealer or agent.

We always welcome feedback and

comments from our valued

customers.

General Information

efore operating, perform ing

maintenance or repairing the

Hydraflex Hold Cleaner this manual

must be read and understood by the

operator, if in any doubt, ask your

supervisor before using this

equipment.

Local safety regulations must be

followed at all times. Failure to follow

these instructions could result in

damage to the Hydraflex Hold

Cleaner and/or personal injury.

Trelawny SPT Limited disclaims all

responsibility for damage to persons

or objects arising as a consequence

of incorrect handling of the machine,

failure to inspect the machine for

damage or other faults that may

influence the operation prior to

starting work, or failure to follow the

safety regulations listed or applicable

to the job site.

The tool is primarily designed for the

cleaning/washing of ships cargo

holds; it produces a powerful jet of

water, which can also remove flaking

rust and paint.

Operators should be familiar with the

data given in the specification

section.

Please keep these instructions in a

safe and accessible place.

Safety

Do wear Personal Protective

Equipm ent including safety

goggles, footwear, ear defenders

and gloves. In some environments

it will be necessary to wear

facemasks or breathing apparatus.

Do be aware that this tool is not

electrically insulated.

Do be aware that this tool can

create flying debris.

Do be aware of others working

around you.

Do store this tool in a secure and

dry place.

Always observe safe working

practices and local safety

reg lations at all times.

Never aim the Hydraflex hold

cleaner at any person, this

equipment produces a very

powerful jet of water and can

cause serious injury if misused.

Do not operate the Hydraflex,

unless it is securely fixed to its

tripod and situated on a flat

surface.

Do not modify this tool in any way,

as this will invalidate the warranty

and could lead to serious injury.

Do not drag this tool by the water

or air hose.

Please note: Unrestrained air and

water hoses can whip if they

become detached.

Water S pply

Ensure that a minimum 51mm

(2.0”) bore water hose is used and

that all couplings are secure, leak

free and in good condition.

The recommended water

press re is 5.9 bar (85p.s.i.).

Air S pply

Ensure that a minimum 19mm (3/4”)

bore air hose is used and that all

couplings are secure, leak free and

in good condition.

Limit the length of air hose to 30M

(100ft). Where extra length is

necessary, for each additional 15M

(50ft) of air hose used, the pressure

drop is approximately 0.21bar

(3psi).

Recommended air press re is

6.9bar (100 psi).

Do not let the operating pressure fall

below 6.2bar (90p.s.i.) or rise above

7.6bar (110 psi)

Preferably, the compressor should

be able to supply a minimum of 47.2

L/s (100cfm) free air.

Starting Work

Prior to operating the tool check: -

That all fittings are secure, free from

leaks and air hoses are in good

condition.

That the air press re is correct for

this tool 6.9 bar (100 psi).

That the water press re is correct

for this tool 5.9 bar (85psi).

Safe use of this tool requires that the

operator adopt a solid stance and

secure foothold.

Gloves and personal protective

equipment m st be worn when

using this tool.

Care must be taken to avoid

damaging or tripping over the air or

water hose.

Erect the tripod and spread the

tripods legs fully, ensure that the

tripod is placed in a stable position.

Remove the safety pin from the

swivel pin and remove the swivel pin

from the tripod, attach the Hydraflex

to the tripod securing it with the

swivel pin, replace the safety pin.

OPERATION

Pre-Start Check

Always clear the air hose before

connecting it to the Hydraflex, this

is to ensure the removal of any

foreign bodies that may be

present, which would otherwise

block, or choke the valve

assembly.

Connect a 51mm (2.0”) water hose

to the rear of the Hydraflex using

the hose adapter or fit one of the

supplied instantaneous couplings

to the hose and connect to the

adapter.

IMPORTANT: Take precautions to

ensure that the area to be cleaned

is completely free of personnel and

of any electrical equipment that is

exposed or is not protected against

water ingress (IP67 minimum

protection).

Machine Operation

With one operator securely holding

and controlling the Hydraflex a

second person should slowly open

the water valve at the main or pump.

It is very important that the Hydraflex

be held securely while the water is

being turned on and while it is in

use.

The air valve should now be

adjusted carefully to produce a tight

hard-hitting jet of water. Excessive

air will cause the jet of water to

break up and spread, becoming less

effective.

In an emergency or once cleaning

has been completed, close the air

valve and instruct the second

operator to shut off the water supply.

Disconnect the air and water

hoses and wipe all deposits from

the outside of the Hydraflex.

Remove the safety pin and then

taking the weight of the Hydraflex,

remove the swivel pin from the

tripod and remove the Hydraflex.

Replace the tripod swivel pin and

replace its safety pin.

When collapsing the tripod, take

care not to trap fingers or hands.

It is recommended that the joints

and swivel head of the Tripod be

lubricated prior to storage.

Cover the Hydraflex hold cleaner

to protect it and store in a secure

and dry place.

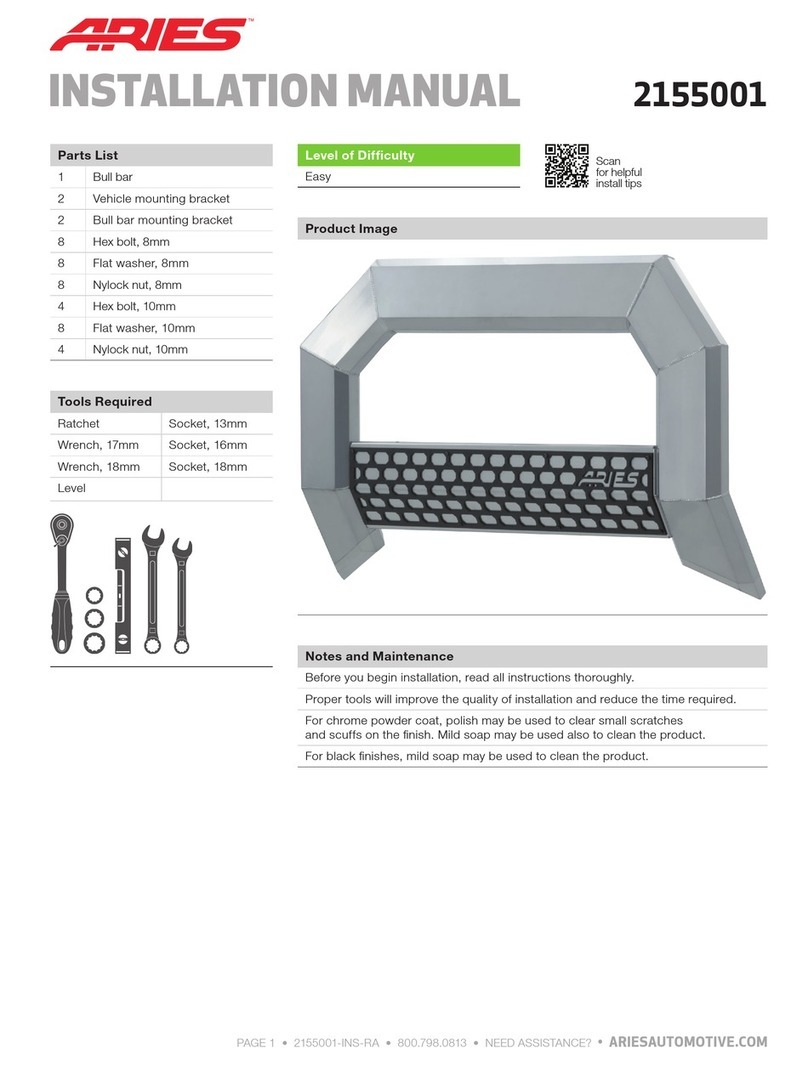

Item No: Part No: Description

1 342.HY02 Tripod

3 342.HY35 Main ody

4 342.HY16 Air inlet adapter

5 828.1000 Air inlet control valve

7 342.HY05 Instantaneous water hose adapter

7a 342.HY03 Water hose coupling 2½” x 2½”

7b 342.HY04 Water hose coupling 2½” x 2.0”

SPECIFICATION

Technical Specifications

If your company has a problem or would like to discuss the possibility of an improvement being made to the

Hydraflex, then please do not hesitate to contact us.

Your comments are both important and appreciated.

Trelawny SPT Ltd

Trelawny House, 13 Highdown Road, Sydenham Industrial Estate, Leamington Spa, Warwickshire,

CV31 1XT, United Kingdom

Telephone: +44 (0)1926 883781

Fax: +44 (0)1926 450352

Email: sales@trelawny.co.uk

Website: www.trelawnyspt.com

© TSPT UK 2007 Part No: 735.5200 issue 4

SURFACE PREPARATION TECHNOLOGY

All rights reserved. Any unauthorised use or copying of the contents or part thereof is prohibited.

This applies to trademarks, model denominations, part numbers and drawings.

Use only genuine Trelawny spares.

The se of non-Trelawny spare parts invalidates the warranty.

At its maxim m working distance of 30 metres, the force of water on the s rface being cleaned is

approximately 10kg

Recommended water pressure 6kg/cm

2

(5.9 bar)

85 psi

Recommended air pressure 7kg/cm

2

(6.9 bar) 100 psi

Estimated water consumption 454 lpm 100 gal/min

Estimated air consumption 33 lps 70 cfm

Recoil 10 to 18 kg. 22 to 40 lbs

Weight (Hydraflex & tripod) 14.1 kg. 31 lbs.

Weight of Hydraflex 5.5 kg. 12 lbs.

Weight of Tripod 8.6 kg. 19 lbs

Length of Hydraflex (including threaded adapter) 770 mm 30”

Length of tripod (closed) 1160 mm 45.5”

Height of tripod (open) 1027 mm 40.5”

Air hose 20 mm ¾”

Water hose 51 mm 2”

Instantaneous coupling (use water hose adapter) 63.5 x 51mm 2½” x 2 “

Instantaneous coupling (use water hose adapter) 63.5 x 63.5mm 2½” x 2½“

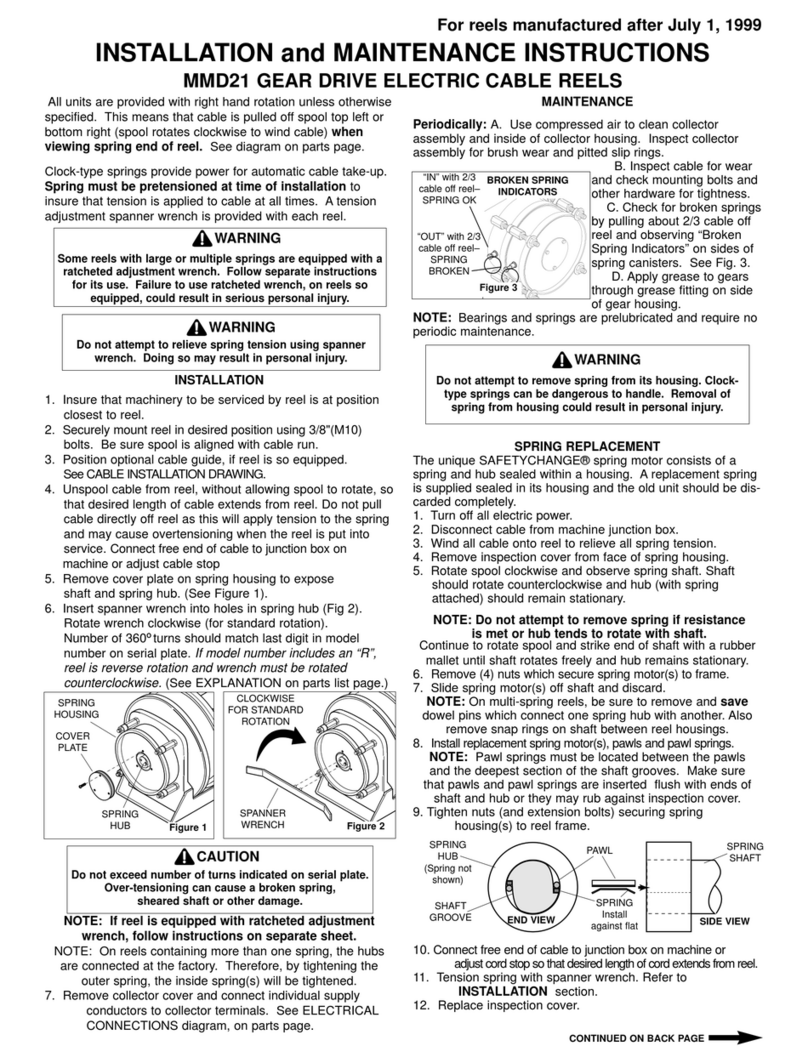

Popular Other manuals by other brands

SodaStream

SodaStream Spirit One Touch quick start guide

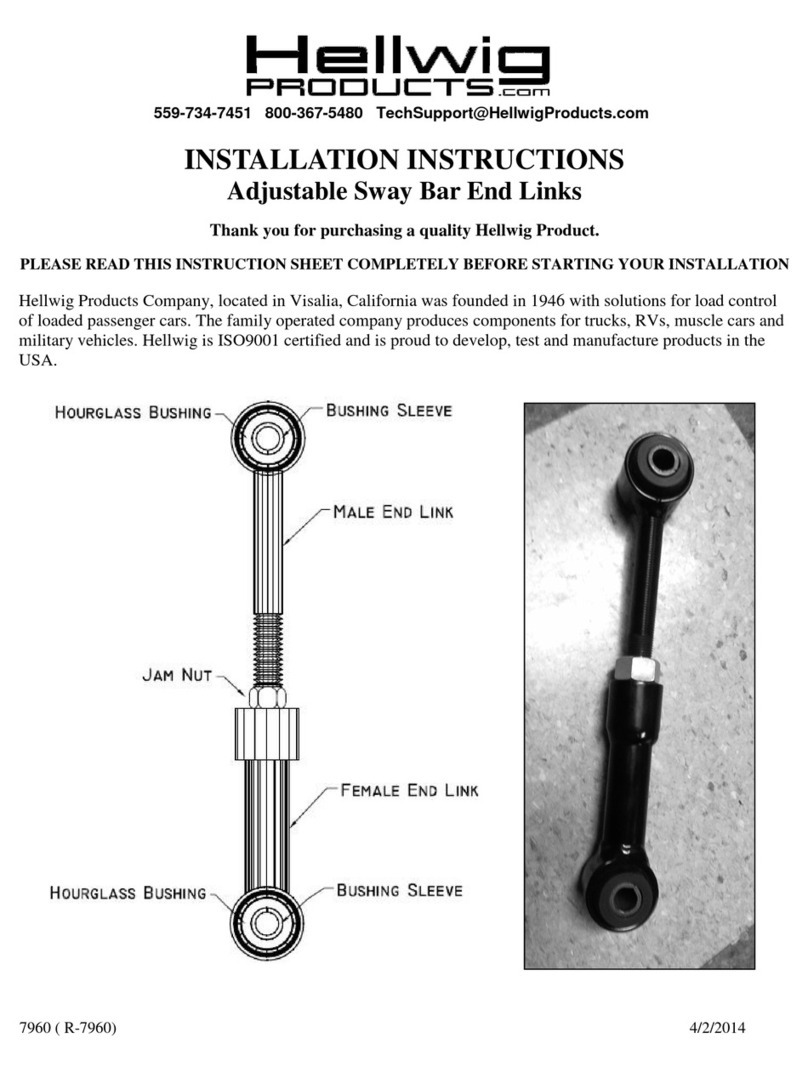

Allen-Bradley

Allen-Bradley MINOTAUR MSR178DP installation instructions

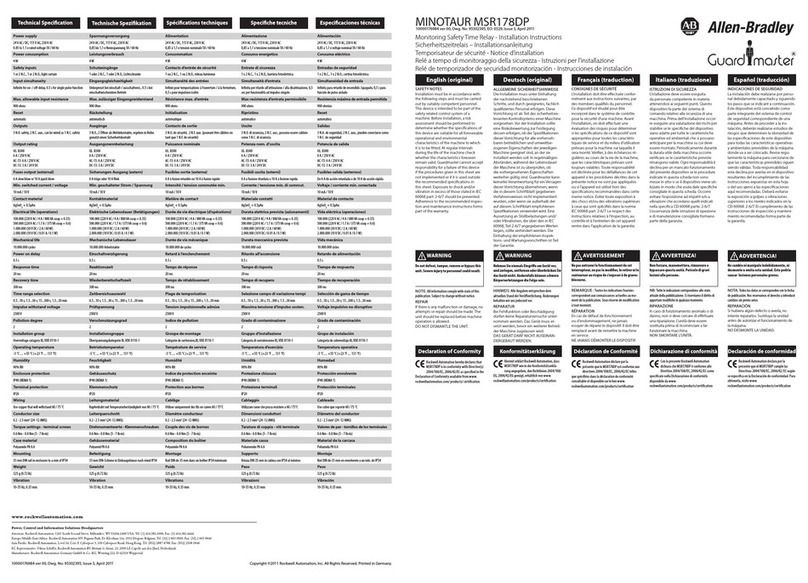

Hubbell

Hubbell MMD21 Installation and maintenance instructions

Ferplast

Ferplast Airfizz Series user manual

Hutt

Hutt HBR 204 Operation and maintenance instruction manual

Sony

Sony TC-KB920S Service manual