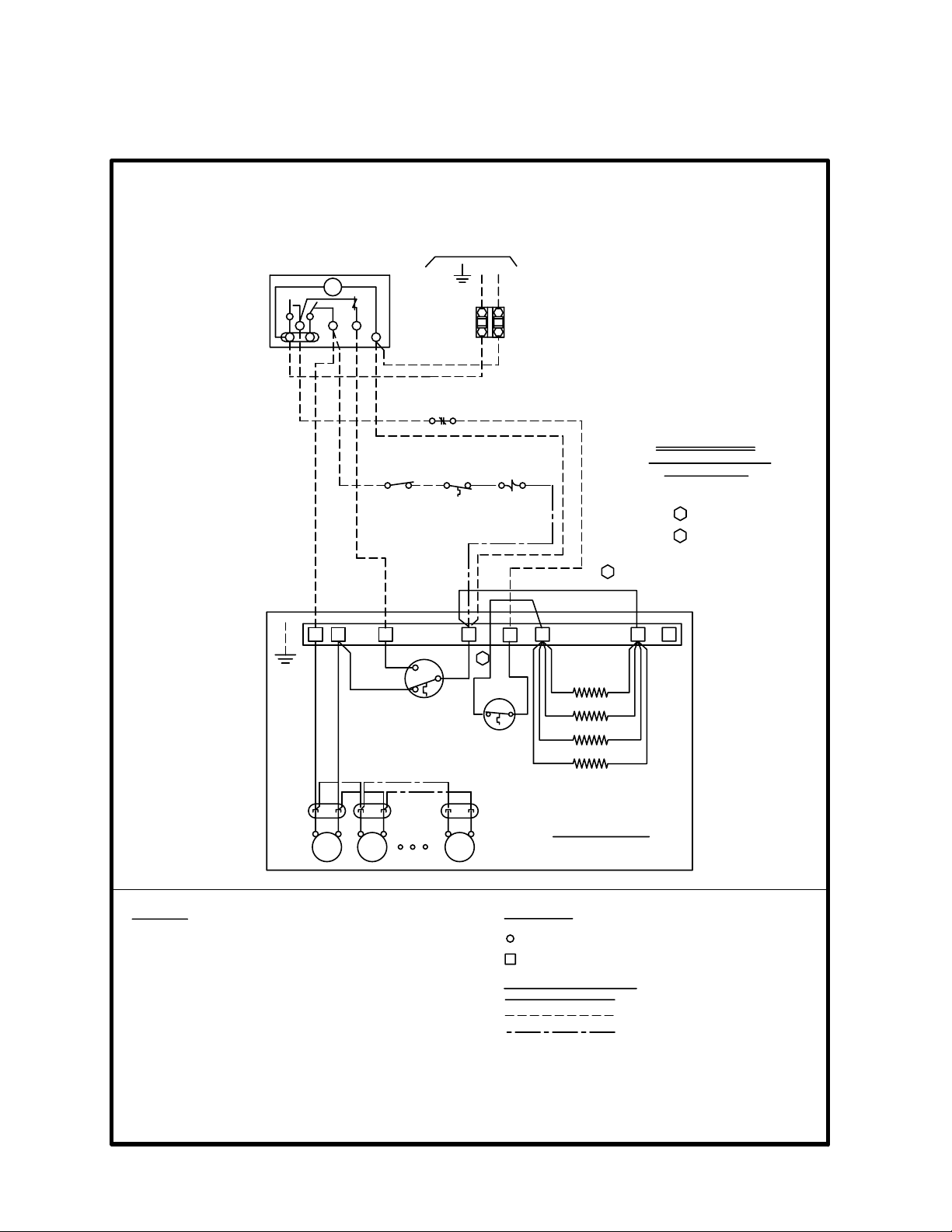

ELECTRICAL DATA -

208-230/1/60 & 208-230/3/60

ELECTRIC DEFROST MODELS

MODEL FPI

FAN MOTORS DEFROST HEATERS

QTY.

PSC MOTORS EC MOTORS TOTAL

WATTS

208-230/1/60 208-230/3/60

HP FLA

TOTAL WATTS MCA

(A)

MAX.

FUSE

(AMPS) HP FLA

TOTAL WATTS MCA

(A)

MAX.

FUSE

(AMPS)

TOTAL

AMPS MCA

(A)

MAX.

FUSE

(AMPS)

TOTAL

AMPS MCA

(A)

MAX.

FUSE

(AMPS)

104ME*

6

1 1/15 0.5 100 0.6 15 1/15 0.6 60 0.8 15 1060 4.6 5.8 15 3.0 3.8 15

106ME* 1 1/15 0.5 100 0.6 15 1/15 0.6 60 0.8 15 1060 4.6 5.8 15 3.0 3.8 15

107ME* 1 1/15 0.5 100 0.6 15 1/15 0.6 60 0.8 15 1060 4.6 5.8 15 3.0 3.8 15

209ME* 2 1/15 1.0 200 1.1 15 1/15 1.2 120 1.4 15 1890 8.2 10.3 15 5.3 6.7 15

211ME* 2 1/15 1.0 200 1.1 15 1/15 1.2 120 1.4 15 1890 8.2 10.3 15 5.3 6.7 15

214ME* 2 1/15 1.0 200 1.1 15 1/15 1.2 120 1.4 15 1890 8.2 10.3 15 5.3 6.7 15

317ME* 3 1/15 1.5 300 1.6 15 1/15 1.8 180 2.0 15 2730 11.9 14.8 15 7.7 10 15

320ME* 3 1/15 1.5 300 1.6 15 1/15 1.8 180 2.0 15 2730 11.9 14.8 15 7.7 10 15

423ME* 4 1/15 2.0 400 2.1 15 1/15 2.4 240 2.6 15 3560 15.5 19.3 20 10 12 15

426ME* 4 1/15 2.0 400 2.1 15 1/15 2.4 240 2.6 15 3560 15.5 19.3 20 10 12 15

532ME* 5 1/15 2.5 500 2.6 15 1/15 3.0 300 3.2 15 4400 19.1 23.9 25 12 15.1 20

639ME* 6 1/15 3.0 600 3.1 15 1/15 3.6 360 3.8 15 5230 22.7 28.4 30 15 18 20

104LE*

6

1 1/15 0.5 100 0.6 15 1/15 0.6 60 0.75 15 1060 4.6 5.8 15 3.0 3.8 15

105LE* 1 1/15 0.5 100 0.6 15 1/15 0.6 60 0.75 15 1060 4.6 5.8 15 3.0 3.8 15

106LE* 1 1/15 0.5 100 0.6 15 1/15 0.6 60 0.75 15 1060 4.6 5.8 15 3.0 3.8 15

207LE* 2 1/15 1.0 200 1.1 15 1/15 1.2 120 1.4 15 1890 8.2 10.3 15 5.3 6.7 15

209LE* 2 1/15 1.0 200 1.1 15 1/15 1.2 120 1.4 15 1890 8.2 10.3 15 5.3 6.7 15

211LE* 2 1/15 1.0 200 1.1 15 1/15 1.2 120 1.4 15 1890 8.2 10.3 15 5.3 6.7 15

314LE* 3 1/15 1.5 300 1.6 15 1/15 1.8 180 2.0 15 2730 11.9 14.8 15 7.7 10 15

317LE* 3 1/15 1.5 300 1.6 15 1/15 1.8 180 2.0 15 2730 11.9 14.8 15 7.7 10 15

419LE* 4 1/15 2.0 400 2.1 15 1/15 2.4 240 2.6 15 3560 15.5 19.3 20 10 12 15

422LE* 4 1/15 2.0 400 2.1 15 1/15 2.4 240 2.6 15 3560 15.5 19.3 20 10 12 15

527LE* 5 1/15 2.5 500 2.6 15 1/15 3.0 300 3.2 15 4400 19.1 23.9 25 12 15.1 20

631LE* 6 1/15 3.0 600 3.1 15 1/15 3.6 360 3.8 15 5230 22.7 28.4 30 15 18 20

103VE*

4

1 1/15 0.5 100 0.6 15 1/15 0.6 60 0.75 15 1060 4.6 5.8 15 3.0 3.8 15

104VE* 1 1/15 0.5 100 0.6 15 1/15 0.6 60 0.75 15 1060 4.6 5.8 15 3.0 3.8 15

105VE* 1 1/15 0.5 100 0.6 15 1/15 0.6 60 0.75 15 1060 4.6 5.8 15 3.0 3.8 15

206VE* 2 1/15 1.0 200 1.1 15 1/15 1.2 120 1.4 15 1890 8.2 10.3 15 5.3 6.7 15

208VE* 2 1/15 1.0 200 1.1 15 1/15 1.2 120 1.4 15 1890 8.2 10.3 15 5.3 6.7 15

209VE* 2 1/15 1.0 200 1.1 15 1/15 1.2 120 1.4 15 1890 8.2 10.3 15 5.3 6.7 15

312VE* 3 1/15 1.5 300 1.6 15 1/15 1.8 180 2.0 15 2730 11.9 14.8 15 7.7 10 15

315VE* 3 1/15 1.5 300 1.6 15 1/15 1.8 180 2.0 15 2730 11.9 14.8 15 7.7 10 15

416VE* 4 1/15 2.0 400 2.1 15 1/15 2.4 240 2.6 15 3560 15.5 19.3 20 10 12 15

419VE* 4 1/15 2.0 400 2.1 15 1/15 2.4 240 2.6 15 3560 15.5 19.3 20 10 12 15

523VE* 5 1/15 2.5 500 2.6 15 1/15 3.0 300 3.2 15 4400 19.1 23.9 25 12 15.1 20

627VE* 6 1/15 3.0 600 3.1 15 1/15 3.6 360 3.8 15 5230 22.7 28.4 30 15 18 20

* = S2 or T3. Refer to Nomenclature for details

60HzTPLP