Treyco 3000 User manual

TreycoModel3000

InstructionManual

Page1

TABLEOFCONTENTS

SafetyandUnpackMachine2

FeaturesofModel30003

Assembly6

Chargehoningdisc7

SharpeningA‐5StyleClipperBlades9

BladeCharts14

HoningDiscReplacement15

Page2

SAFETY PRECAUTIONS

Wear safety glasses and dust mask when operating Treyco Model 3000.

Do not operate machine with loose fitting clothing that can catch in moving parts.

Keep hair pulled back to avoid contact with moving parts.

Do not modify speed of machine.

Use only TREYCO replacement parts and honing disc resurfacing.

Keep work area clean.

Keep children and visitors away from machine while in use.

Do not operate machine until instruction manual is fully read and understood.

Read Material Safety Data Sheets

UNPACK MACHINE

Machine is shipped in three cartons as follows:

One large carton contains assembled machine.

Second carton contains honing disc.

Third carton contains loosely packed accessories as follows:

1# jar honing powder

Powder dispenser (salt shaker)

Atomizer sprayer with oil

Wood charging stick

Metal removal gauge

Instructional DVD

Instruction manual

Allen wrench 5/32

Rabbit pelt

Page3

FEATURESOFMODEL3000

Brakeforquickstoppingofhoningdisc

Linearballbushingslidecompletely

sealedwithrubberbellows

Magneticholdersthatrequirenoadjustments

whensharpeningvarioussizeblades

Page4

TWOSPEEDHONINGDISC

Model3000isequippedwitha2‐speeddrive,machinearrivessetonlowspeed.

Tochangetohighspeedmoveorangebeltfromupperpulleygrooveondrive

platetolowerpulleygroovethenmovebeltfromupperpulleygrooveonmotor

tolower.

Toreturntolowspeedreverseabovedirections.

Lowspeedsetting

Highspeedsetting

Page5

HONINGDISCBRAKE

Machinefeaturesabrakeforstoppingthehoningdiscquickly,thebrakepadthat

pressesontheouteredgeofthediscwillwearandwhenthishappensremove

thescrewontopofpadandliftpadoffandindextoadifferentkeywayand

reattachwithscrew.

Removescrewtoliftoffbrakepad

Brakepadwith4keyways

Page6

ASSEMBLY

Machine is received fully assembled with the exception of mounting the honing disc and preparation of the disc

for sharpening as follows:

STEP 1:

Place machine on sturdy table or bench.

STEP 2: WASH HONING DISC

Wash both sides of honing disc with warm water and mild dish washing detergent (suggest Dawn Dish soap,

DO NOT use detergent for automatic dishwashers).

Scrub disc with soap solution and soft bristle brush.

Rinse in warm water.

Let disc air dry only, DO NOT dry with towel as this will leave lint or fabric on disc.

STEP 3: DISC IDENTIFICATION

Disc is double sided, and stamped in center recess for identification.

“H” side (HOLLOW GROUND) is used for small animal and human hair.

“F” side (FLAT GROUND) is used for large animal blades.

STEP 4: INSTALL HONING DISC

Remove ¼” screw from drive plate and install honing disc onto machine by placing large center hole in disc

onto spindle while aligning the threaded hole in drive plate with small hole in honing disc.

Insert ¼” screw through small hole in honing disc and tighten.

Cover large center hole in disc with a piece of adhesive (duct) tape to prevent honing powder from getting onto

spindle.

Placetapeoverendofspindleshaft Attachdisctospindlewithsuppliedscrew

Page 7

CHARGING HONING DISC

STEP 1

Atomizer spray bottle comes already filled with honing oil, you must pressurize the

bottle with air. This can be done the same as filling a car tire with air or use a

bicycle tire pump. Fill to 50 – 90 pounds air pressure.

Add honing powder into supplied powder dispenser (salt shaker).

STEP 2

Before using a new or resurfaced honing disc you must first do an initial charging

of honing oil and honing powder. Machine is shipped on low speed setting please

leave it on low speed for the initial charging.

1. Spin honing disc by hand.

2. Hold atomizer 8 to 10 inches above disc.

3. Apply a fine spray of honing oil on disc by a 1-2 second burst from atomizer,

honing oil should fall on honing disc as shown below as disc is slowly

revolving.

Fine mist of oil to fall

on disc in this area as

disc s

p

ins slowl

y

.

Page 8

4. Apply honing powder evenly on disc with supplied shaker covering the disc

lightly (approximately 1-2 teaspoons).

5. Place wooden charging stick on honing disc in line with center of disc and

narrow edge of stick on honing disc. Make two revolutions around honing disc

with charging stick to evenly distribute honing powder. Apply light down

pressure on charging stick. This will fill the fine grooves on disc with powder.

6. Mount Oster comb blade size 10 or 15 on holder engraved OSTER COMB.

7. Turn on honing disc and automatic arms.

8. Lower comb blade only gently onto honing disc placing it down when blade is

centered between outer edge and inner edge (do not set blade down at inner or

outer edges of disc).

9. Let blade make 4-6 complete strokes across disc.

10. Lift blade to upright position.

11. Repeat this process FIVE more times.

12. After repeating this process, the entire surface of disc should be a uniform dull

gray in color.

CHARGING STICK

Page9

SHARPENINGA‐5BLADES

STEP1:SETMETALREMOVALGAUGE

1. Disassemblebladesetandwipeoffanydirt,furorhair.

2. Placesideofcombbladetobesharpenedonmetalremovalgaugewiththe

2pinsongaugefaceenteringthe2screwholesoncombblade.

3. Whileholdingcombtighttogaugerotatedialofindicatorsoneedlepoints

tozero.

Pinsthescrewholes

incombbladefiton

Holdcombblade

tighttogaugeand

rotatedialtozero

Aftersharpening

needleshouldbe2

linesfromzero

Page10

STEP2:MOUNTCOMBBLADEONHOLDER

1. PlacecombbladeonholderlabeledA‐5COMBBLADEwiththe2floating

magnetsinthecounterboresthatthebladescrewsgointo.Teethofblade

shouldbepointingdown.

2. WithdiscOFF(notrotating)lowercombbladetohoningdisc.Visuallycheck

thatbothteethandwearbararesittingondiscsurface.

3. Liftarmtoverticalposition

Floatin

g

ma

g

nets

Counterboresthatfloatingmagnets

fitinto

Combblademountedonholder Teethandwearbarsittingondisc

Page11

STEP3:MOUNTCUTTERBLADE

1. PlacecutteronholderlabelledOSTERCUTTERbyhavingthe2formed

magnetsfitintothegroovethatthebladeguideridesandthescrewhead

onholderfitsintocutoutincutterwheretheleverfitsthatdrivescutter

backandforthwhenmountedtoclippermotor.

2. WithdiscOFF(notrotating)lowercutterbladetohoningdisc.Visually

checkthatbothteethandwearbararesittingondiscsurface.

3. Liftarmtoverticalposition.

Screwhead

Formedmagnets

Bladeguidegroove

Cutoutforlever

Cuttermountedonholder Teethandrearwearbarboth

sittingondisc

Page12

STEP4:APPLYOILANDPOWDER

Thisprocessissimilartochargingthedisc.

1. Spindiscbyhand.

2. Holdatomizer8‐10inchesabovedisc.

3. Applya1–2secondburstofoilfromatomizerasdiscrotates

4. Applyhoningpowderevenlyarounddiscwiththesuppliedshaker.

5. Placewoodenchargingstickondiscandmake2‐3revolutionsarounddisc

spreadingpowderandfillingthefinegroovesonthedisc.

6. Thisistobedonewitheachbladesharpened.

STEP5:SHARPENBLADES

1. Turnondiscandautomaticarms.

2. Lowercombontodiscsettingdownbetweeninnerandouteredgesofdisc.

3. Lowercutterontodiscsettingdownbetweeninnerandouteredgesofdisc.

4. Cyclefor2minutesonlowspeed(reducecycleto1minuteifdiscissetto

highspeed).

5. Liftarmsoffdiscwhenholdersarebetweeninnerandouteredgesofdisc.

6. Inspectpowderresidueonblades,powdershouldbemoistenoughto

adheretoblades,ifpowderisdrylikesandorflourthenyouarenotusing

enoughoil,ifpowderiswetlikegreaseortoothpastethenyouareusing

toomuchoil.Ifpowderistoowetsimplyapplypowderonly(nooil)until

powderresidueiscorrect.

7. Washbladesinbladewash,mineralspiritsorkerosenetoremoveall

powderfromblades.Werecommend2containersthefirstcontaineris

whatthebladeiswashedinandthesecondcontainerisforrinsingthe

blade.Recommendusingsmallpaintbrushtocleanbetweentheteethof

blade.

8. Placecombbackonmetalremovalgaugeandmeasureamountofmetal

removedinsharpeningprocess.Needleshouldbe2linesfromzero

indicatingyouremoved.002”fromblade.

Page13

STEP6:REASSEMBLEBLADE

1. Tightenspringtensionifneededbysqueezingspringwhereshapedlike

horseshoewithpliersclosingtheopeningofthehorseshoeslightly,donot

closesomuchthatsocketcannotslidebackintospring,ifyouhave

overtightenedbendhorseshoeopenwithflatbladescrewdriver.

2. Assemblespringandsockettogetherandattachtocombbladewith2

screws.

3. Aligncuttertocombandexaminetipsofcutterteethinrelationtotipsof

combteeth,cutterteethshouldbeslightlybehindcombteethsothesharp

needleliketipsofthecutterteetharenotprotrudingpastthecombteeth

asthiscouldscratchorcutthesurfaceoftheanimalorpersonthebladeis

beingusedon.(seechart)

4. Placebladeonclippermotorandturnon,ifbladerattlestheearsofthe

socketmustbesqueezedclosertogethertoeliminaterattle(thiscanbe

donewithoutdisassemblingblade).

5. Testcutonrabbitpelt.

Tightening

springtension

Adjustingsocket

earstostop

bladerattle

Cuttersetback

Page14

A‐5BLADECHART

BladeSize CutterSetBack

7andlarger 1/16

8½thru30 1/32

40andfiner 1/64

OSTER10,11,and111BARBERBLADES

ANDISBGBLADES

BladeSize CutterSetBack

0000and00000 1/64

000thru0 1/32

0Athru18 1/16

Page15

HONING DISC REPLACEMENT

When a new or resurfaced honing disc is installed on machine the following

adjustments must be verified before machine can be used (this is not required if

turning disc over to use other side). This is due to variations in thickness of honing

discs.

Adjustment of arms parallel to honing disc

The cutter and comb holder arms must be set parallel to the surface of the honing

disc that is on machine (thickness of honing disc changes when resurfaced).

Mount size 10 or 15 comb blade on holder.

Mount cutter on cutter holder.

With disc turned off lower arms to surface of honing disc.

Loosen screws on side of machine this will allow you to raise or lower automatic

assembly and set arms parallel to honing disc.

Screwforadjustingarmsparallelwithhoningdisc,oneoneachsideofmachine

Plasticscrewcovercapsinarmrests

Page16

CENTER HOLDERS

Raise arms to vertical position.

Mount an A-5 comb blade size 10 or 15 on Comb Holder.

Lower arm so comb blade is resting on top of honing disc.

Turn on automatic arms (switch on left) and observe if the comb blade overlaps the

inner and outer edge of honing disc the same amount at each end of its stroke.

If not, turn off automatic arms.

Remove plastic cover from screw hole on top of arm rest and loosen set screw.

Move pivot block assembly left or right on slide rod bearing housing so teeth of

cutter overlap same on inner and outer edge of disc.

Verify by turning on arm motor, replace plastic cover in screw hole cover.

Repeat above step until comb overlaps inner and outer edges of honing disc

equally.

Repeat process on cutter blade holder.

ADJUSTMENT OF HOLDERS TO CENTERLINE OF DISC

Loosen set screw collars on arms and slide holders on arms so the teeth of the

cutter and comb are in line with centerline of honing disc.

Setscrewcollars Centerlineofhoningdisc

Table of contents

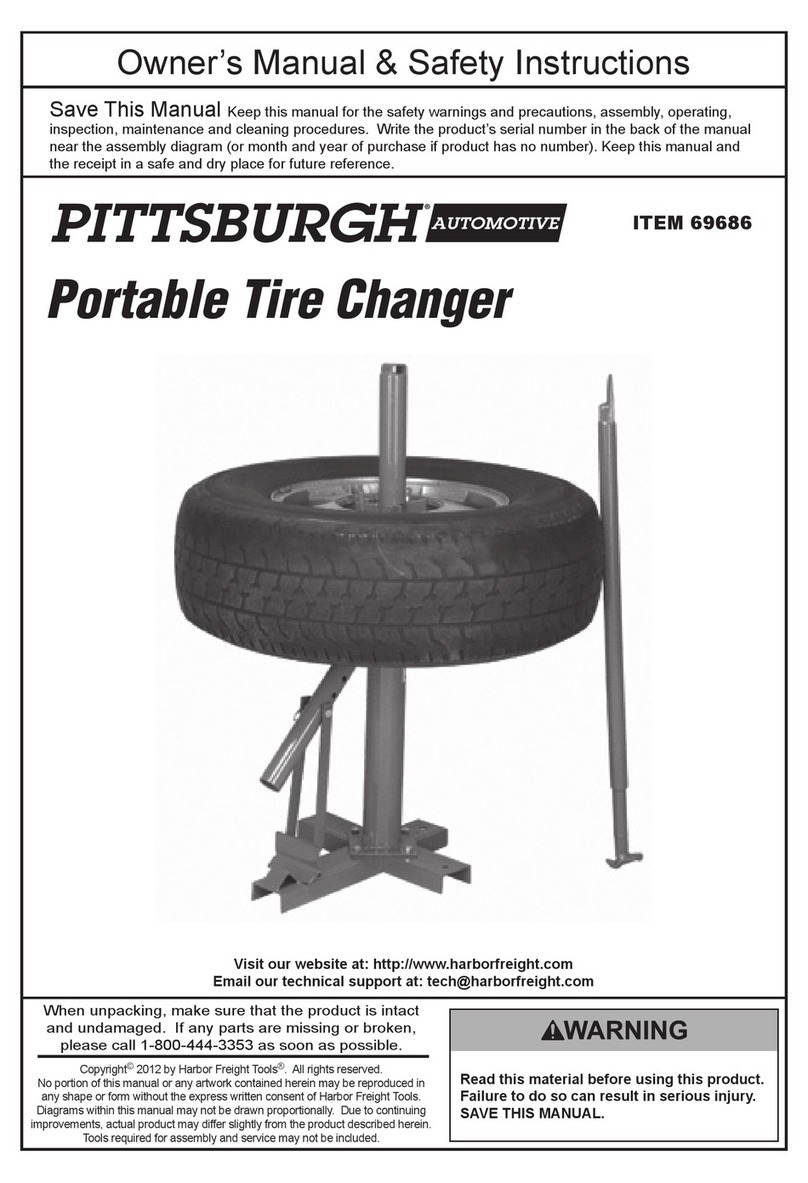

Popular Power Tools manuals by other brands

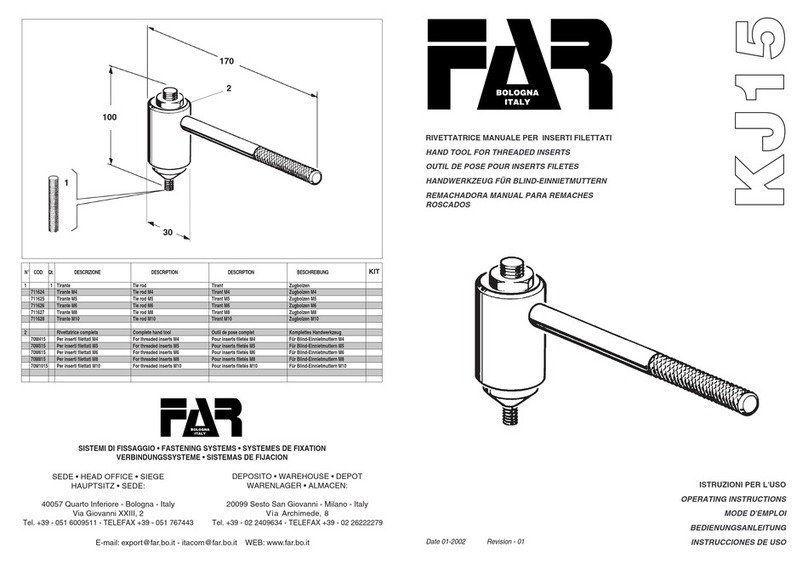

Pittsburgh

Pittsburgh Pittsburgh Automotive Portable Tire Changer Owner's manual & safety instructions

Bosch

Bosch GBH 2 S operating instructions

Cooper

Cooper Weller DS 22 operating instructions

Hilti

Hilti SJT 6-A22 Original operating instructions

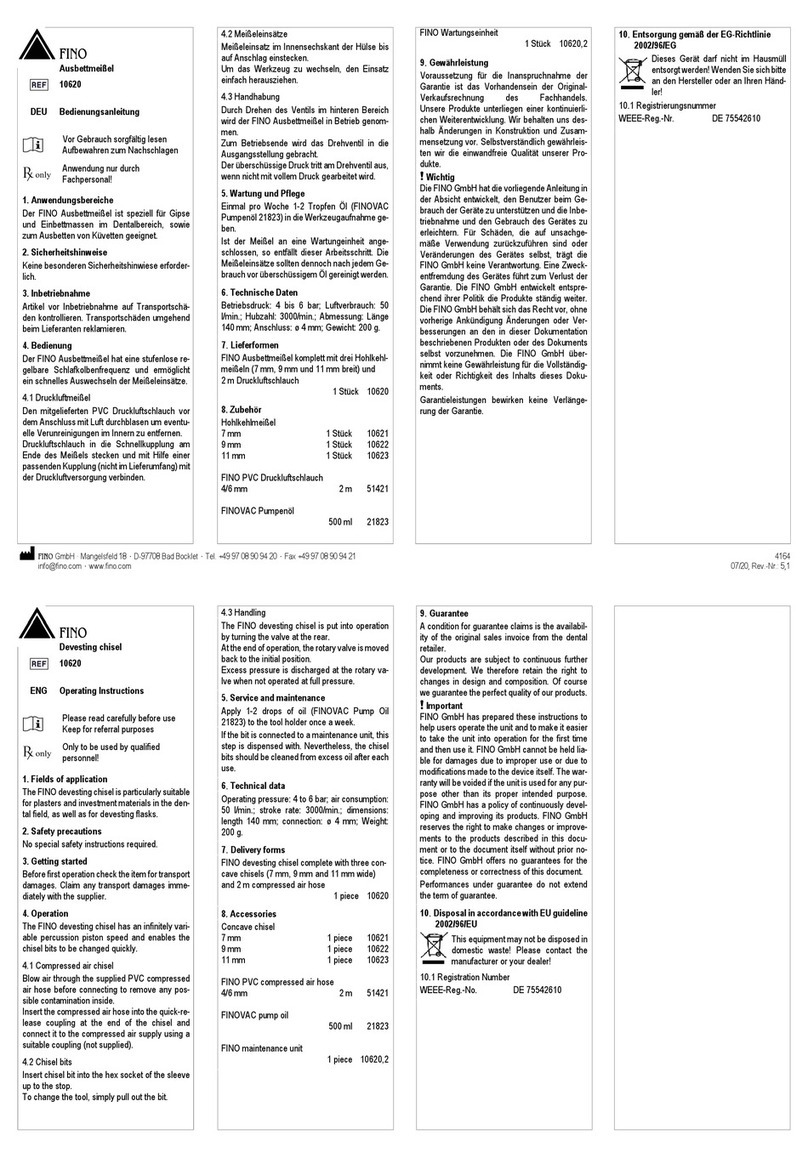

FINO

FINO 10620 operating instructions

Ryobi

Ryobi A90SG01 Guide