TRI-DATA CartriFile 40 User manual

Instruction

Manual

TR

I

DA

TA

800 Maude

Avenue/Mountain

View/CA

94040

-

,I,

Phone (415) 969-3700/TWX 910-379-6978

CartriFile

40

Section

II

III

CONTENTS

INTERFACE

.....

.

DESCRIPTION . . . . .

INTRODUCTION

EQUIPMENT DESCRIPTION

Tape Drive Assembly

Electronics Assembly

Power Supply .

Front

Panel. .

Tape Cartridges

SPECIFICATIONS

Physical Characteristics.

Dimensions and Weight.

Environment . . . .

Title

Input

Power Requirements

Input/Output

and Power Connectors

Operational Characteristics

Input/Output

Signal Levels

Tape Motion . . .

Recording Technique

Record Format

Data

Transfer.

. .

Inter-Record Gaps .

Beginning-of-Tape and End-of-Tape

Data Transfer Rate . . . .

Data Transfer Time Per Record

Load-Point Search Time

Data Storage Capacity .

1000 Series Tape Cartridges

INSTALLATION. .

GENERAL

...

INSTALLATION.

Table-Top Placement

Rack Mounting

Power Connection

Grounding.

. .

Remote Load-Point Search Control.

Interface Connections

OPERATION

.....

INTRODUCTION

CONTROLS AND INDICATORS

Application

of

Power

Cartridge Insertion and Removal.

Remote Load-Point Search Control.

AUTOMATIC OPERATIONS.

Write Sequence and Timing

Read Sequence and Timing

Read Timing Variations. .

Load-Point Search and Status

Bits-Per-Word Format Selection.

1

Page

1-1

1-1

1-1

1-1

1-1

1-2

1-2

1-2

1-2

1-2

1-2

1-2

1-2

1-2

1-4

1-4

1-4

1-4

1-4

1-4

1-4

1-4

1-4

1-5

1-5

1-5

1-5

2-1

2-1

2-1

2-1

2-1

2-1

2-2

2-2

2-2

3-1

3-1

3-1

3-1

3-1

3-1

3-1

3-1

3-3

3-4

3-4

3-4

iii

TRI-DATA

Section

IV

v

iv

CONTENTS (Continued)

THEORY OF OPERATION .

GENERAL

.....

.

RECORDING TECHNIQUE

TAPE TRANSPORT. .

CIRCUIT OPERATION

Power Supplies . .

Title

Power Supply 10947-1 .

Regulator Board 10790-0 .

Motion Control . . . . .

Load-Point

Sensing.

. .

Pinchroller Actuator Driver

Load-Point Search Operation.

Write/Read Start Operations .

Write/Read Stop Operations .

Write Electronics. . . . . .

Timing & Data Board 10748-0

Write Drivers . .

Read

Electronics.

. . . . .

Read Preamplifiers . . . .

Read Amplifier Board 10746-1

Timing & Data Board 10786-0

Interface Electronics.

INTRODUCTION

DAILY MAINTENANCE

YEARLY MAINTENANCE

Capstan Motor Lubrication

Drive Belt Replacement.

Lamp

Replacement.

. .

Actuator Adjustment . .

Electronics Checkout and

Adjustment.

Regulator Board

10790-0.

.

Read Amplifier Board 10746-1

Photosense Board 10972-0

3-

YEAR MAINTENANCE

Capstan Motor

Replacement.

.

Capstan Assembly Replacement .

Cooling Fan

Replacement.

. .

MAGNETIC HEAD MAINTENANCE

Head Alignment . .

Head

Wear

....

Head Replacement .

TROUBLESHOOTING.

"

CartriFile 40

Page.

4-1

4-1

4-1

4-2

4-3

4-3

4-3

4~3

4-4

4-4

4-4

4-4

4-5

4-6

4-6

4-6

4-8

4

...

8

4-8

4-8

4-11

4-11

5-1

5-2

5-2

5-2

5-2

5-2

5-2

5-3

5-4

5-4

5-4

5-5

5-5

5-5

5-5

5-6

5-6

5-8

5-9

5-9

CartriFile

40

Table

1-1

1-2

3-1

3-2

4-1

4-2

5-1

5-2

Figure

1-1

3-1

3-2

4-1

4-2

4-3

4-4

4-5

4-6

4-10

5-1

5-2

5-3

5-4

5-5

5-6

5-7

5-8

5-9

5-10

5-11

5-12

5-13

5-14

5-15

5-16

TABLES

Input Power . . .

Data Transfer Rates .

Write Clock Timing .

Read Clock Timing .

CartriFile 40 Mnemonics

Time Delay Adjustments

Maintenance Schedule

Problem Analysis. . .

Title

ILLUSTRATIONS

Title

Mounting Dimensions and Clearances

Write Timing Relationships

Read Timing Relationships

Write/Read Waveforms of 16-Bit Data Word 1010100110010101.

Tape Transport Mechanism

Photosense Assembly . . .

Write Operation Block Diagram

Write Timing Diagram . . .

Read Operation Block Diagram

Read Timing Diagram . .

Actuator Adjustment Points .

Read Amplifier

TP6.

. . .

Location of Electronics Assemblies, Connectors, and Terminals

Power Supply Terminals . . . . .

Head Alignment Checkout Waveforms.

Azimuth

Alignment.

.

Vertical Alignment . . . .

Head Adjustment Screws . .

Read Amplifier Board 10746-1

Timing & Data Board 10786-0

Motion Control 1 Board Assembly 10788-0

Regulator Board

10790-0.

. . .

Motion Control 2 Board

10968-0

.

Photosense & Lamp Board

10972-0

Actuator Driver Board

10974-0

.

Transport Board

10976-0.

. . .

TRI-DATA

Page

1-2

1-5

3-2

3-4

4-3

4-5

5-1

5-9

Page

1-3

3-2

3-3

4-1

4-2

4-4

4-6

4-7

4-9

4-10

5-2

5-3

5-3

5-6

5-7

5-8

5-8

5-8

5-11

5-12

5-13

5-14

5-15

5-16

5-17

5-18

v

TRJ-OATA

SECTION I

DESCRIPTION

INTRODUCTION

The CartriFile® 40 cartridge-loaded digital magnetic tape unit

is

used with small digital

computers, data terminals, and off-line data entry and readout stations. The

unit

contains

a four-cartridge tape transport, all necessary read/write electronics, and a power supply. Tri-Data 1000 series single-tape

cartridges are used

as

the recording medium. Each cartridge contains an endless-loop magnetic tape, with the photoreflective

load-point marker serving

to

indicate both the beginning and the end of the tape loop. The CartriFile 40 tape unit can

be loaded with one, two, three,

or

four cartridges in any slot

or

combination

of

slots.

CartriFile

40

tape units are available with interface electronics for

all

widely used minicomputers

or

with standard

interfacing for those who wish to build their own special interfaces. Details

of

the interface equipment supplied with

this CartriFile 40 tape unit are presented in the separate INTERFACE section in the front

of

this manual.

EQUIPM

ENT

The CartriFile 40 magnetic tape unit

is

supplied

in

a cabinet suitable for desk

or

table-top

DESCRIPTION

mounting. Four single-cartridges, an a-c power cable, and one copy

of

the CartriFile

Instruction Manual are supplied with each unit. In addition, either the standard interface equipment

or

interfacing for a

specific type of computer

is

furnished,

as

requested. Brackets for mounting the cabinet into a 19-inch equipment rack

are also supplied.

The major assemblies

of

the CartriFile 40 tape unit are the tape transport, the electronics, the power supply, the front

panel, and the cartridges. Descriptions

of

these assemblies are given below. Details

of

operation are given in Section III.

Tape Drive Assembly

The tape drive assembly contains the electromechanical

components for driving the tape, the read/write heads, the

load point sensors and buffers, the write driver amplifiers,

the read amplifiers, and the sensors for detecting proper

cartridge insertion and the write enabled status

of

the

individual tapes. The tape drive assembly

is

mounted

within the cabinet on a hinge

so

that

it can be swung

outward for servicing.

Tape drive occurs in a "forward only" direction and

is

accomplished by a constantly rotating capstan and a

pinchroller actuator. The actuator engages a pinchroller

. (located within the cartridge), clamping the tape against

the capstan. The tape

is

started, driven, and stopped by

energizing and de-energizing the actuator for

that

particular

tape. The four tapes are actuated independently.

The capstan drive motor operates from either

GO-Hz

or

50-Hz power; however, the pulley on the drive shaft

is

equipped with two drive belt grooves

to

accommodate

differences in operating speeds. Units sold domestically

are furnished with the drive belt positioned in the "GO-Hz"

groove; for 50-Hz operation, the pulley must

be

reversed

and the belt engaged with the

"50-Hz"

groove.

®CartriFile

is a

registered

trademark

of

Tri-Data

Corporation.

The front

of

the transport serves

as

a

mount

for

five

lamps and a power switch. The upper and lower lamps

light when the associated tape

is

in

motion. The center

lamp lights when power

is

supplied

to

the tape unit.The

lamps illuminate plastic buttons in the front panel. The

power switch

is

located below the cartridge slots;

it

is

provided

as

a servicing aid and

is

normally left in the

"on"

position.

Electronics Assembly

The electronics assembly card rack contains six printed

circuit boards and an extender board. The printed circuit

boards contain the read and write timing and signal

amplification circuits, data registers, and power regulation

circuits. The boards can be removed from the front of

the cabinet, and the extender board

is

provided

to

bring

any

of

the boards forward for servicing while the unit

is

operating.

Input/output

signals for the tape unit are run through a

single cable from the card cage

to

connector J3, which

is

normally mounted on the rear panel. An alternate

location for J3, toward the front

of

the cabinet, permits

.the installation of an interface circuit board within

the cabinet.

1-1

TRf-OATA

Power Supply

The power supply provides the power requirements

of

the tape unit from an a-c line source and also includes

a small fan for cooling the unit. The power supply

is

an

integral

part

of

the rear panel assembly, which

is

hinged

to

the cabinet frame and swings outward for access

to

power supply components.

The power supply operates at a line frequency

of

either 60

Hz

or 50 Hz. The input voltage can be either

105-125

v

ac

or 210-250 v ac, depending upon the setting

of

a

two-position slide switch mounted on the rear panel.

The primary power input connector, fuseholder, and fuse

are also located on the rear panel.

Connector

J2

on the rear panel

is

provided for optional

remote load-point search control.

By

grounding the

appropriate line through J2, a tape can be brought to

load

point

without a programmed instruction or other

command through the controller.

Front Panel

The front panel

is

attached

to

the CartriFile tape unit

by a stud and catch on each end. To remove the panel,

grasp the panel near the cartridge slot area and pull

outward. The front panel contains no operating controls.

Five plastic buttons to the right

of

the cartridge slots

are illuminated by transport-mounted lamps

to

indicate

"tape

in

motion"

and

"power-on".

Tape Cartridges

Each

1000

series cartridge contains a single endless-loop

tape. A photoreflective Load Point marker on the tape

determines the "beginning" and

"end"

of the tape. Write

lockout

is

provided on the cartridge by a Protect/Enable

switch.

An

integral slide cover encloses the tape completely

when the cartridge

is

not

in use. The front

of

each

cartridge has a surface suitable for writing file identification

information.

SPECI

FICA

TlONS

The specifications which follow include physical dimensions, environmental considerations,

and various operating and timing characteristics

of

the CartriFile

40

tape unit. Specifications

for the Tri-Data tape cartridges are also given. For specifications for the interface equipment supplied with this tape

unit, refer

to

the separate INTERFACE section at the front

of

this manual.

Physical Characteristics

Specifications for CartriFile

40

dimensions, environmental

conditions, power requirements, and connectors are given

below.

DIMENSIONS AND WEIGHT

External dimensions, mounting dimensions, and clearances

for the CartriFile

40

tape

unit

are shown in Figure

1-1.

The tape unit weighs approximately 34 pounds.

ENVIRONMENT

The CartriFile

40

tape unit will operate

in

an ambient

temperature range

of

+40°F to +110°F and

at

any relative

humidity between

20%

and 90% without condensation.

The

unit

will also operate

at

any altitude between sea

level and 10,000 feet.

INPUT

POWER

REQUIREMENTS

Maximum input power of 180 watts

is

required in any

of

four voltage frequency combinations. The CartriFile 40

tape unit

will

meet

all

specifications when the input

power

is

within the ranges given in Table

1-1.

1-2

Table

1-1.

Input

Power

VOLTAGE FREQUENCY

NOMINAL RANGE RANGE

115 vac, 60

Hz

105

vac

to 125

vac

57

Hz

to 63

Hz

115 vac, 50

Hz

105

vac

to

125

vac

47

Hz

to 53

Hz

230 vac, 60

Hz

210

vac

to

250

vac

57

Hz

to

63

Hz

230 vac, 50

Hz

210

vac

to

250

vac

47

Hz

to 53

Hz

INPUT/OUTPUT AND

POWER

CONNECTORS

Connector J3, for data and control inputs and outputs,

is

located

at

the left rear

of

the CartriFile

40

tape unit.

Detailed information on this connector and

the

signals

carried on the connector pins

is

presented in the separate

INTERF

ACE

section.

The power connector, J1,

is

recessed into the rear panel.

A power cord which mates with J1

is

supplied; its

opposite end

is

fitted with a standard male U-ground plug.

I-'

I

~

~

~

~

I-'

I

I-'

~

o

s::

:::l

0;

::s

!IO.

t:1

s"

(!)

::s

en

g"

en

§

c..

9

(!)

i

(!)

en

,------1

--,

1

1 I

I 1 1-3/4 1I

'I

r I

l-------~-------~

-------

--

--...,

1 1

1

1

\

\

\

\\\ \

9_

112

TAPE TRANSPORT

SWING-OUT CLEARANCE

\ \

"-

"-

"-

"

"-

"-

'-

'-

~-____t-I--

- - - - - --,

1 1

1 1

I 1000 SERIES :

I CARTRIDGE

I 1

I 1

I

I

1

L_--,

L-_--+-L

______

..J

1

1

1

1

----.

I

1

1

1

1

I

1

:----

TAPE TRANSPORT 1

r------.....J

1

1

1

I

_.-1

I 1

1 1

1 I

: I

I

I

I

I

I

I

POWER I

SUPPLY I

r>--.....

A-C

POWER

CABLE

:.------:3:--

I.~

------------------l

I I I

I

I

I

I

1

I

I

I

1

1

1

CLEARANCE

FOR

ELECTRONICS CARD

ON

EXTENDER BOARD

I 1

I ELECTRONICS 1

I CARD CAGE 1

I I

1

I 1 I 1

---

L

_________

_ L

_________________

~

L

___

~

1I\

110

CONNE~TOR

I

I

I ;

--------~--------,

C I'

Ii

r::=::::s

\

~

)

t~13/41-

SPECIAL

INTERFACE CARD

(NORMAL POSITION)

OPTIONAL

ADDITIONAL

CARD POSITIONS

r--

-

-----

---

I

I

I

I

I

I

I

I

CARTRIDGE

INSERTIONIREMOVAL

CLEARANCE

L

_______

,

__

_

....

1-3/4

...

)

RACK MOUNT

BRACKET

13-1/2

.1__

2-3/4_

-------1

I

1--

I

I I

I

~RACKMOUNT

i BRACKET

I

I

I

L_

-L

318

REMOVE

FEET

FOR

RACK MOUNTING

I

1

1

17

-

----

----------------,

13_1/

1

POWER SUPPLY

SWING-OUT CLEARANCE

/

./

./

/'

/'

/'

/'

/

/

/

/

/

/

/

/

/

/

/

!

/

/, ,

/

I

I

/

/

,

I

I

I

1131

Operational Characteristics

The following paragraphs describe the operational

characteristics

of

the CartriFile

40

tape unit: signal

levels, tape motion, data transfer rate and storage capacity,

and so forth.

INPUT/OUTPUT SIGNAL LEVELS

CartriFile

40

input

and output circuitry uses

Transistor-Transistor Logic (TTL), +2.5 to +5.0 v for

High

and

-0.5

to

+0.5 v for Low. Sink current requirements

for a Low input

will

not exceed 2 rna. The outputs can

supply 1 rna

at

minimum

High

voltage and can sink

10

ma

at

maximum Low voltage.

TAPE MOTION

The tape

is

driven at 10 inches per second in a

"forward"

direction in the three operating modes: Write Tape, Read

Tape, and Load-Point Search. "Reverse" or "backspace"

tape movement

is

not

possible.

RECORDING TECHNIQUE

The CartriFile

40

tape unit employs a bit-serial

phase-encoded, two-track recording technique with

record-error detection.

RECORD FORMAT

Records of sequential data words are written on the tape,

with the records separated by

gaps.

Each record may

contain any number of words,

as

determined by the

external control unit during writing.

The data words may contain 8, 12, or 16 bits. Either

8 or

12

bits-per-word formats may

be

program-selected

by the external control unit

or

fixed by wiring the select

input

to

ground

at

the interface. For 16 bpw,

no

ground

connection

is

required.

DATA TRANSFER

The data words are transferred in and out bit-parallel.

The data are written on the tapes bit-serial, with internal

circuitry making the parallel-to-serial conversion during

Writing and the serial-to-parallel conversion during Reading.

The using external control unit (e.g., digital computer)

has wide latitude in servicing the data transfers during

both

Writing and Reading. During Writing, a Write Data

Clock pulse

output

occurs

at

a fixed rate; the using control

unit has the major portion

of

the period between each

Data Clock

to

input

the data word with a Write Data

Transfer

input

pulse. During Reading, the data outputs

may be sampled by the external control unit at any time

1-4

during the major portion

of

the period between Read

Clock pulse outputs. Precise timing for the data transfers

is

given in Section III, OPERATION.

INTER-RECORD

GAPS

In Writing each record, a Write Start delay

of

16 msec

and a Write Stop delay

of

8 msec accommodate the

start-

and stop-tape motion transients and provide the

time for writing a 0.16-inch (maximum length) inter-record

gap. Internal circuitry times both delays and controls the

tape motion and gap writing.

After reading each record, internal circuitry recognizes

the inter-record

gap

remaining

to

accommodate the start

transient prior to reading the next record. The Read

Start and Read Stop delays are 9.5 msec and 4.75 msec,

respectively.

BEGINNING-OF-TAPE AND END-OF-TAPE

A 3-inch long photoreflective Load Point marker affixed

to the continuous-loop tape marks both the beginning

and the end

of

the tape. Each tape passes a photosensor

before reaching the magnetic head; the 1.45-inch separation

between the photosensorand head provides for the following

beginning-of-tape timing and end-of-tape warning.

On

writing the first record on a tape, a Write Start delay

of 375 msec

is

initiated after the Load Point marker passes

the photosensor

to

assure adequate beginning-of-tape

gap. The resulting total Write Start or Read Start delay

for the first record

is

therefore between 375 and 675

msec, depending upon the exact Load Point position

of

the tape when the Start Command

input

occurs.

An

end-of-tape warning

is

provided during Writing when

the leading edge of-the marker passes under the photosensor

and causes the Load Point status line for the tape to

go

True.

When

this occurs, 1.2 inches of the tape (up to

180

8-bit

words) may be written before a Write Stop

Command

is

mandatory.

DATA TRANSFER RATE

The bit rate

is

18,000 bits per second, recording 900

bits

to

the inch (at

10

inches per second) on two tracks.

The written tape format

is

bit-serial, and a Start bit

is

added to each half-word prior

to

writing

it

on

the tape.

The transfer rate during either writing or reading

is

therefore:

18,000

Transfer Rate =

B+2

words per second,

where B

is

the number

of

data bits in each word

at

the

data input and data

output

(Table 1-2).

Table

1-2.

Data Transfer Rates

Word Length Peak Transfer Rate

8 bits 1800 words/second

12 bits 1286 words/second

16 bits 1000 words/second

DATA

TRANSFER

TIME

PER

RECORD

When

writing records

at

the maximum rate, the elapsed

time for each record

is

Time per record

where B

N

0.025

(B +

2)N

18,000 + 0.025 second,

data bits per word

record length in words, and

the sum

of

the Write

Start

and Write

Stop delays,

with the exception

that

an additional

0.375-

to 0.675-sec

Write Start delay occurs

at

the beginning

of

each tape.

When reading records

at

the maximum rate, the elapsed

time for each record

is

(B +

2)N

Time per record = 18,000 + 0.020 second,

where B

N

0.020

data bits per word (8, 12,

or

16),

record length in words, and

the sum

of

the Read

Start

and Read

Stop delays,

with the exception

that

an additional

0.375-

to

0.675-sec

Read Start delay occurs at the beginning

of

each tape.

LOAD-POINT

SEARCH TIME

Upon receipt

of

a Load-Point Search command input,

the tape

is

advanced

at

10 inches per second until the

Load Point marker

is

reached. Load-Point Search time

is

directly proportional to the length

of

tape remaining

on the tape loop

at

the time

of

the Load-Point Search

command input.

L

Load-Point Search Time = 10 seconds,

where L

is

the length

of

tape remaining (in inches).

Average search time for a

150-foot

file

is

90 seconds.

TRI-OATA

DATA

STORAGE CAPACITY

The data storage capacity on each tape varies with the

bits-per-word and words-per-record format written and

the length

of

the tape. The total storage available

in

the

unit without reloading

is

the capacity

of

the four tapes

with which it

is

loaded. The tape length required per

record

is

(B +

2)N

Tape length per record = 2 x 900 + 0.16 inch,

where B

N

900

0.16

data bits per word,

words per record,

CartriFile recording density in bits

per inch, and

inter-record

gap

(maximum).

The tape length required

to

store a number

of

records

is

the sum

of

the lengths required for each record plus

3 inches for the Load Point marker and initial record

gap.

For

fixed record lengths, the capacity

of

a tape in

records

is

. Total inches tape - 3 inches

Record capaCIty = Inches Tape per Record

The capacity in words

is

the capacity in records times

the words per record.

For

data in 1,000-character records,

the capacity

of

a

150-foot

tape

is

300,000

8-bit

words.

System capacity for the same data

is

1,200,000

8-bit

words.

1000

Series Tape Cartridges

Tape Length

Size

File Protect

Tape

Certification

Model 1010:

Model 1025:

Model 1050:

Model 1150:

10

feet

25 feet

50 feet

150

feet

4 inches wide by 6 inches long

by

7/8

inches thick.

Self-locking switch with integral

position indicator.

Endless loop

of

1/4-inch

wide

computer-grade magnetic tape. One

per cartridge.

Tape

is

tested and certified

error-free.

1-5

TRf-OATA

SECTION II

INSTALLATION

GENERAL

The CartriFile 40 tape unit shipment consists

of

the tape

unit

itself, four

1000

Series

single-tape cartridges, one Instruction Manual, an a-c power cord,

and

interface equipment.

Brackets and hardware for rack mounting are also included. The interface equipment shipped depends

on

the type

of

interface ordered. Refer

to

the INTERFACE section for information on the equipmentsupplies and installation instructions.

Be

certain

that

all parts have been unpacked before discarding

the

packing material.

INST

AL

LA

TION The CartriFile 40 tape unit

is

designed for operation

at

sites

that

are

not

subject

to

shock,

vibration, or wide ranges

of

ambient temperature. The CartriFile cabinet

is

suitable for placing

on a desk or table top. Brackets for mounting the cabinet

into

a standard 19-inch rack are included. In either case, the unit

should be

mounted

to

provide access

to

the front and rear

of

the cabinet. Installation consists

of

placing the

unit

in its

selected location and making the power and interface connections.

Table-Top

Placement

If

the CartriFile tape

unit

is

to

be positioned on a desk

or

table top, the only requirements are a level surface, a

location close enough

to

the

computer

or controlling

device

to

provide for safe installation

of

the connecting

cables and the power cord, and availability

of

access

to

the front

of

the cabinet for cartridge insertion and removal.

Access

to

the rear

of

the cabinet

is

necessary only for

cable installation and for servicing.

Four

rubber feet are

provided

on

the

bottom

of

the cabinet

to

prevent marring

the mounting surface.

Rack

Mounting

The CartriFile 40 cabinet requires 7 inches

of

vertical

space in a standard 19-inch equipment rack. In addition,

the

10404-0

Rack Mount Adapter Assembly (two brackets

and

two covers, plus hardware) must be installed

on

the

cabinet. Installation

is

as

follows.

1.

Two

1/4-20

socket drive set screws are located near

the front

of

each side panel on the cabinet. Carefully

remove enough paint

to

insert a

l/S-inch

hex key and

withdraw the set screws.

2.

Note

that

there

is

a

left-hand

and a right-hand

bracket. Install each one

on

its matching side panel using

the

1/4-20

hardware provided.

3.

Remove the four rubber feet from the

bottom

of

the cabinet, then

mount

the cabinet in the equipment

rack.

4. Install the

rack-mount

covers by engaging the lip

with the

bottom

of

the bracket.

Lift

up against the spring,

push in at the top, then release. The spring will pull

the cover down, engaging the pin

at

the top.

Power Connection

CAUTION

The CartriFile tape

unit

may be operated

at

115 v nominal or

at

230 v nominal.

To avoid damaging the equipment, the

line selector slide switch on the rear

panel must be in

the

proper position

before connecting power

to

the tape unit.

An a-c power switch

is

located behind the

front

panel

below the cartridge slots on the transport. This switch

is

normally left in the

"on"

position so

that

power

is

applied when the power cable is connected.

Connect the female end

of

the

a-c power

cord

to

the

recessed power receptacle, J1,

on

the rear panel. The

male end

of

the power

cord

connects

to

any standard

V-ground receptacle.

The CartriFile power supply will operate

at

a line frequency

of

50

Hz

to

60 Hz. The capstan drive

motor

will also

operate

at

either frequency,

but

pulley diameters

must

be

changed

to

accommodate the differences in rotational

speed. The pulley on the

motor

shaft

is

provided with

two grooves for the drive belt: units sold domestically

are furnished with the belt positioned on the 60-Hz

2-1

TRI-DATA

(smaller diameter) pulley groove. The change from 60-Hz

to

50-Hz operation

is

made

as

follows.

1.

Remove the front panel by reaching through a

cartridge slot, grasping the panel, and pulling outward.

The front panel

is

held by two spring catches, one

at

the

extreme left center and one

at

the extreme right center.

2.

Remove the transport retaining screw (above the

upper right-hand corner

of

the transport), and swing the

transport outward on its hinge.

3. Disengage the drive belt from the groove in the

small pulley, then withdraw it over the capstan flywheel.

4. Loosen the two set screws in the

motor

pulley

with a 0.050-inch hex key. Remove the pulley from the

motor

shaft.

5. Reverse the pulley and place

it

back

on

the shaft.

Align the large diameter (50-Hz) pulley groove with the

groove in the capstan flywheel, then tighten the two set

screws securely.

6. Install the drive belt first

in

the flywheel groove,

then stretch

it

gently and engage it in the groove in the

large pulley.

7.

Swing the transport back into the cabinet, install

the transport retaining screw, and snap the front panel

onto

the cabinet.

2-2

Grounding

On the CartriFile rear panel are two ground terminals,

SIGNAL and CHASSIS. The tape

unit

is

shipped with these

terminals tied together. Depending

on

system grounding

requirements, the jumper can be removed from these

terminals; however, CartriFile SIGNAL and CHASSIS

grounds must be connected together

at

some

point

in

the system.

Remote Load-Point

Search

Control

Connector

J2

on

the

CartriFile rear panel provides for

optional remote control

of

the Load-Point Search operation.

Supplying a ground through the mating plug (Switchcraft

12CL5M), switches tape 1 (pin 1), tape 2 (pin 2), tape 3

(pin 3),

or

tape 4 (pin 4)

into

the Load-Point Search

mode. (Pin 5

is

ground.) The mating plug may be ordered

through Tri-Data

as

part

no. 00021':'015.

Interface Connections

Installation

of

the interface equipment supplied with

the CartriFile

40

tape

unit

is

presented in the separate

INTERFACE section in the front

of

this manual. Interface

equipment manufactured by Tri-Data Corporation can

be used in the various CartriFile models: when referring

to

the INTERFACE section, note

that

the information

presented covers the CartriFile

40

tape

unit

and the other

CartriFilemodels which use the same interface equipment.

SECTION

III

OPERATION

INTRODUCTION

The CartriFile

40

tape

unit

operates automatically

under

the control

of

a data processing

system. Under Automatic control, the data processing

or

controlling system may command

the CartriFile tape

unit

to

Read, Write, or Load-Point Search its tapes. (Refer to Section I for limitations regarding

such commands.) Manual operations are limited

to

inserting and removing the tape cartridges.

CONTROLS

AND

The CartriFile

40

front panel contains

five

plastic indicator

buttons

which are lighted,

IN

DI

CA

TO

RS

from behind by lamps mounted on the tape transport. The

upper

and lower (white) indicators

are lighted whenever the associated tape

is

"busy",

i.e., in motion during a Read, Write, or Load-Point Search operation.

The center (red) indicator

is

lighted whenever power

is

applied

to

the CartriFile tape unit.

An a-c power switch

is

located behind the front panel below the cartridge slots on the transport. This switch

is

primarily

a service aid and

is

normally left in the

"on"

position. On the rear panel, provision

is

made for optional remote control

of Load-Point Search operations through connector J2.

Application

of

Power

Connect the a-c power cable

to

a power outlet and check

that

the transport power switch, located below the

cartridge slots,

is

in the

"on"

position. The center

indicator on the front panel will light (red) when power

is

applied.

,Cartridge Insertion

and

Removal

Before inserting a cartridge, move the cover door to its

recessed position and set the Protect/Enable switch

appropriately.

When

the cartridge switch indicates

PROTECT, the tape

is

file-protected. Moving the switch

in and to the right sets the switch in the ENABLE

position, permitting data

to

be written on the tape. A

plastic switch lock can be inserted on the

top

of

the slide

switch

to

keep the switch from being accidentally moved.

Slide the cartridge into the cartridge slot until it seats.

To remove the cartridge, simply pull outward.

If

the

cartridge

is

not

to be used again immediately, slide the

cover door

out

and across the open end to exclude dust

and other contaminants from the tape and pinchroller.

Remote Load-Point Search Control

Connector

J2

on the CartriFile rear panel

is

provided for

optional remote control

of

Load-Point Search, an operation

normally initiated

by

command from the data handling

system. Grounding the appropriate line

(J2-1

for tape 1,

J2-2

for tape 2,

J2-3

for tape 3,

J2-4

for tape 4) places

the tape

in

the Load-Point Search mode.

AUTOMATIC

The automatic operations initiated by commands from the data processing system include

OP

E

RA

T

IONS

the Write sequence and timing, the Read sequence and timing, and the Load-Point Search

sequence. These operations and the bits-per-word format selection are described in the paragraphs which follow. The

CartriFile

40

tape

unit

operates in either the Write mode

or

the Read mode for only one selected tape

at

a time. The

Load-Point Search mode can be initiated for any tape

at

any time.

Write Sequence

and

Timing

Figure

3-1

shows the time relationships

of

input

and

output signals associated with writing a record on a tape.

Only one tape can

be

processed

at

a time. With the Write

Select Tape (1, 2, 3,

or

4)

input

True, a Write Start

input

pulse commits the selected tape

to

write a record. The

Write Mode and Busy (1,

2,

3, or 4) status lines

go

True

at

the initiation

of

the pulse. At the fall

of

the pulse,

the tape drive circuits are enabled and an internal Write

Start delay

is

initiated.

A Write Clock

output

pulse occurs 16 msec after the

fall

of

the Write Start

input

pulse (the delay

is

between

375 and 675 msec

at

the beginning

of

each tape), and

subsequent Write Clock outputs occur

at

a fixed rate

until a Write Stop

input

pulse

is

received.

3-1

TRI-DATA

TAPE

SELECT

WRITE START

(WSTC)

TAPE BUSY

WRITE MODE

+5V

OV

WRITE CLOCK

(RWCL)

~

-

-

-

WRITE WORD

TRAN

(WXFR)

SFER

DATA BITS (DBT)

WRITE STOP

(WSPC)

w---

r

A

W r

.I

,

,

16

msec, except at

beginning

of

tape:

375 to 675 msec

1

WXFR -r

BPW

PERIOD

8 0.4 msec

12 0.5

msec

16 0.8

msec.r

r

'1'

-

OV

'0'

-

+5V

A

,

,

Ji

r

.A

, ......---

A

'r

r---

A

.,

BPW

RWCL PERIOD

8 0.56 msec

__

8msec_

12 0.78 msec

16 1.00 msec

.A

W W W W r

C\

.1

.A

t:1WA

v/A~

WdLJ

V///hi

,

t%'WORD

OJ

VWORD/j

VWOR~

.A

J

'L/AVLl

,

Figure 3-1. Write Timing Relationships

After each Write Clock

output

pulse, either a Write

Word Transfer

input

pulse or a Write Stop input pulse

must occur within a fixed time period (as listed in

Table 3-1),

or

else the last previously transferred data

word

will

be repeated on the tape. A Write Word

Transfer input pulse will set the data input registers

being used

to

a

"1"

or

"0"

state, determined by whether

the data bit inputs are

ONE

or ZERO at the time the

Write Word Transfer pulse occurs. At the end

of

the fixed

period, if a Write Stop input pulse has not been received,

internal circuitry samples the input registers

and

transfers

the data

to

a parallel-to-serial converter.

As

the data are

written on the tape from the converter, the

input

register

is

ready

to

accept the next data word.

Table 3-1. Write Clock Timing

TIME SPAN FOR WRITE

WORD

TRANSFER OR WRITE STOP

TIME BETWEEN WRITE INPUT INSERTION

BITS-PER-WORD SELECTION CLOCK OUTPUTS FOLLOWING WRITE

CLOCK OUTPUT

8 bits 0.56 msec 0.4 msec

12

bits 0.78 msec 0.6 msec

16 bits 1.00 msec 0.8 msec

3-2

A Write Stop input commits the tape

that

is

writing to

terminate the record and stop. Further Write Clock

outputs are inhibited.

At

the time

at

which the next Write

Clock would have occurred had the Write Stop input

not

occurred, the tape drive circuitry

is

de-energized and

an internal 8-msec assurance time delay

is

initiated.

At

the

end

of

this delay, the Write Mode and Busy status

lines

go

False.

An

exception

to

this happens when

a Load-Point Search input occurs while the record

is

being written:

at

the completion

of

the record, the Busy

status line will remain True and a Load-Point Search

operation will begin immediately. The Write Mode status

will

go

False.

Note

that

the CartriFile

40

tape

unit

can be operated

as

a Write Only unit by removal

of

the Read Amplifier

circuit board. Removing this board inhibits the Read

Start command.

TAPE

SELECT

READ

START

(RSTC)

TAPE BUSY

READ MODE

READ CLOCK

(RWCL)

DATA BITS

(DBT)

+5V

OV

(MAY

BE

SAMPLED

AT ANY TIME BETWE

RWCL RISE AND NEX

=::L

-

-

-

EN

TFALL

U

__

y

-A

W y

A

Y

~

Y

16 msec, except

at

~

beginning

of

tape:

375 to 675 msec.

.A

r

'1'

~OV

'0'

= +5V

I%'

WORD

/:

r

U-

TRI-DATA

Read

Sequence and

Timing

Figure

3-2

shows the time relationships

of

the

input

and

output

signals associated with reading a record from the

tape.

With the Read Select Tape (1, 2, 3,

or

4)

input

True, a

Read Start

input

pulse commits the tape to read a record.

The Read Mode and Busy (1, 2, 3,

or

4) status lines go True

at

the initiation

of

the pulse.

At

the fall

of

the

pulse,

the tape drive circuits are enabled and an internal Read

Start delay

is

initiated.

The first data word

is

encountered and read from the

tape approximately 16 msec after the fall

of

the

Read

Start

input pulse

(at

the beginning

of

the tape,

the

delay

will be between 375 and 675 msec). Subsequent Read

Clock

outputs

occur

as

each data word

is

read from the

A

r

A

r

I---

.4

~r

I---

.4

y

BPW

RWCL PERIOD

8 -0.56 msec

12 -0.78 msec

16 -1.00 msec

J

U-

W y

~W9RD

:/

!«'WORDX

V,/;

WORD

//.

A

----

f--

""

0.5 msec ,

~

INTER-RECORD

GAP

~

3 msec

DETECTED I

INTERNALLY

I

Figure

3-2.

Read Timing Relationships

3-3

TRI-OATA

tape. The data bit outputs will be ONE or ZERO,

representing the word read from the tape continuously

from the time

of

the fall

of

the Read Clock

output

pulse until the time

of

the next Read Clock

output

pulse.

When the last word

of

the record has been read, internal

circuitry recognizes the absence

of

data in the inter-record

gap

and de-energizes the tape drive. After a 4.75-msec

delay, the Read Mode and Busy status lines

go

True.

An exception

to

this happens when a Load-Point Search

input occurs while the record

is

being read:

at

the

completion

of

the record, the Busy status line will

remain True and a Load-Point Search operation will

begin immediately. The Read Mode status will

go

False.

If

an error has been detected, the Record Error

output

goes True

at

the time

of

the Read Clock output and

remains True until the Read Start Command for the next

record occurs,

at

which time Record Error

is

reset to False.

Read

Timing Variations

The 16-msec Read Start Delay and the times between

Read Clock outputs (shown in Figure

3-2,

in Table 3-2,

and in Section

I)

are determined by times

at

which data

are read from the tape; they are therefore varied by

all

conditions

that

change the tape length or the tape speed

between writing and reading the data. The CartriFile

has adequate margin

to

operate normally with the Read

tape speed departing from the Write tape speed by

as

much

as

±20%.

Table 3-2. Read Clock Timing

BITS-PER-WORD NOMINAL TIME BETWEEN

SELECTION READ CLOCK OUTPUTS

8 0.56 msec

12

0.78 msec

16

1.00

msec

Load-Point

Search

and

Status

A Load-Point Search

input

pulse normally causes one

of

three actions on the tape and its status outputs.

If

the tape

is

at

Load Point when the Load-Point Search

input occurs, no tape motion results.

It

is

recommended

however,

that

a Load-Point Search command always be

given

to

a newly loaded tape for

the

following reason:

the

output

of

a flip-flop

in

the Load Point circuitry

3-4

determines whether a normal (short) start delay

or

a Load

Point (long) start delay will be initiated. The short delay

is

used during normal writing

or

reading. The

output

of

this flip-flop may

be

set such that a normal (short)

start delay will be actuated even though a new cartridge

tape which

is

already at Load Point

has

been inserted

and the long start delay

is

required to clear the Load

Point Marker. A Load-Point Search command, however,

will reset the flip-flop so

that

the long start delay will

be

actuated.

If

the tape

is

not

at

Load Point and

not

being written

or

read when the Load Point Search

input

occurs, a

Load Point Search sequence results. The Busy status

output

goes True, and the tape

is

advanced until

it

reaches its Load Point.

At

Load Point, the tape stops and

the Busy status

output

goes False.

If

the tape

is

being written

or

read when the Load

Point Search

input

occurs, writing

or

reading will continue

until the record

is

completed. Then the Load-Point

Search sequence described above will occur.

The Load Point status

output

is

True when the tape

is

at

Load Point and False when

it

is

not.

Bits-Per-Word Format Selection

The data

input

and

output

registers provide for up to

16 parallel data bits in each word. The internal circuitry

is

set by the Bits-Per-Word Select inputs

to

write and

read

8-bit

parallel data words using only the first 8 data

bit inputs and outputs, or for

12-bit

parallel words using

the first 12, or for

16-bit

parallel words using all 16.

The word transfer rate for each bits-per-word format

is

a different constant since the data are written on the

tapes bit-serially

at

a constant

bit

rate.

If

the bits-per-word format

to

be used in a particular

CartriFiIe installation

is

to

be fixed, the Bits-Per-Word

Select input may be pre-wired

at

the interface for the

format used.

If

the bits-per-word format

is

selected under

program control:

The Bits-Per-Word Select

input

must

be

held True

during writing a record from the time

of

initiation

of

the

Write Start pulse until the record

is

complete.

The Bits-Per-Word Select

input

must be held True

during reading a record from the time

of

initiation

of

the

Read

Start

pulse until the record has been completed,

and the select input must be the same

as

that

used in

writing the record.

TRI-OATA

SECTION

IV

THEORY OF OPERATION

GENERAL The CartriFile 40 tape unit consists essentially

of

a tape transport mechanism for driving

four magnetic tapes, tape motion control logic, Read/Write electronics, and power supplies.

In this section, the recording technique and the tape transport are discussed first, followed by circuit descriptions for

all

of

the circuit boards within the tape unit. Interface circuit boards are discussed in the separate INTERFACE section.

In

general, the CartriFile 40 tape unit performs three basic operations: writing data, reading recorded data, and searching

for the Load Point marker. In a Write operation, after tape motion

is

initiated, input data bits in parallel form are converted

to serial form, phase-encoded, and recorded on the tape on two tracks. At the end of a record, tape motion

is

stopped

by command. In a Read operation, tape motion

is

initiated, and flux transitions on the tape are detected. Timing is

reconstructed and the data assembled bit by bit. There

is

also error detection.

When

a word

is

completely assembled in a

register,

it

is

made available for strobing

out

in parallel form. Detection of the inter-record gap automatically stops tape

motion.

When

Load-Point searching, the selected tape

is

driven forward until a photoreflective marker attached to the tape

loop

is

sensed, generating a signal which stops tape motion.

RECORDING The recording technique used in the CartriFile 40 tape unit

is

the phase-encoded,

TECHNI

au

E non-return-to-zero type, which

is

self-clocking. Figure

4-1

shows the recording and playback

waveforms

of

a

16-bit

data word. Data "ones" are recorded

as

positive transitions and "zeros"

as

negative transitions.

Note that there

is

always a transition at data times, and a half-cell transition occurs only if the next data cell hasthe

same data value. The half-cell transition

is

opposite to the next data cell value.

DATA

CELL

I i 1 I

VALUE

ISYNC 1 I 1 I 0 I 1 o I 0 I 0

CHANNEL

A . I I I I I I I

________

+H

CHANNEL

B

WRITE

DATA

...,

Mag.

Field

l:iJ

CHANNEL

A

READ

DATA

(emf)

CHANNEL

B

READ

DATA

(emf)"

r

r:

I s I I I

I y I 0 I I

I N I 0 0 I

·1

0

c

I I I I

-------+H

L..-

__

....,~(f-r

_ .....f:

I I

~

1/2

CELL

TRANSITION

(SAMPLE)I

I

~DATATRANSITION

I

141'----

SYNC

TRANSITION

I

I I

1 I

________

+V

--------v

-------+v

_____

-V

Figure

4-1.

Write/Read Waveforms

of

16~Bit

Data Word 1010100110010101

4-1

TRI-DATA

Information

is

recorded on the tape in serial-bit form

at

900 bits per inch on two tracks, designated channel A and channel

B.

The data word

is

broken into two half-words: the odd-numbered bits are recorded on channel

A,

the even-numbered

bits on channel

B.

The channels are independent

of

each other, except

at

the start of each word when both tracks are

made to record a "one". The detection

of

this .first positive transition

is

used

as

a

"start"

bit for timing purposes during

reading.

TAPE The Tape Transport consists

of

the capstan and drive motor, two pinchroller actuator

TRANSPORT

assemblies, two actuator drivers, and Read/Write head assemblies, Write drivers, Read

preamplifiers, and Load Point sensing circuits. The electronics associated with the Tape Transport

are

located on three circuit

boards mounted to the transport frame. The pinchroller.

is

part of the cartridge itself and

is

mechanically coupled to the

pinchroller arm when the cartridge

is

inserted into the transport. A Protect/Enable switch for the tape and a cartridge-insert

switch for each cartridge are used for interlocking and status indications.

When

power

is

applied

to

the tape unit, an a-c motor continuously drives the capstan (Figure 4-2). Each cartridge

contains a continuous-loop tape which passes in front of its pinchroller. The solenoid-actuated arm, engaged with the

pinchroller, pulls the pinchroller againstthe capstan, forcing the tape against the capstan.

While

in contact with the

capstan, the tape

is

driven

at

10

inches per second. In this manner, the tape

is

pulled past a two-track magnetic head

assembly. (The same head

is

used for both Read and Write functions.)

4-2

TAPE

PACK

ARMATURE-

PINCHROLLER ARM

R/WHEAD

SOLENOID

CARTRIDGE

Figure 4-2. Tape Transport Mechanism

PINCHROLLER

CAPSTAN

A-CMOTOR

TRI-DATA

CI RCU IT The electronic operation

of

the CartriFile 40 tape

unit

is

described below under four major

OPERATION

'divisions: Power Supplies, Motion Control, Write Electronics, and Read Electronics. The

circuitry

is

contained primarily on six printed circuit boards

in

the card cage and two printed circuit boards

mounted

on the transport. The transport frame also mounts the photosense circuit board and the tape motion indicator lamps.

The power supply chassis

is

located on the hinged rear panel. In tracing some

of

the functional operations, it

is

necessary

to follow signal paths on several

of

the schematics; the schematics carry the assembly numbers of the circuit boards and

are located in Section VI. The overall interconnection diagram

is

schematic 99005.

The logic circuits used throughout are TTL and DTL types. Logic operation

is

described in terms of Positive Logic, where

a high

is

+2.5

to

+5

volts and a low

is

-0.5

to

+0.5 volts. CartriFile mnemonics for the signals are listed in Table 4-1.

A bar over the mnemonic on a signal line indicates

that

the

"true"

level

is

low for

that

function. Integrated circuit gates

are shown as NAND gates on the schematics. References to logic sections

of

an integrated circuit package are made by

package number and

output

pin: for example, ML4-6 designates pin 6

of

package ML4.

Table

4-1.

CartriFile 40 Mnemonics

MNEMONIC FUNCTION

BPW

8,

12

Bits per word select (8

or

12)

CISW

(X) Cartridge insert switch (tape

X)

DBT (1-16) Data

bit

(1

through 16)

FPSW

(X) File-protect switch (tape

X)

FWD

(X) Forward drive (tape

X)

HSLD (X) Head (X) selected for write

or

read

LPA (X) Load Point attained (tape X)

LPSC Load-Point Search command

PSN

(X) Photosensor for tape (X)

RDCL Read data clock

RESET Resets certain circuits

at

power-on

RERR Record error

RM

Read mode

RSLD (X) Read selected (tape

X)

RSTC Read Start command

RWCL

Read or Write clock

TSLP Tape selected

is

at

Load Point

T(X)BY Tape (X) busy

T(X)FP Tape (X) file-protected

T(X)LP Tape (X)

at

Load Point

T(X)OL Tape (X) on line

T(X)SL Tape (X) select

T(X)SM Tape (X) in Search mode

WDCL

Write clock

WM

Write mode

WSLD

(X) Write selected (tape

X)

WSPC

Write Stop command

WSTC

Write Start command

WXFR Write word transfer

(X) indicates tape 1,

2,

3, or 4

Power Supplies

All

the necessary power for the internal operation

of

the

tape unit and, in some cases, power for external interface

circuitry

is

supplied by two units, the Power Supply and

the Regulator board.

POWER

SUPPLY 10947-1

Incoming a-c power

is

applied

to

transformer T1 through

a switch on the

front

of

the transport. Switch

Sl

is

used for changing the T1 primaries from parallel

to

series

connection when the a-c

input

is

230 v

ac

instead

of115

v ac. Three

of

the four secondaries

of

T1 connect to

full-wave rectifier-capacitor circuits

to

supply the +15

v,

-15

v,

and

+5

v regulators. The +30 v unregulated supply

is

used for the pinchroller actuators and

load-point

lamp

regulator.

B1

is

a fan (115

v)

placed across one

of

the

T1 primaries.

REGULATOR BOARD 10790-0

The Regulator board contains the circuitry for power

regulation and Reset control and some circuits associated

with the Write Clock and Load-Point Search functions.

With power off, the normally

off

contact

of

K1

grounds

the Reset line. When power

is

applied initially, a 100-msec

delay occurs before the Reset line

is

switched

to

"high".

The delay results from

C1

charging up to

10

volts (set

by Zener diode CR3),

at

which

point

Q1, Q2 turns on

and energizes K1.

ML18, ML19, and ML17 and associated components

are series regulators for the +5

v,

+15

v,

and

-15

v supplies,

respectively. The regulators are current-limited

by

R23,

R22, and R24, with the

output

voltages adjusted by

potentiometers R20, R13, and R16.

Q3

and Q4 are used

to turn

off

the 15 v supplies rapidly to avoid Write

transients when power

is

turned off. The falling of the

+5

v supply turns off Q3, allowing Q4 to

turn

on (since

the unregulated +20 v remains high for a longer period),

thereby switching

off

the 15 v regulators through CR5

and CR6.

4-3

Table of contents

Popular Storage manuals by other brands

Apacer Technology

Apacer Technology AH190 user manual

Hitachi

Hitachi Freedom Storage Lightning 9900 V series Error code list

Seagate

Seagate Medalist Pro Family product manual

LaCie

LaCie 301460KUA - 320GB USB 2.0 LaCinema Rugged Multimedia Hard... user manual

Integra

Integra HDR-1 instruction manual

Vivanco

Vivanco N 23430 user manual

Quantum

Quantum DLTtape SDLT 600 quick start guide

Marantz

Marantz PMD620 user guide

Panasonic

Panasonic RP-SDUB08GAK operating instructions

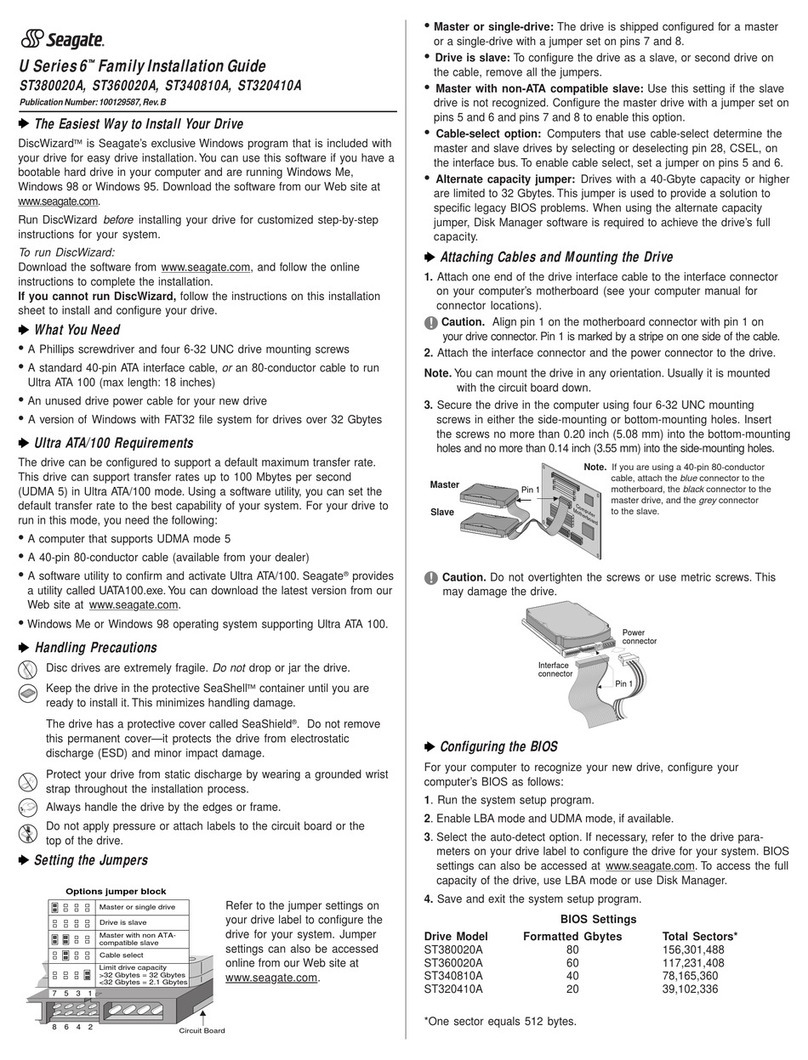

Seagate

Seagate ST380020A installation guide

Stardom

Stardom SR2-B31 Quick setup guide

Western Digital

Western Digital WD1200B05RNN - 120 GB External Hard Drive user manual