Tri-sure Pneumatic Tab-Seal User manual

1

Issued by: Arnold Bos / www.tri-sure.com Issue no.: MAN-1000029 Version: 2Date: 11-02-2015

Trade-marks

Tri-Sure® metal closures, Tri-Sure® plastic

closures, Tab-Seal® caps, SambaCapTM,

UNI-GRIP® spouts, ULTRA-BOND® spouts,

PLASTIPLUGTM plugs, Push-LockTM caps,

PLASTICAPTM screw caps, PLASTIROB®

taps, CDS® dispense closures

Disclaimer: all information on our behalf in relation to our products, whether in nature of date, recommendations or otherwise, is supported by research and believed reliable, but we assume no liability

whatsoever in respect of application, processing or use made of the aforementioned information or products or any consequence thereof. The user undertakes all liability in respect of the application.

Processing or use of the aforementioned information or products, whose quality and other properties he shall verify, or any consequence thereof. No liability whatsoever shall attach to us for any

infringement of the rights owned or controlled by a third party on intellectual, industrial or other property by reason of the application, processing or use of the aforementioned information or products by

the user.

Pneumatic Tab-Seal®Cap Closing tools,

Pneumatische Tab-Seal®Cap sluitapparaten,

Pneumatische Tab-Seal®Kapselverschlussgeräte,

Appareils pneumatique a sertir les Capsules Tab-Seal®,

INSTALLATION- AND OPERATING INSTRUCTIONS

MONTAGE- EN BEDIENINGSVOORSCHRIFT

INSTALLATIONS- UND GEBRAUCHSANWEISUNG

INSTRUCTIONS D'INSTALLATION ET D'UTILISATION

2

Issued by: Arnold Bos / www.tri-sure.com Issue no.: MAN-1000029 Version: 2Date: 11-02-2015

Trade-marks

Tri-Sure® metal closures, Tri-Sure® plastic

closures, Tab-Seal® caps, SambaCapTM,

UNI-GRIP® spouts, ULTRA-BOND® spouts,

PLASTIPLUGTM plugs, Push-LockTM caps,

PLASTICAPTM screw caps, PLASTIROB®

taps, CDS® dispense closures

Disclaimer: all information on our behalf in relation to our products, whether in nature of date, recommendations or otherwise, is supported by research and believed reliable, but we assume no liability

whatsoever in respect of application, processing or use made of the aforementioned information or products or any consequence thereof. The user undertakes all liability in respect of the application.

Processing or use of the aforementioned information or products, whose quality and other properties he shall verify, or any consequence thereof. No liability whatsoever shall attach to us for any

infringement of the rights owned or controlled by a third party on intellectual, industrial or other property by reason of the application, processing or use of the aforementioned information or products by

the user.

Table of Contents

GENERAL INFORMATION 3

APPLICATION OF TRI-SURE®PNEUMATIC CLOSING TOOLS 6

LUBRICATION OF TRI-SURE®PNEUMATIC CLOSING TOOLS 7

INSTALLATION- AND OPERATING INSTRUCTIONS 8

ENGLISH /ENGLISH 8

DUTCH /NEDERLANDS 9

GERMAN /DEUTSH 10

FRENCH /FRANÇAIS 11

CHINESE /中国 12

RUSSIAN /PУССКИЙ 13

SPANISH /ESPAÑOL 14

PORTUGUESE /PORTUGUÊS 15

ITALIAN /ITALIANO 16

SWEDISH /SVENSKA 17

NORWEGIAN /NORSK 18

DANISH /DANSK 19

FINNISH /SUOMI 20

POLISH /POLSKI 21

CZECH /ČEŠTINA 22

SLOVAK /SLOVENČINA 23

HUNGARIAN /MAGYAR 24

3

Issued by: Arnold Bos / www.tri-sure.com Issue no.: MAN-1000029 Version: 2Date: 11-02-2015

Trade-marks

Tri-Sure® metal closures, Tri-Sure® plastic

closures, Tab-Seal® caps, SambaCapTM,

UNI-GRIP® spouts, ULTRA-BOND® spouts,

PLASTIPLUGTM plugs, Push-LockTM caps,

PLASTICAPTM screw caps, PLASTIROB®

taps, CDS® dispense closures

Disclaimer: all information on our behalf in relation to our products, whether in nature of date, recommendations or otherwise, is supported by research and believed reliable, but we assume no liability

whatsoever in respect of application, processing or use made of the aforementioned information or products or any consequence thereof. The user undertakes all liability in respect of the application.

Processing or use of the aforementioned information or products, whose quality and other properties he shall verify, or any consequence thereof. No liability whatsoever shall attach to us for any

infringement of the rights owned or controlled by a third party on intellectual, industrial or other property by reason of the application, processing or use of the aforementioned information or products by

the user.

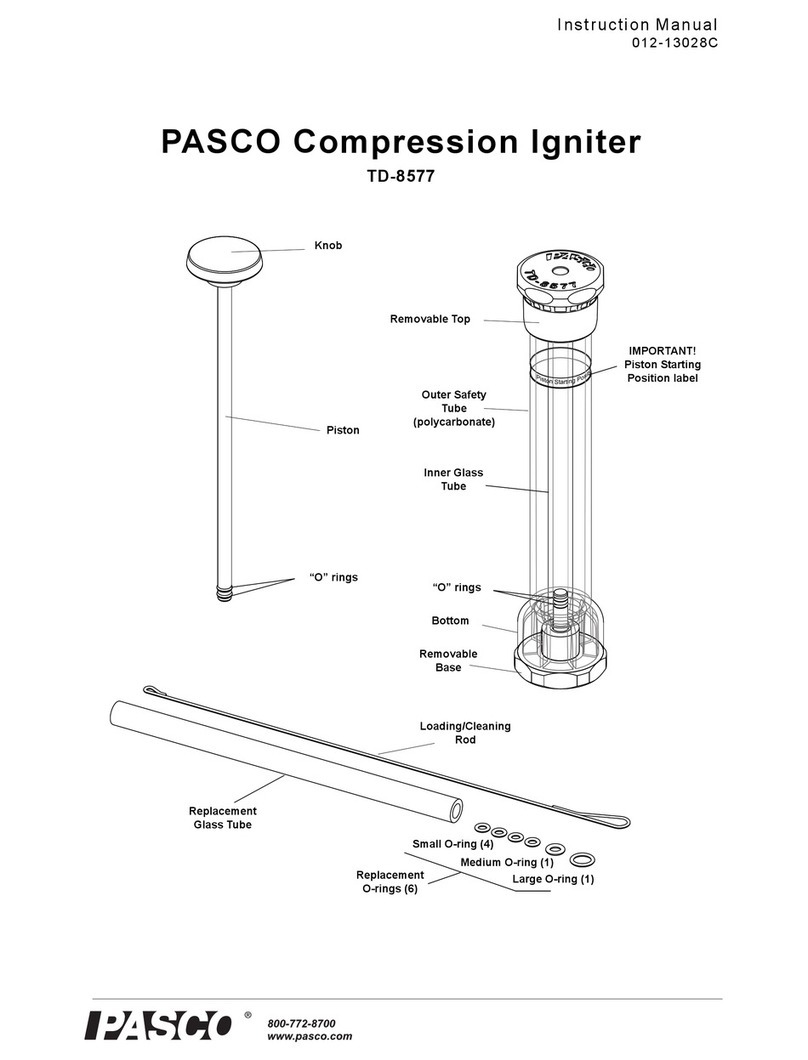

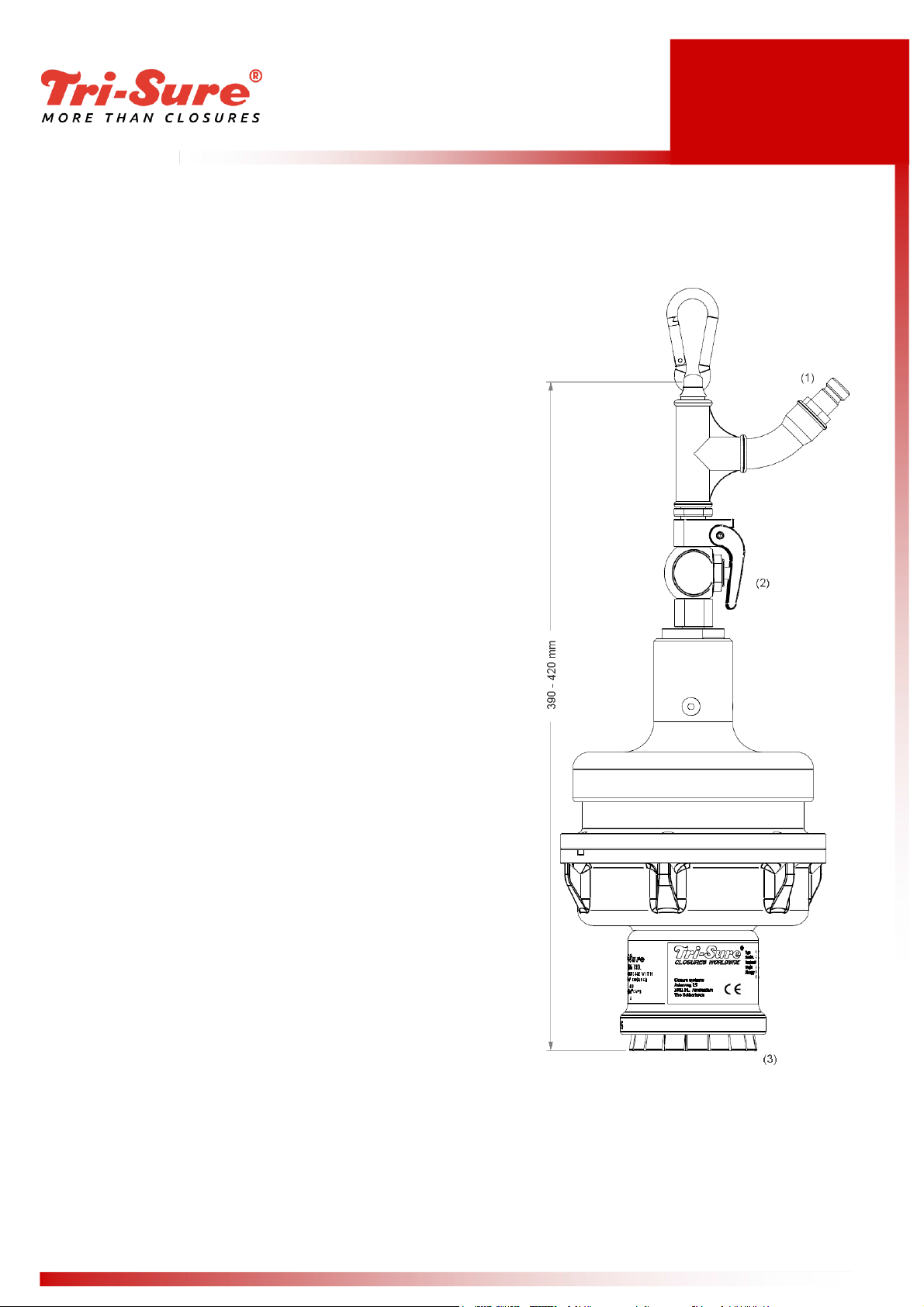

General Information

Pneumatic Tab-Seal®Cap closing tools

Pneumatische Tab-Seal®Cap sluitapparaten

Pneumatische Tab-Seal®Kapselverschlussgeraete

Appareils pneumatique a sertir les Capsules Tab-Seal®

type 2IPT- ... G2 (steel or plastic TSC)

type 3IPR- ... G3/4 (steel or plastic TSC)

type 60IPU- ... Uni-Grip

1) air connection/ luchtaansluiting/ luftanschluss/

Raccordement de l’air : Tema iso 3/8” male

2) Control valve/ Stuurklep/ Steuerventil/

Valve de commande

3) Jaws/ Klauwen/ Klemmbacken/ Les mâchoires

Airpressure/ Luchtdruk/ Luftdruck/ Pression d’air

Max. : 6,0 bar

Nom. : 5,5 bar

Min. : 5,0 bar

Weight/ Gewicht/ Gewicht/ Poid : 7,5 kg

Lubrication Smering/ : ISO VG 15 f.e.

Schmierung/ Lubrification : Shell Alvania RL2

Pressurized air/ Persluch : Oiled and filtered

Druckluft / air comprime, : ISO 8573-1:2010

Operating temp./ Bedrijfstemp. : Min -5°C / Max 50 °C

Betriebstemp./ Temp. de fonctionnement

Soundlevel(dBa)/ Geluid(dBa) : 67 dBa

Schalldruck(dBa)/ Niveau de bruit(dBa)

Vibration level/ Vibratie niveau : < 2.5 m/s2

Vibrationsniveau / niveau de vibration

Luchtverbruik/ Airconsumption : ±1,5 ltr/cycle

Luftverbrauch/ Consomption d’air

Manufactured by/ Gefabriceerd door

Hergestellt von/ Fabrqué par,

Tri-Sure®Netherlands

Asterweg 25,1031HL

Amsterdam, The Netherlands

www.Tri-Sure.com

4

Issued by: Arnold Bos / www.tri-sure.com Issue no.: MAN-1000029 Version: 2Date: 11-02-2015

Trade-marks

Tri-Sure® metal closures, Tri-Sure® plastic

closures, Tab-Seal® caps, SambaCapTM,

UNI-GRIP® spouts, ULTRA-BOND® spouts,

PLASTIPLUGTM plugs, Push-LockTM caps,

PLASTICAPTM screw caps, PLASTIROB®

taps, CDS® dispense closures

Disclaimer: all information on our behalf in relation to our products, whether in nature of date, recommendations or otherwise, is supported by research and believed reliable, but we assume no liability

whatsoever in respect of application, processing or use made of the aforementioned information or products or any consequence thereof. The user undertakes all liability in respect of the application.

Processing or use of the aforementioned information or products, whose quality and other properties he shall verify, or any consequence thereof. No liability whatsoever shall attach to us for any

infringement of the rights owned or controlled by a third party on intellectual, industrial or other property by reason of the application, processing or use of the aforementioned information or products by

the user.

5

Issued by: Arnold Bos / www.tri-sure.com Issue no.: MAN-1000029 Version: 2Date: 11-02-2015

Trade-marks

Tri-Sure® metal closures, Tri-Sure® plastic

closures, Tab-Seal® caps, SambaCapTM,

UNI-GRIP® spouts, ULTRA-BOND® spouts,

PLASTIPLUGTM plugs, Push-LockTM caps,

PLASTICAPTM screw caps, PLASTIROB®

taps, CDS® dispense closures

Disclaimer: all information on our behalf in relation to our products, whether in nature of date, recommendations or otherwise, is supported by research and believed reliable, but we assume no liability

whatsoever in respect of application, processing or use made of the aforementioned information or products or any consequence thereof. The user undertakes all liability in respect of the application.

Processing or use of the aforementioned information or products, whose quality and other properties he shall verify, or any consequence thereof. No liability whatsoever shall attach to us for any

infringement of the rights owned or controlled by a third party on intellectual, industrial or other property by reason of the application, processing or use of the aforementioned information or products by

the user.

We, Wij, Wir, Nous,

Tri-Sure®The Netherlands, Amsterdam,

Declare that, Verklaren dat, Erklaeren dasz, Declarons que,

Tri-Sure®pneumatic Tab-Seal®Cap closingtools

Tri-Sure®pneumatische Tab-Seal®Cap krimpapparaten

Tri-Sure®pneumatische Tab-Seal®Kapselverschlussgeraete

Appareils pneumatiques a sertir les capsules Tab-Seal®Tri-Sure®

Type/model/typ/modele: CATT 2IPT....; CATT 3IPR….; CATT 60IPU…..;

Are in conformity with the Requirements relating to Machinery 2006/42/EG, App. II.1.A

Voldoen aan de bepalingen van de Machinerichtlijn 2006/42/EG, bijlage II.1.A

Gemaess den Richtlinien 2006/42/EG, Blatt II.1.A, ausgefuhrt sind

Sont en conformite avec la directive concernant Machinery 2006/42/EG, App. II.1.A

6

Issued by: Arnold Bos / www.tri-sure.com Issue no.: MAN-1000029 Version: 2Date: 11-02-2015

Trade-marks

Tri-Sure® metal closures, Tri-Sure® plastic

closures, Tab-Seal® caps, SambaCapTM,

UNI-GRIP® spouts, ULTRA-BOND® spouts,

PLASTIPLUGTM plugs, Push-LockTM caps,

PLASTICAPTM screw caps, PLASTIROB®

taps, CDS® dispense closures

Disclaimer: all information on our behalf in relation to our products, whether in nature of date, recommendations or otherwise, is supported by research and believed reliable, but we assume no liability

whatsoever in respect of application, processing or use made of the aforementioned information or products or any consequence thereof. The user undertakes all liability in respect of the application.

Processing or use of the aforementioned information or products, whose quality and other properties he shall verify, or any consequence thereof. No liability whatsoever shall attach to us for any

infringement of the rights owned or controlled by a third party on intellectual, industrial or other property by reason of the application, processing or use of the aforementioned information or products by

the user.

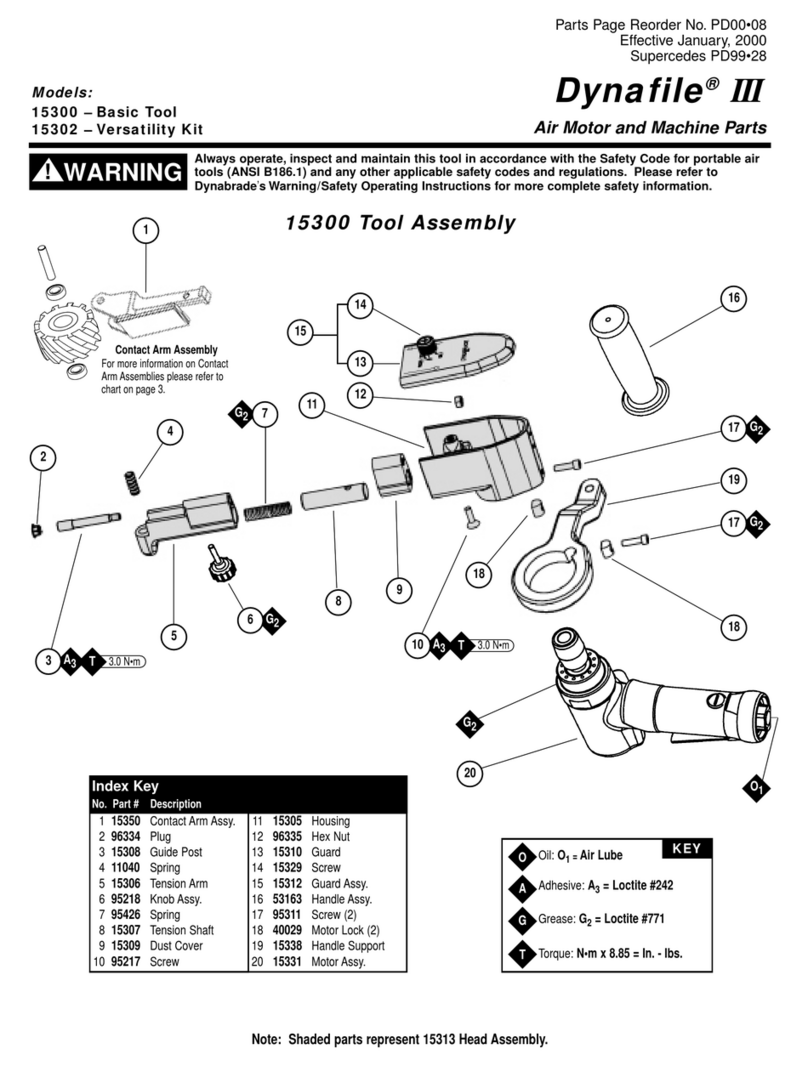

Application of Tri-Sure® pneumatic closing tools

Tool with: Yellow bell

for Steel Tab-Seal®cap

G2 or G3/4

Tool with: Grey bell

for plastic Tab-Seal®cap

G2 or G3/4

Tool with: Red bell

for Uni-Grip®60c spout

Steel Tab-Seal®cap

Plastic Tab-Seal®cap

Uni-Grip®60c spout

7

Issued by: Arnold Bos / www.tri-sure.com Issue no.: MAN-1000029 Version: 2Date: 11-02-2015

Trade-marks

Tri-Sure® metal closures, Tri-Sure® plastic

closures, Tab-Seal® caps, SambaCapTM,

UNI-GRIP® spouts, ULTRA-BOND® spouts,

PLASTIPLUGTM plugs, Push-LockTM caps,

PLASTICAPTM screw caps, PLASTIROB®

taps, CDS® dispense closures

Disclaimer: all information on our behalf in relation to our products, whether in nature of date, recommendations or otherwise, is supported by research and believed reliable, but we assume no liability

whatsoever in respect of application, processing or use made of the aforementioned information or products or any consequence thereof. The user undertakes all liability in respect of the application.

Processing or use of the aforementioned information or products, whose quality and other properties he shall verify, or any consequence thereof. No liability whatsoever shall attach to us for any

infringement of the rights owned or controlled by a third party on intellectual, industrial or other property by reason of the application, processing or use of the aforementioned information or products by

the user.

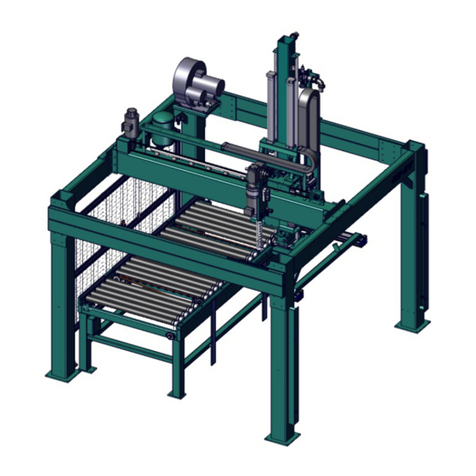

Lubrication of Tri-Sure® pneumatic closing tools

To ensure a smooth operation of the tool, and to avoid “sticking” of the jaws,

it is necessary to clean and lubricate the jaws at regular intervals.

Light oil can be applied with a can, or sprayed onto the jaws.

Example of lubricant, other example could be WD40

8

Issued by: Arnold Bos / www.tri-sure.com Issue no.: MAN-1000029 Version: 2Date: 11-02-2015

Trade-marks

Tri-Sure® metal closures, Tri-Sure® plastic

closures, Tab-Seal® caps, SambaCapTM,

UNI-GRIP® spouts, ULTRA-BOND® spouts,

PLASTIPLUGTM plugs, Push-LockTM caps,

PLASTICAPTM screw caps, PLASTIROB®

taps, CDS® dispense closures

Disclaimer: all information on our behalf in relation to our products, whether in nature of date, recommendations or otherwise, is supported by research and believed reliable, but we assume no liability

whatsoever in respect of application, processing or use made of the aforementioned information or products or any consequence thereof. The user undertakes all liability in respect of the application.

Processing or use of the aforementioned information or products, whose quality and other properties he shall verify, or any consequence thereof. No liability whatsoever shall attach to us for any

infringement of the rights owned or controlled by a third party on intellectual, industrial or other property by reason of the application, processing or use of the aforementioned information or products by

the user.

INSTALLATION- AND OPERATING INSTRUCTIONS

English / English

INSTALLATION- AND OPERATING INSTRUCTIONS

for pneumatic Tri-Sure®Tab-Seal®cap closingtools

type IPT-S G2

type IPR-S G3/4

type 60IPU Uni-Grip

1. INSTALLATION

- Install the tool as indicated in drawing TSN939080

- Adjust the balancer in such a way that the tool is appr. 20 cm above the top of the

drum.

- Check that the airsupply includes an airvalve, lubricator unit, and pressure regulator.

- Adjust the airpressure to 5,5 bar.

- Adjust the lubricator in such a way that regular lubrication takes place.

2. OPERATION

- Before use, operate the tool a few times to ensure proper functioning of the tool.

Ensure that the jaws move freely.

- Regularly lubricate the jaws lightly with oil, and inspect the jaws for contamination

that could prevent proper functioning of the tool.

- Place the Tri-Sure® Tab-Seal® cap on the Tri-Sure closure. Place one hand on the

upper cylinder and one hand at the control valve and move the tool above the

closure. Excercise light downward pressure till the tool sits on the closure.

- Operate the airvalve. Release the airvalve as soon as the crimping operation has

been completed.

- Move the tool away from the closure and visually inspect if the Tri-Sure® Tab-Seal®

cap has been fitted correctly.

3. SAFETY

- The use of gloves, eye protection, hearing protection, and safety footwear is

compulsory.

- Always operate the tool with both hands.

- Remove compressed air supply if the tool is not used.

- Remove compressed air supply during maintenance.

- Do not touch the jaws when the air supply is connected to the tool.

- Use this tool only for the purpose for which it is designed.

9

Issued by: Arnold Bos / www.tri-sure.com Issue no.: MAN-1000029 Version: 2Date: 11-02-2015

Trade-marks

Tri-Sure® metal closures, Tri-Sure® plastic

closures, Tab-Seal® caps, SambaCapTM,

UNI-GRIP® spouts, ULTRA-BOND® spouts,

PLASTIPLUGTM plugs, Push-LockTM caps,

PLASTICAPTM screw caps, PLASTIROB®

taps, CDS® dispense closures

Disclaimer: all information on our behalf in relation to our products, whether in nature of date, recommendations or otherwise, is supported by research and believed reliable, but we assume no liability

whatsoever in respect of application, processing or use made of the aforementioned information or products or any consequence thereof. The user undertakes all liability in respect of the application.

Processing or use of the aforementioned information or products, whose quality and other properties he shall verify, or any consequence thereof. No liability whatsoever shall attach to us for any

infringement of the rights owned or controlled by a third party on intellectual, industrial or other property by reason of the application, processing or use of the aforementioned information or products by

the user.

Dutch / Nederlands

MONTAGE- EN BEDIENINGSVOORSCHRIFT

voor pneumatische Tri-Sure®Tab-Seal®Cap Sluitapparaten

type IPT-S G2

type IPR-S G3/4

type 60IPU Uni-Grip

1. MONTAGE

- Monteer het apparaat zoals aangegeven in tekening TSN939080

- Stel de balanceerunit zo af dat het apparaat ca. 20 cm vrij hangt boven het vat.

- Let erop dat de luchttoevoer naar het apparaat is voorzien van een afsluiter, een

smeerunit, en een reduceerunit.

- Stel de luchtdruk af op 5,5 bar.

- Stel de smeerunit zo af dat regelmatige smering plaatsvindt.

2. GEBRUIK

- Voor gebruik, bedien het apparaat enkele malen om de juiste werking van het

apparaat te controleren. De klauwen moeten goed in- en uitgaan.

- Smeer de klauwen regelmatig licht in met olie, en controleer op verontreinigingen die

de goede werking van het apparaat kunnen verstoren.

- Plaats de Tri-Sure® Tab-Seal® Cap op de Tri-Sure® sluiting. Plaats een hand op de

boven cilinder en een hand bij de bedieningsknop en breng het apparaat boven de

sluiting. Oefen lichte neerwaartse druk uit tot het apparaat zich op de sluiting bevindt.

- Bedien de luchtklep. Laat de luchtklep los zodra de krimpbewerking beëindigd is.

- Beweeg het apparaat weg van de sluiting en controleer of de Tri-Sure® Tab-Seal®

Cap goed gekrompen is.

3. VEILIGHEID

- Het gebruik van handschoenen, oog bescherming, gehoor bescherming en

veiligheidsschoenen is verplicht. Perslucht verwijderen als het apparaat niet wordt

gebruikt. Perslucht verwijderen tijdens onderhoudswerkzaamheden.

- Kom niet in aanraking met de klauwen als de perslucht aangesloten is.

- Bedien het apparaat altijd met beide handen.

- Gebruik dit apparaat alleen voor het doel waarvoor het is ontworpen.

10

Issued by: Arnold Bos / www.tri-sure.com Issue no.: MAN-1000029 Version: 2Date: 11-02-2015

Trade-marks

Tri-Sure® metal closures, Tri-Sure® plastic

closures, Tab-Seal® caps, SambaCapTM,

UNI-GRIP® spouts, ULTRA-BOND® spouts,

PLASTIPLUGTM plugs, Push-LockTM caps,

PLASTICAPTM screw caps, PLASTIROB®

taps, CDS® dispense closures

Disclaimer: all information on our behalf in relation to our products, whether in nature of date, recommendations or otherwise, is supported by research and believed reliable, but we assume no liability

whatsoever in respect of application, processing or use made of the aforementioned information or products or any consequence thereof. The user undertakes all liability in respect of the application.

Processing or use of the aforementioned information or products, whose quality and other properties he shall verify, or any consequence thereof. No liability whatsoever shall attach to us for any

infringement of the rights owned or controlled by a third party on intellectual, industrial or other property by reason of the application, processing or use of the aforementioned information or products by

the user.

German / Deutsh

INSTALLATIONS- UND GEBRAUCHSANWEISUNG

für pneumatische Tri-Sure® Kapselverschlussgeraete

Typ IPT-S G2

Typ IPR-S G3/4

Typ 60IPU Uni-Grip

1. INSTALLATION

- Installieren Sie das Geraet, gemaess der Zeichnung Nr. TSN939080

- Richten Sie den Federzug so ein, dass der Hoehenunterschied zwischen

Fassoberboden und Unterseite des Kapselverschlussgeraetes ca. 200 mm betraegt.

- Pruefen Sie die Funktionalitaet des Oelers in der Wartungseinheit

- Stellen Sie die Druckluft auf ca 5,5 bar ein.

2. BENUTZUNG DES GERAETES

- Betaetigen Sie vor Gebrauch einige Male das Tastventil und Pruefen Sie die

Functionalitaet des Geraetes.

- Pruefen Sie regelmaessig die Segmente auf Verschmutzung, um eine einwandfreie

Verkapselung zu gewaehrleisten.

- Legen Sie zuerst die Kapsel auf den verschraubten Verschluss und fuehren danach

das Geraet mit beiden Haenden auf den Verschluss bis es aufliegt.

Betaetigen Sie das Ventil bis der Kapselvorgang beendet ist (ca 2 Sekunden).

- Heben Sie das Geraet nach dem Arbeitsgang in seine Ausgangsposition ueber dem

Fass zurueck.

- Pruefen Sie die Versiegelung des Verschlusses.

3. ARBEITSSICHERHEIT

- Die Verwendung von Handschuhen, Schutzbrille, Gehörschutz, und

Sicherheitsschuhe ist Pflicht.

- Entfernen Druckluftzufuhr, wenn das Werkzeug nicht verwendet wird

- Entfernen Druckluftzufuhr bei der Wartung

- Das beruehren der Segmente, wenn Druckluft anliegt, ist zu vermeiden.

- Halten Sie das Geraet beim Arbeitsvorgang mit beiden Haenden.

- Benutzen Sie das Geraet nur fuer das Verarbeiten der entsprechenden Kapseln.

11

Issued by: Arnold Bos / www.tri-sure.com Issue no.: MAN-1000029 Version: 2Date: 11-02-2015

Trade-marks

Tri-Sure® metal closures, Tri-Sure® plastic

closures, Tab-Seal® caps, SambaCapTM,

UNI-GRIP® spouts, ULTRA-BOND® spouts,

PLASTIPLUGTM plugs, Push-LockTM caps,

PLASTICAPTM screw caps, PLASTIROB®

taps, CDS® dispense closures

Disclaimer: all information on our behalf in relation to our products, whether in nature of date, recommendations or otherwise, is supported by research and believed reliable, but we assume no liability

whatsoever in respect of application, processing or use made of the aforementioned information or products or any consequence thereof. The user undertakes all liability in respect of the application.

Processing or use of the aforementioned information or products, whose quality and other properties he shall verify, or any consequence thereof. No liability whatsoever shall attach to us for any

infringement of the rights owned or controlled by a third party on intellectual, industrial or other property by reason of the application, processing or use of the aforementioned information or products by

the user.

French / français

INSTRUCTIONS D'INSTALLATION ET D'UTILISATION DES APPAREILS

Pneumatiques a sertir les capsules Tab-Seal®cap Tri-Sure®

modèle IPTS G2

modèle IPRS G3/4

modèle 60IPU Uni-Grip

1. INSTALLATION

- Installer l'outillage selon les indications contenues dans le plan TSN939080.

- Ajuster le balancier équilibreur de telle sorte que la base de l'appareil à sertir soit

approximativement à 20 cm au dessus du fût.

- S'assurer que l'ensemble de traitement d'air puisse être isolé et comprenne un

dispositif de lubrification et un régulateur de pression.

- Régler la pression d'air à 5,5 bars.

- Régler le dispositif de lubrification de façon à obtenir un débit d'huile régulier.

Débit d'huile conseillé: 1 goutte pour environ 20 sertissages.

Huile préconisée: de type ISO.VG.15.

2. UTILISATION

- Avant utilisation, s'assurer du bon fonctionnement de l'appareil. Vérifier le libre

mouvement des mâchoires.

- Lubrifier légèrement et régulièrement les mâchoires. Vérifier que celles ci ne soient

pas encrassées afin d'éviter un dysfonctionnement de l'appareil.

- Placer la capsule Tab-Seal® Tri-Sure® sur la bonde Tri-Sure®. Positionner l'appareil

à l'aplomb de la bonde en plaçant une main sur le carter supérieur et l'autre sur la

valve de commande. Exercer une légère pression de l'appareil vers le bas en

l'appliquant sur la fermeture.

- Actionner la valve de commande. La relâcher dès que l'opération de sertissage est

effectuée.

- Dégager l'appareil de la bonde et vérifier visuellement que la capsule Tab-Seal®

Tri-Sure® est parfaitement sertie.

3. SECURITE

- L'utilisation de gants, protection des yeux, protection auditive, et chaussures de

sécurité est obligatoire

- Retirez l'alimentation d'air comprimé si l'outil ne est pas utilisé

- Retirez l'alimentation d'air comprimé lors de l'entretien

- Ne pas toucher aux mâchoires de l'appareil lorsque celui-ci est connecté au réseau

d'air.

- Utiliser toujours les deux mains pour faire fonctionner l'appareil.

- Utiliser cet appareil uniquement pour l'usage qui lui est attribué.

12

Issued by: Arnold Bos / www.tri-sure.com Issue no.: MAN-1000029 Version: 2Date: 11-02-2015

Trade-marks

Tri-Sure® metal closures, Tri-Sure® plastic

closures, Tab-Seal® caps, SambaCapTM,

UNI-GRIP® spouts, ULTRA-BOND® spouts,

PLASTIPLUGTM plugs, Push-LockTM caps,

PLASTICAPTM screw caps, PLASTIROB®

taps, CDS® dispense closures

Disclaimer: all information on our behalf in relation to our products, whether in nature of date, recommendations or otherwise, is supported by research and believed reliable, but we assume no liability

whatsoever in respect of application, processing or use made of the aforementioned information or products or any consequence thereof. The user undertakes all liability in respect of the application.

Processing or use of the aforementioned information or products, whose quality and other properties he shall verify, or any consequence thereof. No liability whatsoever shall attach to us for any

infringement of the rights owned or controlled by a third party on intellectual, industrial or other property by reason of the application, processing or use of the aforementioned information or products by

the user.

Chinese / 中国

安装及操作说明

气动Tri-Sure®Tab-Seal®cap 夹具

类型 IPT-S G2

类型 IPT-S G3/4

类型 60IPU Uni-Grip

1. 安装

- 按照图示 TSN939080 来安装工具

- 调节平衡器使得工具处于桶盖上方大约 20cm 的位置

- 检查包括气压阀门,润滑器和气压调节阀等气源设备

- 调节气压至 5.5bar

- 调节润滑器至需要进行定期润滑的位置

2.. 操作

- 使用前,试着操作几次来确保工具是能够正常工作的,并确保夹具牙齿能够平滑的伸

缩。

- 定期的对夹具牙齿进行少量的润滑,并观察牙齿是否沾染污垢,来保持工具能够正常工作。

- 先放置 Tri-Sure 的防盗盖至桶口件上,然后一只手扶住夹具的上气缸,另外一只手轻放在阀门按钮上,

并且移动工具至桶口件正上方,练习轻轻向下移动夹具直到牙齿扣住桶口件。

- 按下气压阀门,当夹紧动作完成的同时放掉气压阀门。

- 移开夹具并且检查 Tri-Sure 的防盗盖是否正确的夹住在桶口件上。

3. 安全

- 必须使用手套,保护眼镜,耳塞和安全鞋。

- 一直保持双手操作工具

- 在工具不使用时断开压缩气源。

- 在维修工具时断开压缩气源

- 当夹具连通气源时不要用手触碰夹具牙齿

- 仅按照其所设计的目的来使用

13

Issued by: Arnold Bos / www.tri-sure.com Issue no.: MAN-1000029 Version: 2Date: 11-02-2015

Trade-marks

Tri-Sure® metal closures, Tri-Sure® plastic

closures, Tab-Seal® caps, SambaCapTM,

UNI-GRIP® spouts, ULTRA-BOND® spouts,

PLASTIPLUGTM plugs, Push-LockTM caps,

PLASTICAPTM screw caps, PLASTIROB®

taps, CDS® dispense closures

Disclaimer: all information on our behalf in relation to our products, whether in nature of date, recommendations or otherwise, is supported by research and believed reliable, but we assume no liability

whatsoever in respect of application, processing or use made of the aforementioned information or products or any consequence thereof. The user undertakes all liability in respect of the application.

Processing or use of the aforementioned information or products, whose quality and other properties he shall verify, or any consequence thereof. No liability whatsoever shall attach to us for any

infringement of the rights owned or controlled by a third party on intellectual, industrial or other property by reason of the application, processing or use of the aforementioned information or products by

the user.

Russian / Pусский

Инструкция по установке и работе

для пневматического инструмента закрытия горловин

Tri-Sure® Tab-Seal®

тип IPT-S G2

тип IPT-S G3/4

тип 60IPU Uni-Grip

1. Установка

- Установите инструмент как показано на рисунке TSN939080

- Отрегулируйте балансир так, чтобы инструмент находился в 20 см от верхней

части бочки

- Проверьте подвод воздуха, включая воздушный клапан, смазочное устройство,

регулятор давления

- Отрегулируйте давление воздуха до 5,5 бар

- Отрегулируйте смазочное устройство чтобы была регулярная смазка

2. Работа

- Перед использованием проверьте несколько раз верное функционирование инструмента.

Убедитесь что кулачки двигаются свободно.

- Регулярно производите смазку кулачков небольшим количеством масла и проверяйте на

наличие грязи, скопление грязи может привести к выходу инструмента из строя.

- Разместите пломбиратор на пломбе. Положите одну руку на верхнем цилиндре, а другую на

клапане управления и переместите пломбиратор на пломбу. Приложите небольшое

давление

на пломбиратор, пока он не сядет плотно на пломбу

- Нажмите воздушный клапан. Отпустите клапан как только сжимающее действие будет

завершено

- Уберите инструмент от горловины и проведите визуальный осмотр качества

пломбирования.

3. Безопасность

- Использование перчаток, защиты органов зрения и слуха и безопасность спецобувь

обязательно

- При работе с инструментом всегда удерживайте его обоими руками

- Выключайте подачу воздуха когда инструмент не в работе

- Выключайте подачу воздуха во время ремонтных работ

- Не прикасайтесь к кулачкам когда воздух подсоединен

- Используйте инструмент только для работ для которых он предназначен

14

Issued by: Arnold Bos / www.tri-sure.com Issue no.: MAN-1000029 Version: 2Date: 11-02-2015

Trade-marks

Tri-Sure® metal closures, Tri-Sure® plastic

closures, Tab-Seal® caps, SambaCapTM,

UNI-GRIP® spouts, ULTRA-BOND® spouts,

PLASTIPLUGTM plugs, Push-LockTM caps,

PLASTICAPTM screw caps, PLASTIROB®

taps, CDS® dispense closures

Disclaimer: all information on our behalf in relation to our products, whether in nature of date, recommendations or otherwise, is supported by research and believed reliable, but we assume no liability

whatsoever in respect of application, processing or use made of the aforementioned information or products or any consequence thereof. The user undertakes all liability in respect of the application.

Processing or use of the aforementioned information or products, whose quality and other properties he shall verify, or any consequence thereof. No liability whatsoever shall attach to us for any

infringement of the rights owned or controlled by a third party on intellectual, industrial or other property by reason of the application, processing or use of the aforementioned information or products by

the user.

Spanish / Español

INSTRUCCIONES DE INSTALACION E UTILIZACION DE

LOS APARATOS

Neumaticos Tri-Sure®para precintar capsulas Tab-Seal®

Tipo IPT-S G2”

Tipo IPR-S G3/4

Tipo 60IPU Uni-Grip

1. INSTALACION

- Instalar el aparato según se indica en el plano TSN939080.

- Ajustar el equilibrador de tal manera que el aparato este aproximadamente a unos 20 cm.

por encima del bidón.

- Comprobar que la instalación qua suministra aire al aparato, esta equipada con una válvula

de cierre, una unidad de lubricación y regulador de presión.

- Ajustar la presión de aire a 5,5 bar.

- Ajustar el lubricador de tal manera que se obtenga regularmente un débil goteo de aceite.

Reigo de aceite aconsejado: 1gota x cada 20 precintados.

Aceite recomendado: tipo ISO.VG.15.

2. UTILIZACON

- Antes de utilizar el aparato, comprobar el buen funcionamiento del mismo. Verificar el libre

movimiento de los dientes.

- Lubrificar ligeramente y regularmente los dientes, y vigilar que estos no se ensucien

con el fin de prever posibles fallos.

- Colocar la capsula Tab-Seal® sobre el cierre Tri-Sure®. Poner una mano en la parte superior

del cilindro y la otra en la válvula de control, ejerciendo un suave movimiento a la vez que

una ligera presión del aparato sobre la base de aplicación del precintado.

- Accionar la válvula de aire y soltar la misma tan pronto como la operación de precintado se

haya efectuado.

- Quitar el aparato del cierre y comprobar que la cápsula Tab-Seal® ha sido correctamente

precintada.

3. SEGURIDAD

- El uso de guantes, protección ocular, protección auditiva, y

calzado de seguridad es obligatoria.

- Retire el suministro de aire comprimido si no se utiliza la herramienta de

- Retire el suministro de aire comprimido durante el mantenimiento

- No tocar los dientes mientras este conectado el aire al aparato.

- Utilizar siempre las dos manos para trabajar con el aparato.

- Utilizar únicamente este aparato para el uso que se le ha asignado.

15

Issued by: Arnold Bos / www.tri-sure.com Issue no.: MAN-1000029 Version: 2Date: 11-02-2015

Trade-marks

Tri-Sure® metal closures, Tri-Sure® plastic

closures, Tab-Seal® caps, SambaCapTM,

UNI-GRIP® spouts, ULTRA-BOND® spouts,

PLASTIPLUGTM plugs, Push-LockTM caps,

PLASTICAPTM screw caps, PLASTIROB®

taps, CDS® dispense closures

Disclaimer: all information on our behalf in relation to our products, whether in nature of date, recommendations or otherwise, is supported by research and believed reliable, but we assume no liability

whatsoever in respect of application, processing or use made of the aforementioned information or products or any consequence thereof. The user undertakes all liability in respect of the application.

Processing or use of the aforementioned information or products, whose quality and other properties he shall verify, or any consequence thereof. No liability whatsoever shall attach to us for any

infringement of the rights owned or controlled by a third party on intellectual, industrial or other property by reason of the application, processing or use of the aforementioned information or products by

the user.

Portuguese / português

MONTAGE E INSTRUÇÔES DE APARELHO

Pneumaticos Tri-Sure®de Selage do Lacre

Tipo IPT-S G2”

Tipo IPR-S G3/4

Tipo 60IPU Uni-Grip

1. Montage

- O Aparelho deve ser montado conforme o desenho TSN939080.

- Pendorar o mesmo cerca de ±20 cm acima de parte superior do bidon.

- Atenção: A entrada do ar no aparelho tem que ter torneiro de segurança un copo de oleo

unit e uma redução unit.

- Regule o pressão do ar a 5.5 bar.

- Regule o copo de oleo do forma que este faça com frequencia a oliação.

2. USO

- Antes de usar o aparelho verifique o bom foncionamento do mesmo, principalmente e

abertura eo feicho dos grampos.

- Oliar os grampos ligeiramente e com frequência. E manter o aparelho bem limpo o

bom foncionamento do mesmo.

- Usar sempre Lacre Tri-Sure® con Feicho Tri-Sure®.

- Colocar uma mão no cilindro superior e outra no botão de foncionamento.

- Pondo o aparelho em cima do feicho, com um pequeno esforo seguro-o e ponha-o em forma

correta em cima do lacre.

- Carregue no botão do ar. Em seguida solte o mesmo para assim terminar.

- Retirar o aparelho de cima do lacre e control se Lacre Tri-Sure® está bem lacrado.

3. SEGURANÇA

- O uso de luvas, proteção para os olhos, proteção auditiva, e

calçado de segurança é obrigatória.

- Remover fornecimento de ar comprimido, se a ferramenta não é usada

- Remova o suprimento de ar comprimido durante a manutenção

- Não mexer nos grampos com o ar a foncionar.

- Usar o aparelho sempre com as duas mãos.

- Utilizar o aparelho só para esta finalidade.

16

Issued by: Arnold Bos / www.tri-sure.com Issue no.: MAN-1000029 Version: 2Date: 11-02-2015

Trade-marks

Tri-Sure® metal closures, Tri-Sure® plastic

closures, Tab-Seal® caps, SambaCapTM,

UNI-GRIP® spouts, ULTRA-BOND® spouts,

PLASTIPLUGTM plugs, Push-LockTM caps,

PLASTICAPTM screw caps, PLASTIROB®

taps, CDS® dispense closures

Disclaimer: all information on our behalf in relation to our products, whether in nature of date, recommendations or otherwise, is supported by research and believed reliable, but we assume no liability

whatsoever in respect of application, processing or use made of the aforementioned information or products or any consequence thereof. The user undertakes all liability in respect of the application.

Processing or use of the aforementioned information or products, whose quality and other properties he shall verify, or any consequence thereof. No liability whatsoever shall attach to us for any

infringement of the rights owned or controlled by a third party on intellectual, industrial or other property by reason of the application, processing or use of the aforementioned information or products by

the user.

Italian / italiano

INSTALLAZIONE ED ISTRUZION DI FUNZIONAMENTO PER LE

CAPSULATRICI

Pneumatiche Tri-Sure®

Tipo IPT-S G2”

Tipo IPR-S G3/4

Tipo 60IPU Uni-Grip

1. INSTALLAZIONE

- Installare l'unità come mostrato nel disegno TSN 939080

- Regolare il bilanciatore in modo che la capsulatrice resti a circa 20 cm

dal bordo superiore del fusto.

- Controllare che il sistema die rogazione dell’aria includa una valvola, una unità

lubrificatrice, un regolatore di pressione.

- Regolare la pressione a 5.5 bar.

- Regolare il lubrificatore in modo che abbia luogo una regolare lubrificazione.

2. FUNZIONAMENTE

- Prima dell’uso, effettuare qualche prova per assicurarsi che lo strumento funzioni corretta-

mente. Assicurarsi che la ganascia si muova liberamente.

- A cadenza regolare lubrificare leggermente con olio la ganascia ed esaminarla per

scoprire eventuali contaminazioni che potrebbero impedire il corretto funzionamente

dello strumento.

- Posizionare la capsula Tab-Seal® sulla chuisura Tri-Sure®. Appoggiare una mano sul

cilindro superiore e l’altra sulla valvola di controllo e posizionare la capsulatrice sopra la

chiusura. Esercitare una leggera pressione verso il basso fino a quando lo strumento si

appoggia sulla chiusura.

- Azionare la valvola dell’aria. Rilasciarla non appena l’operazione di arricciatura è stata

fissata correttamente.

3. SICUREZZA

- L'uso di guanti, occhiali di protezione, protezione acustica, e

calzature di sicurezza è obbligatoria.

- Rimuovere alimentazione dell'aria compressa se non si utilizza lo strumento

- Togliere alimentazione di aria compressa durante la manutenzione

- Non toccare la ganascia quando la capsulatrice è in funzione.

- Azionare la capsulatrice sempre con due mani.

- Usate questo strumento solo per lo scopo per il quale è designato.

17

Issued by: Arnold Bos / www.tri-sure.com Issue no.: MAN-1000029 Version: 2Date: 11-02-2015

Trade-marks

Tri-Sure® metal closures, Tri-Sure® plastic

closures, Tab-Seal® caps, SambaCapTM,

UNI-GRIP® spouts, ULTRA-BOND® spouts,

PLASTIPLUGTM plugs, Push-LockTM caps,

PLASTICAPTM screw caps, PLASTIROB®

taps, CDS® dispense closures

Disclaimer: all information on our behalf in relation to our products, whether in nature of date, recommendations or otherwise, is supported by research and believed reliable, but we assume no liability

whatsoever in respect of application, processing or use made of the aforementioned information or products or any consequence thereof. The user undertakes all liability in respect of the application.

Processing or use of the aforementioned information or products, whose quality and other properties he shall verify, or any consequence thereof. No liability whatsoever shall attach to us for any

infringement of the rights owned or controlled by a third party on intellectual, industrial or other property by reason of the application, processing or use of the aforementioned information or products by

the user.

Swedish / svenska

INSTRUKTIONER FÖR INSTALLATION OCH ANVÄNDNING AV

Pneumatiska Tri-Sure®Tab-Seal Cap Förslutningsverktyg.

Typ IPT-S G2

Typ IPR-S G3/4

Typ 60IPU Uni-Grip

1. INSTALLATION

- Installera verktyget som visat på ritning TSN939080.

- Justera balansblocket så att verktyget hänger c:a 20 cm över fatets lock.

- Se till att det finns luftventil, smörjning samt tryckregulator i luftsystemet.t

- Justera lufttrycket till 5,5 bar.

- Justera smörjningen till lämplig mängd.

2. ANVÄNDNINGSINSTRUKTIONER

- Före användning, testa verktyget några gånger för att kontrollera att det fungerar på riktigt

sätt. Kontrollera att vertygets tänder rör sig fritt.

- Smörj tänderna regelbundet och kontrollera att det inte har kommit in smuts/skrot

som hindrar funktionen.

- Placera Tri-Sure® Tab-Seal® kapsylen på sprundet. Placera ena handen på övre cylindern

och greppa med andra handen om manöverventilen samt för verktyget till strax ovanför

sprundet/kapsylen. Tryck lätt ned verktyget över kapsylen.

- Tryck in manöverventilen. Släpp ventilen när stukningsoperationen är avslutad.

- Flytta verktyget från sprundet och kontrollera visuellt att Tri-Sure® Tab-Seal® kapsylen

sitter som den skall.

3. SÄKERHET

- Användning av handskar, skyddsglasögon, hörselskydd och

skyddsskor är obligatorisk.

- Ta tryckluft om verktyget inte används

- Ta tryckluft vid underhåll

- Vidrör inte verktygets tänder när det stär under tryck.

- Använd alltid båda händerna vid användning av verktyget.

- Anväbd verktyget endast till vad det är avsett för.

18

Issued by: Arnold Bos / www.tri-sure.com Issue no.: MAN-1000029 Version: 2Date: 11-02-2015

Trade-marks

Tri-Sure® metal closures, Tri-Sure® plastic

closures, Tab-Seal® caps, SambaCapTM,

UNI-GRIP® spouts, ULTRA-BOND® spouts,

PLASTIPLUGTM plugs, Push-LockTM caps,

PLASTICAPTM screw caps, PLASTIROB®

taps, CDS® dispense closures

Disclaimer: all information on our behalf in relation to our products, whether in nature of date, recommendations or otherwise, is supported by research and believed reliable, but we assume no liability

whatsoever in respect of application, processing or use made of the aforementioned information or products or any consequence thereof. The user undertakes all liability in respect of the application.

Processing or use of the aforementioned information or products, whose quality and other properties he shall verify, or any consequence thereof. No liability whatsoever shall attach to us for any

infringement of the rights owned or controlled by a third party on intellectual, industrial or other property by reason of the application, processing or use of the aforementioned information or products by

the user.

Norwegian / norsk

INSTRUKSJONER FOR MONTERING OG BETJENING

av pneumatiske Tri-Sure® kapselapparater

type IPT-S G2

type IPR-S G3/4

type 60IPU Uni-Grip

1. MONTERING

- Monter apparatet som angitt i tegning TSN939080.

- Innstill balanseenheten slik at apparatet henger fritt, ca. 20 cm over fatet.

- Pass på at lufttilførselen til apparatet har en stengeventil, en smøreenhet og en

reduksjonsenhet.

- Juster lufttrykket til 5,5 bar.

- Innstill smøreenheten slik at det foregår en regelmessig smøring.

2. BRUK

- Før bruk er det viktig at apparatet betjenes noen ganger for å kontrollere at det virker

som det skal. Påse at kjevene kan bevege seg fritt.

- Smør kjevene regelmessig med litt olje, og kontroller om det er forurensninger på

kjevene som kan forstyrre apparatets funksjon.

- Sett Tri-Sure® kapselapparatet på Tri-Sure® kapselen. Plasser en hånd på den øvre

sylinderen og den andre hånden ved betjeningsknappen og før apparatet over kapselen.

Press lett nedover inntil apparatet befinner seg på kapselen.

- Betjen luftbryteren. Slipp luftbryteren så snart krympingen er ferdig.

- Beveg apparatet bort fra kapselen og kontroller at Tri-Sure® kapselen er riktig krympet.

3. SIKKERHET

- Bruk av hansker, vernebriller, hørselvern, og

vernesko er obligatorisk.

- Fjern trykklufttilførsel hvis verktøyet ikke benyttes

- Fjern trykklufttilførsel under vedlikehold

- Ikke berør kjevene mens luften er tilkoblet.

- Apparatet må alltid betjenes med to hender.

- Dette apparatet må kun brukes til det formålet det er konstruert for.

19

Issued by: Arnold Bos / www.tri-sure.com Issue no.: MAN-1000029 Version: 2Date: 11-02-2015

Trade-marks

Tri-Sure® metal closures, Tri-Sure® plastic

closures, Tab-Seal® caps, SambaCapTM,

UNI-GRIP® spouts, ULTRA-BOND® spouts,

PLASTIPLUGTM plugs, Push-LockTM caps,

PLASTICAPTM screw caps, PLASTIROB®

taps, CDS® dispense closures

Disclaimer: all information on our behalf in relation to our products, whether in nature of date, recommendations or otherwise, is supported by research and believed reliable, but we assume no liability

whatsoever in respect of application, processing or use made of the aforementioned information or products or any consequence thereof. The user undertakes all liability in respect of the application.

Processing or use of the aforementioned information or products, whose quality and other properties he shall verify, or any consequence thereof. No liability whatsoever shall attach to us for any

infringement of the rights owned or controlled by a third party on intellectual, industrial or other property by reason of the application, processing or use of the aforementioned information or products by

the user.

Danish / dansk

INSTALLATIONS- OG BETJENINGSVEJLEDNING

til pneumatiske Tri-Sure®kapselpåsætningsapparater

type IPT-S G2

type IPR-S G3/4

type 60IPU Uni-Grip

1. INSTALLATION

- Installer apparatet som vist på tegning TSN939080.

- Juster balance-enheden således, at apparatet hænger ca. 20 cm frit over beholderen.

- Kontroller, at luftforsyningen til apparatet er forsynet med en luftventil, en smøre-enhed og

en reduktionsventil.

- Indstil lufttrykket på 5,5 bar.

- Juster smøre-enheden således, at der smøres regelmæssigt.

2. BRUG

- Før brug betjenes apparatet nogle få gange for at kontrollere, om det fungerer korrekt.

Kæberne skal bevæge sig uhindret.

- Kæberne smøres jævnligt med et tyndt lag olie, og det kontrolleres, om tilsmudsning er

til hinder for apparatets korrekte funktion.

- Sæt Tri-Sure® kapslen på Tri-Sure® lukningen. Sæt den ene hånd på den øverste cylinder

og den anden hånd ved betjeningsknappen og før apparatet hen over lukningen. Tryk en

smule nedad, indtil apparatet er på lukningen.

- Aktiver luftventilen. Slip luftventilen, så snart krympningen er afsluttet.

- Før apparatet bort fra lukningen og kontroller, om Tri-Sure® kapslen er sat rigtigt på.

3. SIKKERHED

- Brugen af handsker, øjenbeskyttelse, høreværn og

sikkerhedsfodtøj er obligatorisk.

- Fjern komprimeret luft forsyning hvis der ikke anvendes værktøjet

- Fjern trykluft forsyning under vedligeholdelse

- Når luften er tilkoblet, må man ikke berøre kæberne.

- Apparatet skal altid betjenes med begge hænder.

- Apparatet må kun bruges til det, det er beregnet til.

20

Issued by: Arnold Bos / www.tri-sure.com Issue no.: MAN-1000029 Version: 2Date: 11-02-2015

Trade-marks

Tri-Sure® metal closures, Tri-Sure® plastic

closures, Tab-Seal® caps, SambaCapTM,

UNI-GRIP® spouts, ULTRA-BOND® spouts,

PLASTIPLUGTM plugs, Push-LockTM caps,

PLASTICAPTM screw caps, PLASTIROB®

taps, CDS® dispense closures

Disclaimer: all information on our behalf in relation to our products, whether in nature of date, recommendations or otherwise, is supported by research and believed reliable, but we assume no liability

whatsoever in respect of application, processing or use made of the aforementioned information or products or any consequence thereof. The user undertakes all liability in respect of the application.

Processing or use of the aforementioned information or products, whose quality and other properties he shall verify, or any consequence thereof. No liability whatsoever shall attach to us for any

infringement of the rights owned or controlled by a third party on intellectual, industrial or other property by reason of the application, processing or use of the aforementioned information or products by

the user.

Finnish / suomi

ASENNUS- JA KÄYTTÖOHJE

Pneumaattiset Tri-Sure®-kapselisuljinlaitteet

tyyppi IPT-S G2

tyyppi IPR-S G3/4

tyyppi 60IPU Uni-Grip

1. ASENNUS

- Asenna laite piirustuksessa TSN939080 esitetyllä tavalla.

- Säädä tasapainotusyksikkö siten, että laite riippuu vapaasti noin 20 cm tynnyrin yläpuolella.

- Tarkasta, että laitteeseen johtava paineilmajohto on varustettu sulkuventtiilillä,

voiteluyksiköllä ja paineenalennusyksiköllä.

- Säädä paineilman paineeksi 5,5 bar. Jos paine on pienempi kuin 5 bar.

- Säädä voiteluyksikkö siten, että voitelu on tasaista.

2. KÄYTTÖ

- Kokeile laitetta ennen käyttöönottoa muutaman kerran ja tarkasta, että se toimii oikein.

Leukojen on avauduttava ja sulkeuduttava hyvin.

- Voitele leuat kevyesti öljyllä säännöllisin välein ja tarkasta ettei laitteessa ole likaa,

joka voisi aiheuttaa häiriöitä sen toimintaan.

- Aseta Tri-Sure®-kapseli Tri-Sure®-sulkimen päälle. Tartu toisella kädellä yläsylinteriin ja

vie toinen käsi käyttökytkimelle. Siirrä laite sulkimen yläpuolelle. Paina laitetta kevyesti

alaspäin, kunnes se on kiinni sulkimessa.

- Paina ilmakytkintä. Vapauta kytkin, kun kapselointi on päättynyt.

- Siirrä laite pois sulkimen päältä ja tarkasta, että Tri-Sure®-kapseli on kiinnittynyt hyvin.

3. TURVALLISUUS

- Käyttö käsineitä, suojalaseja, kuulosuojaimia, ja

turvajalkineita on pakollista.

- Poista paineilmatuotantoa jos työkalua ei käytetä.

- Poista paineilma huollon aikana.

- Älä koske leukoihin paineilman ollessa kytketty.

- Käytä laitetta aina molemmin käsin.

- Käytä laitetta vain siihen tarkoitukseen, johon se on tehty.

Table of contents

Popular Industrial Equipment manuals by other brands

SCHUNK

SCHUNK MPG-plus Translation of the original manual

Beisler

Beisler 1265-7 operating instructions

6K Products

6K Products DH0602 Operation and parts manual

Eaton

Eaton NZM4-XU Series Instruction leaflet

GRAVEDA

GRAVEDA GRASPRESSO GP50-15 instruction manual

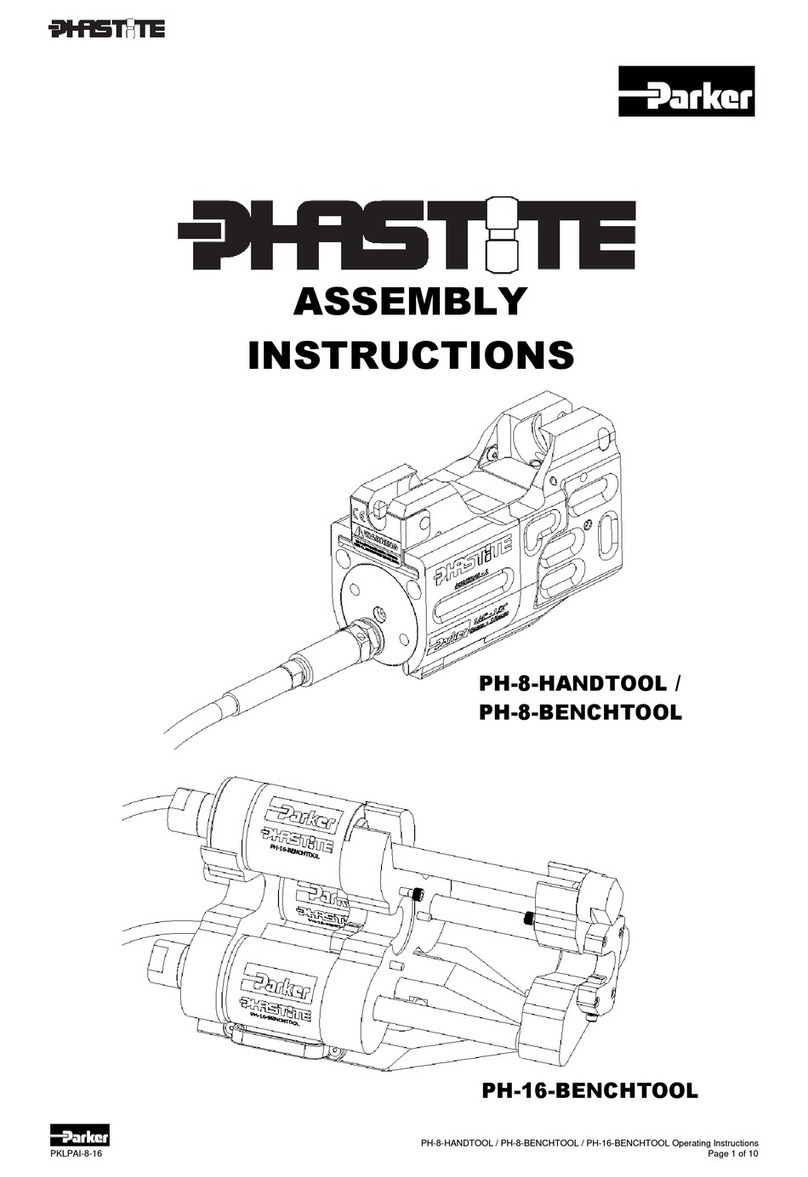

Parker

Parker Phastite PH-8-HANDTOOL Assembly instructions