PASCO Compression Igniter 012-13028C Introduction

2

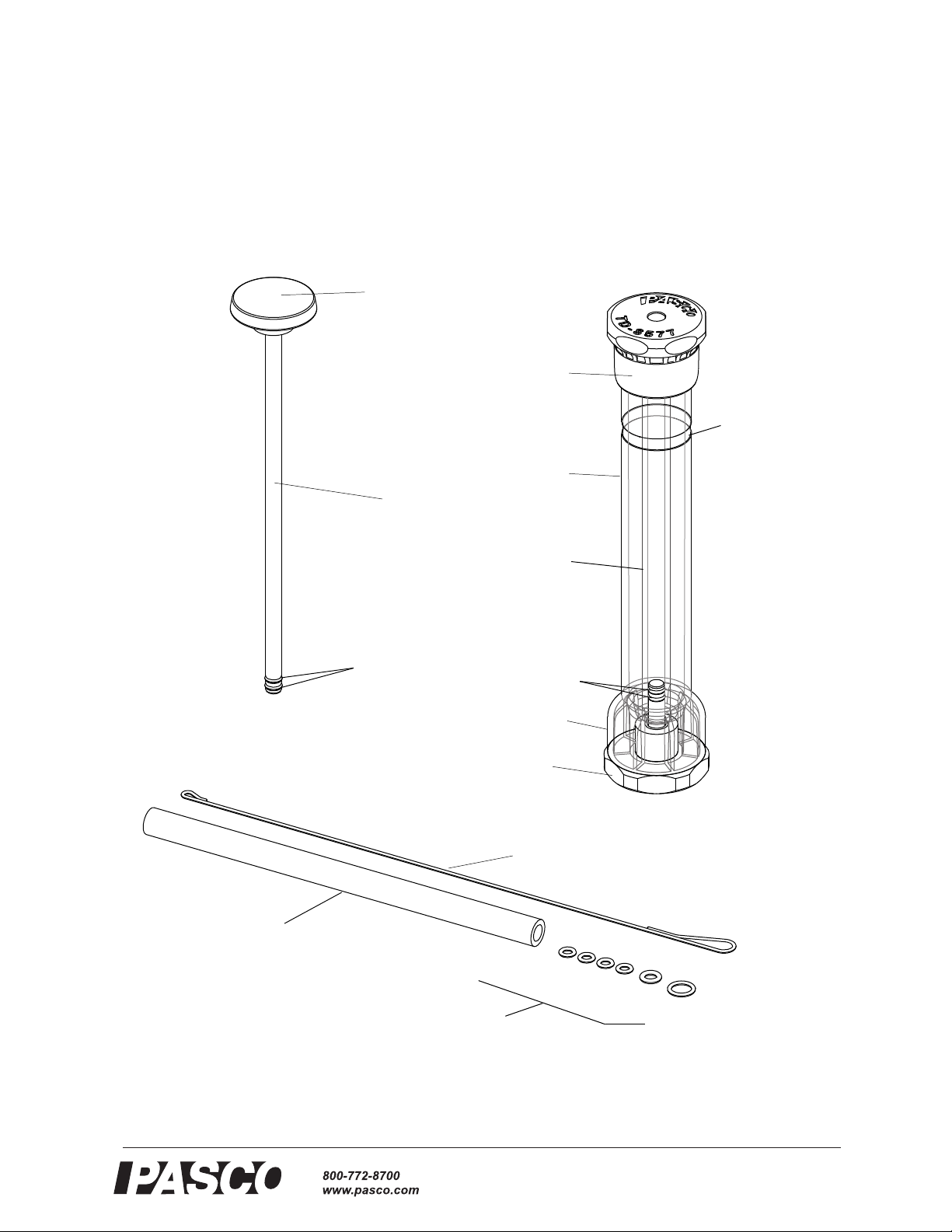

* The TD-8498A Replaceable Glass Tubes includes two replacement tubes and twelve O-rings.

Introduction

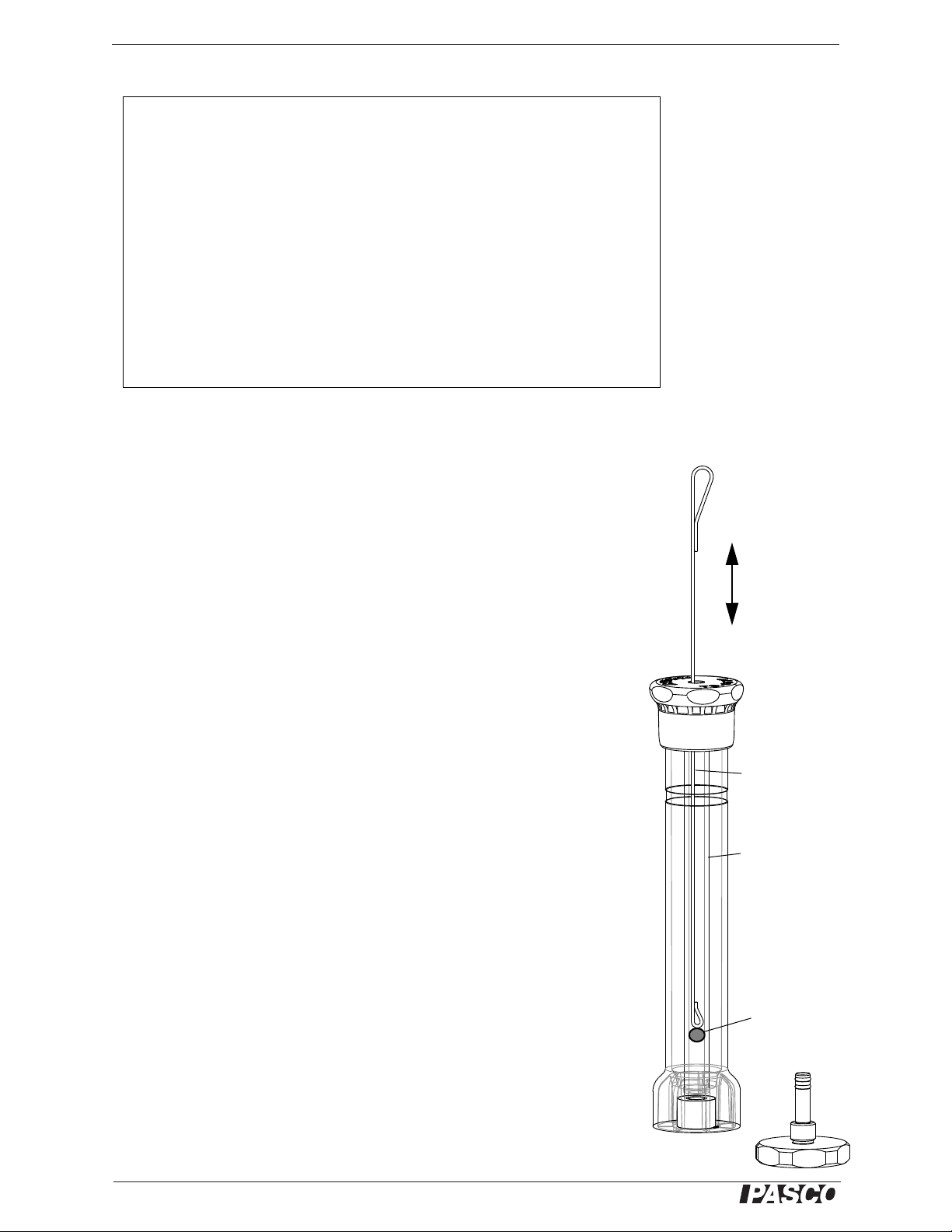

The TD-8577 PASCO Compression Igniter (or “fire syringe”) illustrates what hap-

pens inside the cylinder of a diesel engine. It demonstrates the high temperatures pro-

duced during adiabatic compression of air by igniting a small amount of cotton, tissue

paper, or magician’s “flash paper” inside a replaceable, thick-wall glass tube. The

glass tube is encased in a polycarbonate safety tube that protects users from injury if

the glass tube breaks. The piston has two rubber “O” rings at its end that provide a

tight seal against the inside of the glass tube. When the piston is rapidly pressed down

into the glass tube, the temperature inside the tube rises quickly.

The Compression Igniter comes with one replacement glass tube and six O-rings. The

large O-ring is a replacement for the ring at the top of the inner glass tube. The

medium O-ring is a replacement for the ring at the top of the piston rod where it joins

the knob. The small O-rings are replacements for the rings on the end of the piston

rod and for the rings on the post that is part of the removable base.

Theory

The compression of air inside a hollow cylinder is an adiabatic process since the

compression is so fast that there is no time for thermal energy to leave or enter the

cylinder.

For an adiabatic compression of gas, , where Pis the pressure of the

gas, Vis the volume of the gas, and is the ratio of specific heats of the gas (specific

heat at constant pressure divided by specific heat at constant volume)

Therefore, when the gas in the cylinder is at its original volume V0and pressure P0

and then is compressed to a small volume Vand pressure P,

With the compression igniter, it is possible to compress the gas in the cylinder by a

factor of about 15, so V0= 15V. With this assumption, the final pressure at maximum

compression can be calculated in terms of the initial (atmospheric) pressure:

The quantity that is of interest is the final temperature: Is it high enough to ignite

paper? To arrive at the temperature, assume that the gas is air and that it is an ideal

gas. For an ideal gas,

Included Equipment Included Equipment

PASCO Compression Igniter Replacement Glass Tube*

Loading/Cleaning Rod Replacement O-rings* (6)

Lubricant, silicone compound, (2 packets), not shown Material Safety Data Sheet for Lubricant

Additional Item Needed Cotton, tissue paper, “flash paper”

The ignition temperature of

paper is about 451 °F.

See the science fiction

novel Fahrenheit 451 by

Ray Bradbury.