Trianco QAA73 User manual

R

REMOTE

EMOTE CONTROL

CONTROL

QAA73

QAA73

INSTRUCTIONS FOR THE SERVICEMAN

●Installing, using and programming the QAA73 remote control

●Programming boilers Optima CB ed SB with QAA73

●Application examples of a hydraulic installation

●Application examples of a hydraulic installation with additional zones

●Application examples of cascade systems

– 2 –

OPTIMA CB - SB

OPTIMA CB - SB

Service instructions

Service instructions

CONTENTS:

1 General description of the remote control

. . . . . . . . . . . . . . .

pag. 3

2 Preliminary steps for installation and commissioning

. . .

pag. 3

3 Technical characteristics

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 4

4 Installing the appliance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 4

5 Description of the controls

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 5

6 Displayed information

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 5

7 Operating modes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 5

7.1 Heating circuits

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 5

7.2 Domestic hot water

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 5

8 Room temperature adjustmen

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 6

9 Comfort/economy mode selector button

. . . . . . . . . . . . . . . .

pag. 7

10 Value reading button

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 7

11 User programming

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 8

11.1 List of user parameters

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 8

11.2 Details of the user parameters

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 9

12 Installer programming

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag . 11

12.1 List of installer parameters

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 11

12.2 Details of the installer parameter

. . . . . . . . . . . . . . . . . . . . . . . . .

pag. 12

13 Serviceman programming

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 18

13.1 List of serviceman parameters

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 18

13.2 Details of the serviceman parameter

. . . . . . . . . . . . . . . . . . . . .

pag. 19

14 Access to the boiler

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 25

15

OPTIMA connection wiring diagram . . . . . . . . . . . . . . . . . . .

pag. 26

16

A

CCESS TO THE BOILER

PCB

PARAMETERS USING

THE

QAA 73

REMOTE CONTROL

. . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 27

16.1 Temperatures

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 27

16.2 (Characteristic) heating curves

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 29

16.3 Installation type configuration

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 29

16.4 Timing (or timers)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 29

16.5 Pressures

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 30

16.6 Second circuit - mixed or direct

. . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 30

16.7 Maximum fan speed during heating

. . . . . . . . . . . . . . . . . . . . .

pag. 30

17 Modifying the serviceman parameters

. . . . . . . . . . . . . . . . . .

pag. 31

17.1 1 Modifying the minimum fan speed (switch from

natural gas to LPG or vice versa)

. . . . . . . . . . . . . . . . . . . . . . . . .

pag. 31

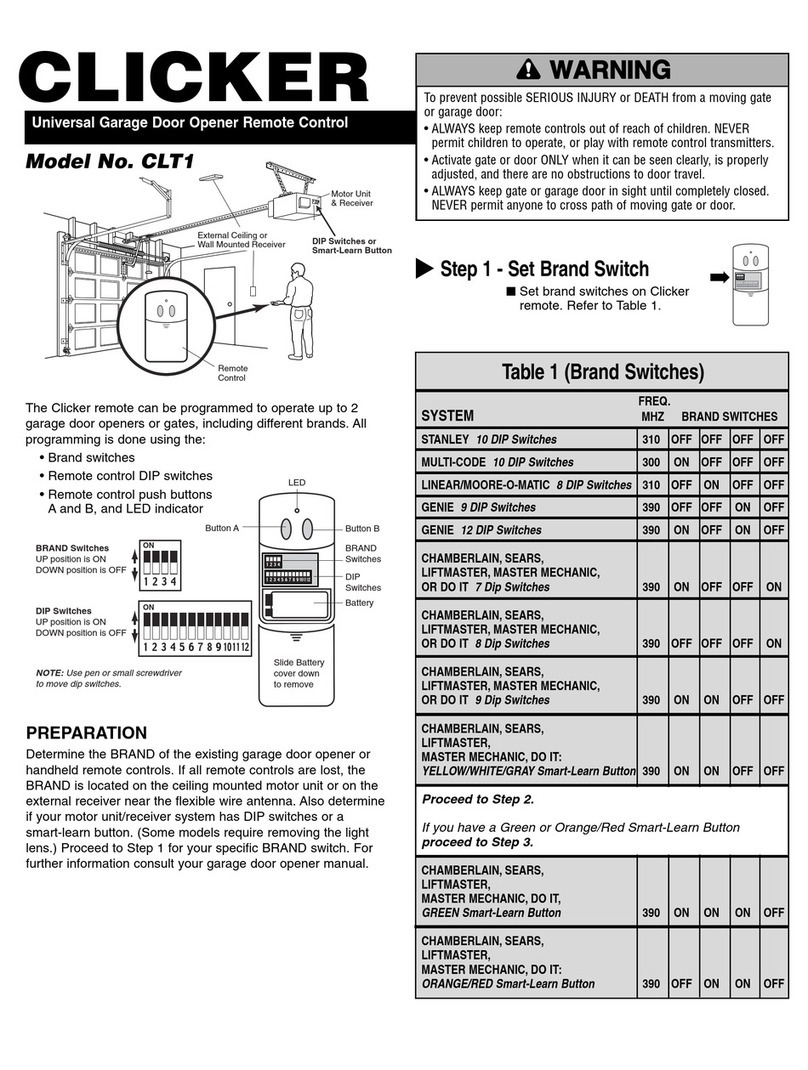

18 Hydraulic diagrams

Application samples

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

pag. 32

– 3 –

OPTIMA CB - SB

OPTIMA CB - SB

Service instructions

Service instructions

The wires used to connect the sensors, remote con-

trols, buses etc.... to the regulator must have double

insulation; alternatively, they must follow a separate

path from that of the mains power supply cables.

Before making the electrical connections,

always ensure that the cables are not live.

Never touch the wires and connections of

the appliance; isolate the appliance from

the electricity mains before making any

connections or disconnections.

QAA73 is a high tech remote control built in complian-

ce with standards , with a weekly timer feature

(with annual date setting), boiler operation and pro-

gramming control functions, zone detector, alarm si-

gnalling and advanced diagnosis.

It guarantees the optimal heat regulation thanks its

microprocessor-based technology. This technical so-

lution allows for the OPTIMA CB and OPTIMA SB

heating units to be controlled according to the chan-

ges in the external temperature.

When programmed correctly and applied to a compa-

tible system, the control unit ensures in real time that

the system heats at the desired temperature and for

the set amount of time.

Warning:

Any other use of this appliance is to be conside-

red improper and consequently dangerous.

For safety reasons, do not open up the regulator

or any of its accessories; all the installation and

maintenance operations and any repair work must

be carried out by authorised professionally quali-

fied servicemen.

The manufacturer will not be liable for any con-

tractual and non-contractual responsibility due to

damages caused by the incorrect installation and

use and, in any case, due to non-compliance with

the instructions provided by the manufacturer.

1 GENERAL DESCRIPTION OF THE REMOTE

CONTROL

2 PRELIMINARY STEPS FOR INSTALLATION

AND COMMISSIONING

– 4 –

OPTIMA CB - SB

OPTIMA CB - SB

Service instructions

Service instructions

47

91

96

96

Auto

04812162024

i

3 TECHNICAL CHARACTERISTICS

Safety class: III (EN 60 730)

Degree of protection: IP20

Operating temperature range: 0÷50°C

Humidity: < 85% relative humidity

connection via “OpenTherm BUS”

Cable: 2 wires

(interchangeable)

Maximum length: 50m

Cable resistance: max 2 x 5 Ohm

Battery life: >12h

fig. 3-1

- Remove the plinth from the front of the appliance as

illustrated in figure 4-2

- Secure the plinth to the wall using screws and the

holes made on the same (fig. 4-3). Warning: the fa-

stening screws are not supplied.

4 INSTALLING THE APPLIANCE

fig. 4-2

- To determine the position of the remote control in

the room, please refer to the figure below

150 cm

min. 20 cm

fig. 4-1

fig. 4-3

12

fig. 4-4

fig. 4-5 fig. 4-6

- Connect the wires to the terminals as indicated in

fig. 4-4 and 4-5

- Replace the front of the appliance as indicated in fig.

4-6.

If the remote control is not installed in a room, but

used momentarily by the serviceman to modify the

parameters, access the electrical parts of the boiler

directly, as illustrated in paragraph 14 herein and con-

nect to the PCB as indicated on page 26.

If on the other hand the remote control is installed in a

room, keep to the instructions below.

– 5 –

OPTIMA CB - SB

OPTIMA CB - SB

Service instructions

Service instructions

5 DESCRIPTION OF THE CONTROLS 7 OPERATING MODES

7.2 DOMESTIC HOT WATER

DOMESTIC HOT WATER TEMPERATURE CONTROL

The temperature value is entered by means of parameter 7;

to access this parameter and modify the value, follow the

instructions provided in paragraph 11 (User parameters).

PROGRAMMING THE DOMESTIC HOT WATER (D.H.W.)

PRODUCTION PERIOD

By modifying the parameters of the remote control QAA73,

you can choose the type of D.H.W. production period pro-

gramming; depending on the parameters set, the produc-

tion may take place continuously (24 hours a day), by fol-

lowing the heating programme one hour ahead or following

the heating programme (again taking into account a certain

advance on the activation of the latter), or even by following

the D.H.W. production programme set on lines 30 ... 36.

The appliance parameters are factory set for the production

of domestic hot water to take place according to the heating

programme one hour ahead (HC - 1 hour).

7.1 HEATING CIRCUITS

Auto

0 4 8 12 16 20 24

i

Prog

1

2

3

4

5

6

7

8

9

Auto

0 4 8 12162024

B

D

A

C

1 - Room temperature control knob

2 - Programme line selector buttons

3 - D.H.W. ON/OFF button

4 - Display

5 - Automatic / permanent / pilot flame operation but-

ton

6 - Parameter value modification buttons

7 - Value reading button

8 - Comfort/economy mode selector button

9 - Flap

To access the internal buttons 2, 3, 5 and 6, pull open

the flap 9 on the control panel.

6 DISPLAY INFORMATION

fig. 5-1

fig. 6-1

A - Current operating mode (horizontal black bars)

B - Normal or modification operation

C - Bars indicating the periods of operation

D - Indication of:

- Burner on

- Comfort mode enabled

- Economy mode enabled

- Anti-frost protection enabled

- Boiler shutdown alarm

To enable the desired function, press button 5 until the hori-

zontal black bar on the display indicating the current opera-

ting mode is positioned underneath the desired function

symbol.

Warning: using the function buttons reserved for central

heating does not affect the production of domestic hot water

in any way, except during programmed holidays and when

the telephone remote control is enabled.

“

AUTOMATIC

”function (Auto ""); enabling it leads to the fol-

lowing conditions:

•Heating circuits 1 and 2 enabled, depending on the timing

programmed on lines 10...16 and 20...26

•Reference temperature according to the heating program-

me

•Anti-frost protection enabled

•Automatic summer/winter commutation enabled

•Holiday programme enabled

“

PERMANENT

”function (dd); enabling it leads to the following

conditions:

•Heating circuits 1 and 2 in continuous operation, irrespecti-

ve of the timing

•room temperature adjustment on the relevant control knob

•protection functions enabled

•automatic summer/winter commutation disabled

•Holiday programme disabled

“

STAND

-

BY

“function (oo); qenabling it leads to the following

conditions:

•central heating turned off

•temperature according to the anti-frost protection

•protection functions enabled

•automatic summer/winter commutation enabled

•holiday programme enabled

– 6 –

OPTIMA CB - SB

OPTIMA CB - SB

Service instructions

Service instructions

The central heating system uses three different configurable re-

ference values:

- reference value for the room temperature described herein

(adjustment via knob ref. 1, figure par. 5)

- reference value for the room temperature in economy mode

(adjustment line 6)

- reference value for the room temperature for the anti-frost

protection (line 5)

EFFECTS OF THE TEMPERATURE ADJUSTMENT

When the reference temperature is enabled, the rooms are

heating according to the adjustment made on the relative con-

trol knob. When you turn the knob, the room temperature re-

quested is displayed as well as set and, if the remote control

QAA73 controls two circuits (HC1 and HC2, for example), the

value will be applied to both circuits.

EFFECTS ON THE DIFFERENT HEATING MODES:

Auto ""The adjustment acts during the set heating periods

dThe adjustment acts continuously

oThe adjustment has not effect whatsoever

Note:

The adjustment made on the control knob has priority over the

reference value for the economy mode of the room temperatu-

re set (line 6), especially if the value set with the knob is lower.

Comfort mode (set with the control knob)

Economy mode (defined on line 5; adjustment range:

between the anti-frost protection value –line 6 –and the

value set with the control knob)

Anti-frost protection (set on line 6; adjustment range:

between 4°C and the economy mode value)

8

ROOM TEMPERATURE ADJUSTMENT

fig. 8-1

MODELS WITH INSTANT HOT WATER PRODUCTION

(OPTIMA CB):

For those models designed to produce hot water instantly,

we recommend you set the hourly D.H.W. production pro-

gramme to “24 hours/day”.

Per eseguire l’impostazione, agire come segue:

- Select line 91 (D.H.W. production mode) by following the

instructions provided in paragraph 12 and set “24

hours/day”.

Activate the D.H.W. production by pressing button 3on the

remote control QAA73 (a horizontal black bar appears be-

neath the symbol s).

MODELS SB (WITHOUT DOMESTIC HOT WATER PRO-

DUCTION DESIGNED TO BE CONNECTED TO A WA-

TER HEATER) WITH A REMOTE WATER HEATER CON-

TROLLED VIA AN NTC SENSOR:

For the D.H.W. programming of these models, proceed as

follows:

- Select line 91 (D.H.W. production mode) by following the

instructions provided in paragraph 12 and choose the de-

sired programme; if you want a programme independen-

tly from the central heating programme, set “prog A.C.S."

("D.H.W. prog.”); at this stage, the programming lines

(from 30 to 36) relative to the D.H.W. production are acti-

vated.

- Activate the D.H.W. production by pressing button 3(a ho-

rizontal black bar appears beneath the symbol s).

FOR MODELS SB (WITHOUT D.H.W. PRODUCTION DE-

SIGNED TO BE CONNECTED TO A WATER HEATER)

WITH A REMOTE WATER HEATER CONTROLLED VIA

A THERMOSTAT:

The D.H.W. temperature is adjusted on the indirect cylinder

thermostat.

The production of domestic hot water starts on closing of

the thermostat contacts.

The remote control QAA73 has no control over the indirect

cylinder; button 3is disabled.

– 7 –

OPTIMA CB - SB

OPTIMA CB - SB

Service instructions

Service instructions

Press this button repeatedly to display the

following information in sequence:

1 - Correct time, room temperature measured and opera-

ting mode

2 - Error indication

3 - Service display

4 - Correct time and operation of the heating circuit 1

5 - Correct time and date

6 - Current value of the external temperature

7 - Minimum value of the external temperature *

8 - Maximum value of the external temperature *

9 - Current value of the room temperature

10 - Minimum value of the room temperature *

11 - Maximum value of the room temperature *

12 - Current value of the domestic hot water temperature

13 - Current value of the boiler temperature

14 - Current value of the flow temperature

15 - Burner modulation

16 - Central heating circuit pressure

Based on the parameter set on line 150, the display

can be continuous or it can return to the normal rea-

ding after 8 minutes of inactivity.

* - Absolute minimum and maximum temperature recorded

on activation of the remote control QAA73; to reset the

recording, press buttons +/- at the same time for 3 se-

conds.

10

VALUE READING BUTTON

i

fig. 10-1

During the "automatic“(Auto")) and ”perma-

nent“(dd)heating circuit operating modes, this

button allows you to switch automatically from

the comfort mode to the economy mode.

Effect on the “AUTOMATIC”mode (Auto"):

The operating mode switches simultaneously from comfort

to economy mode or vice versa; the effect will be reflected

on the heating circuits 1 and 2, or only on circuit 1, depen-

ding on the setting made by the serviceman on line 153

Effect on the “PERMANENT”mode (dd):

The operating mode switches simultaneously from comfort

to economy mode and vice versa.

This switch does not affect the D.H.W. production or the ho-

liday programme.

In the event of the automatic summer/winter variation, the

switch is disabled.

9

COMFORT/ECONOMY MODE SELECTOR

BUTTON

i

fig. 9-1

– 8 –

OPTIMA CB - SB

OPTIMA CB - SB

Service instructions

Service instructions

Push-button

Indication Line

11

2

from 1 to 50

11

USER PROGRAMMING

Below is the generalised sequence of use of the buttons to modify

the parameters reserved for the user.

i

Prog

i

Prog

Press one of the line selec-

tor buttons to access the

programming operations.

Press one of these selec-

tor buttons to access the

desired line

Push-button

Indication Line

3

4Continuous

Display

i

i

Press the adjustment but-

tons to set the desired va-

lue; the value is stored

when you quit the pro-

gramming or when you

change line

Press the VALUE REA-

DING button to quit the

programming.

Factory Setting Range of

Line Function

setting made value

CLOCK:

01 Time setting - …

00:00÷23:59

02 Date (day, month) -

…

01.01÷31.12

03 Year -

…

1999÷2099

SETTING THE OPERATING TEMPERATURES

05 Temperature value for the economy mode (TRRw) 16,0 …

TRF…TRN

06 Anti-frost protection value of the room temperature (TRF) 10,0 …4…TRRw

07 Nominal value of the domestic hot water temperature (TBWw) 55,0 …

TBWR…TBWmax

PROGRAMMING THE HEATING CIRCUIT 1 TIMES

10 Selection of the programming period --.-- …

Mo…Sun, week

11 Start of the first heating period 06:00 …

--:--…24:00

12 End of the first heating period 22:00 …

--:--…24:00

13 Start of the second heating period --.-- …

--:--…24:00

14 End of the second heating period --.-- …

--:--…24:00

15 Start of the third heating period --.-- …

--:--…24:00

16 End of the third heating period --.-- …

--:--…24:00

PROGRAMMING THE HEATING CIRCUIT 2 TIMES

20 Selection of the programming period --.-- …

Mo…Sun, week

21 Start of the first heating period 06:00 …

--:--…24:00

22 End of the first heating period 22:00 …

--:--…24:00

23 Start of the second heating period --.-- …

--:--…24:00

24 End of the second heating period --.-- …

--:--…24:00

25 Start of the third heating period --.-- …

--:--…24:00

26 End of the third heating period --.-- …

--:--…24:00

PROGRAMMING THE D.H.W. TIMES:

30* Selection of the programming period --.-- …

Mo…Sun, week

31* Start of the first D.H.W. period 06:00 …

--:--…24:00

32* End of the first D.H.W. period 22:00 …

--:--…24:00

33* Start of the second D.H.W. period -- …

--:--…24:00

34* End of the second D.H.W. period -- …

--:--…24:00

35* Start of the third D.H.W. period -- …

--:--…24:00

36* End of the third D.H.W. period -- …

--:--…24:00

HOLIDAY PROGRAMMING:

40 Start of the holiday period (day, month) --.-- …

1 jan…31 dec

41 End of the holiday period (day, month) --.-- …

1 jan…31 dec

42 Type of operation of the heating circuit during …Anti-frost

the holiday period Anti-frost or reduced

GENERAL:

45 Resetting the settings made on lines 10...16, 20...26 and 30...36 No - Yes/No

(Keep the + and - buttons pressed together for more than 3 seconds)

46 Winter/summer commutation temperature value 17,0 …8…30

47 language Italian -

50 Error display -- - 0…255

11.1

LIST OF USER PARAMETERS

* - Only enabled when parameter 91 (installer parameters, see the next paragraph) is set to “Prog d.h.w”.

– 9 –

OPTIMA CB - SB

OPTIMA CB - SB

Service instructions

Service instructions

LINE 15: the adjustment buttons (+) or (-) allow you to

set the starting time of the third heating period

of the day or period selected in line 10: by kee-

ping the buttons pressed, the minutes change

quickly.

LINE 16: the adjustment buttons (+) or (-) allow you to

set the stopping time of the third heating period

of the day or period selected in line 10: by kee-

ping the buttons pressed, the minutes change

quickly.

Warning:

- If the starting and stopping times of the heating are

different for each day of the week, the parameters

will have to be set for each day; if the two times coin-

cide, select the block “1-7”in line 10 and set the ti-

mes.

- For the selection of the heating period, the time in-

creases in 10-minute intervals until 00.00 or 24.00 of

the day set in line 10. If you have to set the time for

the next day, first set the number of the day in line

10.

- The time set for the heating period to stop may not be

before, or coincide with the starting time of this same

period.

- When you first programme them, “--.--”appears in li-

nes 11…16. To enter the time, press the “–”button

once: you will see “24.00”on the display; now you

can enter the desired time.

PROGRAMMING THE HEATING TIMES OF CIRCUIT 2

(LINES 20 - 26):

The programming of the heating periods for circuit 2 follow

the same procedure used for circuit 1; therefore, to set it

you can follow the instructions from line 10 to line 16.

PROGRAMMING THE DOMESTIC HOT WATER HEA-

TING TIMES (LINES 30 - 36 ):

To programme the domestic hot water production, you must

do the same as for the heating circuits; therefore, to set it

you can follow the instructions from line 10 to line 16.

The programming can be carried out only if “Prog. dhw”has

been set in line 91.

PROGRAMMING THE HOLIDAY PERIOD:

The programming of lines 40...42 can only be carried out in

automatic mode (Auto").

Line 41 can be programmed only if an initial date has been

set in line 40.

During the period set in lines 40 and 41, the boiler operates

according to the value set in economy mode or according to

the anti-frost protection value, depending on how line 42

was programmed.

During the holiday programme, the domestic hot water pro-

duction is blocked.

LINE 1: the adjustment buttons (+) or (-) allow you to

set the correct time: by keeping the buttons

pressed, the minutes change quickly.

LINE 2: the adjustment buttons (+) or (-) allow you to

set the correct date: by keeping the buttons

pressed, the days change quickly.

LINE 3: the adjustment buttons (+) or (-) allow you to

set the correct year: by keeping the buttons

pressed, the numbers change quickly.

TEMPERATURE

LINE 5: the adjustment buttons (+) or (-) allow you to

set the ECONOMY SET POINT (ECONOMY

MODE REFERENCE VALUE) referring to the

value of the room temperature. If this tempera-

ture drops below the reference value, the boiler

will start and will continue to operate until the

room temperature reaches the value set.

LINE 6: the adjustment buttons (+) or (-) allow you to

set the ANTI-FROST PROTECTION SET

POINT (ANTI-FROST PROTECTION REFE-

RENCE VALUE) referring to the value of the

room temperature. If this temperature drops

below the reference value, the boiler will start

and will continue to operate until the room tem-

perature reaches the value set.

LINE 7: the adjustment buttons (+) or (-) allow you to

set the SET POINT (REFERENCE VALUE) of

the domestic hot water temperature value.

PROGRAMMING THE HEATING CIRCUIT 1 TIMES:

LINE 10: the adjustment buttons (+) or (-) allow you to

select the day (or the block 1-7) to be program-

med

LINE 11: the adjustment buttons (+) or (-) allow you to

set the starting time of the first heating period

of the day or period selected in line 10: by kee-

ping the buttons pressed, the minutes change

quickly.

LINE 12: the adjustment buttons (+) or (-) allow you to

set the stopping time of the first heating period

of the day or period selected in line 10: by kee-

ping the buttons pressed, the minutes change

quickly.

LINE 13: the adjustment buttons (+) or (-) allow you to

set the starting time of the second heating pe-

riod of the day or period selected in line 10: by

keeping the buttons pressed, the minutes

change quickly.

LINE 14: the adjustment buttons (+) or (-) allow you to

set the stopping time of the second heating pe-

riod of the day or period selected in line 10: by

keeping the buttons pressed, the minutes

change quickly.

11.2

DETAILS OF USER PARAMETERS

– 10 –

OPTIMA CB - SB

OPTIMA CB - SB

Service instructions

Service instructions

LINE 47: the adjustment buttons (+) or (-) allow you to

select the language of the display on the

screen.

LINE 50: error code indication reading.

The appliance is designed to identify and di-

splay errors which occur inside it or in the cir-

cuit. In the event of internal errors or circuit

malfunction, the symbol comes up on the di-

splay.

Once line 50 has been selected, “error”comes

up on the display, followed by the relevant co-

de and a brief description of the error itself.

The codes and their meanings are indicated in

the instruction manual for the boiler installer.

Once the set holiday period is over, the normal weekly pro-

gramming will be restored.

The dates indicating the beginning and the end of the holi-

day are automatically reset when the holiday is over.

To reset or interrupt the programme in advance, select line

40 or 41 and keep buttons + and - pressed for 3 seconds.

LINE 40: the adjustment buttons (+) or (-) allow you to

select the day on which the holiday period is to

be activated. By keeping the buttons pressed,

the days change quickly.

LINE 41: the adjustment buttons (+) or (-) allow you to

select the day on which the holiday period is to

be deactivated. By keeping the buttons pres-

sed, the days change quickly..

LINE 42: the adjustment buttons (+) or (-) allow you to

select the boiler's operating mode during the

holiday programme (economy mode or anti-fro-

st protection).

GENERAL

LINE 45: restoring the default settings in lines 10...16,

20...26 and 30...36 (keep the buttons + and -

pressed for at least 3 seconds).

LINE 46: the adjustment buttons (+) or (-) allow you to

set the temperature commutation between

SUMMER / WINTER, calculated according to

the average value of the external temperature

over a set period of time and to the type of buil-

ding (installer parameters) for heating circuit 1

(ref. Diagram in figure 11.2-1). As soon as this

value exceeds the set temperature by 1 de-

gree, the boiler automatically activates the do-

mestic hot water production, while, if the same

value drops 1 degree below the set value, the

boiler will activate both the heating function

and the domestic hot water production (please

note that, if there is a sudden temperature

drop, the heating is not activated).

The increase in this value results in the change

being brought forward in WINTER and delayed

in SUMMER; whereas, the decrease in this va-

lue results in a delayed activation in WINTER

and an early activation in SUMMER.

The function only has effect if it is carried out in

automatic mode (Auto").

ON

17

T (°C)

THG

TAged

OFF

t (min)

THG +1 °C

THG –1 °C

16

18

19

20

Taged = average value of the external temperature calcula-

ted

THG = winter/summer commutation temperature value

Central heating turned off (switch from winter to summer po-

sition) when: TAged > THG +1°C

Central heating turned on (switch from summer to winter po-

sition) when: TAged < THG -1°C

fig. 11.2-1

Central heating

– 11 –

OPTIMA CB - SB

OPTIMA CB - SB

Service instructions

Service instructions

Factory Setting Range of

Line Function

setting made values

SERVICE VALUES

51

Reading of the room temp. in the current mode of heating circuit 1.

--0…35,0

°C

Comfort, economy mode or anti-frost protection value

52

Reading of the room temp. in the current mode of heating circuit 2.

--0…35,0

°C

Comfort, economy mode or anti-frost protection value

53

Reading of corrected external temperature.

- - -50…+50 °C

Adjustable to the current value by pressing the + and - buttons for at least 3 seconds

54

Reading of mixed external temperature

- -50…+50 °C

55 Not available - - -

56 Not available - - -

57

Reading of the current value of the D.H.W. return temperature

- -40…+127°C

58 Not available - - -

59 Not available - - -

61 Not available - - -

62 Open therm mode Plus - Plus

63 Reading of flow set value for heating circuit HC1 - - 0…100 °C

64 Reading of flow set value for heating circuit HC2 - - 0…100 °C

HEATING CIRCUITS HC1 AND HC2

70 Slope of heating curve HC1 (- - = not active) 15,0 …2,5…40,0

71 Min. limit of boiler flow temperature (TVmin) 8 …8…TVmax

72 Max. limit of boiler flow temperature (TVmax) 80 …

TVmin…TKmax

TKmax= max. boiler temperature

73 Parallel shift of the heating curve for circuit 1 0,0 …-4,5…+4,5

74 Type of building Light …

light/heavy

75 Influence of room

(None, on HC1, on HC2, on HC1 + HC2)

su HC1 …

76 Room temperature commutation differential ––.–0,5…4,0

––.–= inactive

77 Adjustment of the heating curve Active …

active/inactive

78 Max. advanced starting time to optimise the control of the ignition 100 min …0…360 min

79 Max. advanced starting time to optimise the control of the stopping 30 min …0…360 min

80 Slope of heating curve HC2 (––.–= inactive) 15,0 …2,5…40,0

81 Min. limit of the flow temperature for heating circuit 2 (TV2min) 8 …8…TV2max

82 Max. limit of the flow temperature for heating circuit 2 (TV2max) 80 …

TV2min…TKmax

83 Parallel shift of the heating curve for circuit 2 0,0 …-4,5…+4,5

DOMESTIC HOT WATER

90 Adjustment of the reduced temperature of D.H.W.

40 …8…TBWw

91 Domestic hot water production mode

HC -1h

…

24hours/day, Prog HC -1h, Prog HC, Prog d.h.w.

92 Legionnaire's disease function (OFF, weekly, daily) Weekly

…

93

Activation (with ECO)/deactivation (without ECO) comfort mode in D.H.W without ECO

…

with / without ECO

GENERAL

95 Operation blockage OFF

…

OFF / ON

96 Reference clock (master) QAA73 QAA73

QAA73/External

97 Date of time change, from summer time to standard time (+1h)

25 mar 25 mar 01jan…31dec

98 Date of time change, from summer time to standard time

25 oct 25 oct 01jan…31dec

12.1

LIST OF INSTALLER PARAMETERS

12

INSTALLER PROGRAMMING

Below is the generalised sequence of use of the buttons to mo-

dify the parameters reserved for the installer.

Push-button

Indication Line

3

from 51 to 98

4

5Continuous

diaplay

i

Prog

Press one of these selec-

tor buttons to access the

desired line

i

i

Press the adjustment buttons

to set the desired value; the va-

lue is stored when you quit the

programming or when you

change line.

Press the VALUE REA-

DING button to quit the

programming.

Push-button

Indication Line

11

251

i

Prog

i

Prog

Press one of the line selector

buttons to access the pro-

gramming operations.

Keep both buttons indicated

opposite pressed simulta-

neously until you select pro-

gramming line 51, and then

release them

– 12 –

OPTIMA CB - SB

OPTIMA CB - SB

Service instructions

Service instructions

LINE 51:

Reading of the value set for the current hea-

ting mode which is active in circuit 1

(comfort, economy or anti-frost protection).

LINE 52:

Reading of the value set for the current hea-

ting mode which is active in circuit 2

(comfort, economy or anti-frost protection).

LINE 53:

The corrected external temperature is the room

temperature simulated in a fictitious building

without a source of internal heat. This means

that the external temperature alone affects the

room temperature.

The corrected external temperature is genera-

ted by the regulator. It is constantly calculated

according to the actual external temperature.

The corrected external temperature only has

direct influence on the summer/winter commu-

tation.

The corrected external temperature has an in-

direct effect, via the mixed external temperatu-

re, on the control of the flow temperature..

No direct adjustment can be made. The gene-

ration of the corrected external temperature

cannot be affected.

Nonetheless, the corrected external temperatu-

re can be reset.

For example:

12.2

DETAILS OF INSTALLER PARAMETERS

LINE 54: The mixed external temperature is the

combination of the actual external tempe-

rature and the corrected external tempera-

ture calculated by the regulator.

The mixing of the actual and corrected ex-

ternal temperature depends on the con-

struction characteristics of the building (li-

ne 74) and takes place as follows:

TYPE OF MIXED EXTERNAL

BUILDING TEMPERATURE

Heavy TAgem = 1/2 TAakt + 1/2 TAged

Light TAgem = 3/4 TAakt + 1/4 TAged

The mixed external temperature acts as a

reference value (compensation variable)

for the adjustment of the flow temperature,

in order to adapt it to the current atmo-

spheric conditions.

It also acts on the “automatic limitation of

daily heating" to stop heating.

For example:

LINE 62: OpenTherm “Plus”is the protocol used for

the communication between the boiler

adjustment (PCB) and the remote control

(Ecotronic); it also allows for the reading

and modification of a number of functions

via the bus.

18:00

13

14

15

16

17

TA

°CTAakt

TAged

06:00 18:00 06:00 18:00 t

TAakt - current external temperature

TAged - corrected external temperature

18:00

13

14

15

16

17

TA

°CTAakt

TAged

TAgem1

TAgem0

06:00 18:00 06:00 18:00 t

TAakt - external temperature measured

TAged - corrected external temperature

TAgem1 - mixed external temperature for light con-

struction building

Tagem0 - mixed external temperature for heavy con-

struction building

fig. 12.2-1

fig. 12.2-2

– 13 –

OPTIMA CB - SB

OPTIMA CB - SB

Service instructions

Service instructions

LINE 70: the adjustment buttons (+) or (-) allow you

to set the slope of the heating curve for the

heating circuit; the correct adjustment of

the latter allows you to establish a constant

room temperature despite any variations in

the external temperature. The curve must

be set according to the type of system and

the type of building. Consequently, before

you modify its value and to ensure the opti-

mum operation of the installation, ask an

authorised service centre for advice.

The regulator generates the flow reference

temperature according to the selected hea-

ting curve.

––. –

All the heating circuit functions

are deactivated; the anti-frost

protection is active only for the

heating module and the indirect

cylinder.

2.5...40.0

All the heating circuit functions

are activated

LINE 71: the adjustment buttons (+) or (-) allow you

to set the minimum limit of the boiler flow

temperature.

LINE 72: the adjustment buttons (+) or (-) allow you

to set the maximum limit of the boiler flow

temperature.

LINE 73: Produces a parallel shift of the heating

curve for circuit 1.

The modification of the values entered will

increase or decrease the reference tem-

perature. This is a basic setting which,

although having the same effect as an

adjustment carried out using the knob, ac-

20 10 0 -10 -20 -30

90

80

70

60

50

40

30

°C

°C

40 35 30 27,5 25 22,5

20

17,5

15

12,5

10

7,5

5

2,5

100

tually influences the position of the set-

tings on the knob.

Note:

The adjustment made on the knob will be

out of phase compared to the resetting,

which makes it possible to calibrate the

settings.

Parallel shift

Any further reference temperature adjust-

ment, whether it be by means of the set

value or the type of operation, results in a

parallel shift of the heating curve.

LINE 74:

the adjustment buttons (+) or (-) allow you

to set the type of building.

It is a function which takes into account the

thermal inertia of the building.

The setting will modify the generation of

the mixed external temperature, which will

allow the system controlled to be adapted

to the type of building.

Heavy construction: (building with thick or

well insulated walls):

The room temperature will respond more

slowly to the variations of the external tem-

perature.

Light construction (building with thin walls):

The room temperature will respond more

rapidly to the variations of the external tem-

perature.

20 10 0 -10 -20 -30

90

80

70

60

50

40

30

°C

°C

100

0

10 10

0

30

TR w

TA

TV

TV Flow temperature

TA Mixed external temperature

TRw Reference room temperature

(also known as room reference temperature)

fig. 12.2-4

Flow temperature

External temperature calculated

slope of the curve

fig. 12.2-3

– 14 –

OPTIMA CB - SB

OPTIMA CB - SB

Service instructions

Service instructions

LINE 75: Influence of the room temperature, i.e. the

shifts in values between the actual room

temperature and the reference room tem-

perature are measured and taken into ac-

count in the adjustment of the temperatu-

re. Hence the return signal of the room

temperature allows you to obtain a more

precise adjustment of the temperature.

The setting will activate or deactivate the

effect of the room temperature shifts on

the temperature adjustment.

To use this function, the following condi-

tions must apply:

The external sensor must be connected to

the boiler

The “Influence of the room temperature"

(75) setting must be active (it must not be

set to “None”).

No regulated thermostatic valve must be

installed inside the room with the boiler (if

there is one, it must be in the "completely

open" position).

NONE Influence of the room temperature inacti-

ve; the room temperature measured has

no effect on the temperature adjustment.

ONHC1 Influence of the room temperature active

on the circuit HC1: the room temperature

measured affects the adjustment of the

temperature of the heating circuit 1.

ONHC2 Influence of the room temperature active

on the circuit HC2: the room temperature

measured affects the adjustment of the

temperature of the heating circuit 2.

ONHC1 Influence of the room temperature active

+HC2 on the circuits HC1 and HC2: the room

temperature measured affects the adjust-

ment of the temperature of both the hea-

ting circuits.

LINE 76: controls the room temperature by means

of heating circuits with circulation pumps.

Prevents the room temperature from be-

coming too high in heating circuits with cir-

culation pumps.

Effect:

The commutation differential for the on-off

control will be modified.

-.- = the differential is inactive;

the circulation pump

always remains active

Decrease = The commutation diffe-

rential takes on a lower

value; the circulation pum-

ps are activated and

deactivated more frequen-

tly.

The room temperature va-

ries within a narrower in-

terval

Increase = The commutation diffe-

rential takes on a higher

value; the circulation pum-

ps must be activated and

deactivated less frequen-

tly.

The room temperature va-

ries within a narrower in-

terval

Room temperature adjustment

In heating circuits with circulation pumps,

heat production is controlled by the activa-

tion and deactivation of circulation pumps.

This is carried out using an on-off control

of the room temperature differential.

OFF

ON

°C

°C

TRx

TRw+SDR

TRw

t

ON

w

OFF

Circulation

pump

Circulation

pump

76

fig. 12.2-5

Legend:

TRx = Current room temperature value

TRw = Room temperature setpoint

SDR = Room temperature commutation differential

°C = Temperature

t = Time

w = Setpoint

– 15 –

OPTIMA CB - SB

OPTIMA CB - SB

Service instructions

Service instructions

LINE 77: The self-adjustment function takes into ac-

count the different heating situations and

adapts the adjustment to the heating cir-

cuit regularly.

The self-adjustment function automatically

matches the heating characteristic to the

type of building and heat requirements.

The self-adjustment takes into account the

shifts in room temperature, the variation of

the external temperature and the sensiti-

vity to adjustment.

Adjustment inactive: the heating curve will

use the set parameters

Adjustment active: the heating curve will

be adjusted automatically and continuou-

sly according to the parameters set in line

75.

Note:

For an optimal self-adjustment, it would be

best if the circumstances listed below oc-

curred as rarely as possible, in particular

just after commissioning, otherwise the

adjustment calculation is partially incor-

rect:

- Manual correction of the heating curve

- Power supply cut off

- Heating characteristic set to -- --

- Modification of the reference room

temperature

An analysis of the room temperature adju-

stment for the previous day is carried out

at midnight. This analysis leads to an au-

tomatic correction of the heating curve.

SIMPLE SELF-ADJUSTMENT (RANGE 3):

For average external temperatures below

4 °C, only the slope of the heating curve is

adjusted. The correction of the slope is

balanced, within this range of temperatu-

res, by the factor f2 and the sensitivity to

adjustment 2.

COMBINED SELF-ADJUSTMENT (RANGE 2):

For average external temperatures

between 4 and 12 °C, the slope is partially

adjusted, and so is the parallel shift the

curve. The correction of the shift is balan-

ced, within this range of temperatures, by

the factor f1 and the sensitivity to adjust-

ment 1.

The correction of the slope is balanced,

within this range of temperatures, by the

factor f2 and the sensitivity to adjustment 2.

NO SELF-ADJUSTMENT (RANGE 1):

For average external temperatures in ex-

cess of 12 °C, the heating curve is not

adjusted.

For example, for a reference room tempe-

rature in comfort mode of 20 °C:

LINE 78: This is a function that precedes the star-

ting of the system according to the pro-

grammed time, to obtain the required

comfort level once the automatic commu-

tation time has been reached.

The function is only effective when line 75

is active (it is not in the “None”position).

In underfloor heating systems (with the

heat coming from the floor), the time in ad-

vance must be greater compared to that of

systems which use heat emitters (radia-

tors).

LINE 79: This is a function that precedes the turning

off of the system according to the pro-

grammed time, to obtain the required re-

duction level once the automatic commu-

tation time has been reached.

The function is only effective when line 75

is active (it is not in the “None”position).

0

TA

12 4 -4 -12

0,5

1

f

20

ged

f

1

f

2

ZAF1 ZAF2

f Factor

f1 Factor for the parallel shift

f2 Factor for the slope

TAged Corrected external temperature

ZAF1 Sensitivity to adjustment 1

ZAF2 Sensitivity to adjustment 2

fig. 12.2-6

– 16 –

OPTIMA CB - SB

OPTIMA CB - SB

Service instructions

Service instructions

LINE 80: As for line 70, but for heating circuit 2

LINE 81: As for line 71, but for heating circuit 2

LINE 82: As for line 72, but for heating circuit 2

LINE 83: As for line 73, but for heating circuit 2

LINE 90: Defines the minimum temperature limit va-

lue at which the D.H.W. (D.H.W. economy

reference temperature) will be maintained

during the D.H.W. programme periods (li-

nes 19 ...25) which are not for the produc-

tion of domestic hot water.

Note:

If the domestic hot water production is

controlled by a thermostat, the D.H.W.

economy reference temperature will not

be applicable.

LINE 91: This is where the timing system for the

production of D.H.W. is chosen; according

to the set parameters, the production can

be continuous (24 hours a day), in accor-

dance with the heating programme (taking

into account the advance time period com-

pared to the activation thereof) or in accor-

dance with the D.H.W. production pro-

gramme set in lines 30 ... 36.

The D.H.W. function may be activated or

deactivated by pressing the corresponding

button (s).

The D.H.W. anti-frost temperature is set at

5 °C and it is always active.

Some examples of the effect of set para-

meters

24H/DAY

ACCORDING TO THE HEATING PROGRAM-

ME, WITH 1 HOUR IN ADVANCE

ACCORDING TO THE HEATING PROGRAMME

ACCORDING TO THE DOMESTIC HOT WATER

PRODUCTION PROGRAMME (LINES 30 …36)

LINE 92: The anti-Legionnaire’s disease function

ensures that the domestic hot water

(D.H.W.) contained in the storage indirect

cylinder is brought to a temperature of at

least 60°C regularly, to prevent the prolife-

ration of bacteria that cause Legionnaire’s

disease.

The function will be activated every

Monday morning with the first D.H.W. hea-

ting and it will remain active for a period of

at least two and a half hours.

Note:

This function is only available if the

D.H.W. production is authorised by the

D.H.W. production programme.

If the anti-Legionnaire’s disease function

is hindered during the period it is normally

scheduled for (Mondays), it will be repea-

ted the next time the D.H.W. is heated.

Legionnaire’s disease

In certain conditions in stagnant water,

bacteria may form and build up, causing

serious infections such as Legionnaire’s

disease, for example. To minimise this ri-

sk, the temperature of the water must be

raised regularly to a set number of de-

grees.

The risk of Legionnaire’s disease sprea-

ding mostly arises in central heating sy-

stems with a widespread network of pipes,

as well as in air conditioning systems.

To minimise the risk of infection, these sy-

stems must be installed and serviced cor-

rectly.

In large systems, the water outlet tempe-

rature must be at least 60 °C and the tem-

perature of the water in the piping network

must not drop below 5 °C.

0 6 11 17 2422 h

C

0 6 12 18 24 h

065111716 2422 h

C

0 6 12 18 24 h

C

fig. 12.2-7

fig. 12.2-8

fig. 12.2-9

fig. 12.2-10

– 17 –

OPTIMA CB - SB

OPTIMA CB - SB

Service instructions

Service instructions

LINE 93: This parameter is used in the CB models

for which you wish to use the D.H.W.

comfort function.

Press button 3 repeatedly to display the

following information in sequence:

D.H.W. production

active, D.H.W.

comfort active in

this case, after

drawing water, the

boiler maintains the

D.H.W. temperature at the value set with

parameter 607 (D.H.W. comfort reference

temperature) for the adjustment of the boi-

ler (see par. 16) for the amount of time set

with parameters 602 and 603.

D.H.W. production

active, D.H.W.

comfort inactive: in

this case, after

drawing D.H.W.,

the boiler does not

perform a comfort

cycle.

D.H.W. production

deactivated.

LINE 95: When the parameters set are considered

to be final, it is possible to use this func-

tion to block the appliance and avoid any

tampering.

Off: all functions are accessible and can

be modified

On: all functions are displayed but cannot

be modified (if you try to modify them, the

symbol appears)

TEMPORARY DEACTIVATION OF THE

BLOCKING FUNCTION

The function may be temporarily deactiva-

ted to allow the parameters to be pro-

grammed or set (or adjusted).

To do this, keep the buttons❷!and ❿

pressed simultaneously for at least 3 se-

conds. This temporary deactivation of the

function lasts until you leave the program-

ming mode (by pressing button ).

PERMANENT DEACTIVATION OF THE

BLOCKING FUNCTION

Press the buttons ❷!and ❿simultaneou-

sly for at least 3 seconds and set parame-

ter 95 to OFF.

LINE 96: Determines the appliance to which the sy-

stem refers in terms of the correct time.

QAA73 = remote control QAA 73

Esterno= another appliance

LINE 97 This function allows you to change the ti-

me on the clock automatically, from stan-

dard time to summer time.

The clock goes on to summer time the

Sunday after the set date.

LINE 98 This function allows you to change the ti-

me on the clock automatically, from sum-

mer time to standard time.

The clock goes on to standard time the

Sunday after the set date.

i

3

3

3

– 18 –

OPTIMA CB - SB

OPTIMA CB - SB

Service instructions

Service instructions

Push-button

Indication Line

11

2

3CODE

Press the sequence of but-

tons

5 stars will be displayed; if the

code is correct, direct access

will be provided to the servi-

ceman parameters; however,

if it is incorrect, the display will

indicate the installer parame-

ter settings.

Below is the generalised sequence of use of the buttons to

modify the parameters reserved for the serviceman.

i

Prog

i

Prog

i

Prog

Press one of the line selec-

tor buttons to access the

programming operations.

Keep the selector buttons

pressed together for more

than 9 seconds until the indi-

cation “code OEM _ _ _ _

_”appears, then release

them

i

i

Push-button

Indication Line

4from 100 to

199

5

6

6Continuous

display

i

Prog

Press one of these selec-

tor buttons to access the

desired line

i

i

Press the adjustment but-

tons to set the desired va-

lue; the value is stored

when you quit the pro-

gramming or when you

change line

Press the VALUE REA-

DING button to quit the

programming.

Factory Setting Range of

Line Function

setting made values

HEATING

100

Maximum room temperature reference value (TRwMax)

35°C

…

TRwMin…35

101

Minimum room temperature reference value (TRwMin)

10°C

…

4…

TRwMax

102

Influence factor of the room temperature (KORR) 4

…

0…20

103 Accelerated drop constant (KON; without room sensor) 2

…

0 ÷20

104 Accelerated heating - excess heating beyond the reference 5°C

…

0 ÷20

room temperature value (DTRSA)

105 Flow reference temperature increase limit 5

…

0…15

106 Correction of the room temperatures measured 0

…

-3,0…3,0

DOMESTIC HOT WATER

130 Maximum D.H.W. reference value (TBWmax) 60

…

TBWw…80

TBWw = reference value of the flow temperature in D.H.W. comfort mode.

131 Anti-Legionnaire’s disease function reference value 65

…

8…95

SERVICE FUNCTIONS

150 Information display

temporary

…

tempor./perm.

151 Frost warning (-.- = disabled) 3,0°C

…

-10…+10

152 Control (or reference value) knob free

…blocked/free

153 Effect of the COMFORT/ECONOMY mode commutation button

onHC1+HC2

…

on HC1+HC2

or on HC1

199 Remote control QAA73 software version - - 0…99.9

13.1

LIST OF SERVICEMAN PARAMETERS

13

SERVICEMAN PROGRAMMING

– 19 –

OPTIMA CB - SB

OPTIMA CB - SB

Service instructions

Service instructions

LINE 100: Limits the maximum room temperature re-

ference value (or reference room tempera-

ture).

LINE 101: Limits the minimum room temperature re-

ference value (or reference room tempera-

ture).

LINE 102: Defines the influence of the shift in the re-

ference room temperature on the system.

The influence of the room temperature

can be enabled and disabled (parameter

setting on line75)

This parameter setting will modify the in-

fluence of the room temperature.

Increase: the influence of the temperature

will increase

Decrease: the influence of the room tem-

perature will decrease.

Correction:

The following example shows how and ac-

cording to which formula the reference

room temperature is corrected.

TRwk = Reference room temperature

TRw (Reference room temperature) = 20°C

TRx (Room temperature measured) = 22°C

Correction factor KORR = 10

TRwk= TRw + KORR x (TRw - TRx)

2

TRwk= 20°C+10 x (20°C - 22°C) = 10°C

2

LINE 103:

The accelerated drop constant takes advantage

of the heat accumulation capacity of a building

and modifies the duration of the rapid temperatu-

re rise.

The drop constant is only enabled in adjustments

with no influence of the room temperature.

Increase: the drop duration is extended (for well

insulated buildings, which cool down slowly)

Decrease: the drop duration is reduced (for

poorly insulated buildings, which cool down ra-

pidly)

ACCELERATED DROP WITH NO INFLUENCE

OF THE ROOM TEMPERATURE

The accelerated drop starts as soon as there is a

commutation on a lower reference room tempera-

ture (for commutation in automatic mode, for

example).

The circulation pump of the heating circuit is disa-

bled until the end of the accelerated drop dura-

tion, the parameters of which are set on line 103,

of the mixed external temperature and the shift in

the reference room temperature.

The duration of the accelerated drop is limited to

a maximum of 15 hours.

Example of a shift in reference temperature of

4°C (from 20 to 16°C, for example):

Setting on line 103

TAgem 0 4 8 12 15 20

-20000000

- 10 0 0.5h 1h 1.5h 2h 2.5h

0 0 3h 6h 9h 11h 15h

+10 0 5h 11h 15h 15h 15h

LINE 104: This function cuts the amount of time for

the rise in temperature of the part.

The function acts on the heating circuit se-

lected on line 75.

Increase: the duration of the temperature

rise is shorter

Decrease: the duration of the temperature

rise is longer

Accelerated temperature rise

The accelerated temperature rise starts as

soon as there is a commutation on a hi-

gher reference room temperature (hours

of commutation in automatic mode, for

example).

By setting the parameter on line 104, the

reference room temperature is raised until

13.2

DETAILS OF SERVICEMAN PARAMETERS

30

252015

10

5

30

25

20

15

10

5

TRwk [°C]

KORR=4

TRx

KORR=10 °C

TRw

fig. 13.2-1

Correction of the defined value of the room temperature

– 20 –

OPTIMA CB - SB

OPTIMA CB - SB

Service instructions

Service instructions

the room is at the right temperature (TRw-

1/4 °C).

The accelerated temperature rise causes

a rise in the flow reference temperature.

TRx - Room temperature measured

TRw - Reference room temperature

104 - Excess heating beyond the reference

room temperature value

t - Time

LINE 105: This function limits the increase in the flow

reference temperature (K/min).

The limit set applies in this case to both

central heating circuits.

LINE 106: The function allows for the calibration of

the room temperature sensor, in order to

obtain a more precise display of the tem-

perature measured.

By pushing +and –button is possible to

correct ± 3°C the temperature value rea-

ding.

LINE 130: Limitation function for the D.H.W. comfort

reference value.

Advantages:

- Possibility to limit this setting for the end

user.

- Drop in the risk of scalding

- Drop in the risk of limescale build-up

Note: a D.H.W. reference temperature of a

BMU, transmitted via OpenTherm, has prio-

rity and replaces that of QAA73 regulator.

LINE 131: The anti-Legionnaire’s disease reference

temperature is a temperature at which the

D.H.W. is heated during the enabling of

the corresponding function.

LINE 150: It allows you to choose the type of infor-

mation display.

Temporary: the information will remain on

the display for 8 minutes. At the end of

this time, the basic display is restored

(current room temperature + correct time

+ horizontal operating mode reference

bar).

Permanent: the last piece of information

selected is displayed permanently.

LINE 151: It allows for the generation of an alarm as

to the risk of frost depending on an adju-

stable external temperature.

––.–= no frost risk warning

LINE 152: Validates or invalidates the operation of

the reference value knob.

LINE 153: Validates the COMFORT/ECONOMY mo-

de commutation button to act on the cen-

tral heating circuit HC1 alone or on both

circuits.

20

15

°C

t

TR

w

TR

x

ab

104

fig. 13.2-2

Table of contents