tricab M50 User manual

User Guide

PULLER MODELS

M50 / M100

2

is document was prepared to assist users of trenchless pipe replacement systems manufactured by

TRIC Tools Incorporated (TRIC). Information in this document is subject to change without notice

and therefore does not represent any commitment on the part of the manufacturer. e material

contained herein is supplied without warranty of any kind. TRIC assumes no responsibility and shall

have no liability of any kind arising from the supply or use of this document or the material contained

herein. No part of this document may be copied, reproduced, translated, or reduced to any electronic

medium or machine-readable form without prior written consent from TRIC Tools Inc.

TRIC trenchless pipe bursting systems are protected by US Patent No. 6,305,880, issued on

October 23, 2001, and US Patent No. 6,524,031, issued on February 25, 2003.

All other trademarks are the property of their respective owners.

© 2011 TRIC Tools, Inc. All rights reserved.

LEGAL NOTICE

3

Congratulations and thank you for purchasing a TRIC pipebursting system. is visual guide

provides basic yet comprehensive instructions for safe, eective operation and care of your TRIC

equipment. We want to familiarize you with the critical working elements of your TRIC pulling

unit and bursting head assembly, and to illustrate the essential best practices with your system. Our

goal is not to describe every possible bursting scenario, but rather to create a convenient reference

to facilitate more trouble-free operation, and above all to encourage safety on the job.

To that intent, please note the warning symbols in this user guide, which indicate two

levels of concern. e yellow symbol warns against mechanical failure or undue stress

on equipment. e red warning indicates danger of physical injury or death. In some

cases both warning symbols will be displayed at once. In any case, please pay close atten-

tion to all safety topics covered in this manual. SAFETY FIRST!

We are continually improving our products and actively testing them in the eld. We also maintain

working relationships with many of our customers, thus their experience is ours. We are happy to

share this information, along with the latest updates and tips, at www.trictools.com. Or feel free

to call us at 888-883-8742. Welcome to the TRIC Team!

WELCOME

4

CONTENTS

Legal Notice 2

Welcome 3

M50 Assembly 6

M100 Assembly 8

Introduction 10

Bursting Setup 12

Safe Operation 22

Swaged Steel Splitting Head 28

Link-Blade Splitting Head 29

readed Core Bursting Head (1st generation) 30

readed Core Bursting Head (2nd generation) 32

Standard Bursting Head 38

TRIC-Lock Bursting Head 40

Releasing Cable Tension (Detensioning) 44

Glossary 52

5

ILLUSTRATIONS

M50 Puller 6

M50 Wheel & Plate 7

M100 Puller 8

M100 Wheel & Plate 9

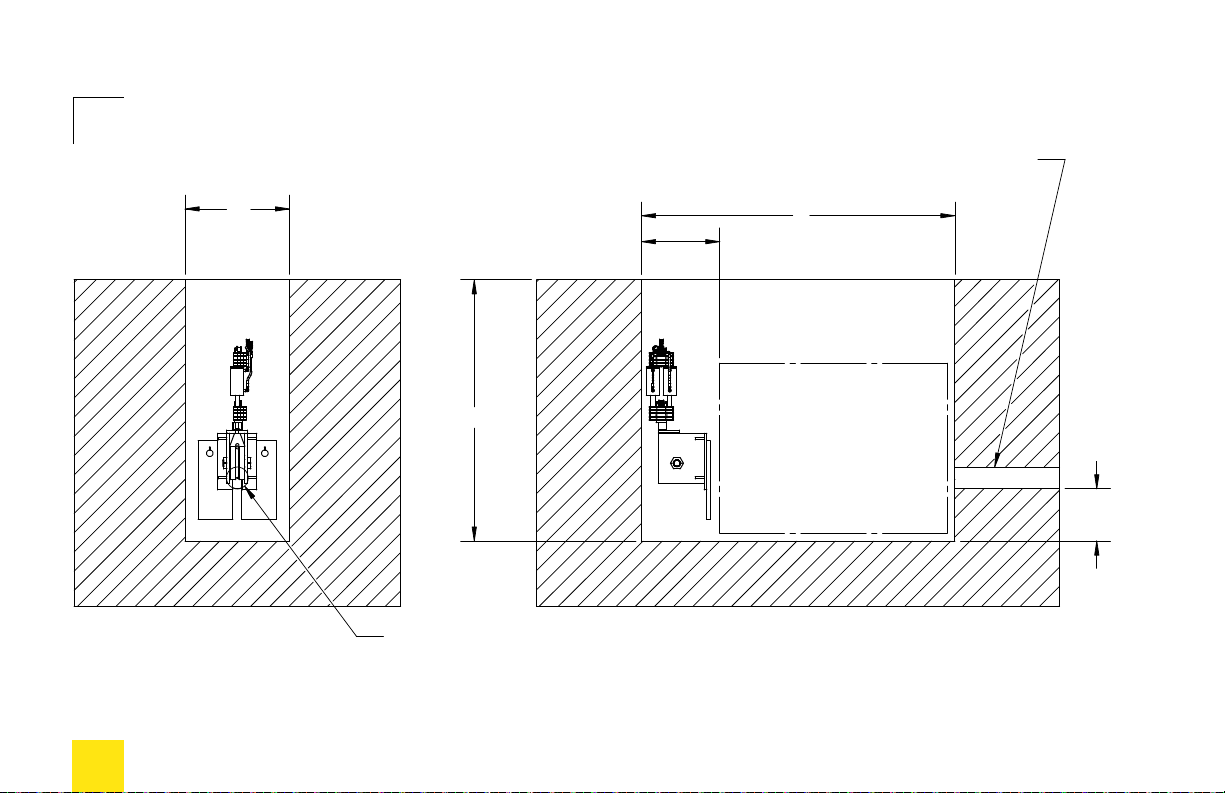

Figure 1: Head Selection Table 12

Figure 2: Entry Pit (Municipal) 14

Figure 3: Exit or Pulling Pit (Municipal) 16

Figure 4: M100 Cable Insertion (Upper) 18

Figure 5: M100 Cable Insertion (Lower) 18

Figure 6: M100 Gripper Engagement 19

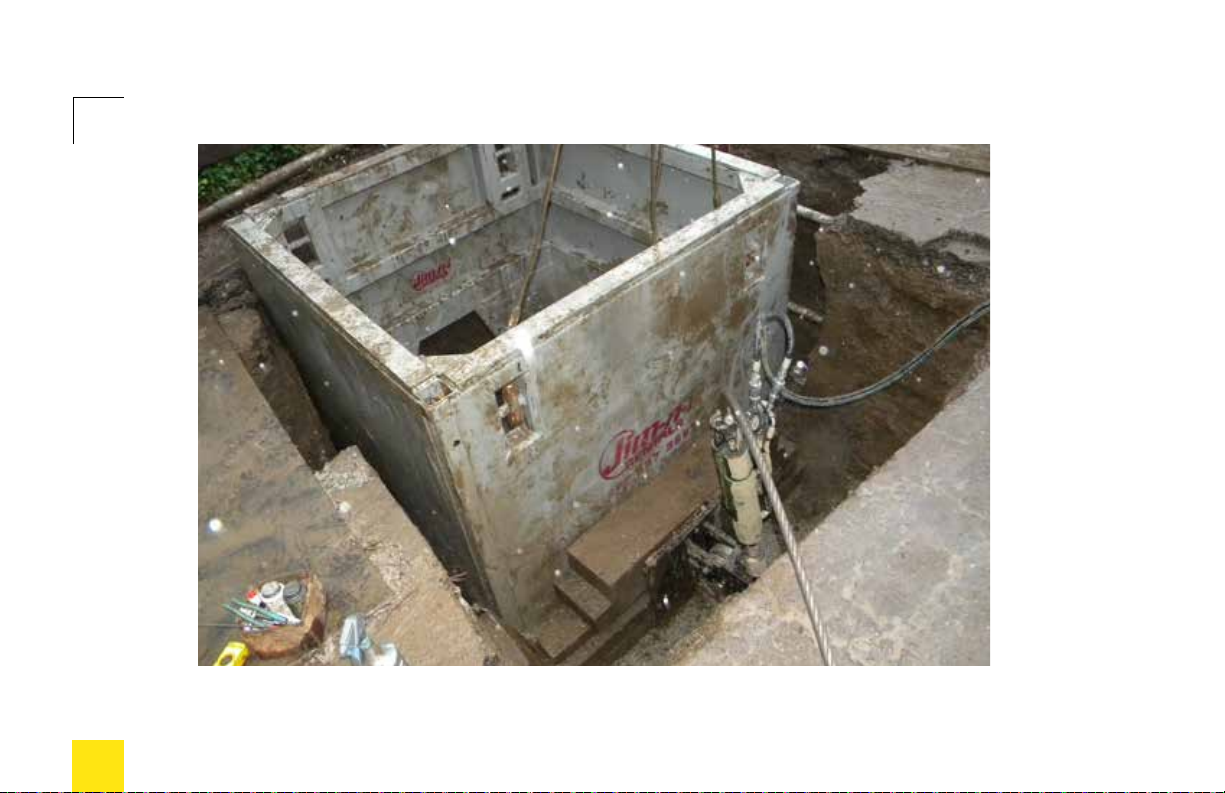

Figure 7: M50 with Manhole Box 20

Figure 8: M100 with Trench Box 21

Figure 9: Pulling Unit Reclining 22

Figure 10: Critical Reaction Zone 24

Figure 11: Rotation of Puller on Wheelbase 24

Figure 12: Unit Misaligned with Pipe Path 24

Figure 13: Cable Alignment in Puller 25

Figure 14: Hydraulic Pulling Force Table 26

Figure 15: Swaged Wire Rope Specs 27

Figure 16: Swaged Steel Splitting Head 28

Figure 17: Link-Blade Splitting Head 29

Figure 18: readed Core Head (gen. 1) 30

Figure 19: readed Core Head (gen. 2) 32

Figure 20: Standard Bursting Head 38

Figure 21: TRIC-Lock Bursting Head 40

6

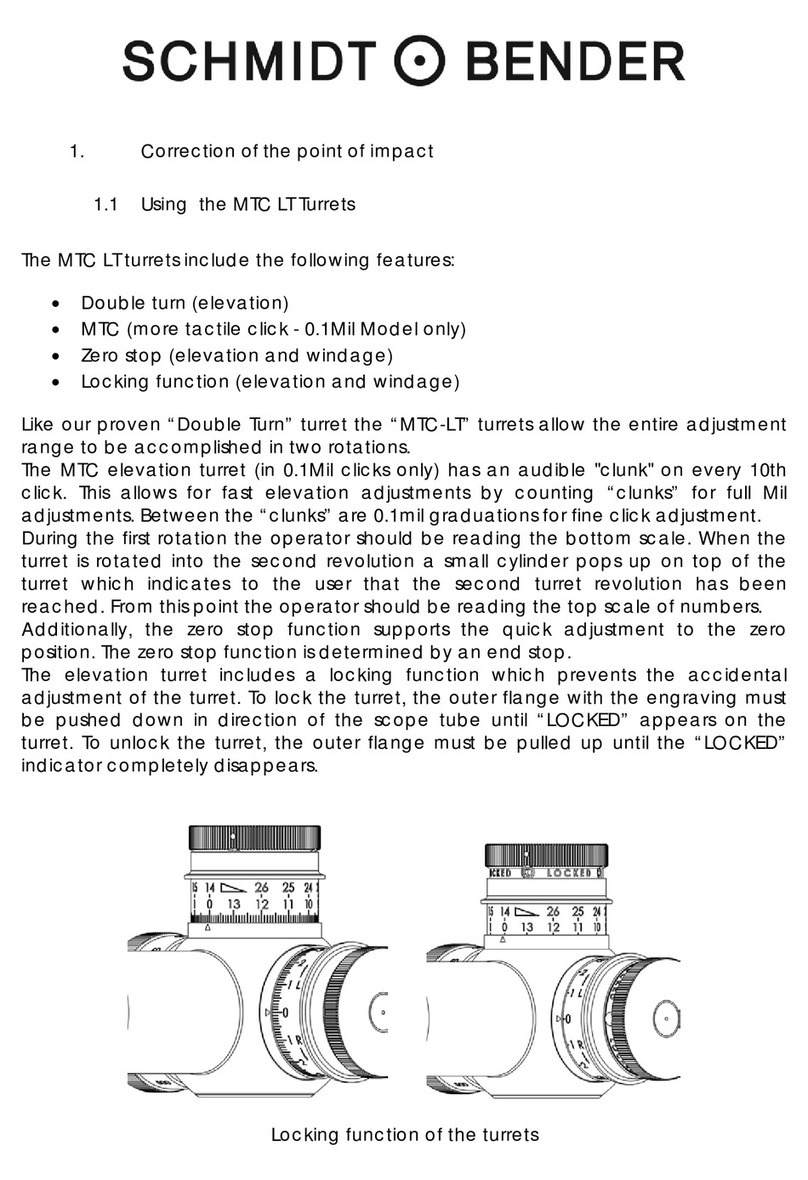

M50 ASSEMBLY

Hydraulic Fittings

Handle

Pressure Gauge

Pulling Bridge

Grippers (Pulling)

Cover Plates

Cover Plate Screws

Hydraulic Hose

Cylinder

Cylinder Port

Piston Shaft

Yokes

Yoke Towers

Grippers (Retaining)

Retaining Bridge

Nose

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1 2 3 4 5 6 7 8 9 11 12 13 14 15 1610

7

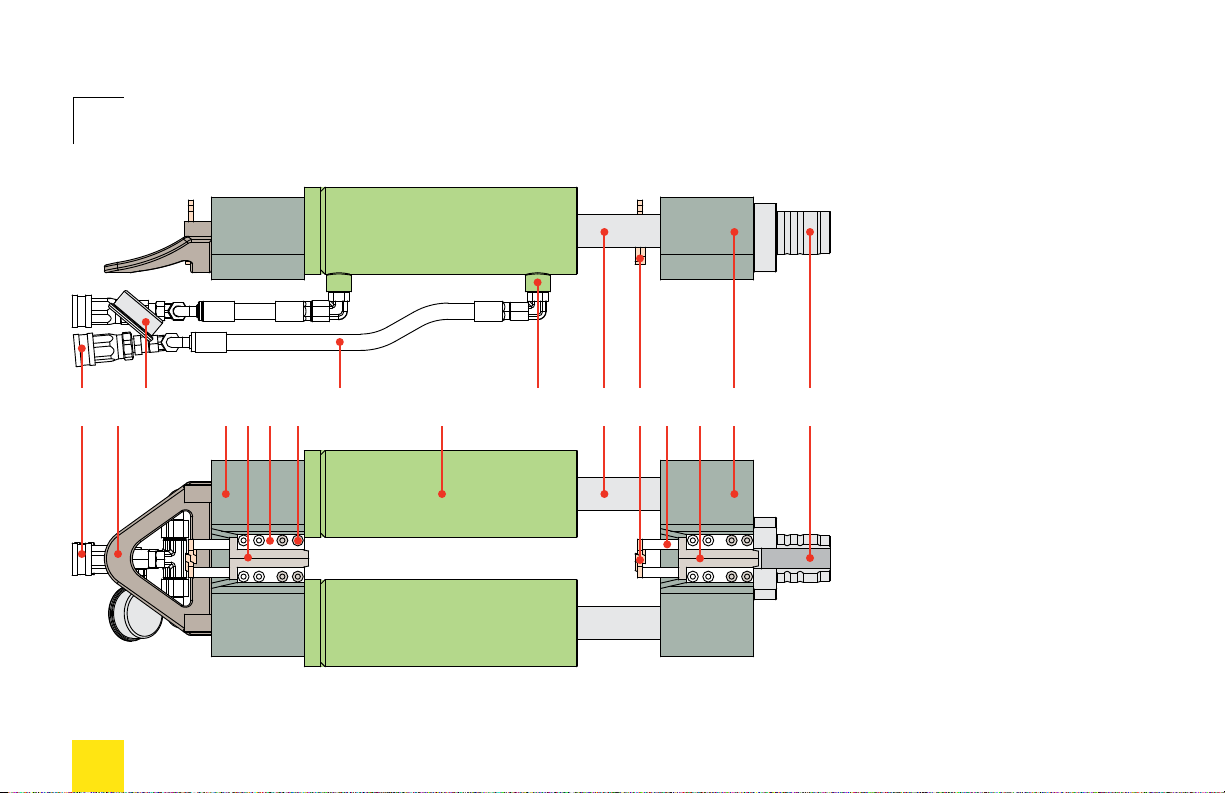

M50 ASSEMBLY

17 19

20 21 22 23 24

25 2618

17 Resistance Plate

18 resistance plate bolt

19 Pulley Base

20 front plate

21 side plate

22 axle

23 top plate

24 wheel (12”)

25 annulus

26 locking pins

8

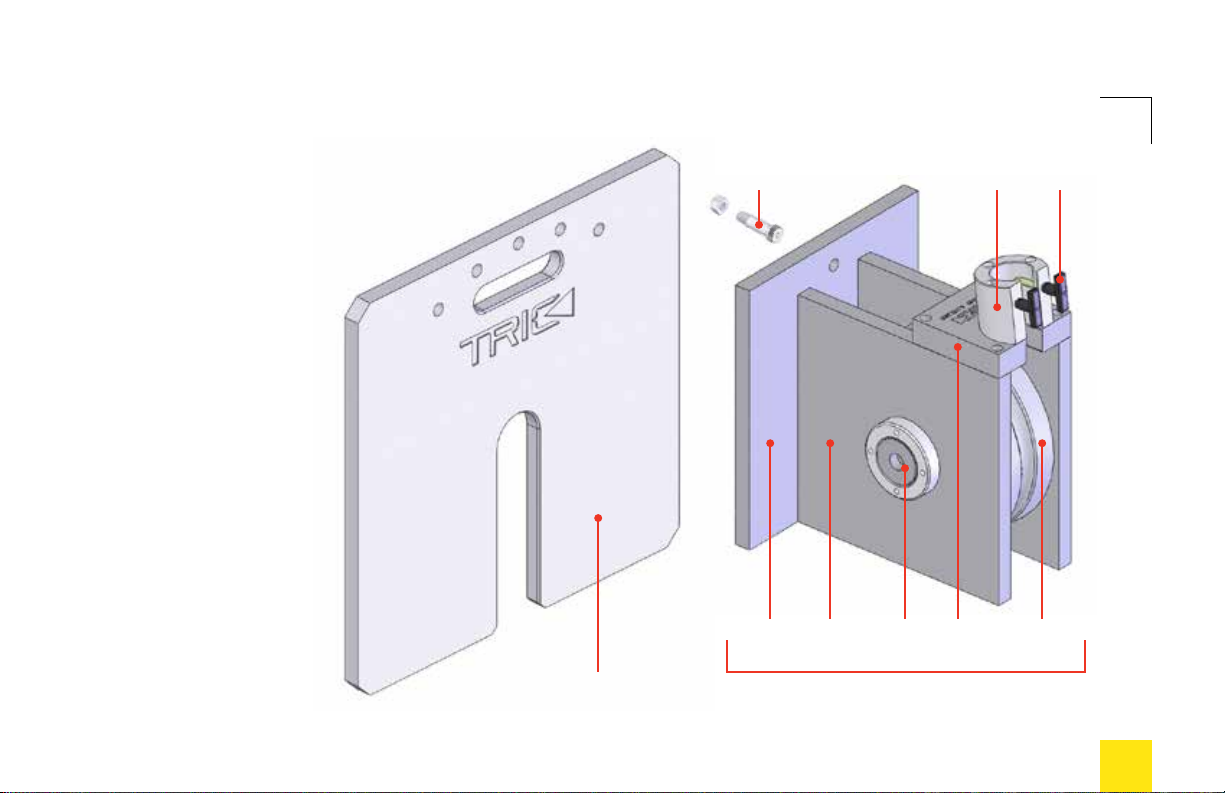

M100 ASSEMBLY

Handle

Hydraulic Fittings

Yoke Assembly

Gripper Stop Screws

Cover Plates

Pulling Bridge

Grippers (Pulling)

Cover Plate Bolts

Cylinder

Piston Shaft

Gripper O-Ring Screws

Retaining Bridge

Grippers (Retaining)

Nose

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1 2 3 5 6 7 8 94 10 1211 13 14

9

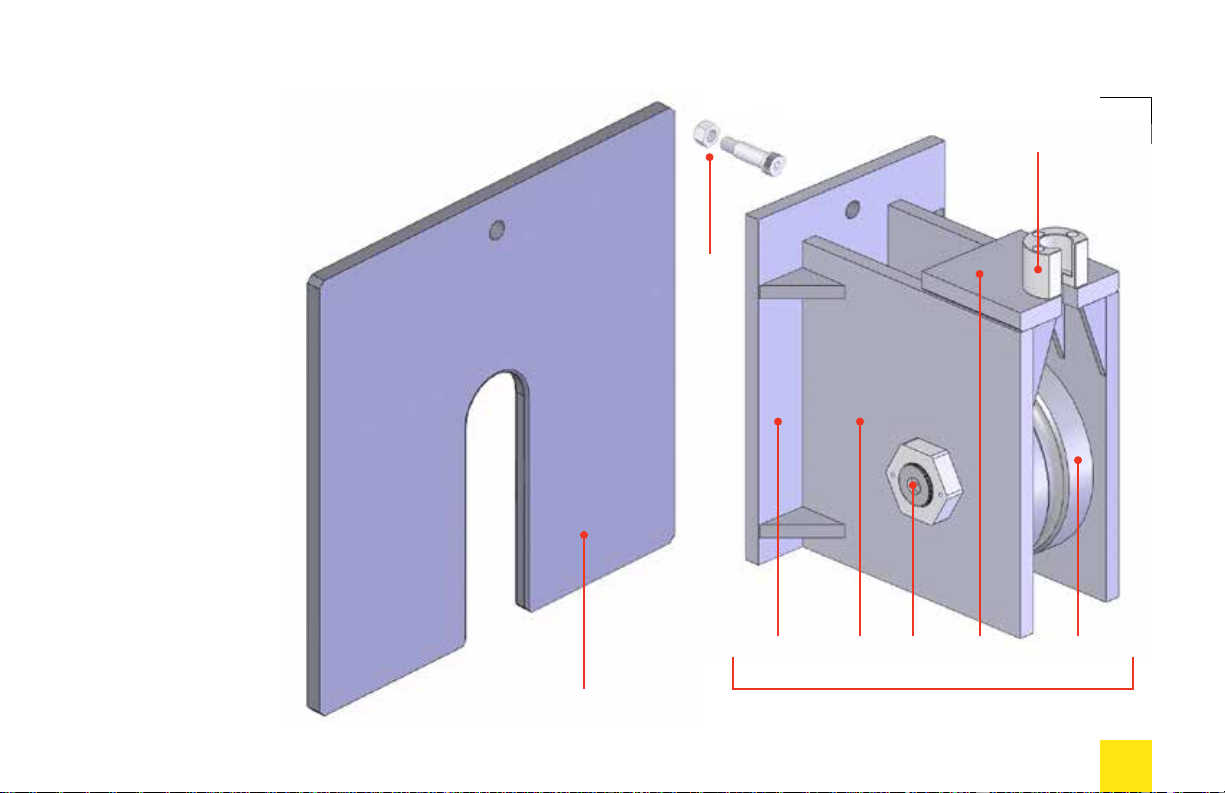

M100 ASSEMBLY

15 17

18 19 20 21 22

23

15 Resistance Plate

16 resistance plate bolt & nut

17 Pulley Base

18 front plate

19 side plate

20 axle

21 top plate

22 wheel (15”)

23 annulus

16

10

INTRODUCTION

e heart of every TRIC pipebursting system

is a cable-pulling device. Cable, or wire rope,

has been essential to the TRIC method since the

company introduced trenchless home sewer lateral

replacement in America back in 1996. Residential

sewers typically have directional changes between

the building foundation exit point and the property

line or municipal sewer main connection. A cable is

the best way to negotiate these bends. By contrast,

larger municipal sewer pipes generally maintain a

straight ow path, and each change of direction

becomes an accessible service point, or manhole.

TRIC equipment leverages the unique qualities of

steel cable to replace more pipe with less excavation,

especially in dicult easements and other hard-to-

access areas. is is also true for other underground

utilities such as water and gas.

11

Steel cable is valued for its exibility, compactness,

resiliency, and high strength-to-weight ratio. e

standard TRIC conguration employs a wheel that

directs cable and pulling force from horizontal (pipe

ow path) to vertical. is conguration allows for

great power in a relatively small footprint, and also

provides easier access to the puller and grippers.

As with all heavy-duty construction equipment, the

TRIC system must be used with caution and good

planning. e following pages illustrate the safe and

eective use of your TRIC M-Series pipebursting

system. Please review this information carefully.

NOTE: Your hydraulic power source (i.e., pump

or power-pack, PTO device, or excavation equip-

ment) is not covered in this manual. Please refer

to original manufacturers for further information.

INTRODUCTION

12

BURSTING SETUP

1Vitreous Clay

2Cast Iron

3Asbestos Concrete

4Reinforced Concrete

5Fiber Conduit

6Plastic

7Ductile Iron

8Steel

9Copper

BURSTING HEAD PIPE MATERIAL

Standard 1, 2, 3, 4, 5, 6

Impact 1, 2, 3, 4, 7, 8

Swaged Splitter 2, 6, 8, 9

Link-Blade Splitter 2, 6, 7, 8, 9

Figure 1

Bursting Head Selection Table

13

BURSTING SETUP

e rst step in any pipebursting job is to locate

and expose the existing pipe at each end of the

service line to be replaced. Drain lines should

be recently inspected and located by video, with

all depths, bends, transitions, connections, and

service points marked on the ground surface.

Entry and exit pits are congured dierently

from one another, and can have vastly dierent

excavation requirements. Figures 2 and 3 on the

following pages illustrate entry (launch) and exit

(pulling) pit congurations.

TRIC M-Series pipebursting units are designed

primarily to serve the municipal utilities market.

is includes underground sewer, water, and gas

lines in a variety of pipe materials ranging from

2” (50mm) to 20” (500mm) in diameter.

TRIC also manufactures a variety of bursting or

splitting heads, each specic to the type and size

of pipe to be replaced. Please see Figure 1 on the

opposite page for a selection of bursting heads to

replace dierent host pipes.

14

BURSTING SETUP

Figure 2

Entry or Launch Pit (Municipal)

a

b

a

c

30º

e

d

15

BURSTING SETUP

HDPE pipe is exible, which is indispensable

for pipebursting applications. e combination

of pipe diameter and wall thickness (known as

SDR or Standard Dimensional Ratio) deter-

mines the level of exibility for each pipe size.

A safe formula for the excavation of entry pits

for municipal sizes of HDPE pipe is a 30º access

angle or ramp down to pipe level. is translates

to a surface cut that is roughly twice as long as

the pipe is deep. Smaller pipe sizes (150mm and

under) have smaller bending radii. Figure 2 on

the facing page illustrates a typical municipal

entry scenario.

a= Variable

b= 2’ (60cm)

c= 6”–12” (15–30cm)

d= 36” (90–100cm)

e= 8”–12” pipe (200–300mm)

16

Figure 3

Exit, Receiving, or Pulling Pit (Municipal)

BURSTING SETUP

a

c

b

b

e

d

e

17

Municipal pipelines (especially drains and

sewers) generally require larger entry and exit

pits due to their size and depth. When using the

M-Series units (especially the M100), a trench-

box is indispensable for stabilizing the pulling

assembly, and for extracting the bursting head

at the end of the pull. Figure 3 on the opposite

page illustrates setup behind a trench box.

Figures 7 and 8 on pages 20 and 21 show typical

eld applications of the M50 and M100 in

conjunction with manhole boxes or heavy-duty

trench boxes.

BURSTING SETUP

a= 48” minimum (120cm)

b= Variable

c= 36” minimum (90–100cm)

d= 18”–24” (45cm–60cm)

e= 8”–12” pipe (200–300mm)

18

BURSTING SETUP

Figure 4

Inserting cable to upper grippers

Figure 5

Pulling cable slack to help insert cable to lower grippers

19

BURSTING SETUP

e M100 (shown here) is typically equipped

with either 1-1/8” (28mm) or 1-1/4” (32mm)

compact swaged wire rope. ese cable sizes

are much heavier than those used with TRIC

lateral systems. When loading the cable into

the M100, it is sometimes helpful to engage the

top (pulling) grippers rst, and then extend the

puller to draw slack out of the cable and bring

it into the lower or retaining grippers (Figures

4 and 5 on page 18). Also, the M100 may have

gripper stop-screws at the top of the cover plates.

In Figure 6 at left, red arrows indicate holes for

stop-screws (5/32” or 4mm allen-type), which

must be loosened or removed to allow full

opening of grippers to insert cable. When the

cable is fully engaged, attach gripper O-rings

to bolts on cover plates and grippers (yellow

arrows), to keep grippers engaged to the cable.

Figure 6

M100 gripper engagement

20

Figure 7

M50 with manhole box

BURSTING SETUP

This manual suits for next models

1

Table of contents

Other tricab Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

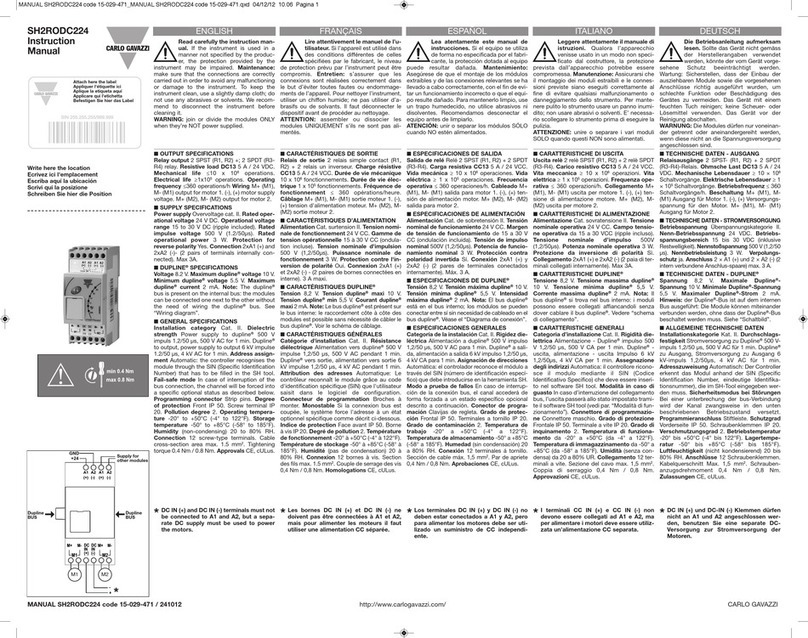

CARLO GAVAZZI

CARLO GAVAZZI SH2RODC224 instruction manual

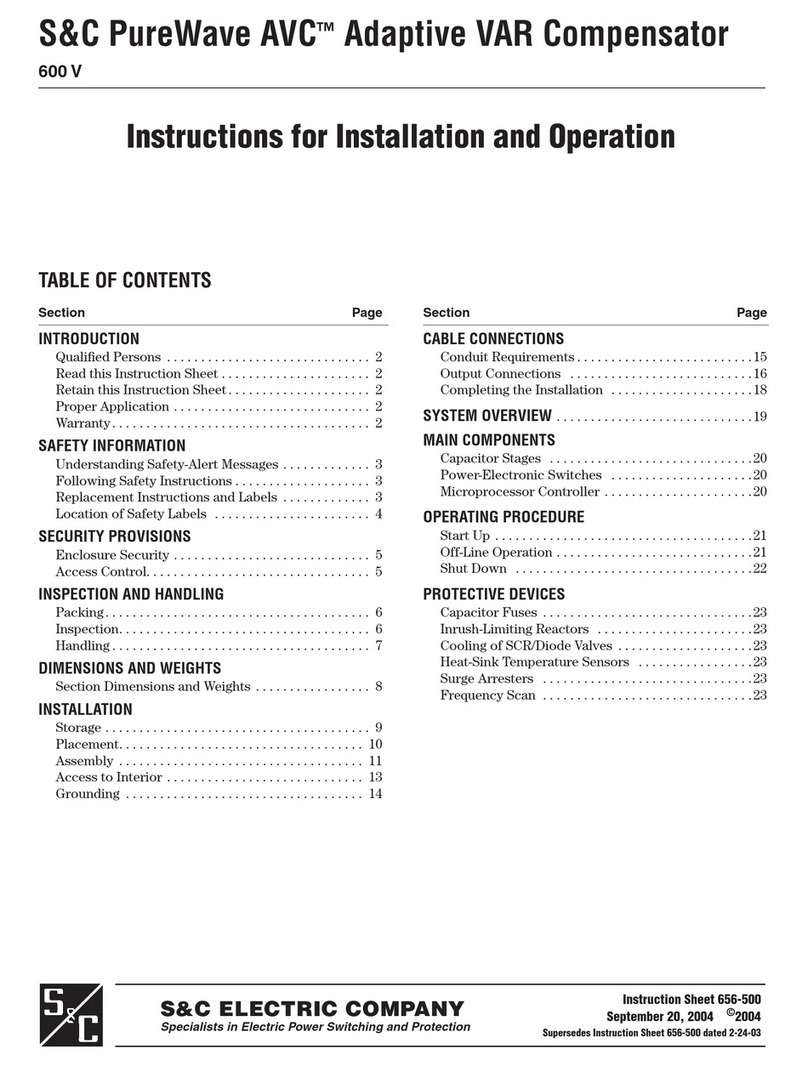

S&C

S&C PureWave AVC Instructions for installation and operation

ZIEHL-ABEGG

ZIEHL-ABEGG ZA top SM200.15D Assembly instructions

Mecc Alte

Mecc Alte ECP3 Series Operating and maintenance instructions

TNA

TNA TX7302 Installation and operation manual

Mars

Mars Comfort-aire Century Compact HBH Series Installation operation & maintenance