656-500 8

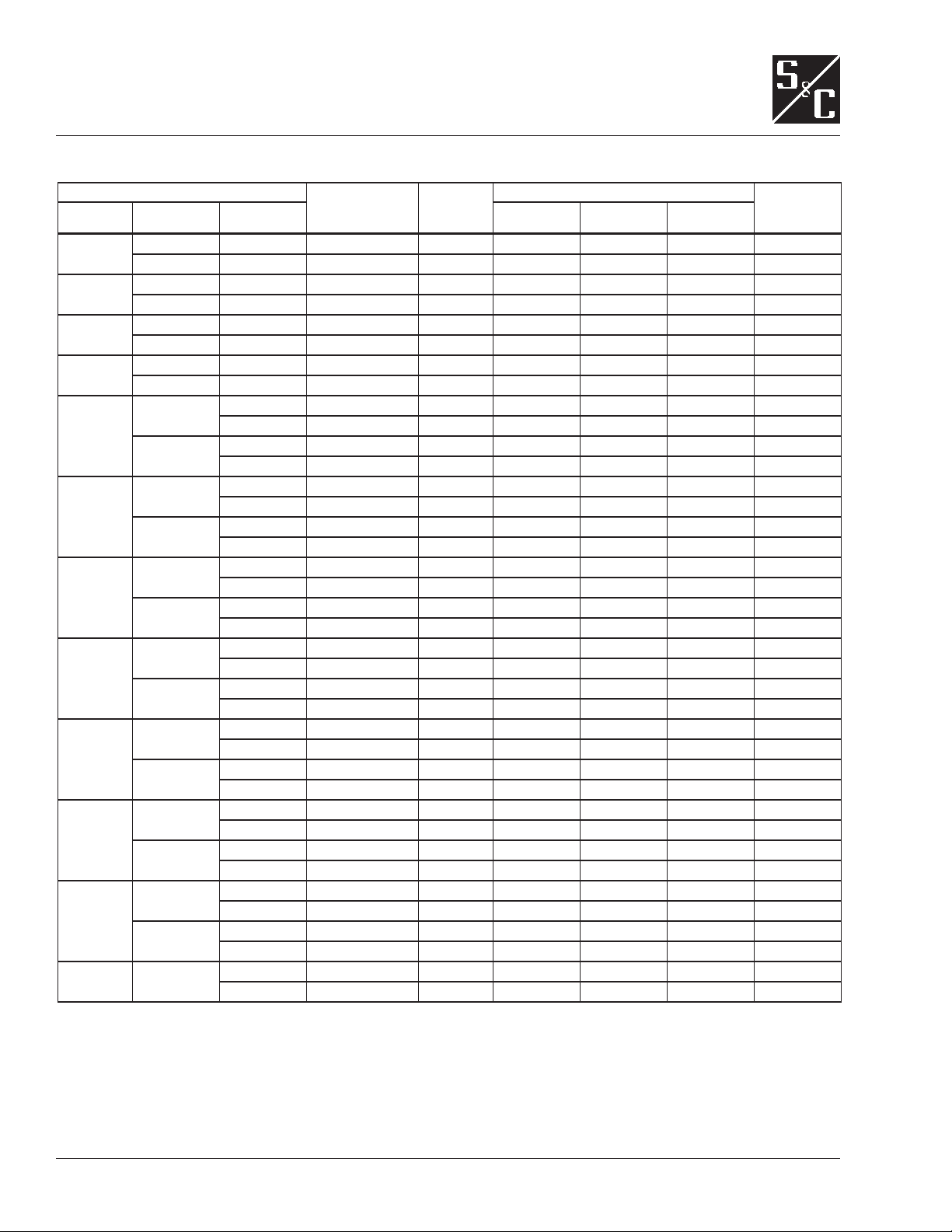

DIMENSIONS AND WEIGHTS

Section Dimensions and Weights

System Dimensions

L

D

H (in.)11

11

Number of

Sections

Approximate System Weight (lbs.) Total System

Weight (lbs.)

KVAR Voltage Stages Control

Section

Capacitor

Section 1

Capacitor

Section 2

500 480 3 87 37 121 1 6,000 — — 6,000

600 3 87 37 121 1 5,500 — — 5,500

625 480 3 87 37 121 1 6,500 — — 6,500

600 3 87 37 121 1 6,000 — — 6,000

750 480 3 87 37 121 1 7,500 — — 7,500

600 3 87 37 121 1 7,000 — — 7,000

1000 480 3 87 37 121 1 8,500 — — 8,500

600 3 87 37 121 1 8,000 — — 8,000

1250

480 3 174 37 121 2 7,000 2,500 — 9,500

4 174 37 121 2 7,000 2,500 — 9,500

600 3 87 37 121 1 9,000 — — 9,000

4 87 37 121 1 9,000 — — 9,000

1500

480 3 174 37 121 2 7,500 3,000 — 10,500

4 174 37 121 2 7,500 3,000 — 10,500

600 3 87 37 121 1 9,500 — — 9,500

4 174 37 121 2 7,000 2,500 — 9,500

2000

480 3 174 37 121 2 8,000 3,500 — 11,500

4 174 37 121 2 8,000 3,500 — 11,500

600 3 174 37 121 2 7,500 3,000 — 10,500

4 174 37 121 2 7,500 3,000 — 10,500

2500

480 3 261 37 121 3 8,500 4,000 3,500 16,000

4 261 37 121 3 8,500 4,000 3,500 16,000

600 3 174 37 121 2 8,000 3,500 — 11,500

4 174 37 121 2 8,000 3,500 — 11,500

3000

480 3 261 37 121 3 9,000 4,000 3,500 16,500

4 261 37 121 3 9,000 4,000 3,500 16,500

600 3 174 37 121 2 8,500 3,500 — 12,000

4 174 37 121 2 8,500 3,500 — 12,000

4000

480 3 261 37 121 3 9,500 4,000 3,500 17,000

4 261 37 121 3 9,500 4,000 3,500 17,000

600 3 261 37 121 3 9,000 4,000 3,000 16,000

4 261 37 121 3 9,000 4,000 3,000 16,000

5000

480 3 261 37 121 3 10,000 4,000 4,000 18,000

4 261 37 121 3 10,000 4,000 4,000 18,000

600 3 261 37 121 3 9,500 4,000 3,500 17,000

4 261 37 121 3 9,500 4,000 3,500 17,000

6000 600 3 261 37 121 3 10,000 4,000 4,000 18,000

4 261 37 121 3 10,000 4,000 4,000 18,000

1Height dimension includes outdoor fan. Height dimension with indoor fan is 108 inches. Height dimension with fan housing removed is 102 inches.