Page 1 of 2

( 215-293-0700 7 215-293-0701

Trident Emergency Products, LLC

2940 Turnpike Drive | Suite #9 | Hatboro, PA 19040 USA

World Class Components

AirPrime SC 1906

Installation and Operation

AirPrime for Wildland Vehicles/Skid Units

Self Contained Priming System, Trident Part Number: 31.001.50

Includes Items A through E Listed Below

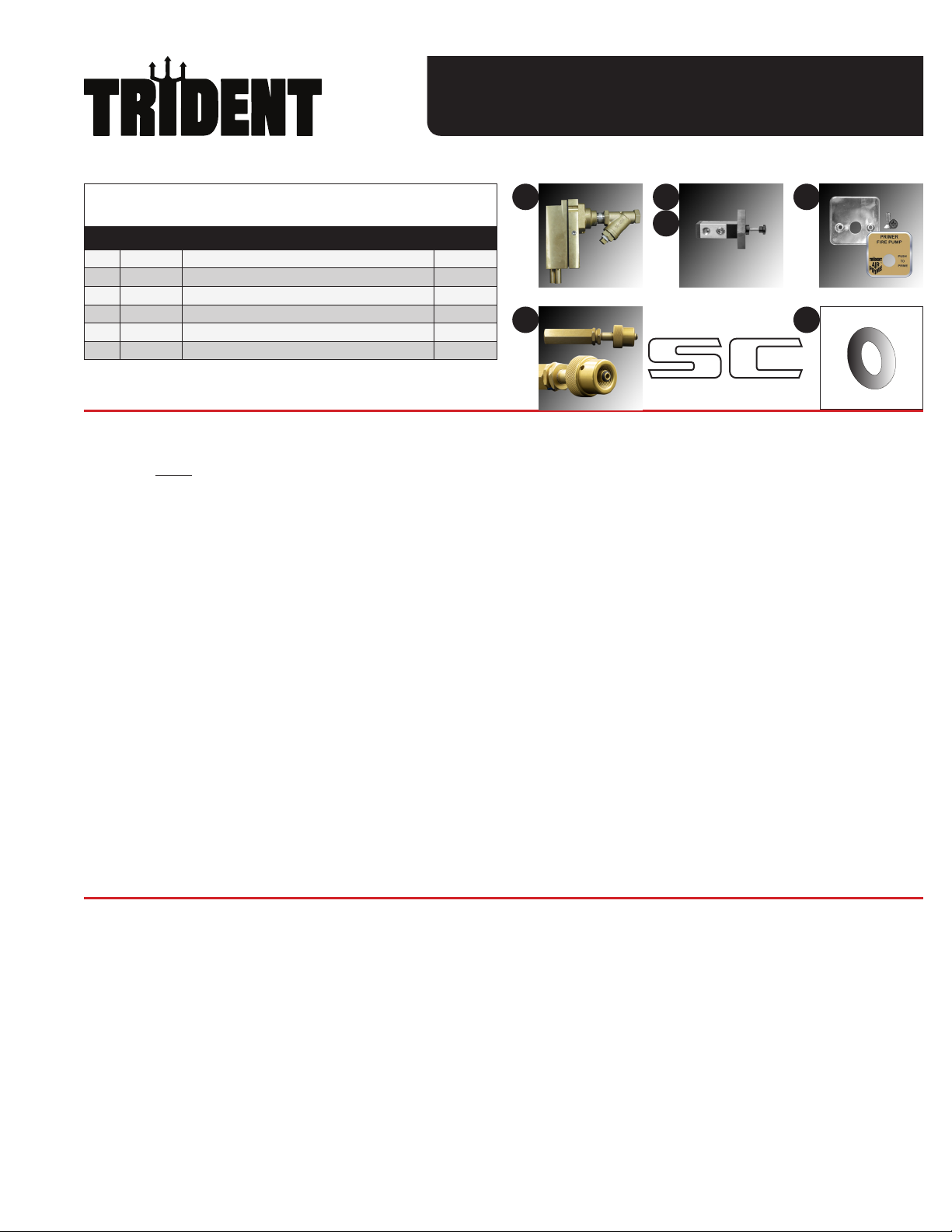

ID # Quantity Description Part #

🅐1 Manual AirPrimer, 3 Barrel 31.001.17

🅑1Panel Valve 30.005.3

🅒1 Plug, 1/4” NPT Socket Head, Brass (Pre Installed) 09.005.2

🅓1 Panel Label Kit 02.006.20

🅔1 Preset Pressure Regulator 14.013.0

🅕Pack of 6 Regulator O-Rings (Available Separately) 27.007.16

A B

C

D

E

Installation of the AirPrime SC 1906

1. Ensure that the wheels are chocked. Vehicle is tagged Out of Service.

2. Fabricate a Primer mounting bracket. See Figure 1 for the hole pattern of the 1/4-20 tapped holes on the primer body. Position the

primer above the highest suction point on the re pump. The primer must be mounted in a vertical position with the three discharge

ports facing down. Note that water may discharge from the primer, so locate the primer in a spot where any discharge will not

damage other components.

3. The mounting bracket must be securely fastened to the vehicle. An example is shown in Figure 2 that secures the primer, primer

control and air source in one compact package.

4. Ensure that the air cylinder is protected from abrasion on the sides and bottom and that it is adequately secured to its mounting

bracket so that it cannot bounce out during transportation. Nylock nuts and or Loctite are to be used on all fasteners.

5. The air cylinder can be positioned away from the control. Avoid placing the cylinder near the engine exhaust system. Ideally the

cylinder should be positioned for easy access to open and close the cylinder valve, ability to read the pressure gauge and ease of

exchanging the cylinder when required.

6. Connect the single port side of the primer control valve to the top of the primer using 1/4" rigid pipe or 1/4" air brake tubing based on

your installation location requirements. Pipe sealant or Teon tape should be used on all threaded connections. NOTE: Avoid excessive

use of sealant that may migrate into the internals of the primer and impede airow.

7. Connect the primer’s 3/4" FNPT Wye Strainer Inlet to the suction priming port on the re pump. Use non-collapsible 3/4" Inside

Diameter hose or tubing.

8. Connect the top non-plugged port of the two port side of the primer control valve to the preset pressure regulator with 1/4" NPT

Fittings and 3/8" Air Brake Tubing. Use ttings/elbows that correspond with your installation locations requirements. Allow enough

length to avoid sharp bends or kinks and keep tubing away from the exhaust system or heat sources.

9. There is a small black O-Ring Figure 3 inside the threaded coupling of the pressure regulator that seals inside the neck of the air

cylinder valve. This is easily lost if the coupling is loosened while under pressure. It is suggested that spare O-Rings be kept on the

vehicle in a clean container. A pack of six (6) O-Rings (P/N 27.007.16) is available from Trident.

Operation of the AirPrime SC 1906

NOTE: All pump operators must be trained and familiar with the use of this device.

1. Check the cylinder pressure before and after using the primer. If cylinder pressure is 500 PSI or below, the cylinder should be replaced

with a full one. Weekly checks of cylinder pressure are suggested for infrequently used trucks. The cylinder valve should always be in

the off position when the primer is not being used.

2. To initiate a prime:

• Connect the suction hose to a water source.

• Start the re pump.

• Fully open the cylinder valve on the air cylinder.

• Push the primer control valve button until a prime is achieved as noted by pressure on the pump discharge gauge or water exiting

the primer outlet.

• Release the primer button.

• When nished, close the cylinder valve. Check that adequate cylinder pressure remains.

SC

1906

Self Contained Priming System

™

F