Tridonic Essence LC 35W 200-350mA stepDIM lp SNC User manual

www.tridonic.com 1

Subject to change without notice. Information provided without guarantee.

Data sheet 11/21-LC888-6

LED Driver

Linear fixed output

Product description

• Constant current built-in LED Driver

• Motion and daylight detection (included in delivery)

• For luminaires of protection class I and protection class II

• Temperature protection as per EN 61347-2-13 C5e

• Selectable fixed output current 350, 300, 250 and 200 mA

• Max. output power 35 W

• Up to 87 % eiciency

• Nominal life-time up to 100,000 h

• 5-year guarantee (conditions at www.tridonic.com)

Housing properties

• Casing Driver: metal, white

• Casing sensor: polycarbonat, white

• Type of protection IP20

Functions

• Overload protection

• Short-circuit protection

• No-load protection

È

Technical data LED Driver, page 3

Product description LED Driver, page 4–6

Technical data Motion Sensor, page 3

Product description Motion Sensor, page 7–9

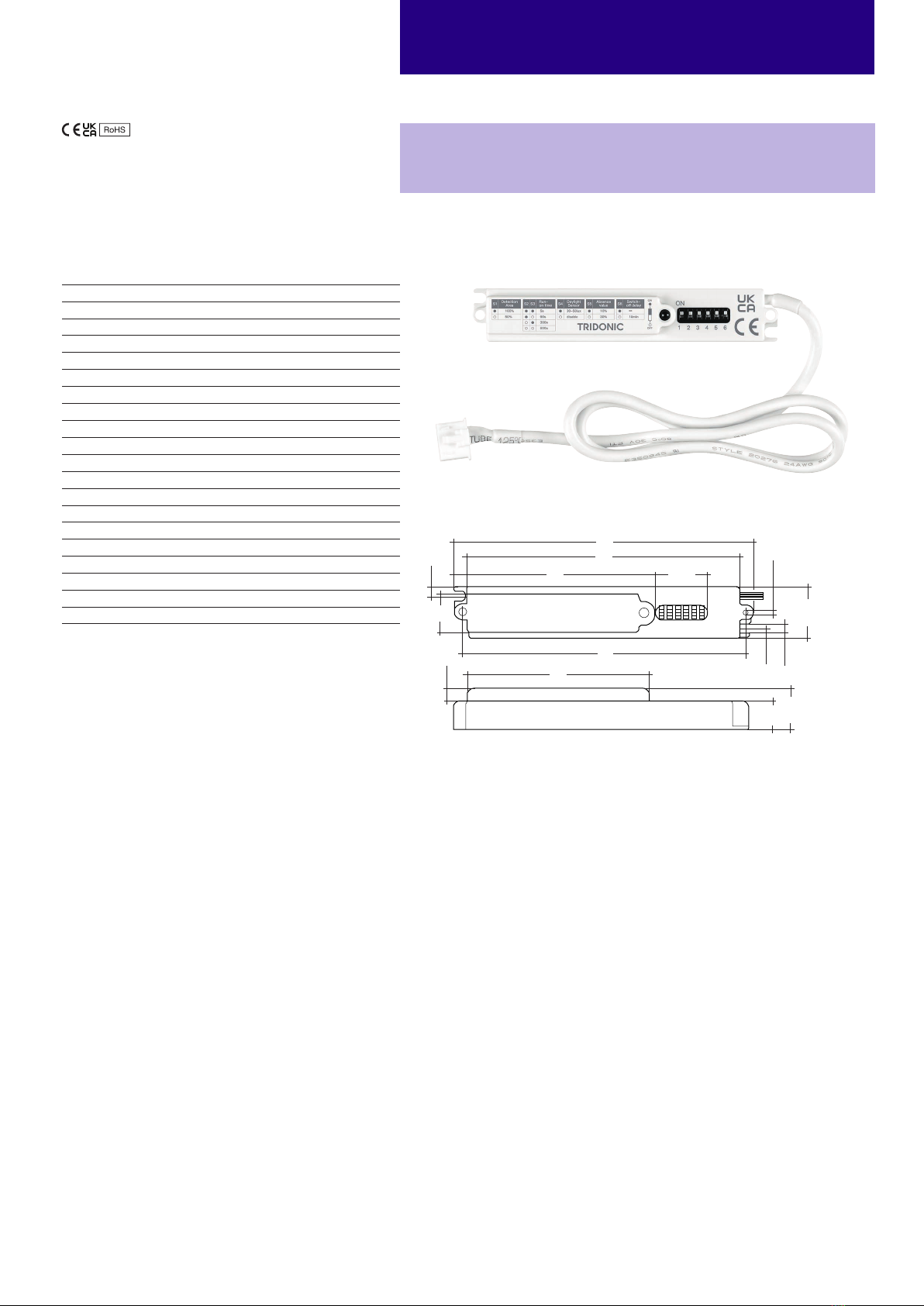

Driver LC 35W 200-350mA stepDIM lp SNC

essence series non-SELV (stepDIM)

LED Driver with sensor (included in delivery)

www.tridonic.com 2

Subject to change without notice. Information provided without guarantee.

Data sheet 11/21-LC888-6

LED Driver

Linear fixed output

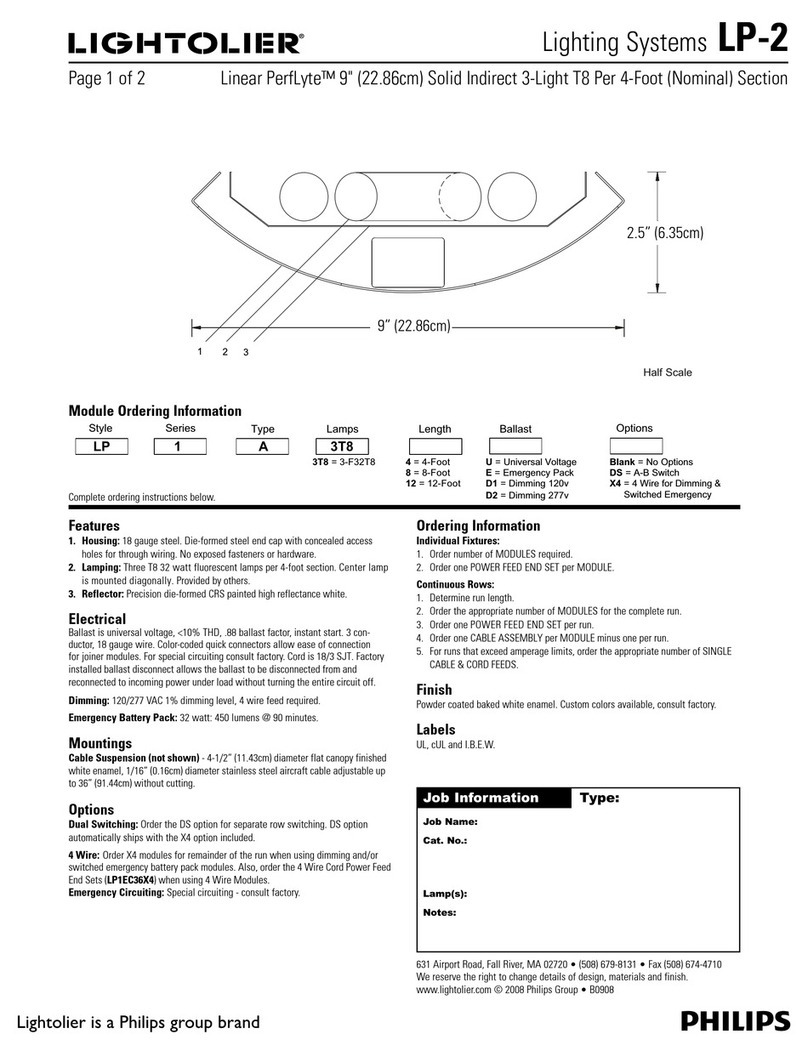

Technical data

Rated supply voltage 220 – 240 V

AC voltage range 198 – 264 V

Input current (at 230 V, 50 Hz, full load) 0.185 A

Leakage current (at 230 V, 50 Hz, full load) < 450 µA

Mains frequency 50 / 60 Hz

Overvoltage protection 320 V AC, 1 h

Output power range 10.4 – 36.4 W

Typ. eiciency (at 230 V / 50 Hz / full load)287 %

λ (at 230 V, 50 Hz, full load)20.95

Output current tolerance3± 7.5 %

Max. output voltage 320 V

THD (at 230 V, 50 Hz, full load)2< 10 %

Max. peak output current at full load2390 mA

Output LF current ripple (< 120 Hz) at full load ± 3 %

Output PstLM (at full load) ≤ 1

Output SVM (at full load) ≤ 0.4

Starting time (at 230 V, 50 Hz, full load) ≤ 0.5 s

Turn o time (at 230 V, 50 Hz, full load) ≤ 0.5 s

Hold on time at power failure (output) 0 s

Ambient temperature ta (at life-time 50,000 h) 60 °C

Storage temperature ts -40 ... +80 °C

Mains burst capability 1 kV

Mains surge capability (between L – N) 1 kV

Mains surge capability (between L/N – PE) 2 kV

Surge voltage at output side (against PE) 4 kV

Life-time up to 100,000 h

Guarantee (conditions at www.tridonic.com) 5 years

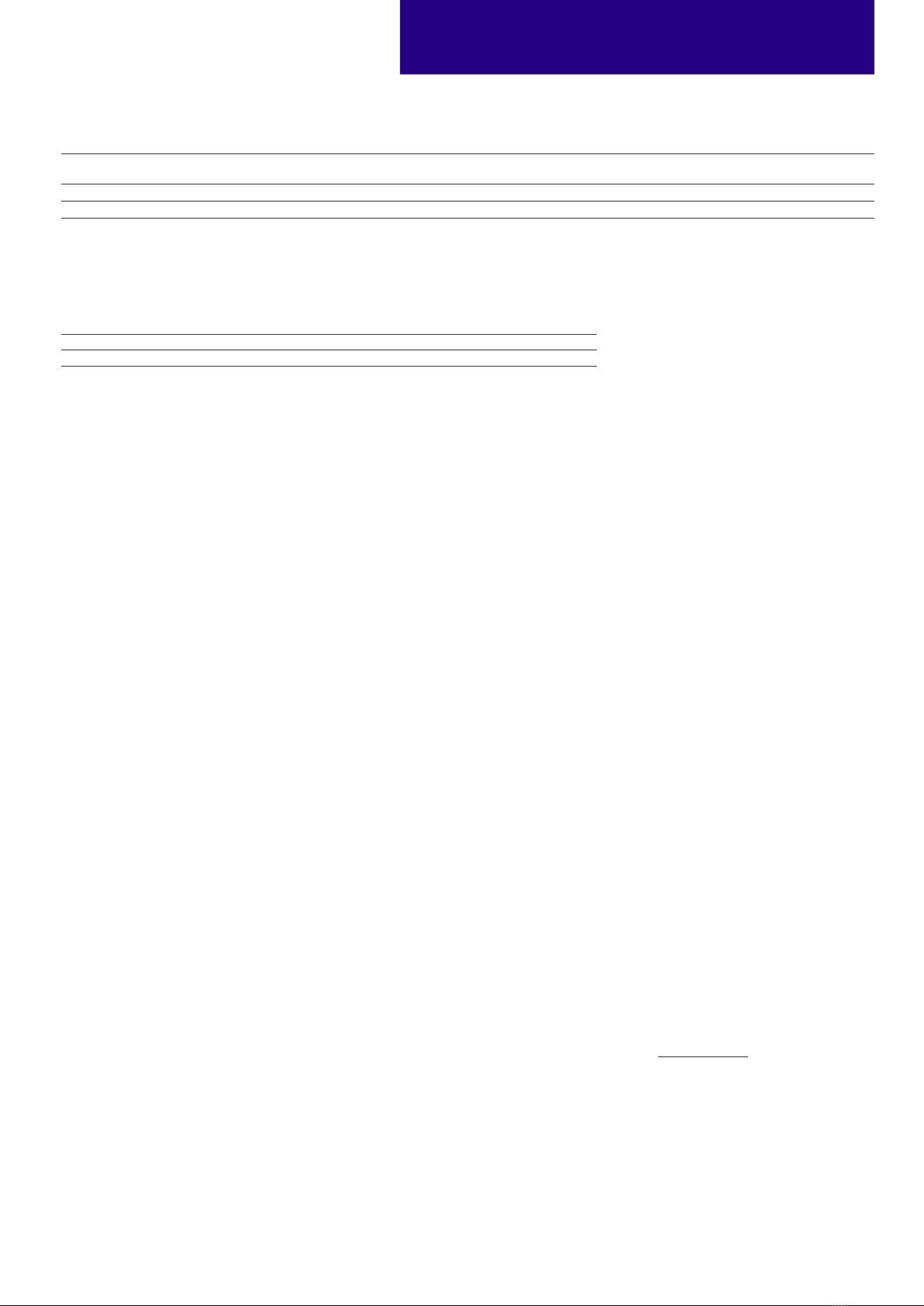

Dimensions L x W x H 230 x 30 x 21 mm

Hole spacing D 218 mm

Driver LC 35W 200-350mA stepDIM lp SNC

essence series non-SELV (stepDIM)

230

21

122.4

tc

4

30

218

ø4.1

tc

16.2

side fixing feature

Ordering data

Type1Article

number

Packaging,

carton

Packaging,

pallet

Weight

per pc.

LC 35/200-350/121 stepDIM lp SNC 20 pc(s). 420 pc(s). 0.158 kg

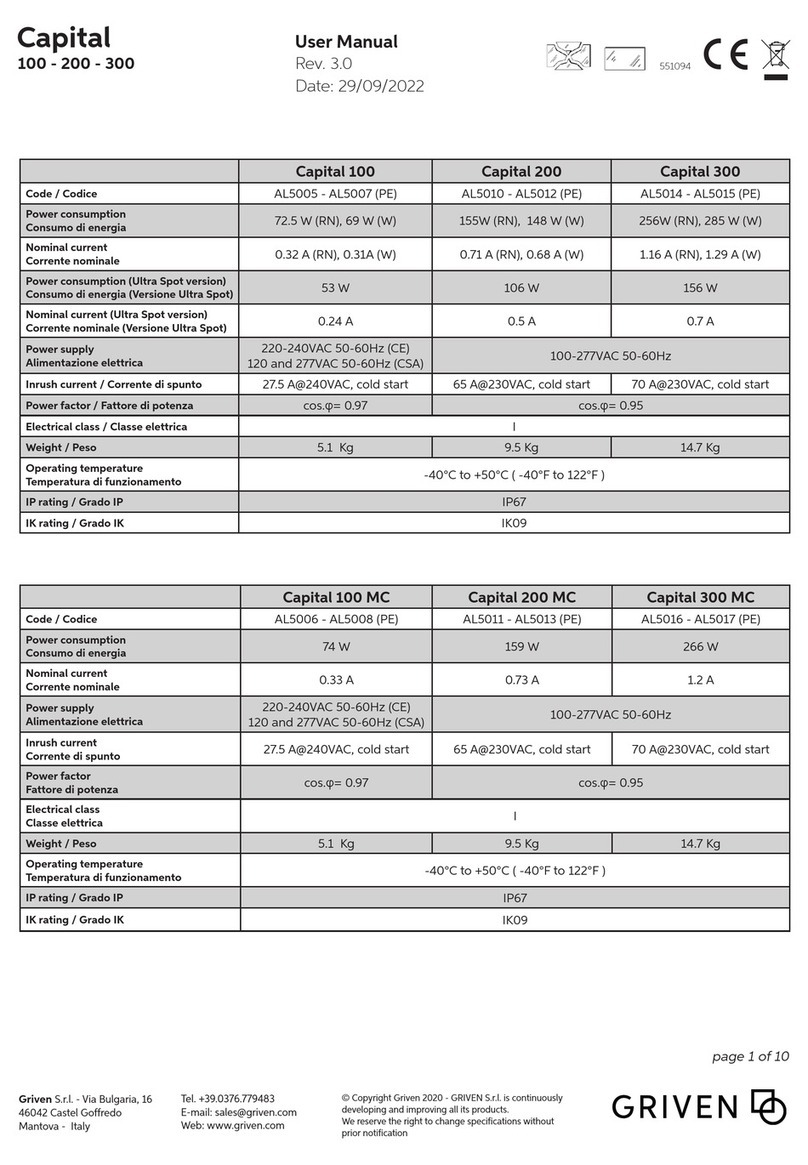

Specific technical data

Type Output

current4

Min. forward

voltage

Max. forward

voltage

Max. output

power

Typ. power consumption

(at 230 V, 50 Hz, full load)

Typ. current consumption

(at 230 V, 50 Hz, full load)

Max. casing

temperature tc

Ambient

temperature

ta max.

Iout select

LC 35/200-350/121 stepDIM lp SNC

200 mA 52 V 121 V 24.2 W 27. 5 W 130 mA 80 °C -20 ... +60 °C 1=off / 2=off

250 mA 52 V 121 V 30.3 W 33.3 W 155 mA 80 °C -20 ... +60 °C 1=off / 2=on

300 mA 52 V 121 V 36.3 W 40.5 W 185 mA 80 °C -20 ... +60 °C 1=on / 2=off

350 mA 52 V 104 V 36.4 W 41.0 W 185 mA 80 °C -20 ... +60 °C 1=on / 2=on

1LED Driver with sensor (included in delivery).

2Test result at 350 mA.

3Test result at 25 °C.

4Output current is mean value.

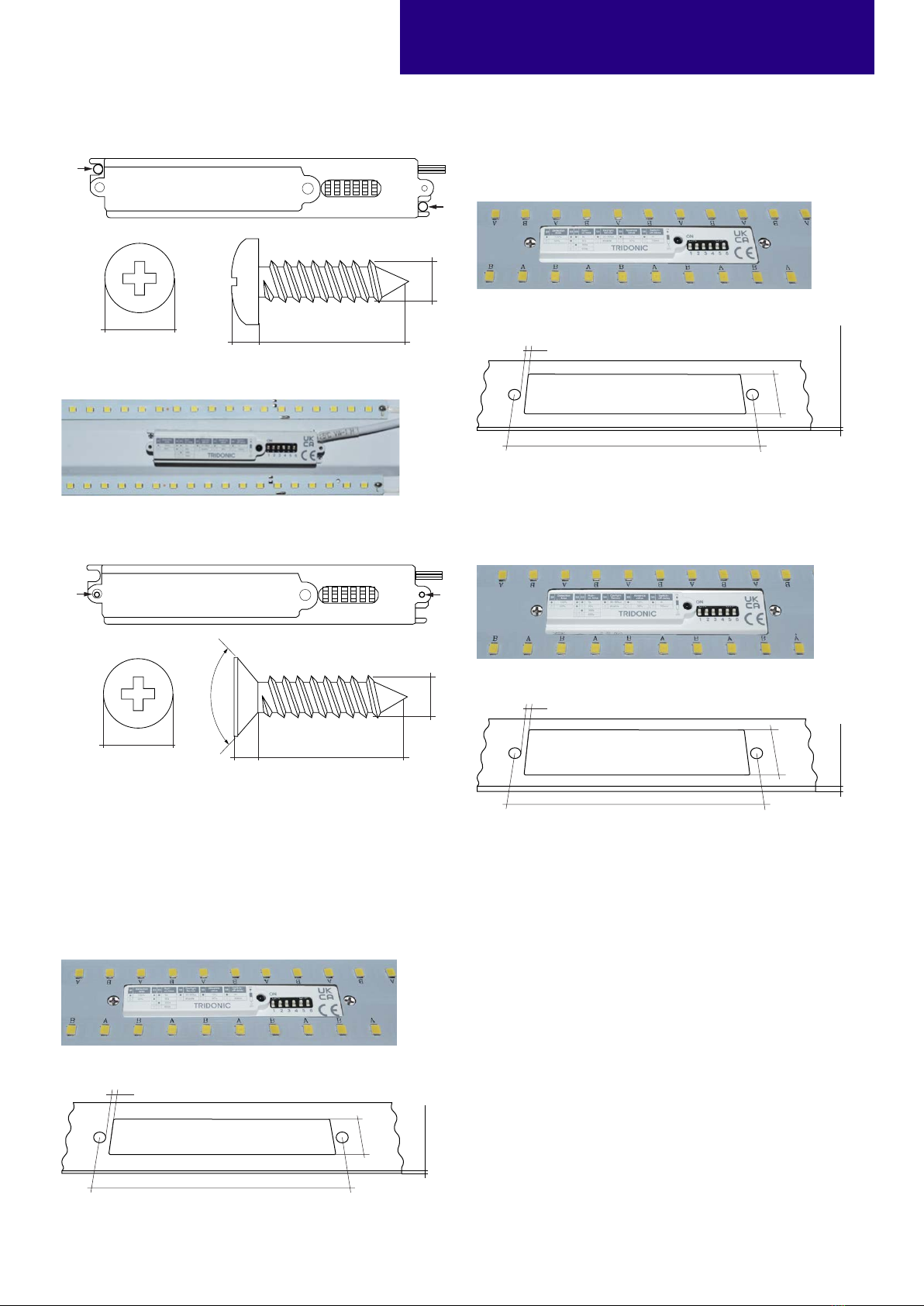

Motion Sensor (included)

Automatic switching based on motion and light level

123456

ON DIP

81

59

55

84

89

15.8

ø1.7

8.5

12.1

11

3.6

15.5

2.7

2.7

2.8

www.tridonic.com 3

Subject to change without notice. Information provided without guarantee.

Data sheet 11/21-LC888-6

LED Driver

Linear fixed output

Technical data

Supply voltage DC 5.3 – 10 V

Current draw 45 mA

Max. input current 50 mA

Output signal 0 – 5 V (PWM 3 kHz)

Power < 0.5 W

Frequency 5.8 GHz ( 75 MHz)

Transmission power < 0.2 mW

Detection angle 150°

Max. detection area1ø 14 m

Max. mounting height 6 m

tc 70 °C

Ambient temperature ta -20 ... +70 °C

Storage temperature ts -20 ... +70 °C

Humidity min. 5 % ... max. 95 %

Type of protection IP20

Protection class Protection class II

Casing material PC, halogen-free

Casing colour White

Dimensions L x W x H 89 x 15.8 x 12.1 mm

Hole spacing D 84 mm

Motion Sensor (included)

Automatic switching based on motion and light level

123456

ON DIP

81

59

55

84

89

15.8

ø1.7

8.5

12.1

11

3.6

15.5

2.7

2.7

2.8

1≥ 3.5 m radius at 1 m/s speed at mounting height 3 m.

www.tridonic.com 4

Subject to change without notice. Information provided without guarantee.

Data sheet 11/21-LC888-6

LED Driver

Linear fixed output

1. Standards

EN 55015

EN 61000-3-2

EN 61000-3-3

EN 61347-1

EN 61347-2-13

EN 61547

EN 62384

EN 60598-1

3.7 Mounting of device

Max. torque for fixing: 0.5 Nm/M4

The LED Driver is designed for a life-time stated above under reference

conditions and with a failure probability of less than 10 %.

2. Thermal details and life-time

2.1 Expected life-time

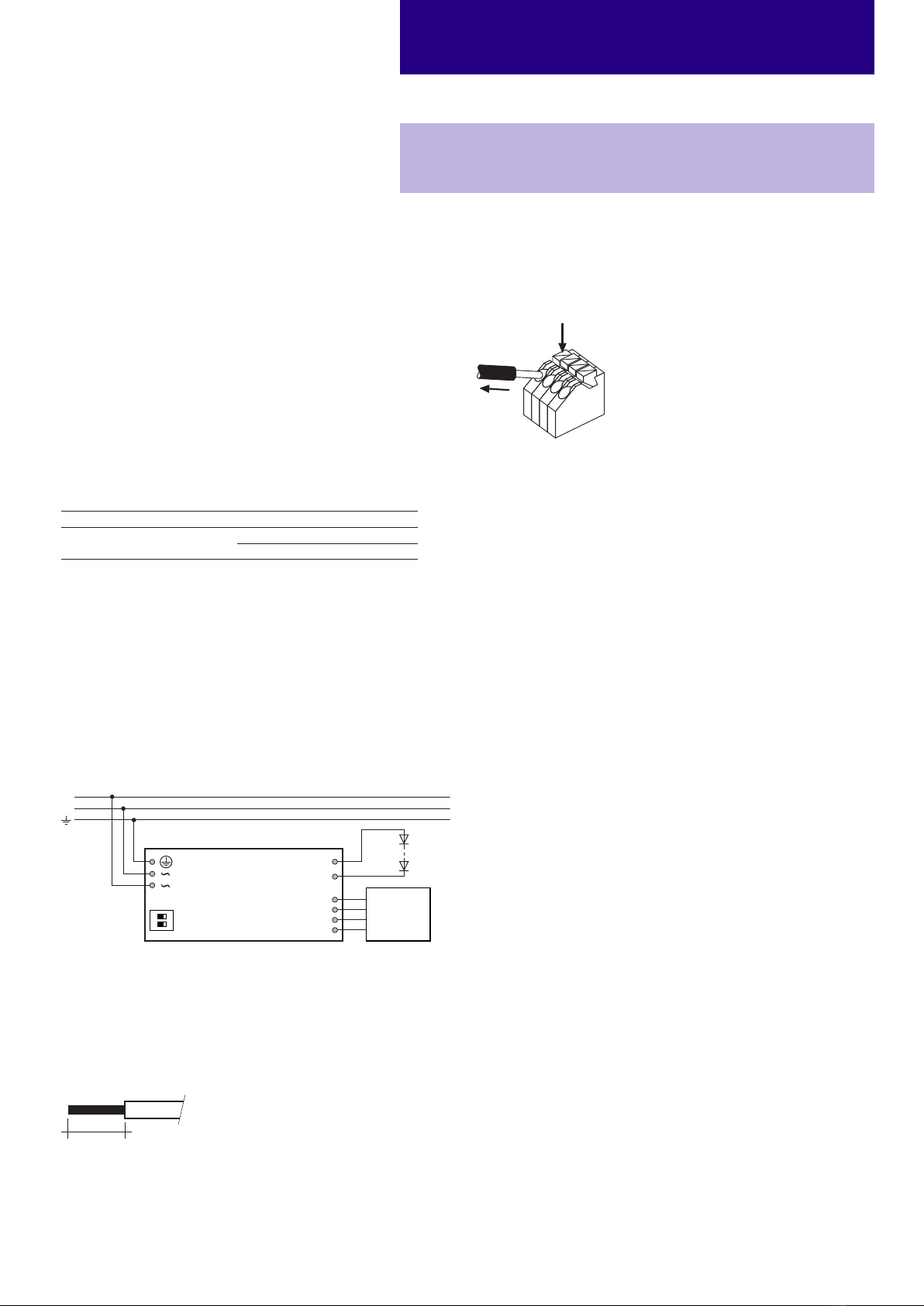

3. Installation / wiring

3.1 Circuit diagram

3.2 Wiring type and cross section

The wiring can be stranded wires with ferrules or rigid wires with a cross

section of 0.5 – 1.5 mm².

Strip 8.5 – 9.5 mm of insulation from the cables to ensure perfect operation

of the push-wire terminals (WAGO 250).

– mm

wire preparation:

– mm²

3.3 Release of the wiring

Press down the “push button” and remove the cable from front.

3.4 Wiring guidelines

• All connections must be kept as short as possible to ensure good EMI

behaviour.

• Mains leads should be kept apart from LED Driver and other leads

(ideally 5 – 10 cm distance)

• Max. length of output wires is 2 m.

• Incorrect wiring can damage LED modules.

• To avoid the damage of the Driver, the wiring must be protected against

short circuits to earth (sharp edged metal parts, metal cable clips, louver,

etc.).

3.5 Earth connection

The earth connection is conducted as protection earth (PE). The LED Driver

can be earthed via metal housing. If the LED Driver will be earthed,

protection earth (PE) has to be used. There is no earth connection required

for the functionality of the LED Driver. Earth connection is recommended to

improve following behaviour.

• Electromagnetic interferences (EMI)

• Transmission of mains transients to the LED output

In general it is recommended to earth the LED Driver if the LED module is

mounted on earthed luminaire parts respectively heat sinks and thereby

representing a high capacity against earth.

For Class II application, protection earth is no need to be connected, below 2

scenarios should be considered:

• If the LED Driver housing is screw on a metal part inside the luminaires,

both LED Driver and LED module must be insulated.

• If the LED Driver housing is screw on a plastic part inside the luminaires,

the LED module need to be insulated.

3.6 Replace LED module

1. Mains off

2. Remove LED module

3. Wait for 30 seconds

4. Connect LED module again

Hot plug-in or output switching of LEDs is not permitted and may cause

a very high current to the LEDs.

SEC

PRI

220–240 V

L

50/60 Hz

+ LED

3.3Vaux

GND

5Vaux

PWM

– LED

N

ON

I-select

LC stepDIM lp SNC

Motion

Sensor

Type ta 50 °C 60 °C

LC 35/200-350/121 stepDIM lp SNC tc 70 °C 80 °C

Life-time 100,000 h 50,000 h

Driver LC 35W 200-350mA stepDIM lp SNC4

Product description

The relation of tc to ta temperature depends also on the luminaire design.

If the measured tc temperature is approx. 5 K below tc max., ta temperature

should be checked and eventually critical

components (e.g. ELCAP) measured. Detailed information on request.

www.tridonic.com 5

Subject to change without notice. Information provided without guarantee.

Data sheet 11/21-LC888-6

LED Driver

Linear fixed output

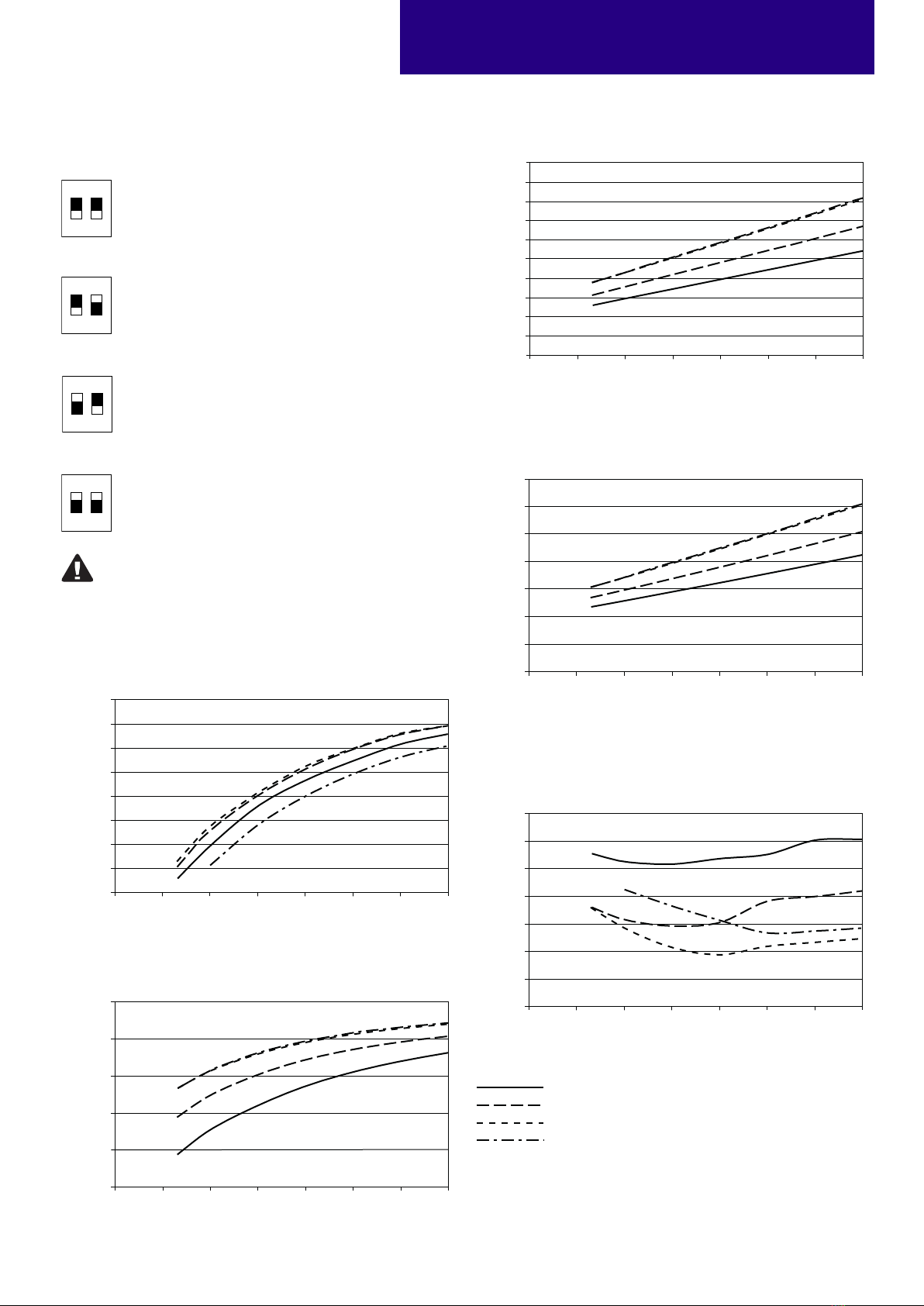

4.5 THD vs load (without harmonic < 5 mA or 0.6 % of the input current)

4.1 Efficiency vs load

4.2 Power factor vs load

4.3 Input power vs load

4.4 Input current vs load

4. Electrical values

THD without harmonic < 5 mA (0.6 %) of the input current:

0

14

30 80 9060 7040 50

100

12

10

2

4

6

8

Load [%]

THD [%]

82

85

86

84

83

87

88

89

90

30 50 7060 80 9040

100

Load [%]

Eiciency [%]

0,75

0,80

0,90

0,85

0,95

1,00

30 60

50 70 80 9040

100

Load [%]

Power factor

0

50

8070 90605030 40

100

5

15

10

25

20

40

45

35

30

Load [%]

Input power [W]

0

210

8070 906030 40 50

100

180

150

120

90

60

30

Load [%]

Input current [mA]

3.8 Current setting

200 mA: Switch 1 = Off, Switch 2 = Off

350 mA: Switch 1 = On, Switch 2 = On

250 mA: Switch 1 = Off, Switch 2 = On

1 2

ON

1 2

ON

1 2

ON

1 2

ON

300 mA: Switch 1 = On, Switch 2 = Off

200 mA

300 mA

250 mA

350 mA

Set the current by DIP switch after mains off.

Use of DIP switch only after mains off.

www.tridonic.com 6

Subject to change without notice. Information provided without guarantee.

Data sheet 11/21-LC888-6

LED Driver

Linear fixed output

6.1 Insulation and electric strength testing of luminaires

Electronic devices can be damaged by high voltage. This has to be considered

during the routine testing of the luminaires in production.

According to IEC 60598-1 Annex Q (informative only!) or ENEC 303-Annex A,

each luminaire should be submitted to an insulation test with 500V DC for

1 second. This test voltage should be connected between the interconnected

phase and neutral terminals and the earth terminal.

The insulation resistance must be at least 2 MΩ.

As an alternative, IEC 60598-1 Annex Q describes a test of the electrical

strength with 1500 V AC (or 1.414 x 1500 V DC). To avoid damage to the electronic

devices this test must not be conducted.

6.3 Additional information

Additional technical information at www.tridonic.com →Technical Data

Life-time declarations are informative and represent no warranty claim.

No warranty if device was opened.

6.2 Conditions of use and storage

Humidity: 5 % up to max. 85 %,

not condensed

(max. 56 days/year at 85 %)

Storage temperature: -40 °C up to max. +80 °C

The devices have to be within the specified temperature range (ta) before

they can be operated.

The LED Driver is declared as inbuilt LED controlgear, meaning it is intended

to be used within a luminaire enclosure.

If the product is used outside a luminaire, the installation must provide

suitable protection for people and environment (e.g. in illuminated ceilings).

Automatic circuit

breaker type

C10 C13 C16 C20 B10 B13 B16 B20 Inrush current

Installation Ø1.5 mm21.5 mm21.5 mm22.5 mm21.5 mm21.5 mm21.5 mm22.5 mm2Imax Time

LC 35/200-350/121 stepDIM lp SNC 36 47 58 73 36 47 58 73 12 A 80 µs

THD 3. 5. 7. 9. 11.

LC 35/200-350/121 stepDIM lp SNC < 10 < 7 < 5 < 5 < 5 < 3

Acc. to 6100-3-2. Harmonics < 5 mA or < 0.6 % (whatever is greater) of the input current are

not considered for calculation of THD.

4.7 Harmonic distortion in the mains supply (at 230 V / 50 Hz and full load)

in %

5. Functions 6. Miscellaneous

5.1 Short-circuit behaviour

In case of a short circuit on the output side (LED) the LED Driver switches off.

After elimination of the short-circuit fault the LED Driver will recover

automatically.

5.2 No-load operation

The LED Driver works in burst working mode to provide a constant output

voltage regulation which allows the application to be able to work safely when

LED string opens due to a failure.

4.6 Maximum loading of automatic circuit breakers in relation to inrush current

These are max. values calculated out of continuous current running the device on full load. There is no limitation due to in-rush current.

If load is smaller than full load for calculation only continuous current has to be considered.

Motion Sensor

Product description

5.3 Overload protection

If the maximum load is exceeded by a defined internal limit, the LED Driver

will protect itself and LED may flicker. After elimination of the overload, the

nominal operation is restored automatically.

www.tridonic.com 7

Subject to change without notice. Information provided without guarantee.

Data sheet 11/21-LC888-6

LED Driver

Linear fixed output

Motion Sensor

Product description

1.1 Glow wire test

according to EN 60598-1 with increased temperature of 850 °C passed.

1. Standards

IEC 61347-1

IEC 61347-2-11

EN 61347-1

EN 61347-2-11

2. Description

• The schell is made of flame retardant, with fire rating of V-0

• Compared with PIR module, microwave motion sensor is better – more

wide detection range, no dead area, no fresnel lens, no aging problem,

no environment interface

• Strong anti-interference ability – it is not affected by temperature,

humidity, airflow, dust, noise, brightness and other factors.

• Avoid installing metal accessories or shells, metal will block

the microwave and affect the effect.

• The antenna surface should avoid large current circuit coverage,

which may cause interference.

• The photosensitive position should avoid being blocked by

opaque objects, which will change the light intensity.

• The recommended installation distance of the sensor is

greater than 1.5 m.

3. Installation

3.1 Circuit diagram

123456

ON DIP

white tighted

heat tube white tighted

heat tube

490

±5

10 ±3

20 ±3 23 ±5

1

3

4

2

1 ... Blank

2 ... Black

3 ... Re

d

4 ... Y

ellow

Cable: White UL 20276 3x24AWG black-red-yellow

Heat tube: φ4.5 UL L = 28 mm

Connector: XH2.5-T 4P white shell with buckle

www.tridonic.com 8

Subject to change without notice. Information provided without guarantee.

Data sheet 11/21-LC888-6

LED Driver

Linear fixed output

3.2 Ceiling installation

3.3 Embedded installation

123456

ON DIP

M3

M3

Tolerance: ± 0.2 mm

5.3

1.9 6

3

123456

ON DIP

M2

M2

Tolerance: ± 0.2 mm

3.7

1.21 8

2

90°

M2

>13

84

M2

1

D < 1 mm

M2

>15

84

M2

1

1 mm < D < 2 mm

M2 >18

84

M2

1

D > 2 mm

When the radar module is embedded in the lamp board or aluminum sub-

strate, the metal is close to the RF hollow width of the lamp board or alu-

minum substrate is required as follows:

1. When the thickness of the baffle plate and the aluminum

substrate (all the metal part) is D < 1 mm, the suggested hollow length is

80 mm, width > 13 mm.

2. When the thickness of the baffle plate and the aluminum substrate

(all the metal part) is 1 mm < D < 2 mm, the suggested hollow length is

80 mm, width > 15 mm.

3. When the thickness of the lamp block plate and the aluminum substrate

(all the metal part )is D > 2 mm, the suggested hollow length is 80 mm,

width > 18 mm.

lamp board:

aluminum substrate:

lamp board:

aluminum substrate:

lamp board:

aluminum substrate:

www.tridonic.com 9

Subject to change without notice. Information provided without guarantee.

Data sheet 11/21-LC888-6

LED Driver

Linear fixed output

Setting the daylight sensor (4. code switch)

Setting the standby dimming (5. code switch)

Setting the second-order delay (6. code switch)

4. Functions

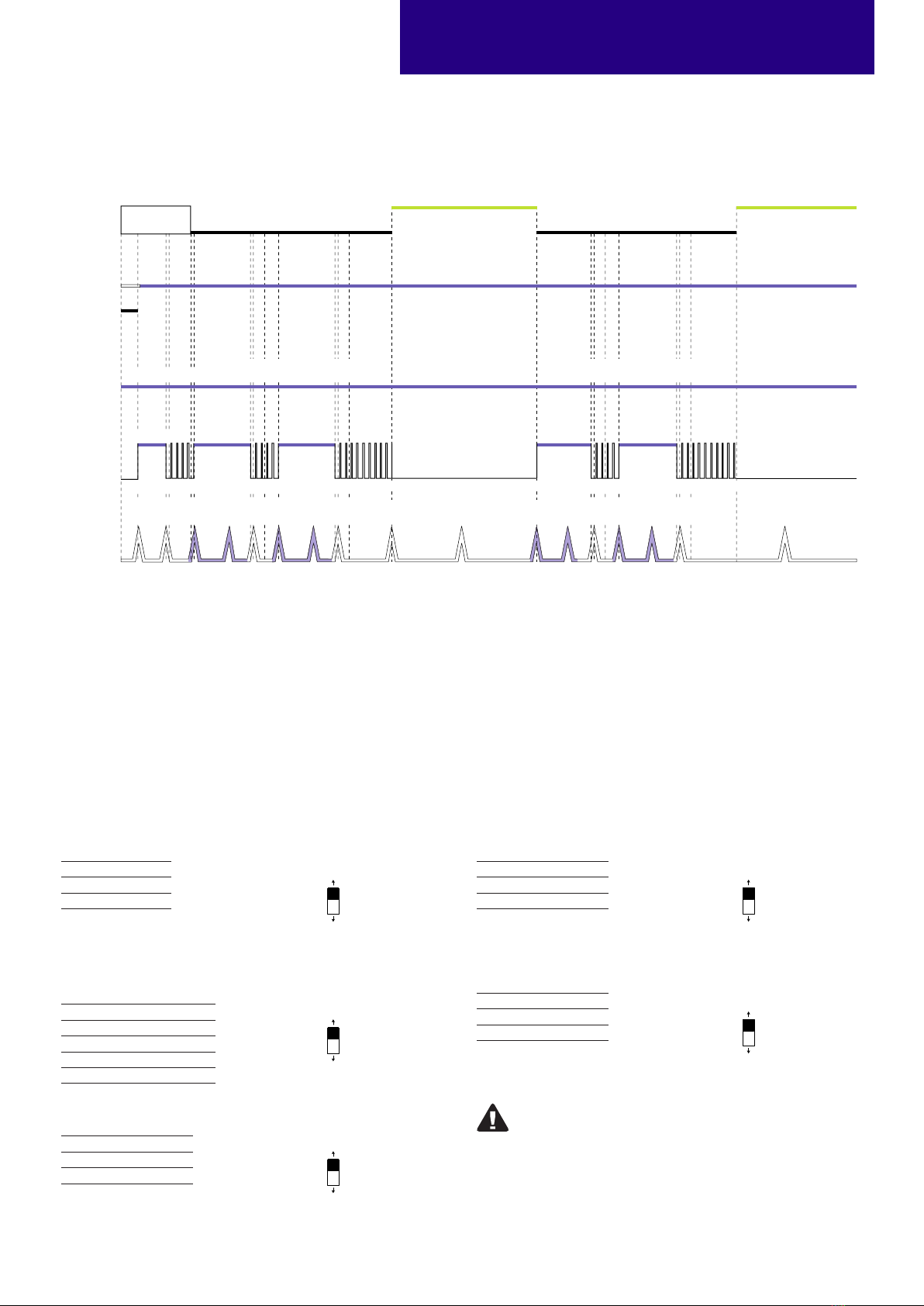

4.1 Process diagram when power on

2 3 Hold time

● ● 5 s (default)

● ○ 90 s

○ ● 300 s

○ ○ 600 s

4 Daylight sensor

●30 lux (default)

○disable

5 Standby dimming

●10 % (default)

○30 %

6 Second-order delay

●∞(default)

○10 min

1 Sensitivity

●100 % (default)

○50 %

Setting the detection area (1. code switch)

Setting the hold time (2. and 3. code switch)

●

○

ON

OFF

●

○

ON

OFF

●

○

ON

OFF

●

○

ON

OFF

●

○

ON

OFF

4.2 Adjustable code switch setting

Initialization

processNight Night

Daytime Daytime

ON

OFF

0s 5s 6s11s 12sTsT+4s

T+1s

Ts T+4s

T+1s

Ts T+4s

T+1s

Ts T+4s

T+1s

100% PWM 100% PWM 100% PWM100% PWM100% PWM

0% PWM 0% PWM 0% PWM10–30% PWM 10–30% PWM 10–30% PWM 10–30% PWM 10–30% PWM

Invalid

trigger

Invalid

trigger

Invalid

trigger

Invalid

trigger

Invalid

trigger

Invalid

trigger

Invalid

trigger

Invalid

trigger

Invalid

trigger

Trigger

valid

Trigger

valid

Trigger

valid

Trigger

valid

Continuous

trigger valid

Continuous

trigger valid

Continuous

trigger valid

Continuous

trigger valid

Model

ON / OF

F

Timing

Output

Monitor

Power losses on stand-by

system < 1 W

Power losses on stand-by

system < 1 W

In this sequence diagram, the default state of dialing is all ON state.

When the PWM output signal changes from 100 % to 10 % or 30 %, the gradual change time is 1 s, followed by a blocking time of about 3 s,

during which there is no induction.

T = the set delay time (5 s, 90 s, 300 s, 600 s) and start timing with the last valid trigger.

Within 20 s after turning on, once daylight is detected, turn off the light directly. After that, there will be a 10-minute photosensitive threshold judgment.

If the daylight continues to be detected, it will finally be judged as daytime mode, and the daytime mode induction is invalid.

When night changes to day, it also needs to pass 10 minutes of photosensitivity threshold before it is judged as day mode.

When day changes to night, it only takes 3 s to trigger directly.

When the 6. digit dialing status is OFF, if the output signal is 10 % or 30 % PWM and there is no human sensing within 10 minutes,

the output signal will become 0 % PWM.

DIP switch factory settings all default ON state.

Set the DIP switch only after mains off.

Hot plug-in is not permitted when connecting sensors.

www.tridonic.com 10

Subject to change without notice. Information provided without guarantee.

Data sheet 11/21-LC888-6

LED Driver

Linear fixed output

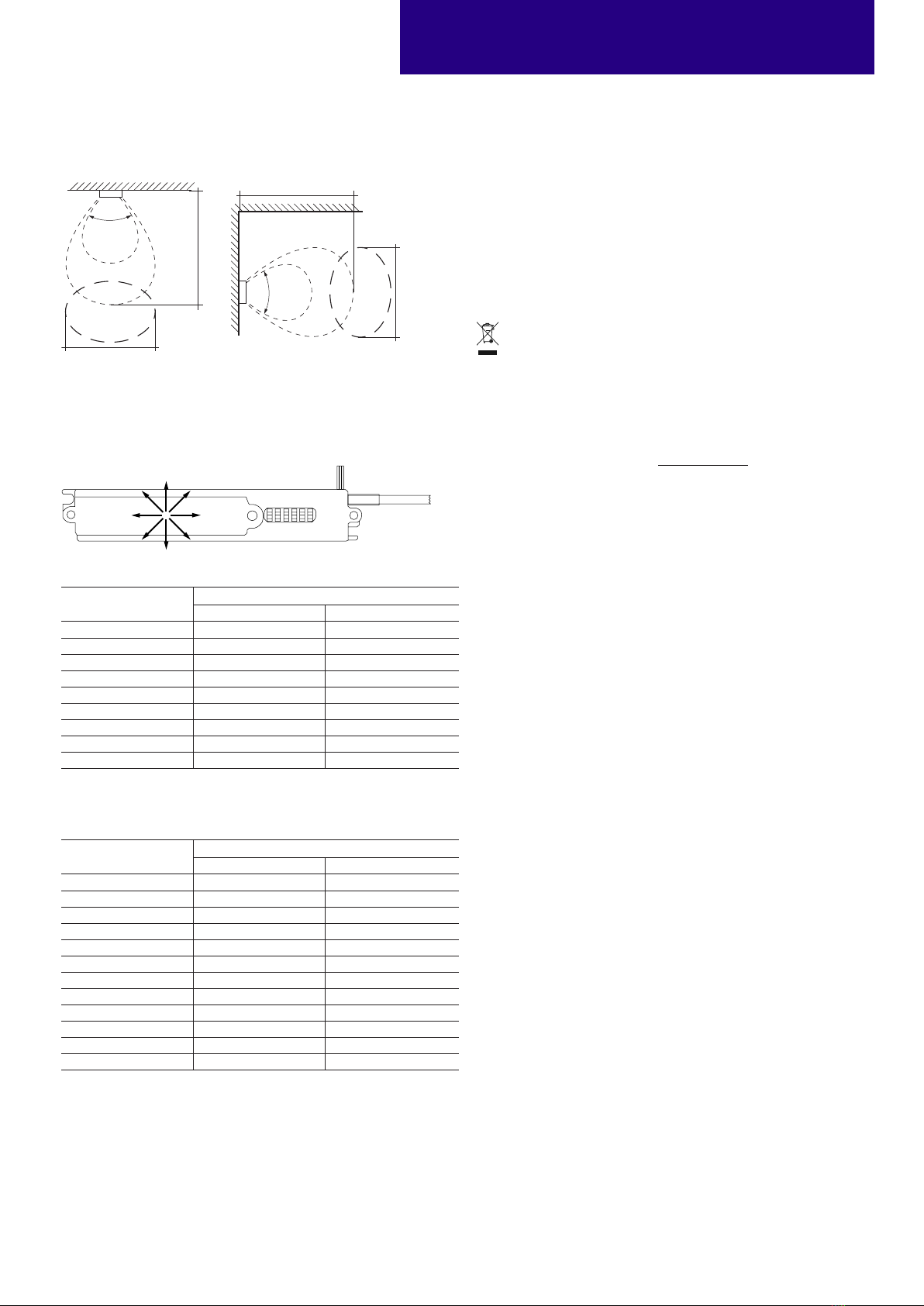

Ceiling mounted: Wall mounted:

h

d

°

4.4 Motion detection

Influence factors of detection distance:

It is related to the speed of the object.

It is related to the size of the object (the area of reception and reflection).

In the open environment and the environment with walls, the distance

difference is related to the reflection of electromagnetic waves in the face

of walls.

4.5 Detection sensibility

Optimized for detection of pedestrians with a speed of 0.5 – 1.5 m/s

corresponds to 1.8 – 5.4 km/h.

Depending on the application and environmental conditions the maximum

detectable speed of object may vary.

5. Miscellaneous

5.2 Additional information

Additional technical information at www.tridonic.com →Technical Data

Lifetime declarations are informative and represent no warranty claim.

No warranty if device was opened.

5.1 Disposal of equipment

Return old devices in accordance with the WEEE directive to suitable

recycling facilities.

h

d

°

Take 3 m as an example, the detected moving target person is:

approx. 170 cm high and weighing approx. 65 kg.

In the test room, the module is installed with the antenna facing down and

the person is moving in the direction of the sensor at a speed of 1 m/s.

A person moved towards the sensor with a speed of 1 m/s during the test in

the test room. The sensing range at different heights is as follows:

123456

ON DIP

Location 1

Location 8

Location 7

Location 6

Location 5

Location 4

Location 3

Location 2

Sensing position

Detection radius at 1 m/s moving speed

100 % sensitivity 50 % sensitivity

Location 1 4.0 m 2.0 m

Location 2 3.5 m 2.5 m

Location 3 3.5 m 2.5 m

Location 4 4.0 m 2.5 m

Location 5 4.0 m 2.5 m

Location 6 3.5 m 2.0 m

Location 7 4.0 m 2.5 m

Location 8 4.0 m 2.5 m

Overall sensing range 3.5 m 2.0 m

Application height

Detection diameter at 1 m/s moving speed

100 % sensitivity 50 % sensitivity

0.5 m 5.0 m 2.5 m

1.0 m 6.0 m 3.0 m

1.5 m 7.0 m 4.0 m

2.0 m 8.0 m 5.0 m

2.5 m 8.0 m 5.0 m

3.0 m 8.0 m 5.0 m

3.5 m 7.5 m 4.0 m

4.0 m 7.0 m 3.0 m

5.0 m 6.0 m 2.5 m

5.5 m 5.0 m 2.0 m

6.0 m 4.5 m 2.0 m

6.5 m 4.0 m 2.0 m

This manual suits for next models

1

Table of contents

Other Tridonic Lighting Equipment manuals

Tridonic

Tridonic LCA PRE OTD User manual

Tridonic

Tridonic PRO Series User manual

Tridonic

Tridonic EM converterLED ST User manual

Tridonic

Tridonic PRO Series User manual

Tridonic

Tridonic EM powerLED ST FX User manual

Tridonic

Tridonic EM converterLED BASIC 203 MH/LiFePO4 90V User manual

Tridonic

Tridonic Excite Series User manual

Tridonic

Tridonic LCAI ECO User manual

Tridonic

Tridonic EM converterLED ST MH/LiFePO4 50 V User manual

Tridonic

Tridonic BASIC Series User manual