2 Introduction

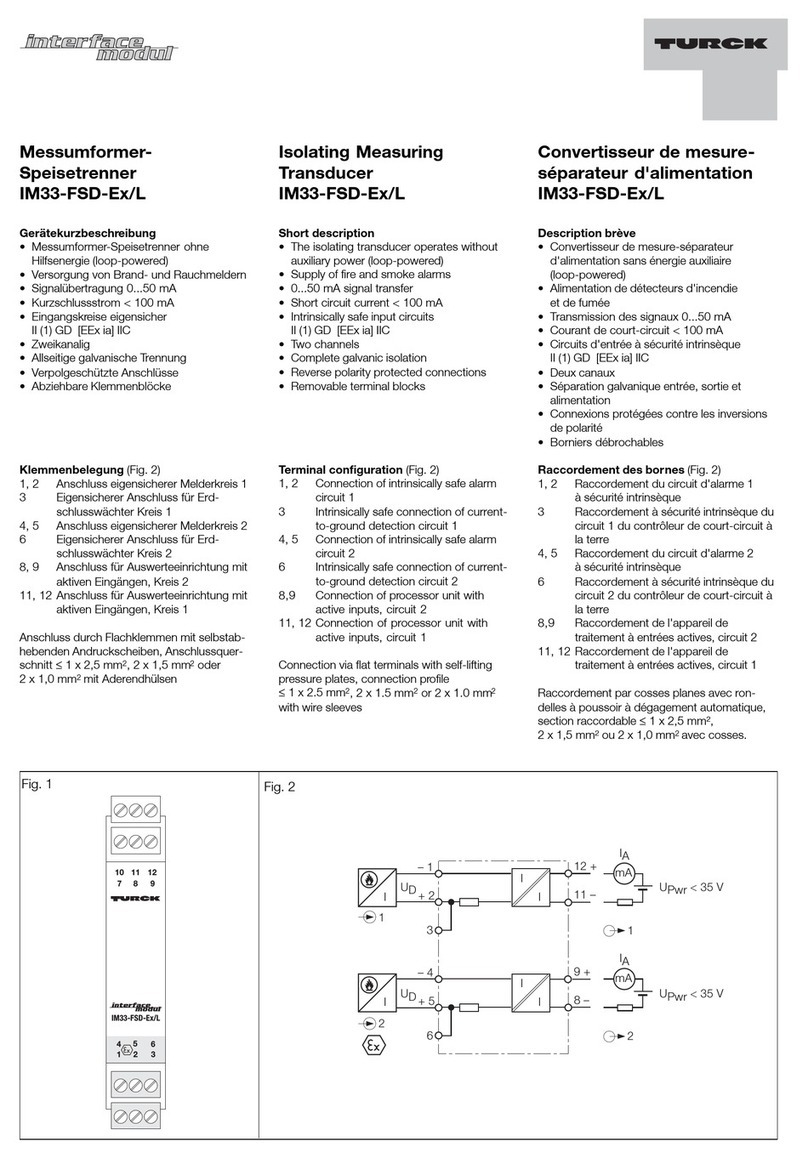

1.1 General arrangement

Thank you for purchasing a Dualpulse Flowmeter. It is important that you read this

manual to gain a full understanding of the capability and operational aspects of the

equipment you are about to install.

This information is provided only to assist in the installation of the product and

does not diminish your obligation to read the manual.

1. Select a location that meets the requirements as illustrated on the guideline

sheet (yellow pages located in the center of this manual). An ideal installation

would provide for 25 diameters of straight pipe upstream from the meter and 10

diameters downstream.

You will also need to know the pipe internal diameter (NB ) and pipe wall thickness

for calculation of the insertion depth. (refer page 5.) Non ideal installations may

require in-situ calibration (refer to the factory for details).

2. After screwing the Dualpulse in place ensure the flow alignment mark located

on the top positioning collar of the meter aligns with the flow in the pipe (refer

page 5). This ensures the paddle is correctly aligned to the flow.

Note. the meter is bi-directional so a flow direction arrow is not provided.

3. Calculate and adjust the height of the Dualpulse (refer page 5).

4. Electrical Installation depends on the model you have purchased.

If the dualpulse is fitted or supplied with a receiving instrument such as a totaliser

or rate totaliser please refer to the appropriate manual and Page 10 of this

manual. For pulse output meters, select the appropriate output and wire to your

receiving device. (refer pages 7 to 9).

5. Calculate the Dualpulse K (scale) factor to suit the installation. For ideal

installations refer to page 11 or 12 or 13 of the Dualpulse Manual. Fo r non ideal

installations the K-factor may be calculated by performing an in-situ calibration.

Enter the appropriate K-factor into your receiving instrument.

Introduction 3

1.2 Overview

Dualpulse insertion flow transducers provide a cost effective and simple means of

measuring the flow of a wide range of low viscosity liquids. Installation is quick and

inexpensive for pipe diameters ranging from 40mm to 900mm (1.5-36") and up to 2500mm

(100") nominal bore for the Hot tap capable model DP525.

Dualpulse has a linear measuring range of 0.3~10.0 metres/sec. (1~33 ft/sec.). Minimum

detectable flow velocity is 0.15 m/sec. (0.5 ft/sec.). When used in conjunction with the RT12

flow rate totaliser NLC feature the linear flow range is extended down to 0.15 m/sec. (0.5

ft/sec.) with an improved linearity.

The Dualpulse is constructed from 316 L (1.4404) stainless steel enabling use in many

applications for metering water and low viscosity chemicals.

Two independent pulse outputs are standard & can directly input to a wide range of

ancillary instruments, PLC’s and computers. Both pulse outputs have a high level of

immunity to electrical interference. Options include a reed switch.

1.3 Operating principle

Flow passes through a pipe causing the rotor to spin. Magnets installed in the rotor pass by

pulse sensors within the transducer body & inturn this produces frequency outputs

proportional to flow rate.

1.4 Specifications ( subject to change without notice )

40mm - 900mm 50mm - 2500mm

( 1.5 – 36 inches ) ( 2 – 100 inches )

0.25 - 6300 litres/sec. 0.4 - 49000 litres/sec.

( 4-99600 USGPM ) ( 6-780000 USGPM )

1.5" or 2” NPT or BSPT 2" NPT or BSPT

0.3 - 10 metres/sec. ( 1 - 33 feet/sec.)

-40C to 100C (-40F to 212F ) – refer options

316L stainless steel (1.4404)

PEEK rotor w ith graphite-PTFE impregnated PEEK bearing

VITON - options available

(a) Voltage output (to 125C)

1.5volt x 10 sec pulse w idth, self -generated (2 wire)

(b) Square wave ( Hall Effect )

5-24vdc, 3wire NPN open collector (20mA max. current sink)

(c) Reed Sw itch (to 100°C)

30vdc max. x 20mA max. (output freq. is 1/3 std. K-factor)

Output freq. @ max. velocity

( a & b ) outputs 220~240 Hz ( c ) output 73~80 Hz

Ultra high temp. coil 204C (400F) or non magnetic

1000 metres ( 3300 feet ) maximum

5 core, screened cable, length 3 metres ( 10 feet )

IP68 submersible ( Nema 6X )

Conduit entry (terminal box)

1.2 kg ( 2.7 lbs.) 1.5 kg ( 3.3 lbs.)