_

_

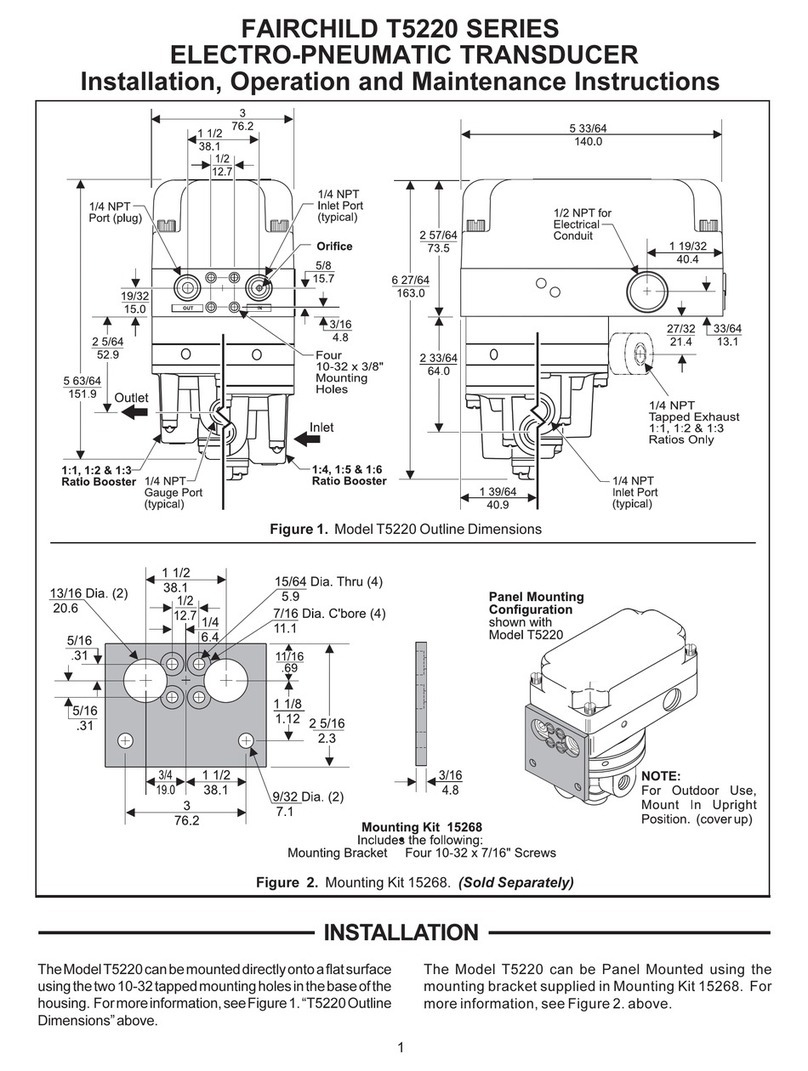

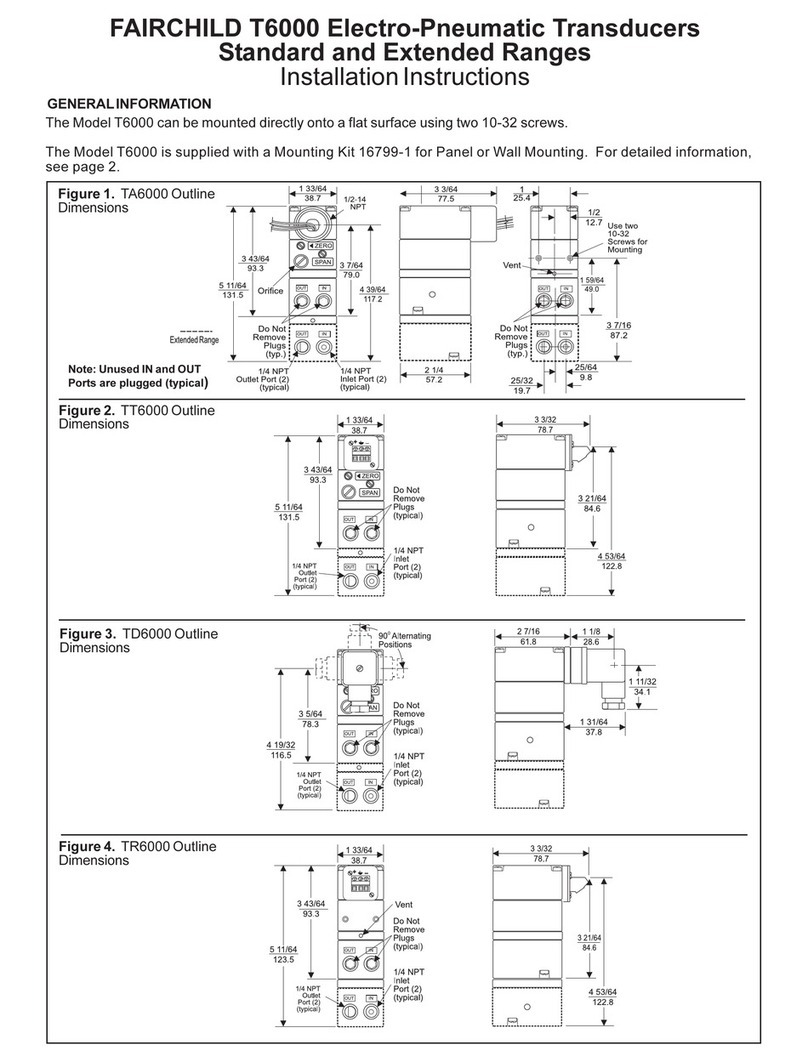

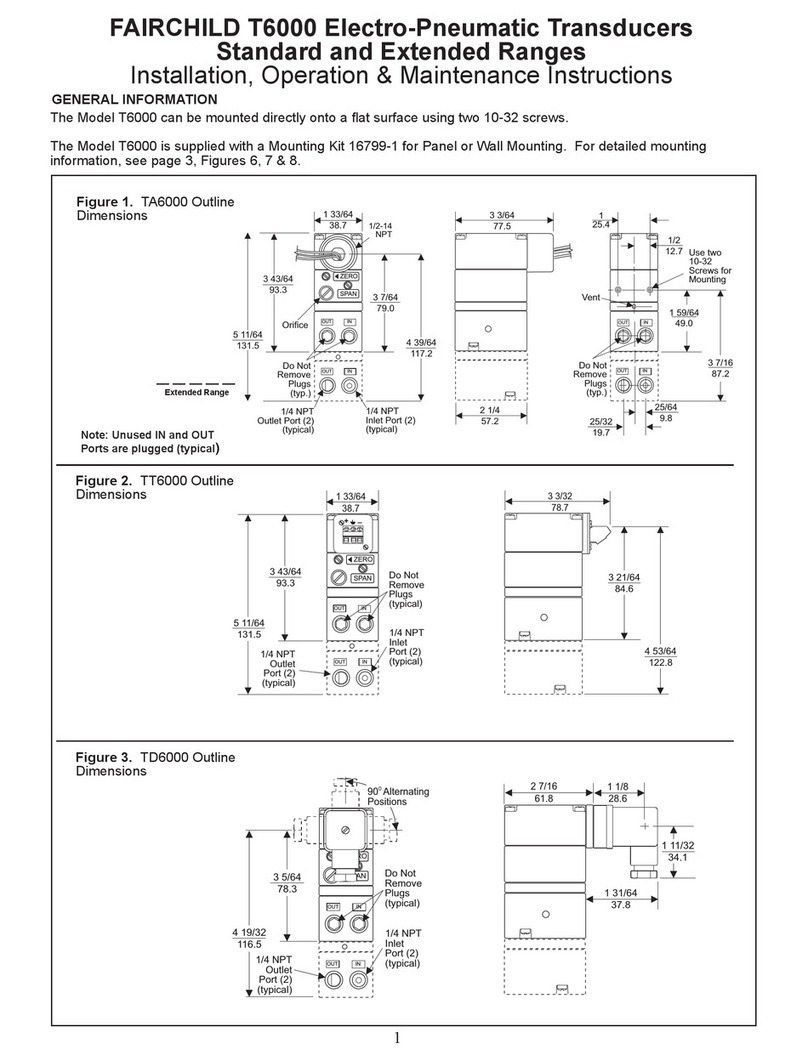

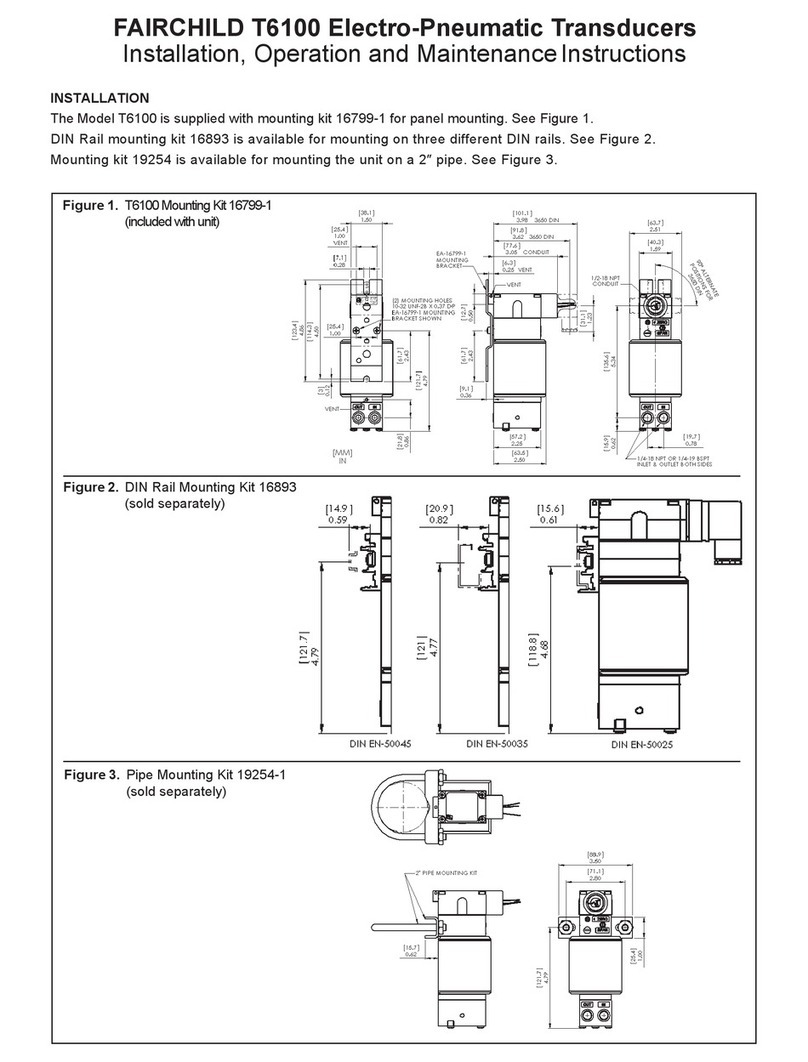

Pneumatic Connections

Clean all pipelines to remove dirt and scale before instal-

lation.

Apply a minimum amount of pipe compound to the male

threads of the fitting only. Do Not use teflon tape as a

sealant. Start with the third thread back and work away

from the end of the fitting to avoid the possibility of

contaminating the transducer. Install the transducer in the

air line.

The inlet and outlet ports are labeled on the end of the

transducer. Tighten connections securely. Avoid under-

sized fittings that will limit the flow through the transducer

and cause a pressure drop down stream. For more

information, see Figure 2. “Outline Drawing” on page 3.

NOTES: Instrument quality air, per ISA Standards D7.3-

1981, is required. Use a filter to remove dirt

and liquid in the air line ahead of the trans-

ducer for correct performance. If an air line

lubricator is used, it MUST be located down-

stream, beyond the transducer.

The user is responsible for insuring that the

environment in which the unit will be in-

stalled, and the operating gas, are compatible

with the materials in the transducer.

Electric Connection

For the T5200 Transducer, make connections to the Ter-

minal Block through a 1/2 NPT Conduit Connector (not

supplied) and a plastic sleeve as shown below in Figure 7.

“Electrical Connections”.

For the TXPD5200 Transducer, make connections from

the Sealed Connector Wires to an external Terminal Block.

The TXPD5200 Transducer has an additional ground wire

that is used. For more information, see Figure 7. “Electrical

Connections” below.

NOTE: The T5200 & TXPD5200 should be wired in

accordance with the wiring diagram inside of

cover.

Wiring in Hazardous Areas

Wiring in hazardous areas should be performed in accor-

dance with the Table 1. and any local codes that apply.

Table 1. Hazardous Location Wiring Practices.

Country Agency Code

U.S.

Canada

FM

CSA

ANSI/ISARP 12.6 & ANSI/NFPA 70

CEC Part 1

Intrinsically Safe Connections

Refer to the latest revision of the indicated drawing.

Table 2. Intrinsically Safe Installation Drawings.

Underwriting Group Drawing Number

To prevent possible ignition of hazardous at-

mosphere, DO NOT REMOVE COVER from the

TXPD5200 Transducer while current is on.

WARNING:

FM (Factory Mutual)

CSA (Canadian Standards)

EC-14007

EC-16097

To maintain Explosion-Proof capability, DO NOT

DAMAGE mating surfaces between cover and

base. NEVER ADD GASKETS.

+

Conduit

Connector

(Forward Mode)

Green Lead

( ) ground

Plastic

Sleeve

1/2 NPT

(typical)

Black Lead

( ) negative

Terminal Block

+

+

_

_

_

Red Lead

(+) positive

RED

RED

GREEN

GREEN

BLACK

BLACK

(Reverse Mode)

+

_

I

N

P

U

T

+

_

I

N

P

U

T

Model T5200

_

Terminal Block

(Forward Mode)

+

_

+

_

I

N

P

U

T

NA

Model TXPD5200

Sealed

Connector

Wires

+

_

+

_

I

N

P

U

T

NA

(Reverse Mode)

Conduit

Connector

Figure 7. Electrical Connections.

6