9

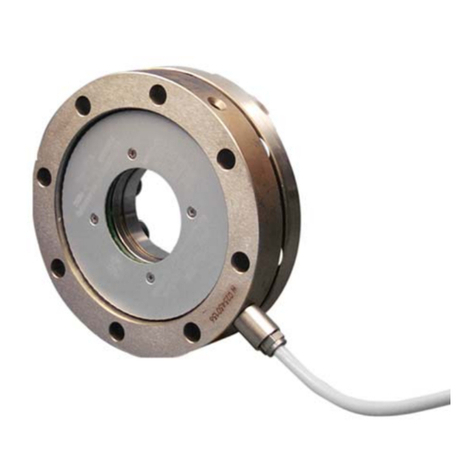

U2B

HBMA03823.3en/de/fr

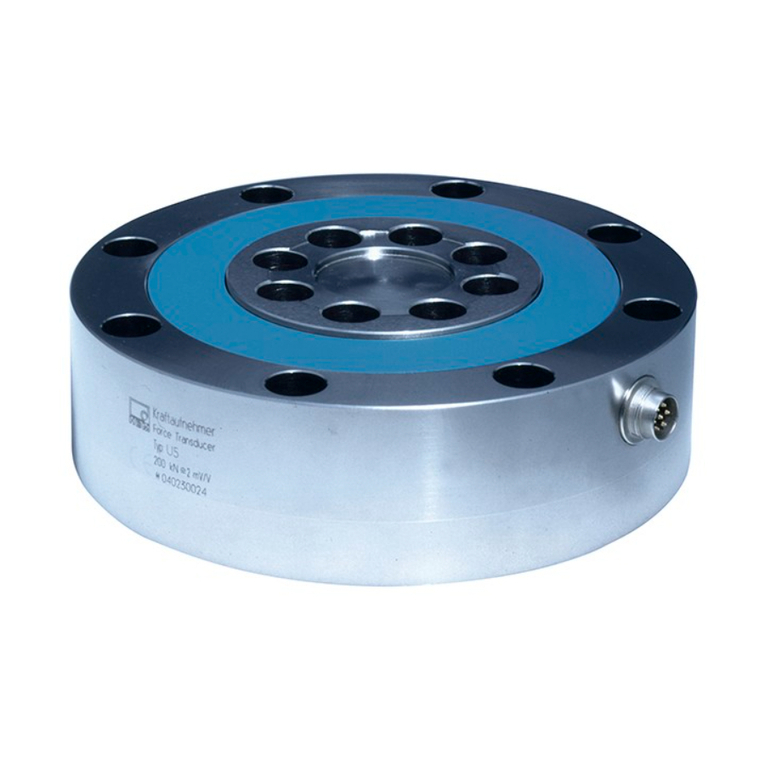

2.3 Measurement process, output signal

A force acting upon the transducer will elasticallydeform the SGs applied to

the measuring body. Their electrical resistance then changes in proportion to

the change in their length. This disturbs the balancing of the measurement

system wired in the form of a Wheatstone bridge, resulting in an output vol

tage UAat contacts 1 and 4 if a bridge excitation voltage UBis present at

points 2 and 3 on the bridge.

The ratio between the voltages, UA/UB, expressed in mV/V, is a measure of

the sensitivityof the force transducer. The change in output voltage UAis

linear to the acting force. Provided the force transducer is connected in ac

cordance with Fig. 5.1 and as specified in the User Manual for the amplifier

concerned, compressive forces are displayed with a positive operating sign

and tensile forces are shown with a negative operating sign. The force trans

ducer is electricallyconnected in 6wire mode (see Section 5.2). To reverse

the polarity, the white and red wires in the cable should be transposed.

2.4 Compensating for disturbance variables

The geometryof the measuring bodyand the positioning of the SGs ensure

that the output signal from the transducer suffers onlyminimal distortion if the

force being measured is affected bysuperimposed lateral forces and/or torsio

nal and bending moments. The specifications for this can be found in the

Technical Data. In the interests of greater accuracy, however, it is generally

better to tryto prevent spurious loadings of this kind altogether. The U2B also

has separate lateral force compensation which reduces lateral force influ

ences to a minimum (see Technical Data).

The influence of temperature on the zero signal and sensitivityare compensa

ted. Changes in ambient pressure have the same effect as additive (substrac

tive) forces (see Section 3.3).