Trimline OpalInstallation instruction 3

English

1 GENERAL INSTRUCTIONS

NOTE

The installation may only be carried out by an authorised

person.

•The appliance must be installed, connected, inspected

according to local standards and regulations.

•

roof face must also meet the requirements outlined in

•The temperature of the walls near the side and back of

the appliance may not exceed the ambient temperature

maximum increase of 60 K gives a maximum temperature

of 80 °C.

•The appliance has been approved in combination with

with European CE standards for gas appliances, and may

therefore only be applied with this system.

•

gas distribution (gas type and gas pressure) as indicated

•The instructions are only applicable if the relevant country

code is stated on the appliance.

•

used. The gas supply pipes therefore need to be vented

•Ignite the appliance according to the user manual and check

must be removed from the glass panel using a glass cleaner

Distance to ammable materials

Maintain the following minimum distances from combustible

materials: front 500mm, side 500mm, top 1200mm to curtains,

distance of 50mm from the back wall.

Distance to non-ammable materials

The appliance needs to be placed a minimum distance

of 25mm from the wall unless stated otherwise in these

instructions.

WARNING

•

appliance, the glass panel surface is considered to be an

active zone. The glass panel surface can become very hot.

•Therefore, you should take care by, for example, keeping

children and those requiring help away from the immediate

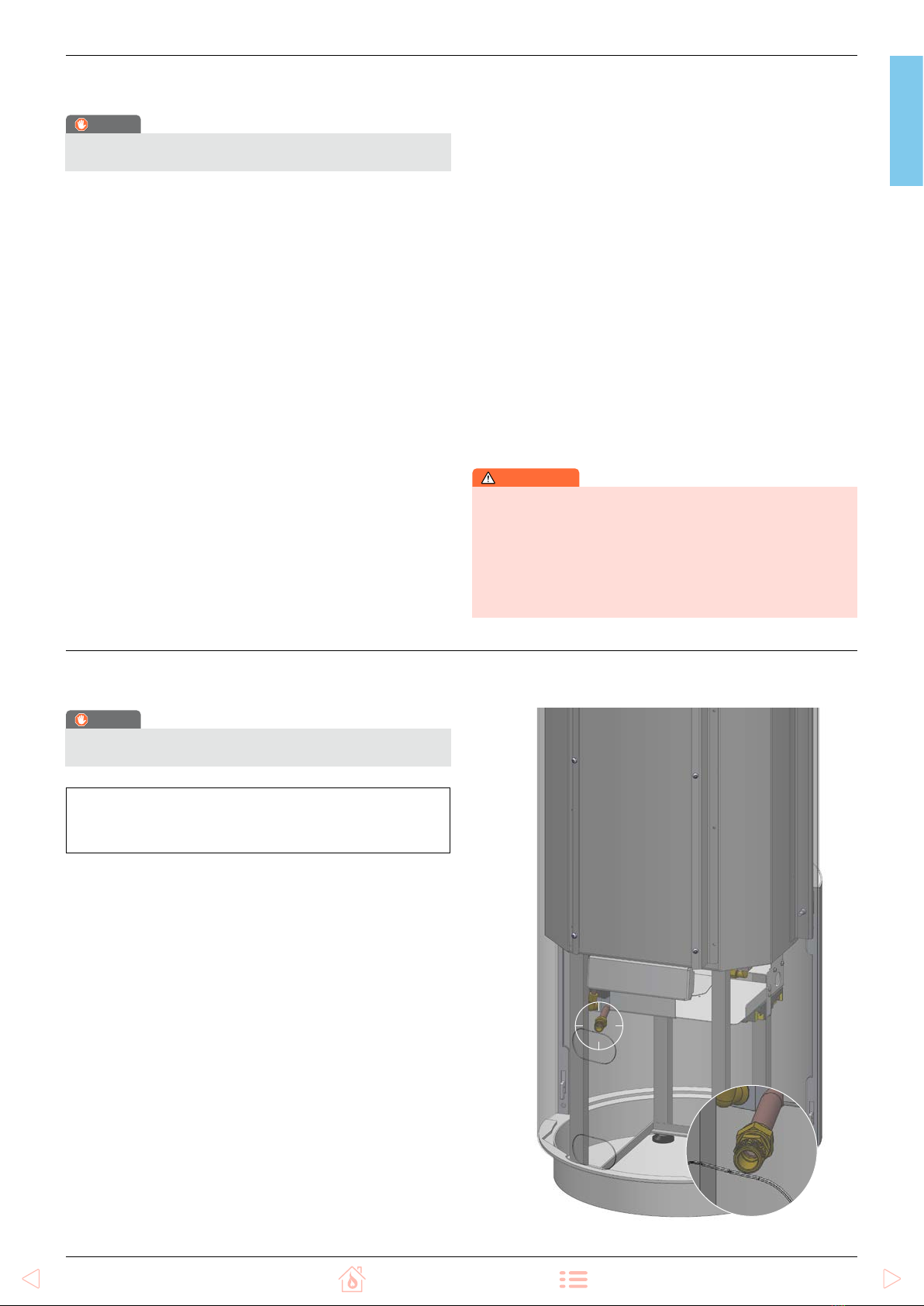

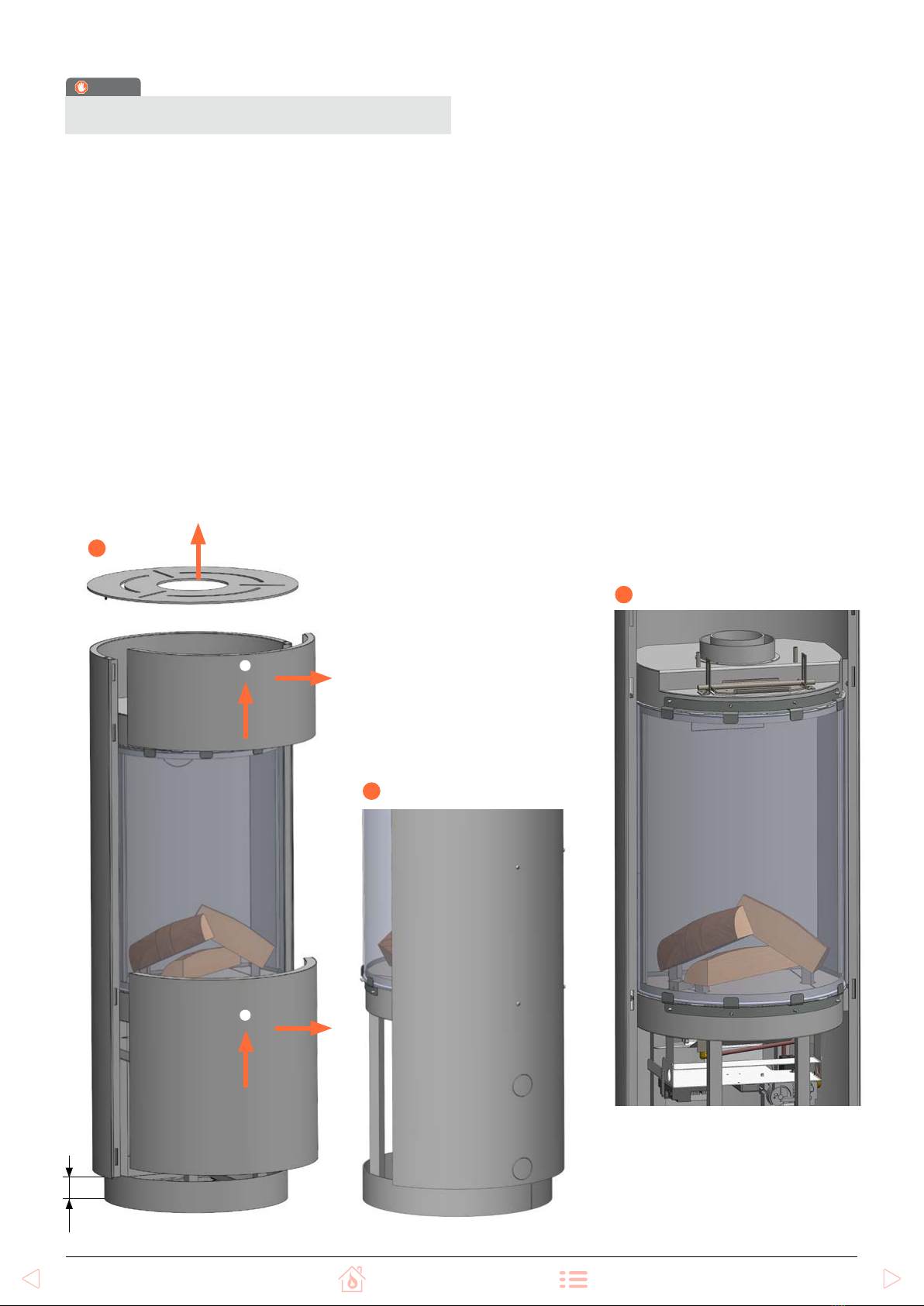

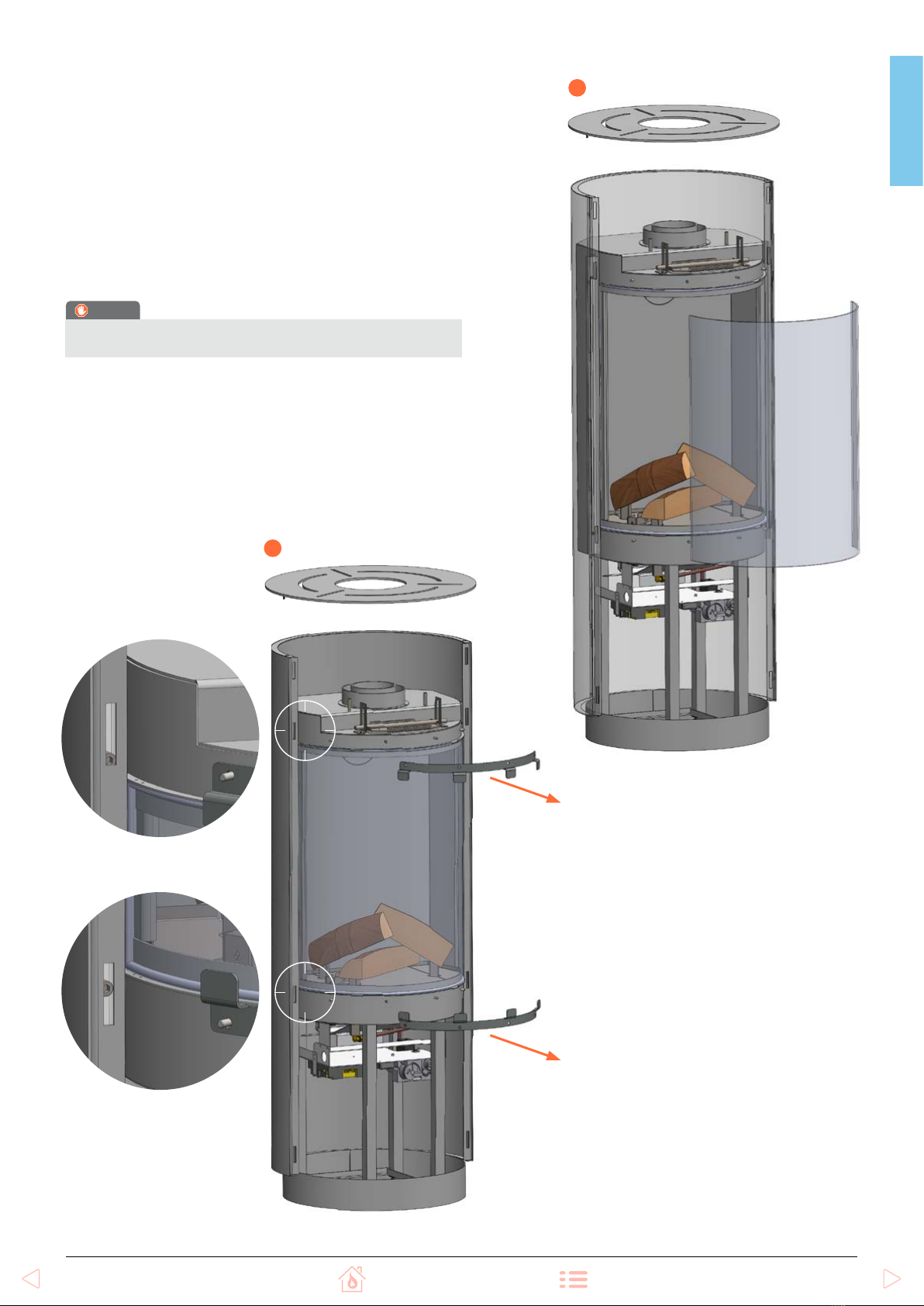

2 PLACING THE APPLIANCE

NOTE

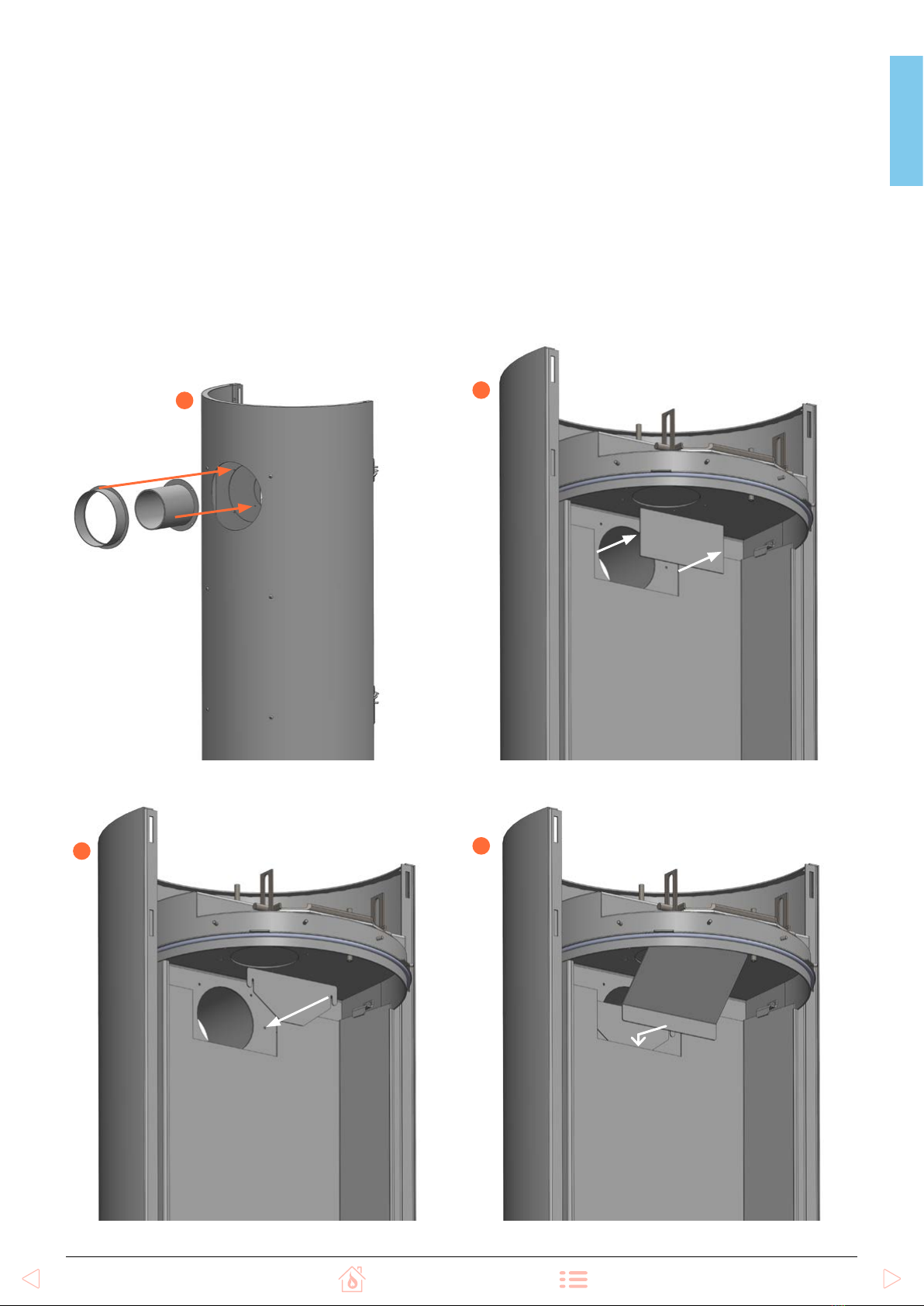

Before installing the appliance, please read Chapter

8Concentric ue system.

Option

Chapter 11 Installing the optional LED glow bed module.

2.1 Preparation and installation

•Check the packaging for damage. Remove the packaging

and check the contents are intact and complete. Report

damage and defects to the supplier immediately.

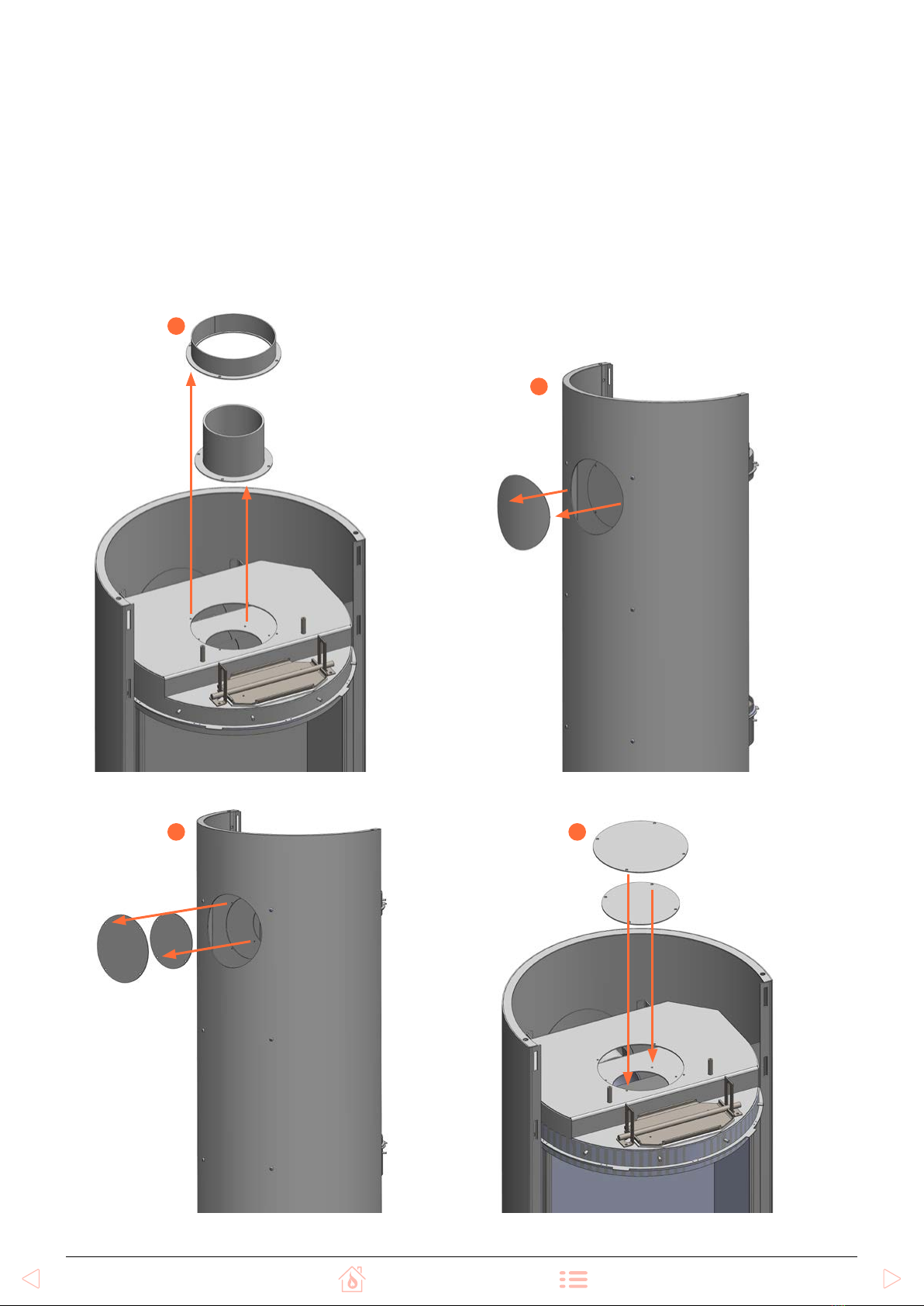

•The packaging contains the following components:

- Appliance

- Remote control

- Ceramic wood set

- dispersion medium

(glass granules and

coal embers)

- restrictor

(top connection)

- restrictor

(rear connection)

-

(rear connection)

- 4 x AA battery

- 2 x AAA battery

- Installation instruction

- User Manual

3/8” connection point