Trina Solar PD06H User manual

Date: Nov 18th, 2020 Doc No: PS-M-0694 Ver: G Page 1 of 23

158.75-cell Backsheet-Glass Framed Module USER MANUAL

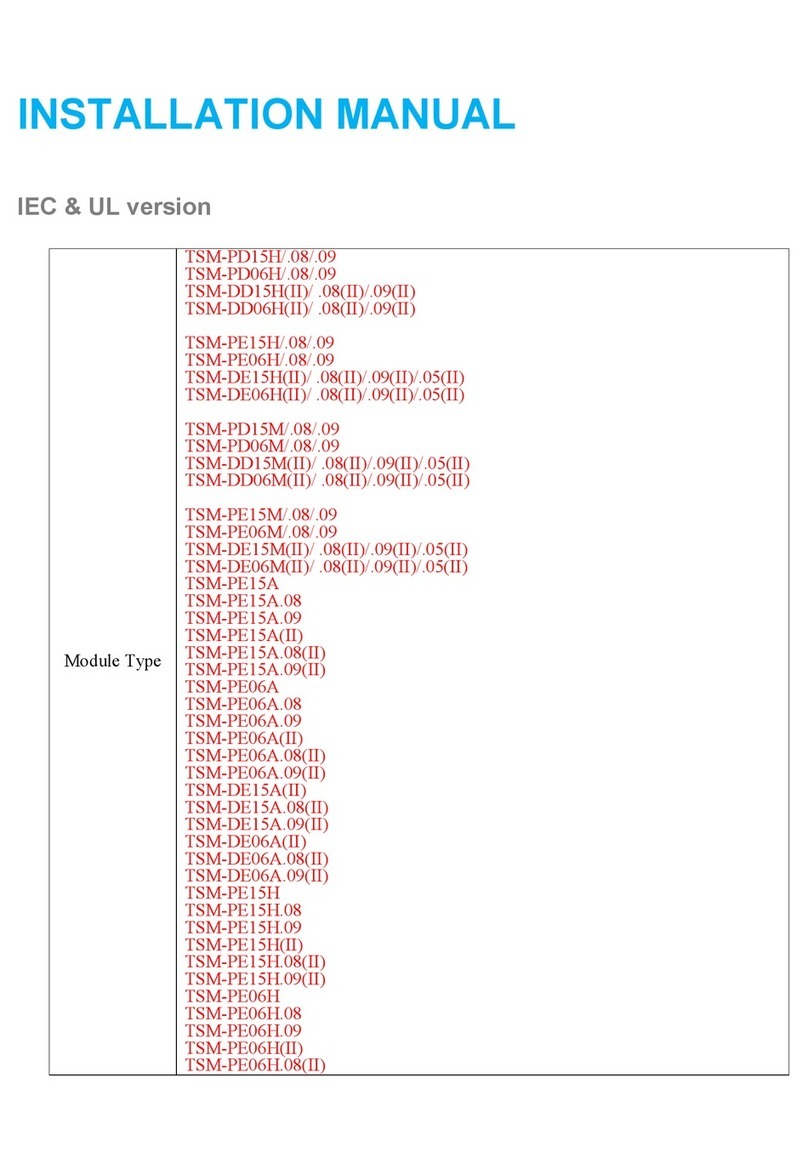

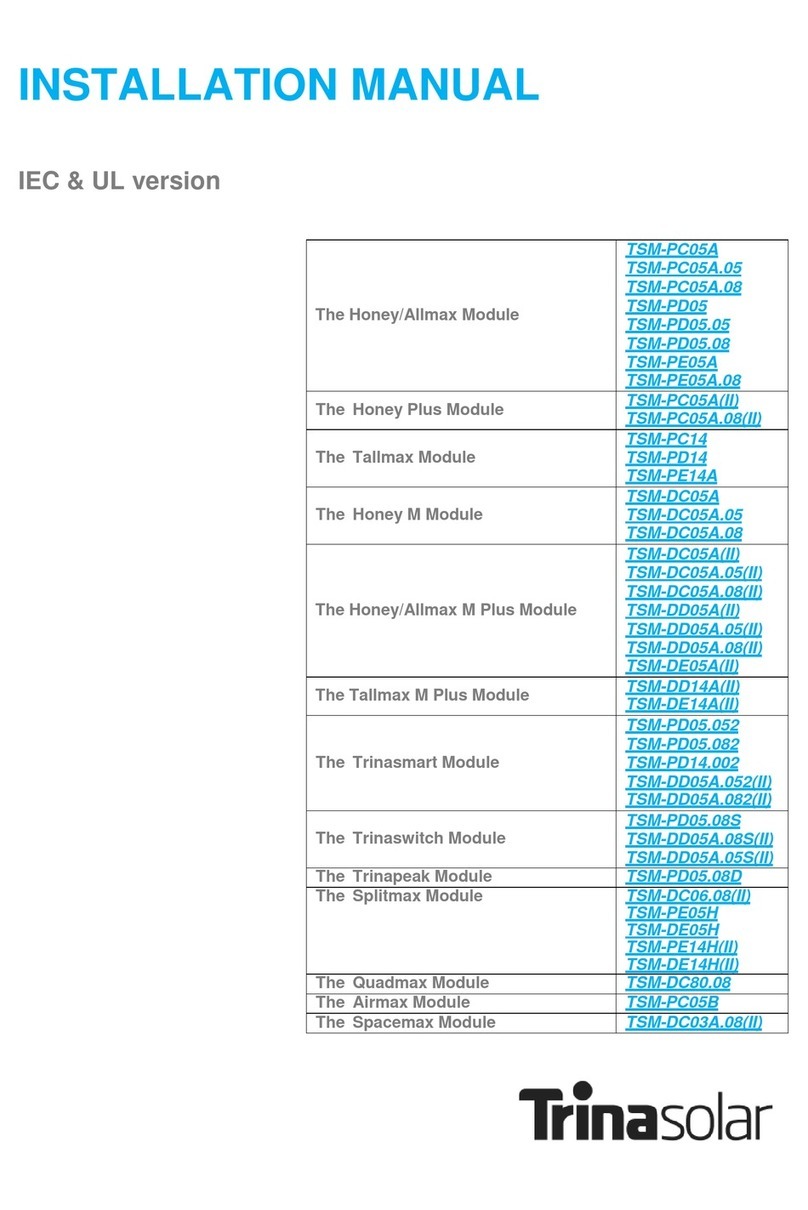

Models:

120cells: PD06H, PE06H, , DD06H(II), DD06H.08(II), DE06H(II),DE06H.08(II), DD06M.05(II),

DD06M.08(II) , DE06M(II), DE06M.08(II)

144cells: PD15H, PE15H, DD15H(II), DE15H(II), DD15M(II), DE15M(II)

USER MANUAL ................................................................................................................ 1

1. INTRODUCTION FOR USER MANUAL...................................................................... 2

1.1 DISCLAIMER ............................................................................................... 2

1.2 LIMITATION OF LIABILITY .......................................................................... 2

2. SAFETY PRECAUTIONS............................................................................................. 2

2.1 WARNING .................................................................................................... 2

2.2 GENERAL SAFETY ..................................................................................... 2

2.3 HANDLING SAFETY .................................................................................... 2

3. UNLOAD/TRANSPORTATION/STORAGE ............................................................... 3

3.1 MARKERS ON OUTER PACKAGING ......................................................... 3

3.2 UNLOADING WARNING ...............................................................................4

3.3 SECONDARY TRANSPORT AND WARNING ........................................ ...5

3.4 STORAGE .................................................................................................... 6

4. UNPACKING INTRODUCTION ................................................................................. 7

4.1 UNPACKING SAFETY ................................................................................. 7

4.2 UNPACKING STEP ..................................................................................... 7

5. SITE SELECTION ...................................................................................................... 8

6. TILT ANGLE ............................................................................................................... 9

7. INSTALLATION ......................................................................................................... 9

7.1 INSTALLATION SAFETY ............................................................................. 9

7.2 INSTALLATION METHOD ......................................................................... 10

7.2.1 MECHANICAL INSTALLATION AND WARNING .........................................10

7.2.2 GROUNDING ............................................................................................. 16

7.2.3 ELECTRICAL INSTALLATION .................................................................. 18

8. INVERTER SELECTION AND COMPATIBILITY .................................................... 20

9. MODULE MAINTENANCE FOR PV MODULE ....................................................... 20

9.1 PANEL VISION INSPECTION AND REPLACEMENT .............................. 20

9.2 CONNECTOR AND CABLE INSPECTION................................................. 21

9.3 CLEANING ................................................................................................. 21

9.3.1 REQUIREMENTS FOR WATER QUALITY .............................................. 22

9.3.2 MODULE INSPECTION AFTER CLEANING ............................................ 22

9.3.3 TROUBLESHOOTING ............................................................................... 22

10. REPORTING TECHNICAL ISSUES or CLAIMS ..................................................... 22

Date: Nov 18th, 2020 Doc No: PS-M-0694 Ver: G Page 2 of 23

1. INTRODUCTION FOR USER MANUAL

This Manual applies to the installation, maintenance and use of the framed series solar modules

manufactured by TrinaSolar Ltd. (hereinafter referred to as Trina Solar). Failure to follow these

safety instructions could result in personal injury or property damage.

Installation and operation of solar modules require specialized skills, and only professional

personnel can engage in the work. Please read the Safety and Installation Instructions carefully

before using and operating the modules. The installer must inform the end customer (or consumer)

of the above matters accordingly.

The term Module or PV Module in this Manual refers to one or more framed series solar modules.

Please keep this Manual for future reference.

1.1 DISCLAIMER

Trina Solar reserves the rights to change this User Manual without prior notice. Failure of the

customer to follow the requirements outlined in this Manual during the installation of the module

will result in the invalidity of product's limited warranty.

1.2 LIMITATION OF LIABILITY

Trina Solar is not responsible for any form of damage, including but not limited to module

operation and system installation error, and personnel injury, hurt, and property loss resulted from

failure to follow the instructions in this Manual.

2. SAFETY PRECAUTIONS

2.1 WARNING

Before installing, wiring, operating, or maintaining Trina modules, you should read and understand

all safety precautions. Direct current (DC) is generated when the battery surface of the module is

exposed to direct sunlight or other light sources, and direct contact with the live parts of the

module, such as terminals, may result in death of personnel whether connected to the module or

not .

2.2 GENERAL SAFETY

All installation work must comply with the local codes and the relevant international electrical

standards.

Trina recommends that PV module installation is conducted by personnel with experience in PV

system installation. Operation by personnel who are not familiar with the relevant safety

procedures will be very dangerous.

DO NOT allow unauthorized persons to access the installation area or module storage area.

DO NOT install modules with damaged glass or damaged backsheet .

DO NOT disassemble or move any part of the module.

DO NOT artificially focus light on the module.

DO NOT connect or disconnect the module when it is energized or connected with an external

power supply

2.3 HANDLING SAFETY

DO NOT stand, walk on or lean on the module directly.

Date: Nov 18th, 2020 Doc No: PS-M-0694 Ver: G Page 3 of 23

DO NOT damage or scratch the front or backside surfaces of the module.

DO NOT scratch the output cable or bend it with force. The insulation of output cable can break

and may result in electricity leakage or shock.

DO NOT use water to extinguish fires of an electrical origin.

DO NOT install or handle modules when they are wet or during periods of high wind. At the

installation site, take care to keep modules and in particular their electrical contacts, clean and dry

before installation. If connector cables are left in damp conditions then the contacts may corrode.

Any module with corroded contacts should not be used.

Please DO NOT loosen or unscrew the PV module bolts. This may lead to a reduction of the

modules load rating and potential damage from a fall.

DO NOT drop PV modules or allow objects to fall down on the PV modules.

DO NOT touch the terminal box or the ends of the output cables (connectors) with bare hands

under sunlight, regardless of whether the PV module is connected to or disconnected from the

system.

Modules should not be shaded by buildings, trees, chimney, etc. at any time of the day.

3. UNLOAD/TRANSPORTATION/STORAGE

Precautions and general safety rules:

•The modules should be stored in the Trina original package before installation. Protect the

package from damage. Unpack the modules as per the recommended unpacking procedures.

The whole process of unpacking, transport and storing should be handled with care;

•DO NOT stand, climb, walk or jump on unpacked pallets of modules;

•Before installation, ensure that all modules and electrical contacts are clean and dry;

•If the modules are required to be stored temporarily, they should be stored under dry and

ventilated conditions;

•Unpacking must be carried out by two or more persons at the same time. It is forbidden to use

the wires or junction boxes of the modules to carry the modules. Handling the modules

requires two or more people with non-slip gloves; DO NOT handle the modules over-head or

stack the modules;

•DO NOT put the modules in a place that is not supported or stable;

•DO NOT allow the modules to come in contact with sharp-pointed objectives to prevent them

from scratches, avoiding a direct impact on the safety of modules.

3.1 MARKERS ON OUTER PACKAGING

3.1.1 DO NOT discard the modules at will; special

recycling is required

3.1.2 Modules must be kept dry, not expose

to rain or moisture

Date: Nov 18th, 2020 Doc No: PS-M-0694 Ver: G Page 4 of 23

3.1.3 Modules in carton are fragile, which must be

handled with care

3.1.4 The packaging must be transported

upright

3.1.5 DO NOT step on the package and module

3.1.6 The carton can be recycled

3.1.7 Modules shall be stacked as required, not

exceeding the maximum number of layers printed

on the outer packaging. ( n = 2 means no more than

two layers and n = 3 means no more than three

layers)

3.1.8 One module shall be handled by at

least two persons together

3.2 UNLOADING WARNING

3.2.1 Use the correct (as picture) lifting fixture to

handle, no more than 2 pallets per lift. Before lifting,

please confirm the tray and the carton are NOT

damaged and the hoisting rope is firm and solid.

Before lowering the carton back on the ground, two

persons must support the two sides of the carton

gently to put it on a relatively flat place.

3.2.2 If the condition permits, use a fork lift

to remove the module pallets from the truck

Put the modules on level ground.

Date: Nov 18th, 2020 Doc No: PS-M-0694 Ver: G Page 5 of 23

3.2.3 Store the module in a dry and ventilated place

3.2.4 DO NOT stack the modules at the

project site.

3.2.5 Cover the module with waterproof material to prevent it from moisture

3.3 SECONDARY TRANSPORT AND WARNING

3.3.1 DO NOT remove the original

packaging if the modules require long-

distance transport or long-term storage.

3.3.2 The finished package can be transported by land,

sea or air. During transport, make sure that the package

is fixed with packing straps securely to the shipping

platform without movement.

3.3.3 Transport: DO NOT Stack more than

two layers on truck;

3.3.4 Only one layer stacking is only allowed for small

truck. Make sure that the package is fixed with packing

straps securely to the shipping platform without

movement.

Date: Nov 18th, 2020 Doc No: PS-M-0694 Ver: G Page 6 of 23

3.3.5 Only one layer stacking is only allowed

for transport at the project site

3.3.6 No transport or handling by pedi-cab as shown

below;

3.3.7 DO NOT transport the module with

rope as shown below:

3.3.8 DO NOT carry the modules on the back of

one person as shown below:

3.4 STORAGE

DO NOT expose the modules to rain or moisture. Store the finished product in a well ventilated,

waterproof and dry place.

DO NOT remove the original packaging if the module requires long-distance transport or long-term

storage.

3.4.1 Storage in project site warehouse (moisture85%, temperature range from -20℃to + 50℃):

120-cell frame module and 144-cell frame module to be stacked separately in two groups

3.4.2 Normal warehouse storage (moisture85% and temperature range from -20℃to + 50℃):

stacking no more than two layers.

Date: Nov 18th, 2020 Doc No: PS-M-0694 Ver: G Page 7 of 23

4. UNPACKING INTRODUCTION

4.1 UNPACKING SAFETY

For unpacking outdoors, it is prohibited to operate in rainy conditions. Because the carton will

become soft and damaged after it gets wet in the rain. The stacked PV modules (hereinafter

referred to as "modules") may tip over, which may cause damage or injury to personnel.

For a windy site, it is necessary to pay special attention to safety. Especially, it is NOT

recommended to transport the modules in high wind conditions. The unpacked modules must be

tied down to avoid any unwanted movement.

The work surface is required to be level to ensure that the package can be placed stably, avoiding

sliding.

Wear protective gloves during unpacking to avoid hand injury and fingerprints on the glass surface.

Module information and unpacking instructions can be found on the outside of each package.

Please read the instructions before unpacking.

Each module shall be handled by two persons. It is forbidden to use the wires or junction

boxes of the modules to carry the module. DO NOT take the module out of the carton by

pulling on the long side frame.

4.2 UNPACKING STEP

4.2.1 Before unpacking, please check the

product name, serial number and related

suggestions on the A4 paper. Please read the

unpacking instructions carefully. NO other

customized unpacking method is allowed.

4.2.2 Cut the two packing belts at shorter sides

of the tray with blade or scissors, and unpack

the side surface of the carton along the vertical

direction.

4.2.3 Cut the tape at shorter edge and hold it

up by 90°from the bottom; and pull out the

cardboard to expose the modules.

4.2.4 Cut the two horizontal packing belts in the

carton and cut the two packing belts near the

bottom of the tray, and remove the packing

belts

Unpacking

instructions

A4 paper (product

name, serial

number, related

suggestions, etc.)

Date: Nov 18th, 2020 Doc No: PS-M-0694 Ver: G Page 8 of 23

4.2.5 When unpacking on a level surface, take

out the module from one side of package to the

other, and then carry it with two persons

(Please refer to 3.1.8)

When unpacking on a sloping surface, please

protect the modules from tipping over or sliding.

As shown below

4.2.6 DO NOT lean the module on the

mounting posts;

4.2.7 If all the modules are NOT removed after unpacking and some of them are left in the

package, the remaining modules shall be laid flat and repackaged to prevent from falling down.

Must be placed by horizontal.

The stacked number of modules: 120-cell frame modules to be stacked NOT more than 20

pieces, 144-cell frame modules NOT more than 16 pieces;

5. SITE SELECTION

Solar modules are recommended to be installed at an optimized tilt angle to maximize the energy

output. It is roughly equal to the latitude of the project site as a rule of thumb, facing toward the

equator. Optimized system designs incorporate other local requirements.

When installing solar modules on a roof, the roof must be covered with a layer of fireproof material

applicable to this class, and adequate ventilation must be ensured between the back sheet and the

installation surface. A safe working area also must be left between the edge of the roof and the

external edge of the solar array

In the case of residential installations on the ground, modules shall be installed following local

regulations, e.g. using fence.

Position the modules to minimize the chances of shading at any time of the day.

Trina Solar recommends that the module should be installed at a working ambient temperature of -

20℃~50℃. The module's limit working ambient temperature range is from -40℃to 85℃. Maximum

altitude less than or equal to 2000m .The maximum mechanical load is 5400 on the front and 2400

on the back.

Try to install modules in a location where there is rare shading throughout the year

If you are planning to use the PV modules where the water damage (Humidity: 85RH%) may be

possible, please consult with Trina local technical support first to determine an appropriate

installation method , or to determine whether the installation is possible.

Date: Nov 18th, 2020 Doc No: PS-M-0694 Ver: G Page 9 of 23

If the module is installed in an area with frequent lightning and thunder, the module must be

protected against lightning strikes. Refer to Trina Solars declaration document for lightning

protection. Please contact with localtechnical support or contact us from

http://www.trinasolar.com/ .

Make sure flammable gases are NOT generated near the installation site.

According to IEC 61701, salt mist corrosion testing of photovoltaic (PV), The module must not

be soaked in the water or in the environment (i.e., fountain, spindrift, etc.) where the module would

touch water (pure water or brine) for a long term. If the modules are placed in an environment of

salt fog (i.e., marine environment) or sulfur (i.e., sulfur sources, volcanoes, etc.), there is a risk

of corrosion. PV Modules certified to IEC 61701 available upon request.

In locations that are 50m ~ 500mm from the ocean, stainless steel or aluminum materials must be

used to contact the PV modules, and the installation position must be processed with anti-corrosion

treatment; refer to the Trina Solar Coastal Application White Paperfor detailed installation

requirements .Please contact with local technical support or contact us from

http://www.trinasolar.com/ .

6. TILT ANGLE

The tilt angle measurement of the PV module refers to measuring the angle between the module

and the horizontal ground surface. For different projects there are different mounting angles. Trina

Solar recommends that the mounting tilt angle should be NOT less than 10, or in accordance with

local regulations or follow the recommendations of experienced PV module installers.

The tilt angle of the PV module is measured between the PV module and a horizontal ground

surface.

In the Northern Hemisphere, the PV modules should typically face south, and in the Southern

Hemisphere, the PV modules should typically face north.

A clearance of at least 115mm (4.5in) (recommended) is provided between modules frame and the

surface of the wall or roof. If other mounting means are employed this may affect the UL Listing or

the fire class ratings.

7. INSTALLATION

7.1 INSTALLATION SAFETY

Trina Solar Modules can be mounted in landscape or portrait orientation (the distance between the

racking and the long side is 150-250mm), and however the impact of dirt shading the solar cells

can be minimized by orienting the product in landscape. Please pay attention that 72-cell/144-cell

framed modules can only be installed in the long side frame on vertical racking not horizontal

racking when customers choose landscape mode, and they cannot be installed in the short frame

side. 60-cell/120-cell framed modules can be installed in both long side frame and short side frame,

but 60-cell/120-cell framed modules cannot installed in the long frame shared with the same

horizontal racking when customers choose landscape mode. Details as shown picture below.

Date: Nov 18th, 2020 Doc No: PS-M-0694 Ver: G Page 10 of 23

Always wear dry insulation protection equipment: insulated tools, head gear, insulated gloves,

safety belt and safety shoes (with rubber soles).

DO NOT wear metallic jewelry which can cause electric shock during installation.

DO NOT install modules under rain, snow or windy conditions.

Please keep the connector dry and clean during installation to avoid the risk of electric shock. It is

recommended to install it immediately after unpacking.

Due to the risk of electrical shock, DO NOT perform any work if the terminals of PV module are wet.

Please install immediately after you unpacking.

The application level of Trina Solar module is Class C, which can be used in systems operating at

greater than 50 V DC or 240 W, where general public contact access is anticipated;

Keep the PV module packed in the Trina carton until installation.

Please use an opaque material to completely cover the PV module surface during PV module

installation and wiring.

DO NOT unplug the connector if the system circuit is connected to a load.

DO NOT stand on the module glass while installing. There is a risk of injury or electric shock if

glass is broken.

DO NOT work alone (always work as a team of 2 or more people).

DO NOT damage the back sheet of PV modules when fastening the PV modules to a support with

bolts.

DO NOT damage the surrounding PV modules or mounting structure when replacing a PV

moduleThe cable length of junction box shall be selected according to the installation mode. When

wiring, the ties for fixing the cables coils shall be removed. The cable shall be fixed on the

installation system (frame or bracket, guide rail) with UV resistant cable ties or wire cards to avoid

direct sunlight or immersion in water and mechanical damage of the cable, otherwise it may cause

accelerated aging of the cable or even leakage and fire. Modules with different color codes are not

recommended to be installed in one block or the same rooftop.

7.2 INSTALLATION METHOD

7.2.1 MECHANICAL INSTALLATION AND WARNING

The connection of the module to the racking system can be created through the mounting

Date: Nov 18th, 2020 Doc No: PS-M-0694 Ver: G Page 11 of 23

holes, with clamps, or an embedded system on the frame. The modules must be installed

according to the following examples and recommendations. If a different installation method is

desired, please contact Trina Solar customer service or technical support team for consultation.

Improperly mounted modules maybe damaged. If alternative mounting method is used and not

approved by Trina, the modules will not continue to have a valid warranty.

The minimum distance between two modules is 10mm (0.4in).

Panels must not be subjected to wind or snow loads exceeding the maximum permissible

loads, and must not be subjected to excessive forces due to the thermal expansion of the

support structures.

The module frame drain holes cannot be blocked in any situation during installation or use.

*Notes :

The design loading of modules have been evaluated by TUV according to IEC61215 with 1.5

times safety factor;The mechanical load bearing is dependent upon the mounting methods

used and failure to follow the instructions of this manual may result in different capabilities to

withstand snow and wind loads;The system installer must ensure that the installation methods

used meet these requirements and any local codes and regulations.

The modules depicted are mounted on continuous rails that extend beneath the modules. If

modules are mounted without continuous rails below them, the maximum allowable loading will

be reduced and is subject to review by Trina.

A. Mounting with Bolts(4-φ9*14mm mounting holes)

Modules can be attached using the mounting holes on the back of the module frame, by fixing

the module to the support rails with bolts. The mounting details are shown in the following

figures.

The frame of each module has 4-φ9*14mm mounting holes, ideally placed to optimize the load

handling capability, to secure the modules to supporting structure.

To maximize mounting longevity, Trina Solar strongly recommends the use of corrosion proof

(stainless steel) fixings

Secure the module in each fixing location with an M8 bolt and a flat washer, spring washer and nut

as shown in Figure 1 and tighten to a torque of 16~20 N.m(140-180lbf.in.).

All parts in contact with the frame should use flat stainless steel washers of minimum 1.5mm

thickness with an outer diameter of 20-24mm(0.79-0.94in).

Fig.1 Backsheet-Glass module

1) Aluminum Frame 2) M8 Stainless Bolt

3) Flat Stainless Washer 4) Spring Stainless Washer

5) HEX Stainless Nut

Date: Nov 18th, 2020 Doc No: PS-M-0694 Ver: G Page 12 of 23

Module

Mechanical Load

Pressure

Safety

factor

Mounting Direction

(The crossbeam is perpendicular to the long

side frame.)

60/120 pcs

Backsheet-Glass

+3600 Pa /-1600Pa

1.5

72/144 pcs

Backsheet-Glass

+3600 Pa /-1600Pa

1.5

*NOTE: The above-described distance is from the middle of the bolts to the middle of the bolts

*NOTE: Need two support rails below the PV module to make sure the Mechanical load.

B. Mounting with Clamps

Trina Solar has tested its modules with a number of clamps from different manufacturers, fixing

bolt of at least M8. The length of clamp ≥40mm(1.57in),thickness≥3mm(0.12in). The clamp must

overlap the module frame by at least 7mm (0.28in) but no more than 10mm (0.39in).

Use at minimum 4 clamps to fix modules on the mounting rails.

Modules clamps should not come into contact with the front glass and must not deform the frame.

Be sure to avoid shadowing effects from the module clamps.

The module frame is not to be modified under any circumstances.

When choosing this type of clamp-mounting method, use at least four clamps on each module, two

clamps should be attached on each long sides of the module (for portrait orientation). Depending

on local wind and snow loads, additional clamps may be required to ensure that modules can bear

the load.

Applied torque should refer to mechanical design standard according to the bolt customer is using,

ex:

M8 ---- 16-20N.m(140-180lbf.in)

End Clamp installation

Middle Clamp installation

Date: Nov 18th, 2020 Doc No: PS-M-0694 Ver: G Page 13 of 23

Module

Mechanical Load

Pressure

Safety Factor

Mounting Direction

60/120 pcs

Backsheet-

Glass

+3600 Pa /-1600Pa

1.5

The crossbeam is perpendicular to the long

side frame.

60/120 pcs

Backsheet-

Glass

+1600Pa /-1600 Pa

1.5

The crossbeam is perpendicular to the short

side frame.

72/144 pcs

Backsheet-

Glass

+3600 Pa /-1600 Pa

1.5

The crossbeam is perpendicular to the long

side frame.

*NOTE: The above-described distance is from the module edge to the middle of the clamp.

*NOTE: Need two support rails below the PV module to make sure the Mechanical load.

*Notes:

Other mounting configurations can be used. However, failure to comply with the above

recommendations will result in a lowering of the load handling capabilities below the product

specification positive design loading of below 3600Pa, and negative design loading 1600Pa, with 1.5

Date: Nov 18th, 2020 Doc No: PS-M-0694 Ver: G Page 14 of 23

times safety factor, and product failure as a result of an overload situation will not be covered by the

Trina Solar warranty.

C. Mounting with Single-axis Tracking System(4-φ7*10mm mounting holes)

Modules can be attached using the mounting holes on the back of the module frame, by fixing

the module to the support rails with bolts. The mounting details are shown in the following

figures.

It is a Single-axis Tracking System, the module is fixed on the axis by bolting long frame.

The frame of each module has 4-φ7*10mm(0.28*0.39in) mounting holes with specific location

shown in Figure 2.

Secure the module in each fixing location with an M6 bolt, two flat washers, a spring washer

and nut as shown in Figure 2.

If a different bolt similar to M6 is used, they need to be tightened to a torque of

16N.m.(140lbf.in).

All parts in contact with the frame should use flat stainless steel washers of minimum 1.5mm

thickness with an outer diameter of 16-20mm (0.63-0.79in.).

The bolt should be made of stainless steel or the other anti-corrosion material.

Mechanical Load Pressure under this method: 30 lbs.ft2 max from the front side & 30 lbs.ft2

max from the rear according to UL1703 , 1600Pa max from the front side & 1600Pa max from

the rear , with 1.5 safety factors, according to UL61730.

Fig 2. Backsheet-Glass module with Single-axis Tracing System

1) M6 hex bolt 2) flat stainless washer

3) spring stainless washer 4) hex stainless nut

Date: Nov 18th, 2020 Doc No: PS-M-0694 Ver: G Page 15 of 23

Module

Mechanical Load

Pressure

Safety

factor

Mounting Direction

72/144 pcs

Backsheet-

Glass

+1600 Pa /-1600 Pa

1.5

*NOTE: The above-described distance is from the middle of the bolts to the middle of the bolts

D. 2V Installation Method

The single module is installed with two φ7*10mm mounting holes and two φ9*14mm mounting

holes, as shown in figure 3. The overall installation method is shown in the table below.

Figure 3 Mounting holes schematic of the single module for the 2V installation method

Module

Mechanical

Load Pressure

Safety

factor

Mounting Direction

72/144 pcs

Backsheet-

Glass

+1200 Pa /-1200

Pa(Special

Requirement,

Need confirm

with Trinasolar)

1.5

*NOTE: Installation hole marked 850 mm pitch is the installation hole of this installation mode.

*NOTE: The above-described distance is from the middle of the bolts to the middle of the bolts

Date: Nov 18th, 2020 Doc No: PS-M-0694 Ver: G Page 16 of 23

7.2.2 GROUNDING

All module frames and mounting racks must be properly grounded in accordance with

appropriate respective National Electrical Code.

Proper grounding is achieved by bonding the module frame(s) and all metallic structural

members together continuously using a suitable grounding conductor. The grounding

conductor or strap may be copper, copper alloy, or any other material acceptable for use as

an electrical conductor per respective National Electrical Codes. The grounding conductor

must then make a connection to earth using a suitable earth ground electrode.

Trina Solar modules can be installed with the use of third party listed grounding devices for

grounding the metallic frames of PV modules. The devices have to be installed in accordance

with the grounding device manufacturer’s specified instructions.

Please refer to the “Product Catalogue” link for detailed grounding hole location and size at

http://www.trinasolar.com/

Grounding hardware comes in a package that includes the grounding screw, flat washer、star

washer and wire

Electrical contact is made by penetrating the anodized coating of the aluminum frame, and

tightening the mounting screw (come with the star washer) to the proper torque of 25lbf.in.

Grounding wire size (6 to 12 AWG solid bare copper) should be selected and installed

underneath the wire binding bolt.

Grounding screw GB845-85-ST4.2*13-F-

H+

#5 star washer

5#flat washer

5# ground wire

Star washer, flat washer, grounding wire are

placed in turn, then screwed into the grounding

hole to bond the adjacent modules

UL61730 Only can use the single grounding method.

We also recommend using the following methods to ground installation properly under UL

investigation

Method 1: Tyco grounding bolt # 2058729-1:

Date: Nov 18th, 2020 Doc No: PS-M-0694 Ver: G Page 17 of 23

Figure 4. Tyco grounding bolt # 2058729-1

1) Wire bolt and slot 2) Mounting wash hex nut

3) Aluminum frame 4) 0.006 to 0.025 in2cable

5) Hex Nut

Tyco grounding hardware comes in a package that includes the grounding bolt, mounting and

grounding hex nut.

Electrical contact is made by penetrating the anodized coating of the aluminum frame, and

tightening the mounting hex nut (come with the star washer) to the proper torque of 25lbf.in.

Grounding wire size (6 to 12 AWG solid bare copper) should be selected and installed

underneath the wire binding bolt.

The wire binding bolt should be tightened to the proper torque of 45lbf.in.

Method 2: Tyco grounding bolt #1954381-2:

Figure 5. Tyco grounding bolt # 1954381-2 (NOT applicable for TRINAMOUNT module

series)

1) Wire slot (available for 0.006 to 0.025in2cable)

2) Slider 3)Bolt 4)Base 5)Nut

Tyco grounding hardware comes in a package that includes the grounding bolt, mounting and

grounding hex nut.

Electrical contact is made by penetrating the anodized coating of the aluminum frame, and

tightening the mounting hex nut (come with the star washer) to the proper torque of 25lbf.in.

Date: Nov 18th, 2020 Doc No: PS-M-0694 Ver: G Page 18 of 23

Grounding wire size (6 to 12 AWG solid bare copper) should be selected and installed

underneath the wire binding bolt.

The wire binding bolt should be tightened to the proper torque of 45lbf.in.

The Tyco grounding bolt is only listed for use with 6 to 12 AWG bare solid copper wire.

Method 3: ERICO grounding bolt # EL6CS14-6

Figure 6. ERICO grounding bolt # EL6CS14-6 (NOT applicable for the TRINAMOUNT

module series)

1) Machine Bolt A 2) Machine Bolt B 3) Belleville washer

4) Flat Washer 5) Clearance hole for #10[M5] machine bolt

6) Aluminum frame 7) Machine box hex nut with lock washer

8) Grounding bolt

The lug should be installed on a surface that is larger than the bottom surface of the lug.

The lug should be installed in the grounding holes provided on the PV module.

Machine bolt A should be torqued to 35lbf.in, to secure the grounding bolt to module frame.

The grounding bolt is only listed for use with 6-12 AWG bare solid copper wire.

For proper wire binding, machine bolt B should be torqued to 35lbf.in.

7.2.3 ELECTRICAL INSTALLATION

All wiring should be performed, by qualified installers, in accordance with the local codes and

regulations.

Modules can be connected in series to increase the operating voltage by plugging the positive

plug of one module into the negative socket of the next. Before connecting modules always

ensure that the contacts are corrosion free, clean and dry.

Product can be irreparably damaged if an array string is connected in reverse polarity to

another. Always verify the voltage and polarity of each individual string before making a

parallel connection. If you measure a reversed polarity or a difference of more than 10V

between strings then check the string configuration before making the connection.

Trina Solar modules are provided with stranded copper cables with a cross sectional area of

4mm(0.006in) which are rated for 1500V DC, 90℃and are UV resistant. All other cables

used to connect the DC system should have a similar (or better) specification. Trina Solar

recommends that all cables are run in appropriate conduits and sited away from areas prone

to water collection.

Recommended maximum series/parallel module configurations; ([1000 V/(1.25*Voc)]/[fuse

rating/Isc+1]

Recommended maximum series/parallel module configurations; ([1000 V/(1.25*Voc)]/[fuse

rating/Isc+1]

Date: Nov 18th, 2020 Doc No: PS-M-0694 Ver: G Page 19 of 23

The maximum voltage of the system must be less than the maximum certified voltage 1500V

typically and the maximum input voltage of the inverter and of the other electrical devices

installed in the system. To ensure that this is the case, the open circuit voltage of the array

string needs to be calculated at the lowest expected ambient temperature for the location.

This can be done using the following formula.

Max System voltage N * Voc * [1 + TCvoc x (Tmin-25)]

N* Voc * [1 + TCvocTmin-25]

Where

N Number of modules in series

Voc Open circuit voltage of each module (refer to product label or data sheet)

TCvoc Thermal coefficient of open circuit voltage for the module (refer to data sheet)

Tmin The lowest expected ambient temperature

When the modules connect in parallel, the output current will be equal to the sum of each

branch current. We suggest that every series SPV module string should be fused prior to be

connected with other strings. Please refer to the applicable regional and local codes for

additional fuse requirements.

Each module has two standards 90℃sunlight resistant output cables each terminated with

plug & play connectors. The wire type and gauge of the output cables are 1500V rated PV

Wire cables and are 12AWG in size. This cable is suitable for applications where wiring is

exposed to the direct sunlight. We require that all wiring and electrical connections comply

with the appropriate National Electrical Code.

The minimum and maximum outer diameters of the cable are 5 to 7mm (0. 038 to 0.076 in2).

For field connections, use at least 4mm2copper wires insulated for a minimum of 90℃and

sunlight resistance with insulation designated as PV Wire.

The minimum bending radius cables should be 43mm (1.69in).

7.2.3.1 WIRING

To ensure proper system operation the correct cable connection polarity (Figures 1 & 2)

should be observed when connecting the modules to each other or to a load, such as inverter,

a battery etc. If modules were not connected correctly, the bypass diode could be destroyed.

PV modules can be wired in series to increase voltage. A series connection is made when the

wire from the positive terminal of one module is connected to the negative terminal of the next

module. Figure 1 shows modules connected in series. PV modules can be connected in

parallel to increase current (Figure 2). A parallel connection is made when the wire from the

positive terminal of one module is connected to the positive terminal on the next module.

The number of modules in series and in parallel shall be designed reasonably according to

the system configuration.

All instructions above have to be obeyed to maintain Trina Solars limited warranty

Connecting in series

Figure 1

Connecting in parallel after connected in

series

Figure 2

Date: Nov 18th, 2020 Doc No: PS-M-0694 Ver: G Page 20 of 23

7.2.3.2 FUSING

When fuses are fitted they should be rated for the maximum DC voltage and connected in

each, non-grounded pole of the array (i.e. if the system is not grounded then fuses should be

connected in both the positive and negative poles).

The maximum rating of a fuse connected in series with an array string is typically 20A but the

actual module specific rating can be found on the product label and in the product datasheet.

This fuse rating value also corresponds to the maximum reverse current that a module can

withstand (when one string is shaded then the other parallel strings of modules will be loaded

by the shaded string and current will flow) and therefore impacts the number of strings in

parallel.

If a different method is desired, please contact Trina Solar customer service or technical

support team for consultation. Improperly method may damage modules. If alternative method

is used and not approved by Trina, the modules will not continue to have a valid warranty.

8. INVERTER SELECTION AND COMPATIBILITY

Choose inverters with isolation transformers in hot and wet areas (such as shores, wetlands),

to ensure proper module function under positive voltage.

9. MODULE MAINTENANCE FOR PV MODULE

9.1 PANEL VISUAL INSPECTION AND REPLACEMENT

The modules in a PV array should be regularly checked for damage. Factors such as glass

breakage, cable breakage, and junction box damage may lead to function and safety

problems. In the case of a damaged module, replace it with the same type of module. Refer to

the appropriate Product Installation Manual for installation and dis-assembly of module.

It is recommended to perform a preventive inspection every six months without changing the

components of the module. If electrical or mechanical appliances are used for inspection or

maintenance, they should be operated by qualified professionals to avoid any electric shock

or loss of life

Trim any vegetation which may shade the solar array, thus impacting performance.

Check that mounting hardware is properly tightened.

Check that all string fuses in each non/earthed pole are operating.

Replacement modules must be of same type. DO NOT touch live parts of cables and

connectors. Use appropriate safety equipment (insulated tools, insulating gloves, etc.) when

handling modules.

Cover the front surface of modules by an opaque material when repairing. Modules when

exposed to sunlight generate high voltage and are dangerous.

Trina Solar PV modules are equipped with bypass diodes in the junction box. This minimizes

module heating and current losses.

oDO NOT open the junction box to change the diodes even if they malfunction.

oIn a system using a battery, blocking diodes are typically placed between the battery and

the PV module output to prevent battery discharge at night.

In the event that a module is damaged (broken glass or a scratch on back sheet) and needs to

be replaced

oObserve the safety precautions listed earlier in this Manual

oWear cut resistant gloves and other personal protective equipment required for the

particular installation.

This manual suits for next models

27

Table of contents

Other Trina Solar Control Unit manuals