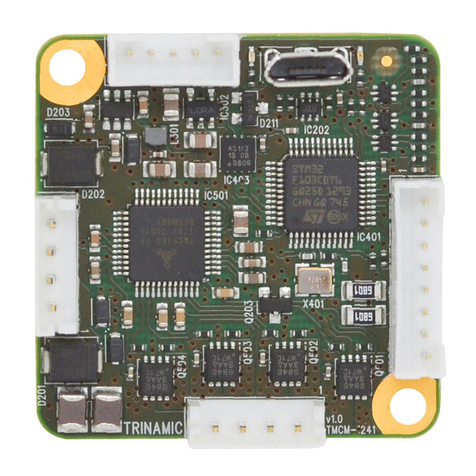

TMCM-101 Manual V1.08 2

Copyright © 2006-2008, TRINAMIC Motion Control GmbH & Co. KG

Contents

1Features........................................................................................................................................................................................3

2Life support policy ....................................................................................................................................................................4

3Technical Data ............................................................................................................................................................................5

4Electrical and Mechanical Interfacing ..................................................................................................................................5

4.1 Dimensions.........................................................................................................................................................................5

4.2 Pin Assignments ...............................................................................................................................................................6

5Operational Ratings ..................................................................................................................................................................7

6Functional Description .............................................................................................................................................................7

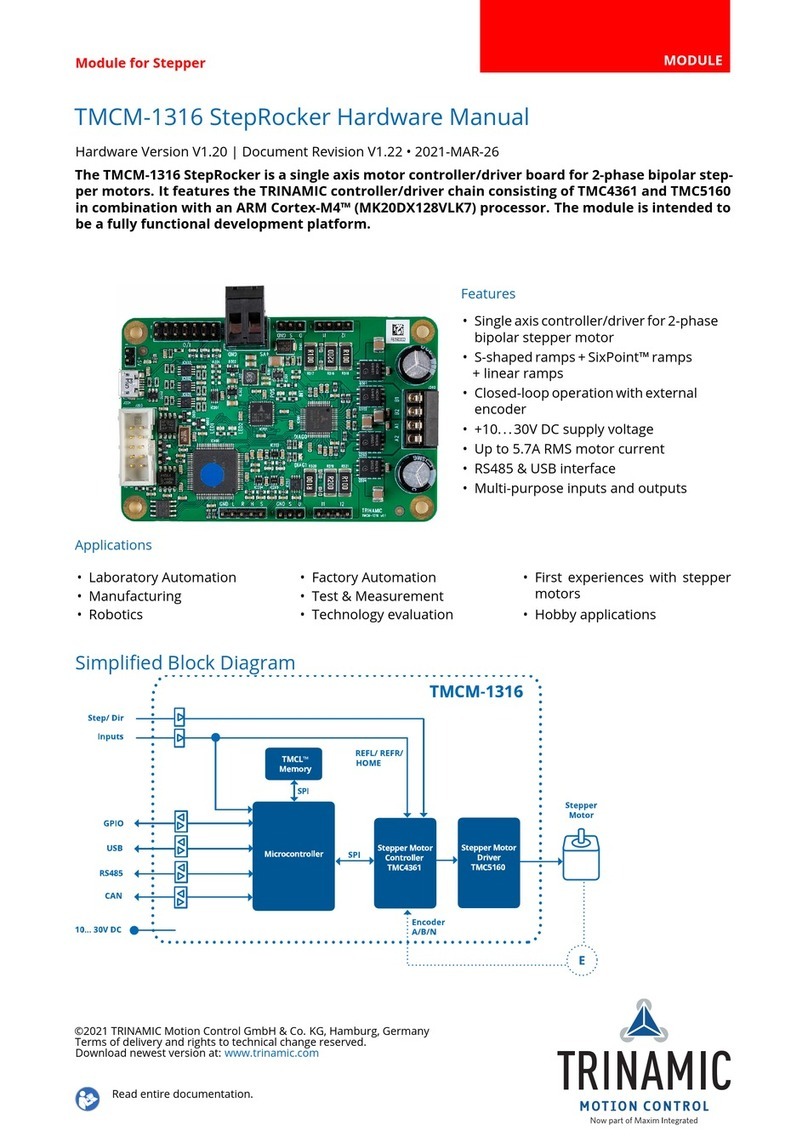

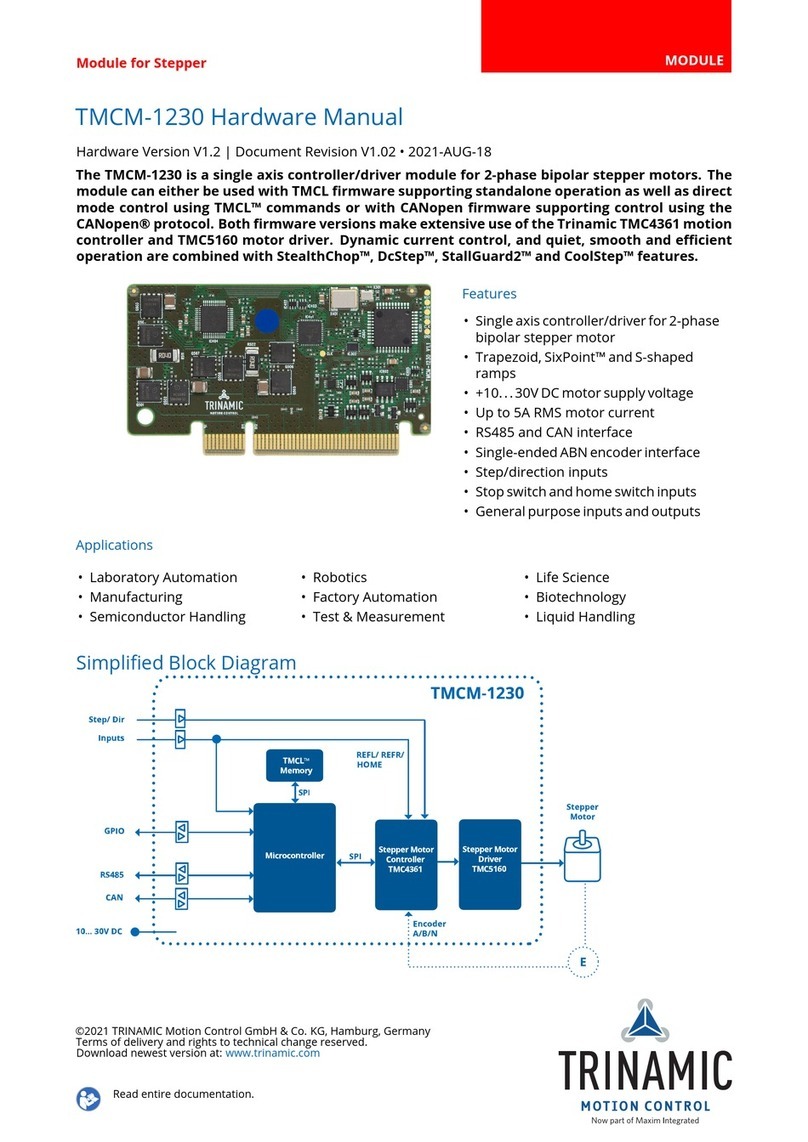

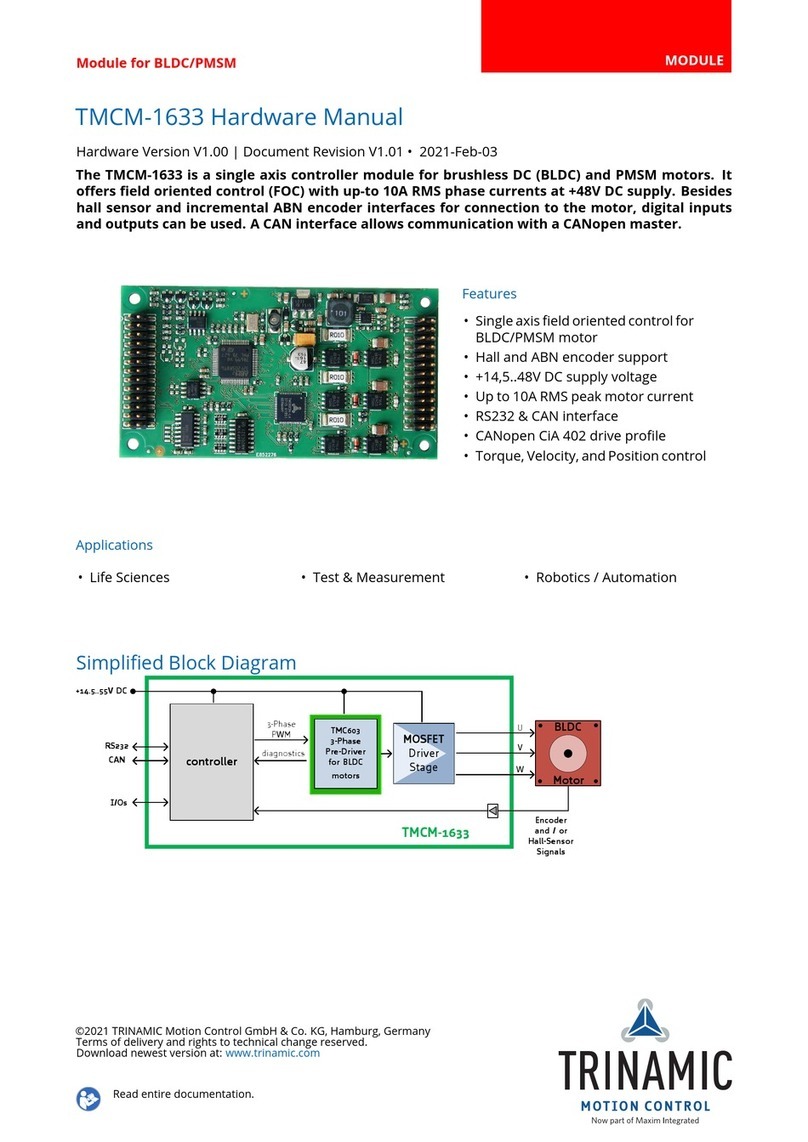

6.1 System Architecture .........................................................................................................................................................8

6.1.1 Microcontroller ............................................................................................................................................................8

6.1.2 TMCL EEPROM...............................................................................................................................................................8

6.1.3 TMC428 Motion Controller........................................................................................................................................8

6.1.4 Stepper Motor Drivers ...............................................................................................................................................8

6.1.5 Incremental encoder interface................................................................................................................................8

6.2 Power supply requirements ..........................................................................................................................................9

6.3 Motor Connection .......................................................................................................................................................... 10

6.4 Encoder interface ........................................................................................................................................................... 11

6.5 Host Communication .................................................................................................................................................... 12

6.5.1 CAN 2.0b..................................................................................................................................................................... 12

6.5.2 RS-232 and RS-422................................................................................................................................................... 12

6.5.3 RS-485.......................................................................................................................................................................... 12

6.6 StallGuard™ - Sensorless Motor Stall Detection .................................................................................................. 13

6.6.1 StallGuard adjusting tool ...................................................................................................................................... 13

6.6.2 StallGuard profiler ................................................................................................................................................... 14

6.7 Reference switches........................................................................................................................................................ 15

6.7.1 Left and right limit switches................................................................................................................................ 15

6.7.2 Triple Switch Configuration.................................................................................................................................. 15

6.7.3 One Limit Switch for circular systems .............................................................................................................. 16

6.8 Port Expansion................................................................................................................................................................ 16

6.9 Miscellaneous Connections......................................................................................................................................... 17

6.10 Resetting the module................................................................................................................................................... 17

6.11 Firmware update............................................................................................................................................................ 17

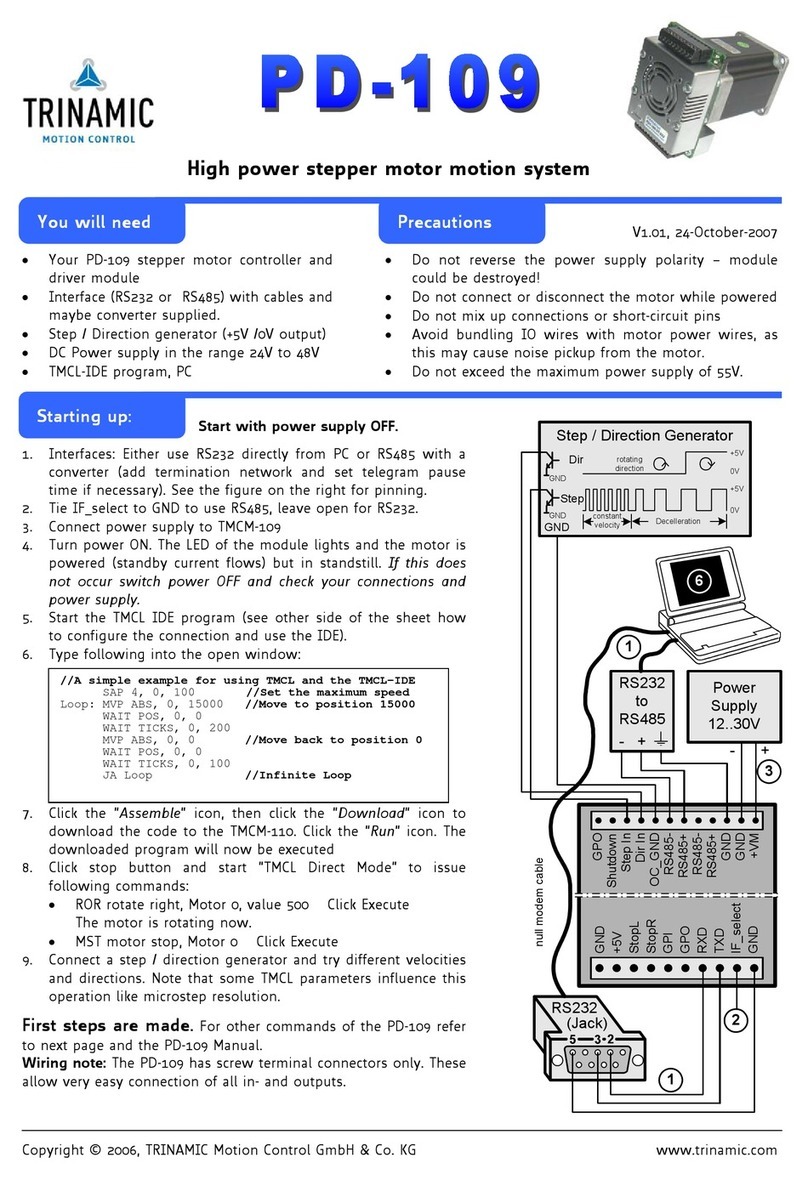

7Putting the TMCM-101 into operation .............................................................................................................................. 18

8Calculating Velocity and Acceleration .............................................................................................................................. 19

9Software.................................................................................................................................................................................... 20

10 Revision History ...................................................................................................................................................................... 21

10.1 Documentation Revision ............................................................................................................................................. 21

10.2 Firmware Revision......................................................................................................................................................... 21

11 References ................................................................................................................................................................................ 21