Trinamic PD 108-28-SE-485 Series User manual

PDx-108-28-SE-485 Hardware Manual (V1.00 / 2010-May-31) 2

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

Contents

1Life support policy ............................................................................................................................ 3

2Features ............................................................................................................................................ 4

3Order codes....................................................................................................................................... 5

4Electrical and mechanical interfacing ................................................................................................ 6

4.1 Size of board.............................................................................................................................. 6

4.2 Size of unit ................................................................................................................................ 7

4.3 Torque curves ............................................................................................................................ 8

4.3.1 PD1-108-28-SE-485 ................................................................................................................. 8

4.4 Connectors ................................................................................................................................. 9

4.4.1 Power and I/O connector...................................................................................................... 9

4.4.2 Motor connector ................................................................................................................... 9

4.5 Power supply ........................................................................................................................... 10

4.6 Inputs and outputs .................................................................................................................. 11

4.6.1 RS485 .................................................................................................................................. 11

4.6.2 General purpose inputs ...................................................................................................... 13

4.6.3 General purpose outputs .................................................................................................... 13

5Functional description..................................................................................................................... 14

6Operational ratings ......................................................................................................................... 15

7Revision History .............................................................................................................................. 16

7.1 Hardware revision.................................................................................................................... 16

7.2 Document revision................................................................................................................... 16

8References....................................................................................................................................... 17

PDx-108-28-SE-485 Hardware Manual (V1.00 / 2010-May-31) 3

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

1Life support policy

TRINAMIC Motion Control GmbH & Co. KG does not authorize

or warrant any of its products for use in life support systems,

without the specific written consent of TRINAMIC Motion

Control GmbH & Co. KG.

Life support systems are equipment intended to support or

sustain life, and whose failure to perform, when properly

used in accordance with instructions provided, can be

reasonably expected to result in personal injury or death.

© TRINAMIC Motion Control GmbH & Co. KG 2010

Information given in this data sheet is believed to be accurate

and reliable. However neither responsibility is assumed for

the consequences of its use nor for any infringement of

patents or other rights of third parties, which may result from

its use.

Specifications are subject to change without notice.

PDx-108-28-SE-485 Hardware Manual (V1.00 / 2010-May-31) 4

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

2Features

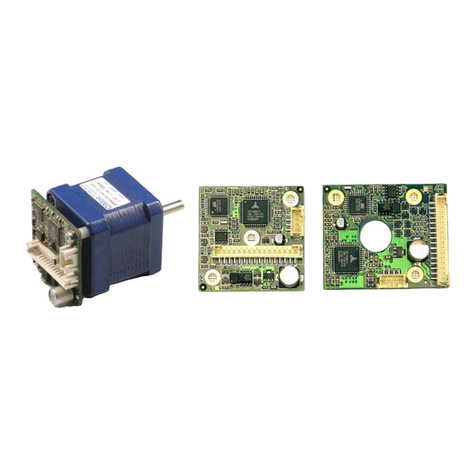

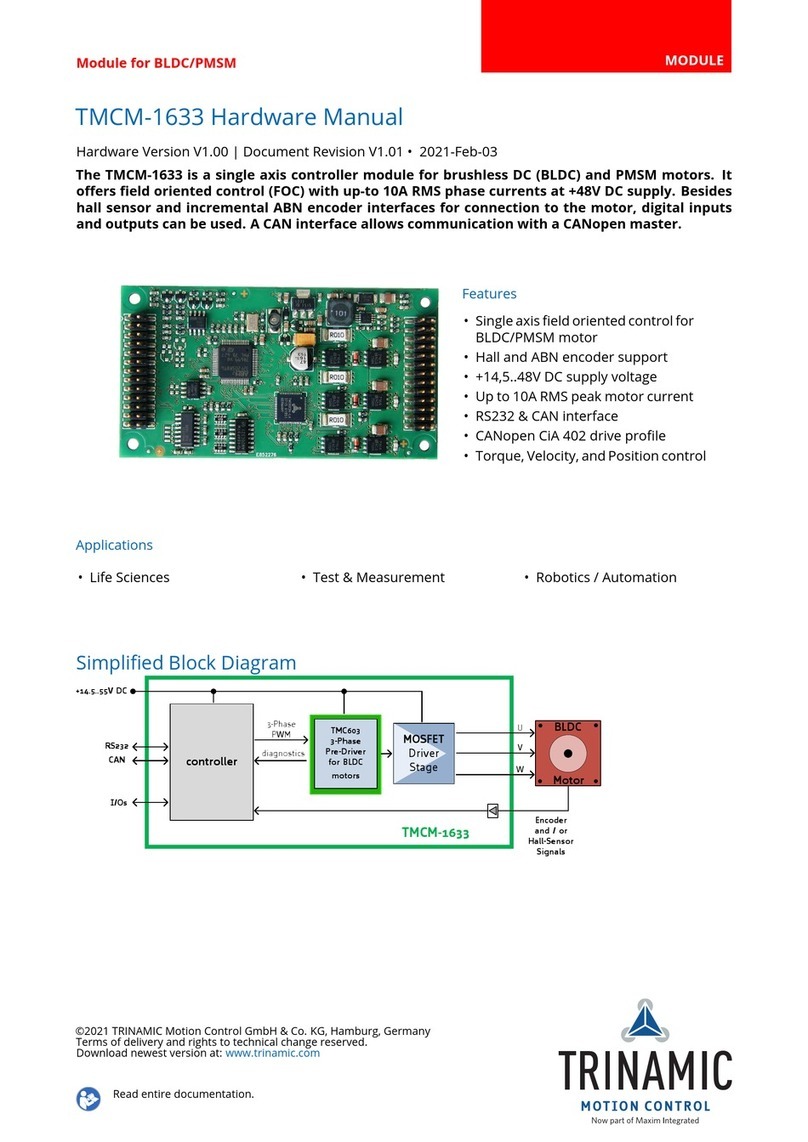

The PDx-108-28-SE-485 is a full mechatronic device consisting of a NEMA 11 (flange size 28mm) stepper

motor, controller/driver electronics and integrated sensOstepTM encoder.

Applications

Extremely compact and decentralized stepper motor solution

Position movement applications, where larger motors do not fit and higher torques are not required

Electrical data

Supply voltage: +9V… +28V DC

Motor current: up to 800mA peak / 560mA RMS (programmable)

Stepper motor data

NEMA 11 (28mm flange size) two phase bipolar stepper motors

Please also refer to the associated motor manual for more detailed information [QSH2818]

Interfaces

2 general purpose inputs

2 general purpose outputs

RS485 2-wire communication interface

Features

PD1-108-28-SE-485: smallest PANdrive™available from TRINAMIC

High-efficient operation, low power-dissipation

Uses TMC222-SI highly integrated controller/driver IC

Up to 16 microsteps per fullstep

Integrated sensOstepTM magnetic encoder (max. 256 increments per rotation) for step-loss detection and

absolute position information

Integrated protection: overtemperature/undervoltage

Software

TMCL™remote (direct mode) and stand-alone operation (memory for 64 TMCL™commands)

Fully supported by TMCL-IDE (PC based integrated development environment)

PDx-108-28-SE-485 Hardware Manual (V1.00 / 2010-May-31) 5

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

3Order codes

The combination of motor and motor mounted controller/driver electronic is currently available with two

stepper motors (different length and holding torque):

Order code

Description

Dimensions [mm3]

PD1-108-28-SE-485

PANdrive 0.05Nm max. holding torque*)

28 x 28 x 45

PD3-108-28-SE-485

PANdrive 0.10Nm max. holding torque*)

28 x 28 x 64

Table 3.1: Order codes

*) Max. holding torque at max. current (800mA peak / 560mA RMS) of the driver electronics

PDx-108-28-SE-485 Hardware Manual (V1.00 / 2010-May-31) 6

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

4Electrical and mechanical interfacing

The PDx-108-28-SE-485 consists of a 28mm / NEMA 11 stepper motor with controller/driver electronics

mounted to the back of the motor. In order to make proper use of the integrated sensOstepTM encoder (the

sensor IC is placed on the bottom of the pcb) the electronics should not be removed/moved relative to the

motor (e.g. mounting it at a different location or with a different distance towards the motor). In case this

encoder feature is not used, the electronics may be mounted according to different user requirements.

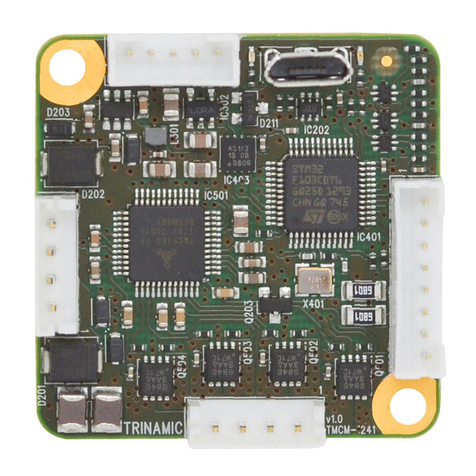

4.1 Size of board

The board with the controller/driver electronics has a size of 28mm x 28mm in order to fit on the back side

of a NEMA11 (28mm flange size) stepper motor.

28mm

28mm

Motor

Power and I/O

1

1

Figure 4.1: Top side of the board with connectors (all values in mm).

PDx-108-28-SE-485 Hardware Manual (V1.00 / 2010-May-31) 7

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

4.2 Size of unit

Currently, there is a choice between two 28mm stepper motors of different lengths and different torques.

Please also refer to the manuals of the related stepper motors QSH2818-32-07-006 and QSH2818-51-07-012.

Connector

43 max20±1

15±0.2

2 max

4.5

Ø05-0.02

Ø022-0.03

28 max

23±0.2

4 x M2.4

deep 3.5

28 max

23±0.2

Figure 4.2: PD1-108-28-SE-485 with 2-phase 28mm stepper motor QSH2818-32-07-006

Connector

62 max20±1

15±0.2

2 max

4.5

Ø05-0.02

Ø022-0.03

28 max

23±0.2

4 x M2.4

deep 3.5

28 max

23±0.2

Figure 4.3: PD3-108-28-SE-485 with 2-phase 28mm stepper motor QSH2818-51-07-012

PDx-108-28-SE-485 Hardware Manual (V1.00 / 2010-May-31) 8

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

4.3 Torque curves

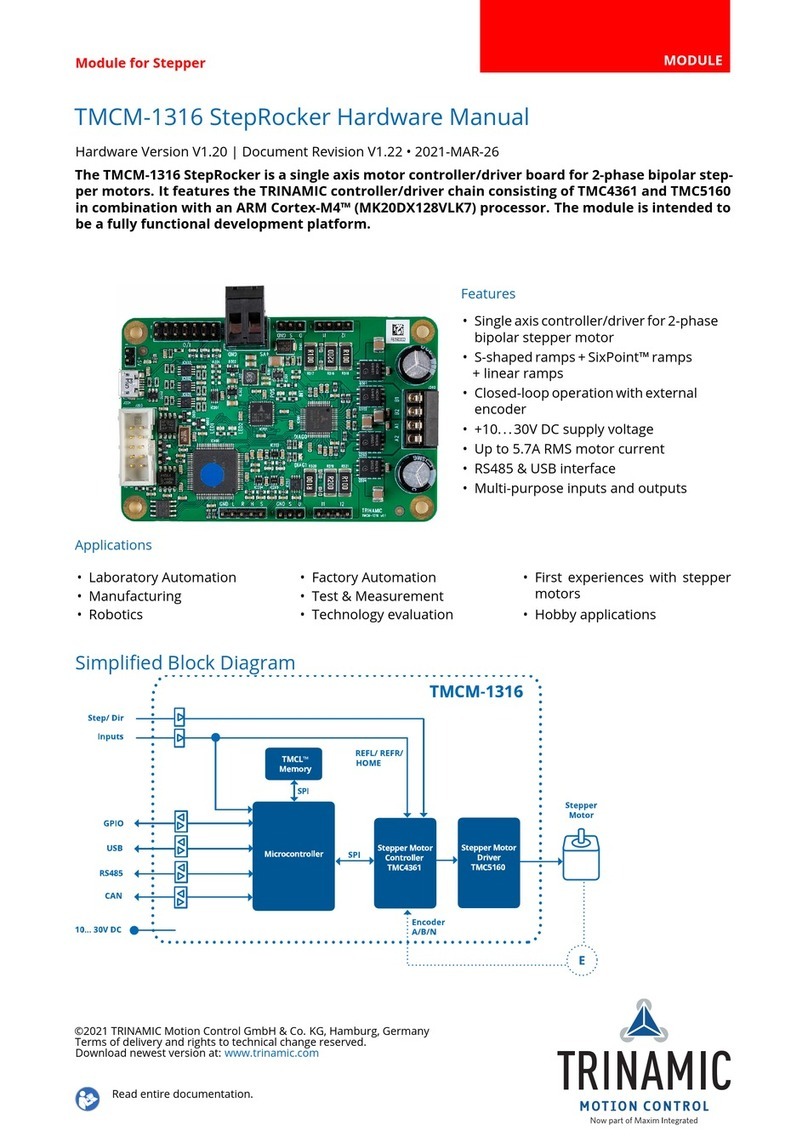

4.3.1 PD1-108-28-SE-485

Please find below the pull-out torque curve for the PD1-108-28-SE-485 integrated motor / electronics unit.

The speed (x-axis) is defined as full steps per second. As the integrated motor offers 200 full steps per

rotation, e.g. 200 full steps per second is equivalent to one rotation per second (rps) or 60 rotations per

minute (rpm).

Figure 4.4: Torque curve for PD1-108-28-SE-485

0

5

10

15

20

25

30

35

40

45

50

100 1000

torque[mNm]

speed[Fullsteps/s]

Unit: PD1-108-28-SE-485, QMOT Motor: QSH2818-32-07-006

PDx-108-28-SE-485 Hardware Manual (V1.00 / 2010-May-31) 9

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

4.4 Connectors

Due to the size of the module the space for connectors is rather limited. The PDx-108-28-SE-485 provides just

one connector with 8 pins for power, communication and general purpose inputs and outputs. A second

connector with 4 pins is used internally for connecting the motor wires.

4.4.1 Power and I/O connector

An 8-pin JST PH-series 2mm pitch single row connector [JST] is used on the board.

18

Pin

Label

Direction

Description

1

GND

Power (GND)

GND

2

VDD

Power (Supply)

VDD (+9V…+28V)

3

RS485

A

Bidirectional

RS-485 interface (+)

4

RS485

B

Bidirectional

RS-485 interface (-)

5

GPI0

Input

Digital (0..+5V, up to +/-28V), analog (0..+5V)

6

GPI1

Input

Digital (0..+5V, up to +/-28V), analog (0..+5V)

7

GPO0

Output

Open collector, max. , 150mA

8

GPO1

Output

Open collector, max. , 150mA

Table 4.1: Power and I/O connector

Mating connector from JST: PHR-8 (housing) and SPH-002T-P0.5S (crimp contact for AWG #30 to 24 / 0.05mm2

to 0.22mm2wires).

4.4.2 Motor connector

The motor connector is used internally for connecting the four motor wires to the electronics.

1

4

Pin

Label

Direction

Description

1

OA1

Output

Pin 1, motor coil 1

2

OA2

Output

Pin 2, motor coil 2

3

OB1

Output

Pin 1, motor coil 1

4

OB2

Output

Pin 2, motor coil 2

Table 4.2: Motor connector

PDx-108-28-SE-485 Hardware Manual (V1.00 / 2010-May-31) 10

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

4.5 Power supply

For proper operation care has to be taken with regard to power supply concept and design. Due to space

restrictions the PDx-108-28-SE-485 electronics includes just about 30µF/35V of supply filter capacitors. These

are ceramic capacitors which have been selected for high reliability and long life time. The module does not

include any protection against over-voltage or reverse polarity.

It is absolutely necessary that the power supply voltage is kept below the upper limit of 29V under all

circumstances (please see also chapter 6, operating values). Otherwise the driver electronics might be

seriously damaged! Especially, when the selected operating voltage is near the upper limit a regulated

power supply is highly recommended.

It is recommended to connect an electrolytic capacitor of significant size (e.g. 470µF/35V) to the power

supply lines next to the PDx-108-28-SE-485!

In addition to power stabilization (buffer) and filtering this added capacitor will also reduce any voltage

spikes which might otherwise occur from a combination of high inductance power supply wires and the

ceramic capacitors. In addition it will limit slew-rate of power supply voltage at the module. The low ESR of

ceramic-only filter capacitors can cause stability problems with some switching power supplies.

PDx-108-28-SE-485 Hardware Manual (V1.00 / 2010-May-31) 11

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

4.6 Inputs and outputs

4.6.1 RS485

For remote control and communication with a host system the PDx-108-28-SE-485 provides a two wire RS485

bus interface. For proper operation the following items should be taken into account when setting up an

RS485 network:

1. BUS STRUCTURE:

The network topology should follow a bus structure as closely as possible. That is, the connection

between each node and the bus itself should be as short as possible. Basically, it should be short

compared to the length of the bus.

c:> node

1

node

n- 1

node

n

Host Slave Slave Slave

RS485

termination

resistor

(120 Ohm)

termination

resistor

(120 Ohm)

}

keep distance as

short as possible

Figure 4.5: Bus structure

2. BUS TERMINATION:

Especially for longer busses and/or multiple nodes connected to the bus and/or high communication

speeds, the bus should be properly terminated at both ends of the bus. The PDx-108-28-SE-485

integrates a 120 Ohm termination resistor that is placed between both RS485 bus wires by

shortening two soldering pads (e.g. soldering dot or zero Ohm SMD resistor (0603)) on the pcb as

shown below.

open: no termination resistor

closed: 120 Ohm termination resistor

Figure 4.6: RS485 termination

As default a zero Ohm resistor is assembled in order to activate 120 Ohm line termination on-board.

This will simplify set-up in case the PDx-108-SE-485 is connected as last / first node in an RS485

PDx-108-28-SE-485 Hardware Manual (V1.00 / 2010-May-31) 12

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

network as there is no additional termination resistor necessary. Nevertheless, in any other case

(e.g. separate bus termination, unit placed somewhere in the middle of the bus, several PDx-108-28-

485 connected together) please make sure the zero Ohm resistor will be removed for proper RS485

operation!

3. NUMBER OF NODES:

The RS-485 electrical interface standard (EIA-485) allows up to 32 nodes to be connected to a single

bus. The bus transceiver used for the PDx-108-28-SE units (SN65HVD485ED) has just half of the

standard bus load and allows a maximum of 64 units to be connected to a single RS485 bus.

4. NO FLOATING BUS LINES:

Avoid floating bus lines while neither the host/master nor one of the slaves along the bus line is

transmitting data (all bus nodes switched to receive mode). Floating bus lines may lead to

communication errors. In order to ensure valid signals on the bus it is recommended to use a

resistor network connecting both bus lines to well defined logic levels. In contrast to the

termination resistors this network is normally required just once for a bus. Certain RS485 interface

converters available for a PC already include these additional resistors (e.g. USB-2-485).

node

n- 1

node

n

Slave Slave

termination

resistor

(120 Ohm)

+5V

GND

pull-up (1k)

pull-down (1k)

RS485- / RS485B

RS485+ / RS485A

Figure 4.7: Bus lines with resistor network

PDx-108-28-SE-485 Hardware Manual (V1.00 / 2010-May-31) 13

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

4.6.2 General purpose inputs

The eight pin connector of the PDx-108-28-SE provides two general purpose inputs. These two inputs can be

programmed in order to accept digital signals as well as analogue signals.

Both inputs are protected with 10k series resistors together with limiting diodes against voltages below 0V

(GND) and above +5V DC.

Figure 4.8: General purpose inputs

4.6.3 General purpose outputs

The eight pin connector of the PDx-108-28-SE provides two general purpose outputs. These two outputs are

open-collector outputs and can sink up to 150mA each. The N-channel MOSFET transistors used [BSS123] can

withstand voltages up to 100V at the outputs when switched off. Nevertheless, the voltages should be

normally limited to the supply voltage of the unit.

Figure 4.9: General purpose outputs

Attention: Please make sure to add external freewheeling diodes when connecting an inductive load (relays

etc.).

PDx-108-28-SE-485 Hardware Manual (V1.00 / 2010-May-31) 14

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

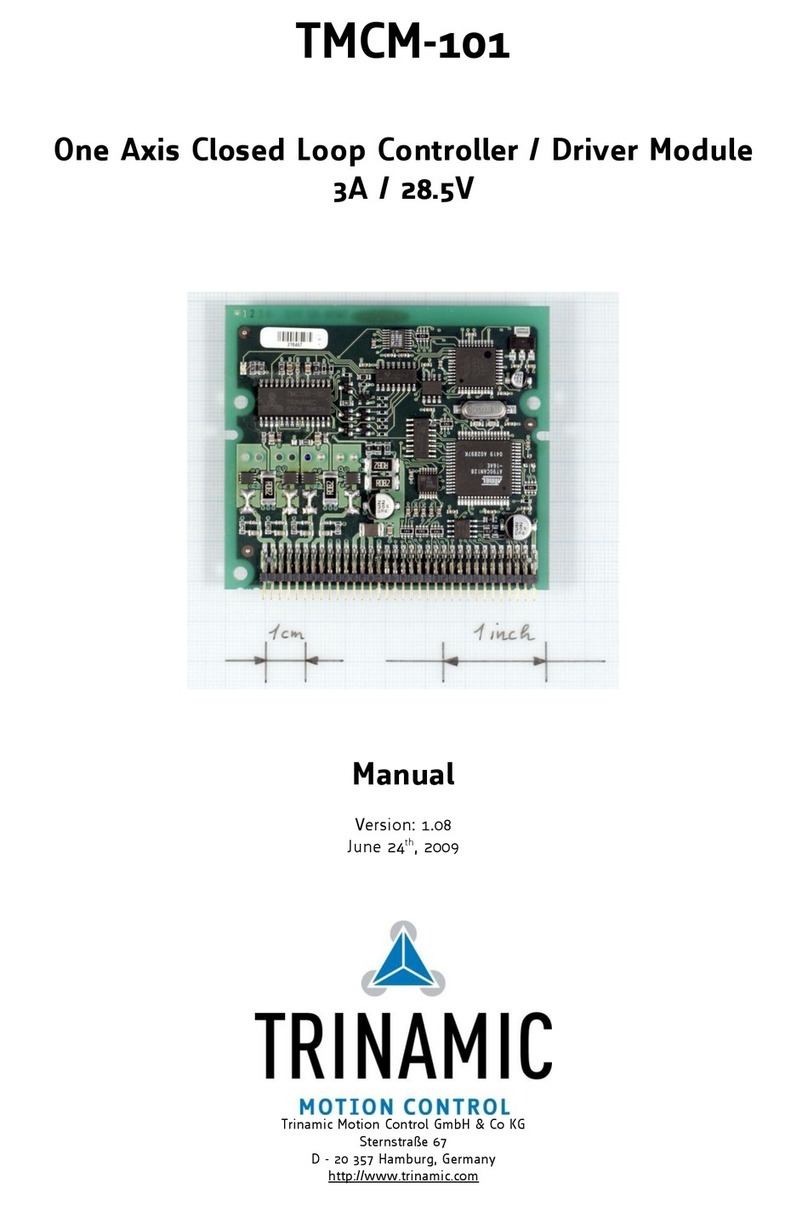

5Functional description

The PDx-108-28-SE-485 is a full mechatronic solution including a 28mm flange (NEMA11) bipolar stepper

motor. It includes the controller/driver electronics, a sensOstep™ encoder and two different motors of

different length and torque.

The PDx-108-28-SE-485 can be controlled via RS485 serial interface. The power supply, interface and the

multipurpose I/Os can be connected via single small JST connectors.

The PDx-108-28-SE-485 comes with the PC based software development environment TMCL-IDE for the

Trinamic Motion Control Language (TMCL™). Using predefined TMCL™ high level commands like move to

position a rapid and fast development of motion control applications is guaranteed. Please refer to the PDx-

108-28-SE-485 Firmware Manual for more information about TMCL™ commands.

Communication traffic is kept low since all time critical operations, e.g. ramp calculation are performed on

board. Full remote control of device with feedback is possible. The firmware of the module can be updated

via the serial interface.

9… 28V DC

µC

TMCL™ Memory

TMCL™ Interpreter

4

I/Os

Step

Motor

RS485

sensOstep™

Encoder

PDx-108-28-SE-485

TMCM-108

Motion

controller

Power

Driver

TMC222

Figure 5.1: Main parts of PDx-108-28-SE-485

PDx-108-28-SE-485 Hardware Manual (V1.00 / 2010-May-31) 15

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

6Operational ratings

The operational ratings show the intended or the characteristic ranges and should be used as design values.

In no case shall the maximum values be exceeded.

Symbol

Parameter

Min

Typ

Max

Unit

Vcc

Power supply voltage for operation

9

12 ... 24

28

V

ICOIL

Motor coil current for sine wave

peak (chopper regulated, adjustable

via software)

0

800

mA

IMC

Continuous motor current (RMS)

0

560

mA

fCHOP

Motor chopper frequency

18

20

22

kHz

IS

Power supply current

<< ICOIL

1.4 * ICOIL

A

TENV

Environment temperature at rated

current (no forced cooling required)

-40

45

°C

Environment temperature at 80% of

rated current or 50% duty cycle

(no forced cooling required)

-40

60

°C

Table 6.1: General operational ratings of the module

Symbol

Parameter

Min

Typ

Max

Unit

VGPO 0/1

Voltage at open collector output

0

+ Vcc

V

IGPO 0/1

Output sink current

150

mA

VGPI_digital 0/1

Input voltage for GPI0 and GPI1

when used as digital input

- Vcc

+ Vcc

V

VGPI_digital_L 0/1

Low level voltage for GPI0 and GPI1

when used as digital input

- Vcc

1,5

V

VGPI_digital_L 0/1

High level voltage for GPI0 and GPI1

when used as digital input

3

+ Vcc

V

VGPI_analogue 0/1

Measurement range for GPI0 and

GPI1 when used as analogue input

0 .. +5

V

Table 6.2: Operational ratings of the general purpost I/Os

Symbol

Parameter

Min

Typ

Max

Unit

NRS485

Number of nodes connected to

single RS485 network

64

Table 6.3: Operational ratings of the RS485 interface

PDx-108-28-SE-485 Hardware Manual (V1.00 / 2010-May-31) 16

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

7Revision History

7.1 Hardware revision

Version

Date

Description

1.00

2007-JAN-19

Initial release

1.10

2007-OCT-22

Electrolytic capacitor has been replaced by ceramic capacitors

1.20

2008-JUN-16

Soldering holes for motor wires have been replaced by JST connector

Figure 7.1: Hardware revision

7.2 Document revision

Version

Date

Author

Description

0.90

2007-JAN-12

GE

Initial version

0.91

2007-SEP-06

GE

Major update

0.92

2008-MAR-27

GE

TMCL™support added

0.93

2008-JUN-23

GE

RS485 pin assignment corrected + TMCL™stand-alone support

0.94

2008-SEP-01

GE

Separate hardware and TMCL™firmware manuals

1.00

2010-MAY-31

SD

Minor corrections

Figure 7.2: Document revision

PDx-108-28-SE-485 Hardware Manual (V1.00 / 2010-May-31) 17

Copyright © 2010, TRINAMIC Motion Control GmbH & Co. KG

8References

[TMCL] TMCL™Reference and Programming Manual (see http://www.trinamic.com)

[QSH2818-32-07-006] NEMA11 / 28mm bipolar stepper motor used in PD1

(reference manual please download from http://www.trinamic.com)

[QSH2818-51-07-012] NEMA11 / 28mm bipolar stepper motor used in PD3

(reference manual please download from http://www.trinamic.com)

[JST] JST PH connector (2.0mm pitch, disconnectable crimp style)

http://www.jst.com

[USB-2-485] USB-2-485 interface converter

(reference manual please download from http://www.trinamic.com)

[BSS123] N-Channel Logic Level Enhancement Mode Field Effect Transistor

(Fairchild Semiconductor http://www.fairchildsemi.com/)

[TMC222] TMC222 datasheet

(please download latest version from http://www.trinamic.com)

This manual suits for next models

2

Table of contents

Other Trinamic Computer Hardware manuals

Trinamic

Trinamic CANopen User manual

Trinamic

Trinamic TMCM-351 User manual

Trinamic

Trinamic TMCL TMCM-142 Use and care manual

Trinamic

Trinamic TMCM-1230 User manual

Trinamic

Trinamic TMCM-1161 User manual

Trinamic

Trinamic BB-100 User manual

Trinamic

Trinamic TMCM-1633 User manual

Trinamic

Trinamic PANdrive PD42-1- 1243-IOLINK Safety guide

Trinamic

Trinamic TMCM-351 Use and care manual

Trinamic

Trinamic TMCM-035 User manual