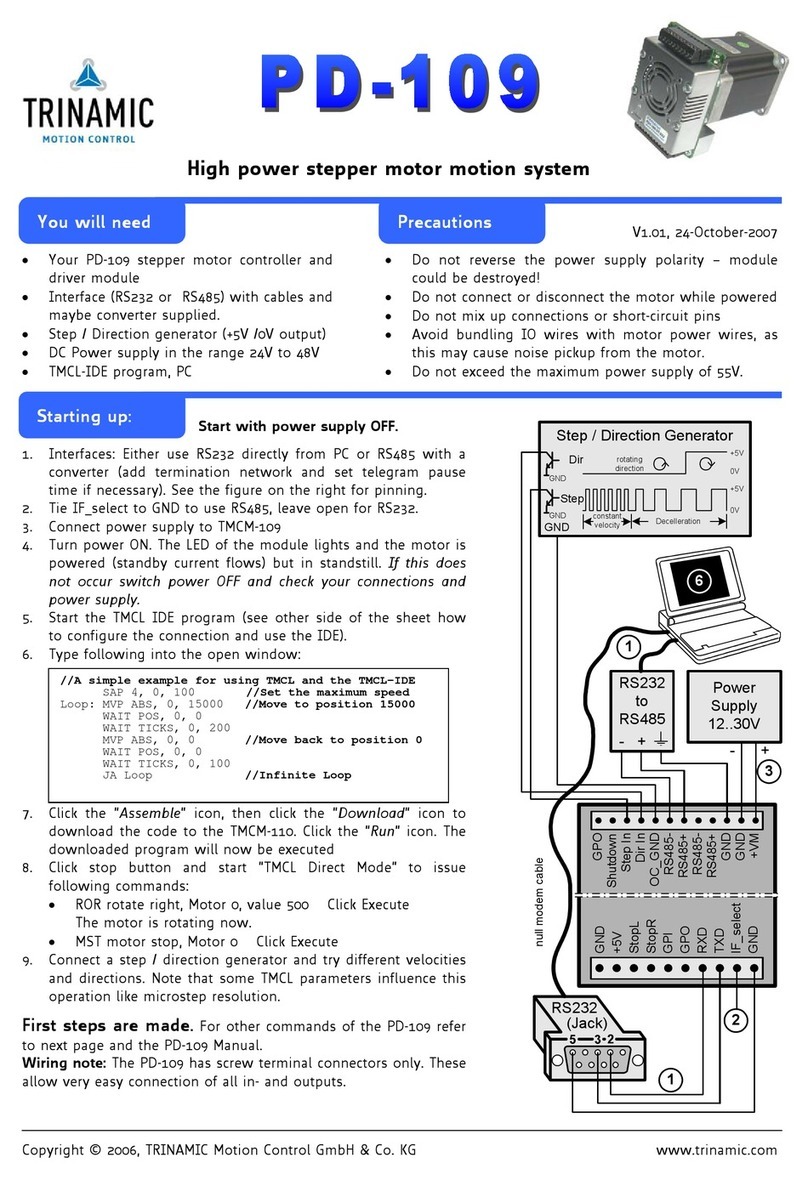

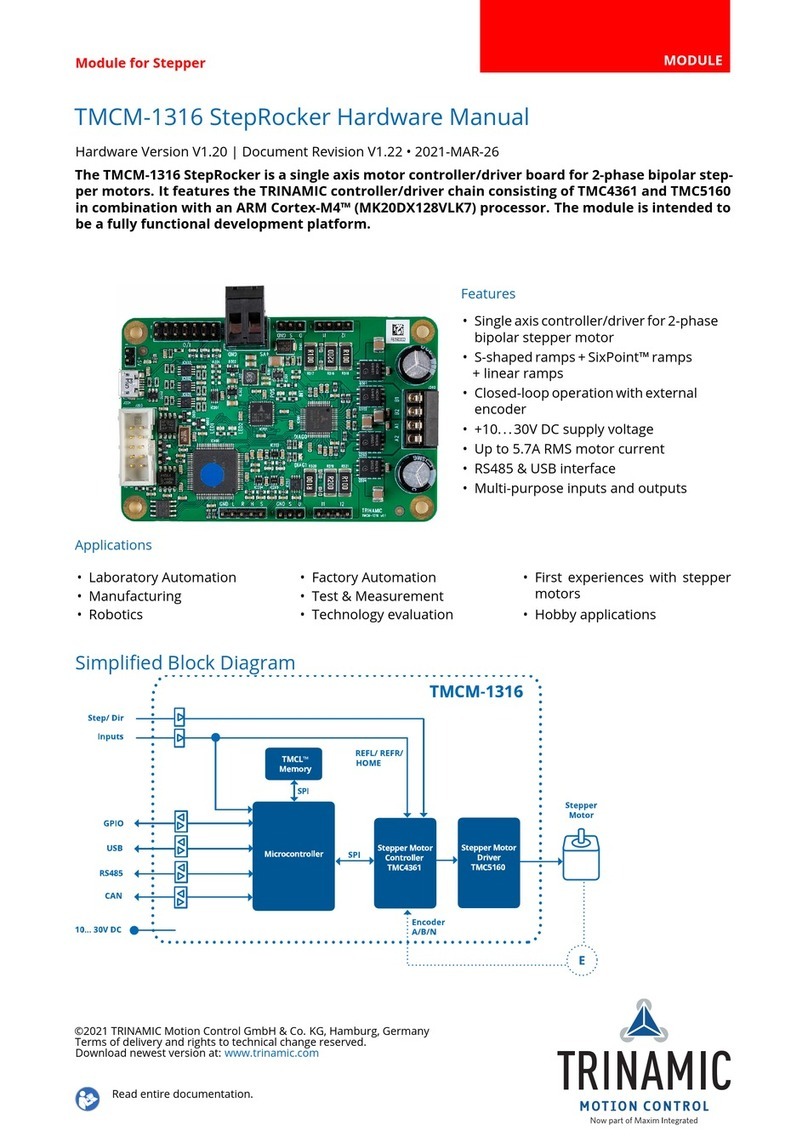

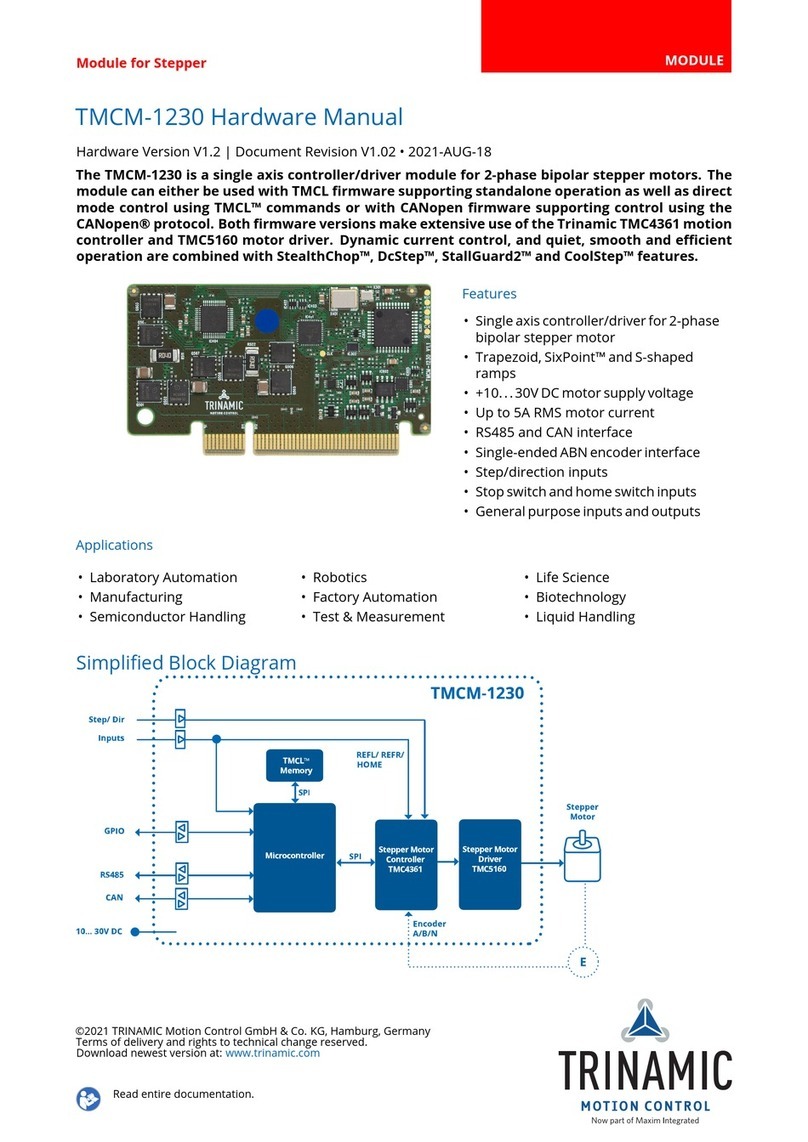

Trinamic TMCM-1633 User manual

Module for BLDC/PMSM MODULE

TMCM-1633 Hardware Manual

Hardware Version V1.00 | Document Revision V1.01 •2021-Feb-03

The TMCM-1633 is a single axis controller module for brushless DC (BLDC) and PMSM motors. It

offers field oriented control (FOC) with up-to 10A RMS phase currents at +48V DC supply. Besides

hall sensor and incremental ABN encoder interfaces for connection to the motor, digital inputs

and outputs can be used. A CAN interface allows communication with a CANopen master.

Features

•Single axis field oriented control for

BLDC/PMSM motor

•Hall and ABN encoder support

•+14,5..48V DC supply voltage

•Up to 10A RMS peak motor current

•RS232 & CAN interface

•CANopen CiA 402 drive profile

•Torque, Velocity, and Position control

Applications

•Life Sciences •Test & Measurement •Robotics / Automation

Simplified Block Diagram

controller

+14.5..55V DC

Encoder

and / or

Hall-Sensor

Signals

BLDC

Motor

MOSFET

Driver

Stage

Energy Efficient

Driver

TMC262

TMC603

3-Phase

Pre-Driver

for BLDC

motors

3-Phase

PWM

diagnostics

U

V

W

TMCM-1633

I/Os

RS232

CAN

©2021 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at: www.trinamic.com

Read entire documentation.

TMCM-1633 Hardware Manual •Hardware Version V1.00 | Document Revision V1.01 •2021-Feb-03 2 / 22

Contents

1 Features 3

1.1 General Features ............................................. 3

2 Order Codes 4

3 Mechanical and Electrical Interfacing 5

3.1 TMCM-1633 Dimensions and Weight ................................. 5

3.2 Mounting Considerations ........................................ 5

4 Connectors 6

4.1 Power Supply and Motor Connector .................................. 8

4.1.1 Power supply requirements ................................. 9

4.2 I/O, Interface and Encoder Connector ................................. 9

4.2.1 Reset the module to factory defaults ............................ 10

4.2.2 Inputs .............................................. 10

4.2.3 Encoder inputs ......................................... 11

4.2.4 Outputs ............................................. 12

5 Status LEDs 14

6 Functional Description 15

7 Operational Ratings and Characteristics 16

7.1 Absolute Maximum Ratings ....................................... 16

8 Abbreviations used in this Manual 17

9 Figures Index 18

10 Tables Index 19

11 Supplemental Directives 20

11.1 Producer Information .......................................... 20

11.2 Copyright .................................................. 20

11.3 Trademark Designations and Symbols ................................. 20

11.4 Target User ................................................ 20

11.5 Disclaimer: Life Support Systems .................................... 20

11.6 Disclaimer: Intended Use ........................................ 20

11.7 Collateral Documents & Tools ...................................... 21

12 Revision History 22

12.1 Hardware Revision ............................................ 22

12.2 Document Revision ............................................ 22

©2021 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

TMCM-1633 Hardware Manual •Hardware Version V1.00 | Document Revision V1.01 •2021-Feb-03 3 / 22

1 Features

TMCM-1633 is a highly integrated single axis controller/driver module for brushless DC motors (BLDC)

with RS232 and CAN interface and support for CANopen. The unit (size: 50mm x 92.5mm) has been

designed in order to be plugged onto a baseboard. It offers hall sensor (TTL or open-drain) and encoder

(incremental a/b/n) inputs and additional inputs and outputs.

1.1 General Features

Main Characteristics

•Supply Voltage +24V or +48V DC nominal (+14.5 . . . +50V DC max.)

•BLDC motors with hall sensors and / or encoder are supported

•10A RMS phase current (programmable) peak

•CANopen firmware

Interfaces

•CAN

•RS232

Inputs

•2 analog inputs and 2 digital inputs

•Encoder interface (incremental ABN with differential, 5V TTL or open-drain signalling)

•Hall sensor interface (5V TTL or open-drain)

Outputs

•3 open-drain outputs

Software

•CANopen™

©2021 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

TMCM-1633 Hardware Manual •Hardware Version V1.00 | Document Revision V1.01 •2021-Feb-03 4 / 22

2 Order Codes

Order Code Description Size (LxWxH)

TMCM-1633-2C-CANopen 1-axis BLDC plug-in controller/driver module,

FOC, 10A RMS peak, +48VDC, RS232 + CAN,

with CANopen firmware

92.5mm x 50mm x 14mm

Table 1: Order code module

©2021 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

TMCM-1633 Hardware Manual •Hardware Version V1.00 | Document Revision V1.01 •2021-Feb-03 5 / 22

3 Mechanical and Electrical Interfacing

3.1 TMCM-1633 Dimensions and Weight

The module TMCM-1633 has a size of approximately 92.5mm x 50mm and an overall height of approx.

14mm including cononectors. It offers four mounting holes (diameter: 3.2mm).

Coordinates (x/y)

All dimensions given in mm

(5.75/11)

(0/0)

(87/11)

(4/4)

(4/46) (88.5/46)

(88.5/4)

Double row

header 2x13pins,

2.54mm pitch

Double row

header 2x13pins,

2.54mm pitch

(92.5/50)

Figure 1: TMCM-1633 mechanical dimensions

Order Code Description Dimensions in mm Weight in g

TMCM-1633-2C-CANopen 1-axis BLDC plug-in controller/-

driver module, FOC, 10A RMS

peak, +48VDC, RS232 + CAN,

with CANopen firmware

92.5mm x 50mm x 14mm ≈29

Table 2: TMCM-1633size and weight

3.2 Mounting Considerations

TMCM-1633 has been designed as a plug-in module. It usually requires a baseboard for operation. Con-

nection to the baseboard is made via two connectors at both ends of the bottom of the pcb. There are

four mounting holes for securing the board / keeping it in position in addition to the connectors. Usually

at least one screw hole at each end of the board should be used to avoid any disconnection of the board

from a baseboard during transportation or operation (vibrations inside a machine etc.).

©2021 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

TMCM-1633 Hardware Manual •Hardware Version V1.00 | Document Revision V1.01 •2021-Feb-03 6 / 22

4 Connectors

The module offers two double row 2.54mm pitch standard connectors, one at each end of the board.

Hall1

+5V

GND

25

23

21

GND

GND

+VM

19

17

15

+VM

U

U

13

11

9

V

V

W

7

5

3

W1

Hall2

Hall3

GND

26

24

22

GND

GND

+VM

20

18

16

+VM

U

U

14

12

10

V

V

W

8

6

4

W2

Velocity

GND

Tacho

25

23

21

LED_Temp

+5V

GND

19

17

15

Enc_A-

Enc_B-

Enc_N-

13

11

9

RS232_RxD

RS232_TxD

n.c.

7

5

3

GND1

+5V

Torque

Dir_IN

1

3

5

Stop_IN

LED_Curlim

GND

7

9

11

Enc_A+

Enc_B+

Enc_N+

13

15

17

CAN_L

CAN_H

n.c.

19

21

23

GND25

I/O, interface and encoder connector Power supply and motor connector

Figure 2: TMCM-1633 Connector

Connector Connector type on-board Mating connector type

I/O, interface and encoder TSM-113-03-L-DV-K-A, 2x13 pins,

double row, 2.54mm pitch, SMT

vertical, Samtec or similar type

Samtec: SSW, SSQ, SSM, BSW, ESW,

ESQ, BCS, SLW, CES, HLE, IDSS

or IDSD series or any double row

2.54mm pitch 2x13pin female con-

nector

Power supply and motor TSM-113-03-L-DV-K-A, 2x13 pins,

double row, 2.54mm pitch, SMT

vertical, Samtec or similar type

Samtec: SSW, SSQ, SSM, BSW, ESW,

ESQ, BCS, SLW, CES, HLE, IDSS

or IDSD series or any double row

2.54mm pitch 2x13pin female con-

nector

Table 3: Connector type and mating connector of the TMCM-1633

NOTICE Do not plug-in or remove unit from baseboard during operation! This may

result in permanent damage of the unit.

NOTICE Pay attention to orientation of unit and alignment of pins when inserting

unit! Please be careful not to insert the unit the other way round. Also, please

make sure all pins are inserted into their mating pins.

©2021 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

TMCM-1633 Hardware Manual •Hardware Version V1.00 | Document Revision V1.01 •2021-Feb-03 7 / 22

Especially for higher motor current an assembly option with a detachable screw connector is available on

request (minimum order quantity required). The 5pin connector will be assembled on top side of board

and includes power supply input (+VM and GND) and motor coil connections (U, V, W):

GND

+VM

U

V

W

Figure 3: TMCM-1633 Connector

The signals are connected 1:1 to the signals with the same label on the double-row power supply and

motor connector on the bottom side of the unit (see Figure 2). Please note that the "power supply and

motor connector" on the bottom of the PCB is still required in case the Hall sensor inputs will be used.

Connector type on-board Mating connector type

RIA AKL 330-05 5pin, 5.0mm pitch header connector 1x RIA AKL 349-05 5pin, 5.0mm pitch detach-

able screw connector (combined power supply

and motor) or 1x RIA AKL 349-02 2pin, 5.0mm

pitch detachable screw connector for power

supply input (+VM and GND) and 1x RIA AKL

349-03 3pin, 5.0mm pitch detachable screw

connector for motor coil connection (U, V, W)

Table 4: Connector type and mating connector for the high current connector option

©2021 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

TMCM-1633 Hardware Manual •Hardware Version V1.00 | Document Revision V1.01 •2021-Feb-03 8 / 22

4.1 Power Supply and Motor Connector

A double row 26pin header with 2.54mm pitch is used for connecting all motor related signals and power

supply input.

Pin Label Description Pin Label Description

1 W Motor coil W 2 W Motor coil W

3 W Motor coil W 4 W Motor coil W

5 V Motor coil V 6 V Motor coil W

7 V Motor coil V 8 V Motor coil W

9 U Motor coil U 10 U Motor coil U

11 U Motor coil U 12 U Motor coil U

13 VM Supply input (positive) 14 VM Supply input (positive)

15 VM Supply input (positive) 16 VM Supply input (positive)

17 GND Supply input (power supply and sig-

nal ground)

18 GND Supply input (power supply and sig-

nal ground)

19 GND Supply input (power supply and sig-

nal ground)

20 GND Supply input (power supply and sig-

nal ground)

21 GND Supply input (power supply and sig-

nal ground)

22 GND Supply input (power supply and sig-

nal ground)

23 GND +5V output (100mA max.) for en-

coder and / or hall sensor supply

24 Hall3 Hall sensor 3 (+5V TTL or open-

collector) signal input

25 Hall1 Hall sensor 1 (+5V TTL or open-

collector) signal input

26 Hall2 Hall sensor 2 (+5V TTL or open-

collector) signal input

Table 5: Power Supply and Motor Connector pin assignment

NOTICE Do not connect or disconnect motor during operation! Motor cable and mo-

tor inductivity might lead to voltage spikes when the motor is (dis)connected

while energized. These voltage spikes might exceed voltage limits of the driver

MOSFETs and might permanently damage them. Therefore, always switch off

/ disconnect power supply or at least disable driver stage before connecting /

disconnecting motor.

NOTICE There is no reverse polarity protection at the supply input!

The module will short any reversed supply voltage and board electronics might

get damaged.

©2021 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

TMCM-1633 Hardware Manual •Hardware Version V1.00 | Document Revision V1.01 •2021-Feb-03 9 / 22

4.1.1 Power supply requirements

The power supply should be able to deliver the required power and keep the supply voltage stable at

the desired maximum motor current. In no case should the supply voltage exceed the upper or lower

voltage limits. In order to be able to cope with high voltage spikes which might be caused by energy

fed back from the motor during deceleration a sufficient power supply capacitor should be added on the

baseboard close to the module. Depending on the motor and motor current please use a 4700uF or larger

capacitor with suitable voltage rating. Additionally, a suitable suppressor diode might be useful.

4.2 I/O, Interface and Encoder Connector

A double row 26pin header with 2.54mm pitch is used for connecting all GPIO, communication (CAN +

RS232) and encoder signals.

Pin Label Description Pin Label Description

1 +5V +5V analog reference as used

by the internal ADC. Max.

load 0.5mA

2 Velocity Analog input (0-10V), may be

used for velocity control in

stand-alone mode

3 Torque Analog input (0-10V), may be

used for torque / max. mo-

tor current control in stand-

alone mode

4 GND Supply input (power supply

and signal ground)

5 Dir_IN Digital input (+5V TTL). On-

board 10k pull-up resistor to

+5V. May be used as direction

input signal in stand-alone

mode

6 Tacho Digital output (open-drain).

May be used as tacho signal

output - e.g. toggles on each

hall sensor change

7 Stop_IN Digital input (+5V TTL). On-

board 10k pull-up resistor to

+5V. May be used as stop

input signal in stand-alone

mode

8 LED-Temp Digital output (open-drain).

Toggling with approx. 3Hz

when temperature pre-

warning is exceeded. Output

will be permanently pulled

low in case of overtempera-

ture of the driver stage

9 LED-Curlim Digital output (open-drain).

Will be pulled low in case cur-

rent limit has been reached

10 +5V +5V output (100mA max.) for

encoder and / or hall sensor

supply

11 GND Power supply and signal

ground

12 GND Power supply and signal

ground

13 Enc_A+ Encoder A channel (non-

inverting)

14 Enc_A- Encoder A channel (inverting)

15 Enc_B+ Encoder B channel (non-

inverting)

16 Enc_B- Encoder B channel (inverting)

17 Enc_N+ Encoder N+ channel (non-

inverting)

18 Enc_N- Encoder N channel (inverting)

19 CAN_L CAN bus signal (inverting) 20 RS232_RXD RS232 receive data input

21 CAN_H CAN bus signal (non-

inverting)

22 RS232_TXD RS232 transmit data output

©2021 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

TMCM-1633 Hardware Manual •Hardware Version V1.00 | Document Revision V1.01 •2021-Feb-03 10 / 22

Pin Label Description Pin Label Description

23 n.c. not connected / do not con-

nect

24 n.c. not connected / do not con-

nect

25 GND Power supply and signal

ground

26 GND Power supply and signal

ground

Table 6: I/O, Interface and Encoder Connector pin assignment

4.2.1 Reset the module to factory defaults

In order to reset the module to factory default values please follow instructions listed below:

1. Switch off power cycle

2. Short input signal RS232_RXD with output signal RS232_TXD

3. Switch on power supply and wait some time

4. Switch off power supply

5. Remove short circuit

4.2.2 Inputs

The TMCM-1633 offers two analog and two digital inputs. The four inputs are availble at the 2x13pin "IO,

interface and encoder" connector.

Pin Label Type Description

2 Velocity analog Either general purpose analog input (0-10V signal) or optional velocity con-

trol input in stand alone mode

3 Torque analog Either general purpose analog input (0-10V signal) or optional torque control

/ motor max. current input in stand alone mode

5 Dir_IN digital Either general purpose digital input (+5V TTL compatible, internal 10k pull-up

to +5V) or optional direction input in stand-alone mode.

7 Stop_IN digital Either general purpose digital input (+5V TTL compatible, internal 10k pull-up

to +5V) or optional emergency stop input in stand-alone mode.

©2021 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

TMCM-1633 Hardware Manual •Hardware Version V1.00 | Document Revision V1.01 •2021-Feb-03 11 / 22

+3.3V

Velocity

ADC input

(microcontroller)

39k2

19k1

100pF

GND

GND GND

+3.3V

Dir_IN digital input

(microcontroller)

10k

100pF

GND GND

+3.3V

Torque

ADC input

(microcontroller)

39k2

19k1

100pF

GND

GND GND

+3.3V

Stop_IN digital input

(microcontroller)

10k

100pF

GND GND

+5V

10k

+5V

10k

Figure 4: TMCM-1633 input circuit for the general purpose analog and digital inputs

4.2.3 Encoder inputs

The encoder input supports differential, +5V TTL push-pull and open-drain encoder A/B/N signals. As line

receiver for differential encoder signals a standard AM26C32 differential line receiver is used.

Pin Label Description

13 Enc_A+ Encoder A channel differential non-inverting input. Maybe used for single ended (ei-

ther TTL +5V push-pull or open-drain) channel A encoder signals, also. Please note: for

non-differential signals on-board termination resistors might have to be removed

14 Enc_A- Encoder A channel differential inverting input

15 Enc_B+ Encoder B channel differential non-inverting input. Maybe used for single ended (ei-

ther TTL +5V push-pull or open-drain) channel B encoder signals, also. Please note:

for non-differential signals on-board termination resistors might have to be removed

16 Enc_B- Encoder B channel differential non-inverting input

17 Enc_N+ Encoder Null / Zero channel differential non-inverting input. Maybe used for single

ended (either TTL +5V push-pull or open-drain) channel N encoder signals, also. Please

note: for non-differential signals on-board termination resistors might have to be re-

moved

18 Enc_N- Encoder N channel differential inverting input

©2021 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

TMCM-1633 Hardware Manual •Hardware Version V1.00 | Document Revision V1.01 •2021-Feb-03 12 / 22

A+

A-

B+

B-

N+

N-

+5V

470R

470R

470R

GND

+5V

4k7

4k7

4k7

3k3 2k2

120R

120R

120R

ENC_A

ENC_B

ENC_N

Termination

Figure 5: TMCM-1633 encoder input circuit

The TMCM-1633 does include 120R termination resistors for differential encoder signals. In case encoder

with single ended +5V TTL push-pull or open-drain signals are used either a level converter should be

inserted or it might be necessary to remove the line termination resistors. Please see figure 6for location

of resistor array.

Figure 6: TMCM-1633 encoder termination resistor array (marked red)

4.2.4 Outputs

The TMCM-1633 offers three open-drain outputs. Two of them (LED-Temp and LED-Curlim) are connected

to on-board LEDs, in addition. Please refer to chapter 5on page 14, also.

Pin Label Description

6 Tacho This open-drain output can sink a maximum of 1A when switched on. It may be

used as general purpose output or tacho signal output, i.e. toggles on each hall

sensor change.

©2021 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

TMCM-1633 Hardware Manual •Hardware Version V1.00 | Document Revision V1.01 •2021-Feb-03 13 / 22

Pin Label Description

8 LED-Temp This open-drain output can sink a maximum of 1A when switched on. It will toggle

with approx. 3Hz when temperature pre-warning threshold has been exceeded

and will go permanently low in case of overtemperature of the driver stage.

9 LED-Curlim This open-drain output can sink a maximum current of 1A when switched on. It

will go in case current limit of the driver stage (programmable) has been reached.

+VM

digital output

(microcontroller)

GND

220

GND

10k

1k

+5V

Tacho,

LED-Temp,

LED-Curlim

Figure 7: TMCM-1633 output circuit (same circuit design for Tacho, LED-Temp and LED-Curlim outputs)

©2021 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

TMCM-1633 Hardware Manual •Hardware Version V1.00 | Document Revision V1.01 •2021-Feb-03 14 / 22

5 Status LEDs

The TMCM-1633 offers four on-board LEDs for power, error indication, current overload and temperature

warning. The LEDs are placed on the back side of the unit. This way they will be still visible when the unit

is plugged onto a baseboard.

Power

Error

Current overload

Temperature warning

Figure 8: TMCM-1633 LEDs

LED Color Description

Power green LED is ON, if the on-board +5V are available

Error red LED is ON in case of error

Current overload red

Flash The current limit LED flashes upon undervoltage switch

off

ON/Flash Motor PWM is reduced as the motor current limit is ex-

ceeded

Temperature warning red

Flash Driver stage temperature has exceeded pre-warning

threshold (100°C)

ON Driver stage temperature has exceeded 125°C. Driver

stage will be switched off until temperature falls below

125°C.

Table 10: LED state description

©2021 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

TMCM-1633 Hardware Manual •Hardware Version V1.00 | Document Revision V1.01 •2021-Feb-03 15 / 22

6 Functional Description

The TMCM-1633 is a highly integrated single axis controller/driver module for brushless DC motors (BLDC)

with RS232 and CAN interface and support for CANopen. The unit (size: 50mm x 92.5mm) has been de-

signed in order to be plugged onto a baseboard. It offers hall sensor (TTL or open-drain) and encoder

(incremental a/b/n) inputs.

In Figure 9the main parts of the TMCM-1633 are shown:

•Microcontroller, responsible for overall control and 3-phase pwm generation

•Pre-driver (based on TMC603)

•power MOSFET driver bridge

•current measurement via three (low-side) shunts

•Encoder and hall sensor interfaces

•digital inputs and outputs

•CAN™interface

µC

(ARM)

Digital Inputs:

Dir_IN, Stop_IN

Outputs (Open-drain):

Tacho, LED_Temp, LED_Curlim

+14.5..+55V

DC

DC

DC

EEPROM

SPI

Encoder

and / or

Hall-Sensor

Signals

BLDC

Motor

MOSFET

Driver

Stage

Energy Efficient

Driver

TMC262

TMC603

3-Phase

Pre-Driver

for BLDC

motors

3-Phase

PWM

diagnostics

current

measurement

U

V

W

+5V +3V3

TMCM-1633

Analog Inputs:

Velocity, Torque

CAN

RS232

Figure 9: TMCM-1633 block diagram

©2021 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

TMCM-1633 Hardware Manual •Hardware Version V1.00 | Document Revision V1.01 •2021-Feb-03 16 / 22

7 Operational Ratings and Characteristics

7.1 Absolute Maximum Ratings

Symbol Parameter Min Typ Max Unit

VSPower supply voltage for operation 14.5 24, 48 50 V

ISPower supply current 0.04 IMOT A

PID Module idle power consumption 1.2 W

I+5V +5V output for supply of external circuits (e.g. encoder and /

or hall sensors)

100 mA

IMC Continuous motor current at max. supply voltage 0 - 8 10 A

IMP Short time motor current e.g. during acceleration periods 0 - 10 A

VDIGI Input voltage on general purpose and hall sensor digital in-

puts

-0.3 +5.3V V

IOSink current on digital outputs (open-drain current) 1 A

VANA Analog input voltage 0 0 - 10 24 V

fCHOP Chopper frequency 20 kHz

T0Environmental temperature for operation at max specified

motor current (air flow might be required, depending on mo-

tor / voltage)

-25 +60 °C

Tboard Temperature of the module as measured by the on-board

sensor (NTC)

<100 125 °C

Table 11: TMCM-1633 Operational Ratings

NOTICE Never Exceed the absolute maximum ratings! Keep the power supply voltage

below the upper limit of +50V! Otherwise the board electronics will seriously be

damaged! Especially, when the selected operating voltage is near the upper limit

a regulated power supply is highly recommended.

©2021 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

TMCM-1633 Hardware Manual •Hardware Version V1.00 | Document Revision V1.01 •2021-Feb-03 17 / 22

8 Abbreviations used in this Manual

Abbreviation Description

BLDC Brushless DC

FOC Field Oriented Control

IDE Integrated Development Environment

LED Light Emmitting Diode

RMS Root Mean Square value

TMCL TRINAMIC Motion Control Language

Table 12: Abbreviations used in this Manual

©2021 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

TMCM-1633 Hardware Manual •Hardware Version V1.00 | Document Revision V1.01 •2021-Feb-03 18 / 22

9 Figures Index

1 TMCM-1633 mechanical dimensions . 5

2 TMCM-1633 Connector ........ 6

3 TMCM-1633 Connector ........ 7

4 TMCM-1633 input circuit for the gen-

eral purpose analog and digital inputs 11

5 TMCM-1633 encoder input circuit . . 12

6 TMCM-1633 encoder termination re-

sistor array (marked red) ....... 12

7 TMCM-1633 output circuit (same cir-

cuit design for Tacho, LED-Temp and

LED-Curlim outputs) .......... 13

8 TMCM-1633 LEDs ............ 14

9 TMCM-1633 block diagram ...... 15

©2021 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

TMCM-1633 Hardware Manual •Hardware Version V1.00 | Document Revision V1.01 •2021-Feb-03 19 / 22

10 Tables Index

1 Order code module ........... 4

2 TMCM-1633size and weight ...... 5

3 Connector type and mating connector

of the TMCM-1633 ........... 6

4 Connector type and mating connector

for the high current connector option 7

5 Power Supply and Motor Connector

pin assignment ............. 8

6 I/O, Interface and Encoder Connector

pin assignment ............. 10

10 LED state description .......... 14

11 TMCM-1633 Operational Ratings . . . 16

12 Abbreviations used in this Manual . . 17

13 Hardware Revision ........... 22

14 Document Revision ........... 22

©2021 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

TMCM-1633 Hardware Manual •Hardware Version V1.00 | Document Revision V1.01 •2021-Feb-03 20 / 22

11 Supplemental Directives

11.1 Producer Information

11.2 Copyright

TRINAMIC owns the content of this user manual in its entirety, including but not limited to pictures, logos,

trademarks, and resources. ©Copyright 2021 TRINAMIC. All rights reserved. Electronically published by

TRINAMIC, Germany.

Redistributions of source or derived format (for example, Portable Document Format or Hypertext Markup

Language) must retain the above copyright notice, and the complete Datasheet User Manual documen-

tation of this product including associated Application Notes; and a reference to other available product-

related documentation.

11.3 Trademark Designations and Symbols

Trademark designations and symbols used in this documentation indicate that a product or feature is

owned and registered as trademark and/or patent either by TRINAMIC or by other manufacturers, whose

products are used or referred to in combination with TRINAMIC’s products and TRINAMIC’s product doc-

umentation.

This Hardware Manual is a non-commercial publication that seeks to provide concise scientific and tech-

nical user information to the target user. Thus, trademark designations and symbols are only entered in

the Short Spec of this document that introduces the product at a quick glance. The trademark designation

/symbol is also entered when the product or feature name occurs for the first time in the document. All

trademarks and brand names used are property of their respective owners.

11.4 Target User

The documentation provided here, is for programmers and engineers only, who are equipped with the

necessary skills and have been trained to work with this type of product.

The Target User knows how to responsibly make use of this product without causing harm to himself or

others, and without causing damage to systems or devices, in which the user incorporates the product.

11.5 Disclaimer: Life Support Systems

TRINAMIC Motion Control GmbH & Co. KG does not authorize or warrant any of its products for use in

life support systems, without the specific written consent of TRINAMIC Motion Control GmbH & Co. KG.

Life support systems are equipment intended to support or sustain life, and whose failure to perform,

when properly used in accordance with instructions provided, can be reasonably expected to result in

personal injury or death.

Information given in this document is believed to be accurate and reliable. However, no responsibility

is assumed for the consequences of its use nor for any infringement of patents or other rights of third

parties which may result from its use. Specifications are subject to change without notice.

11.6 Disclaimer: Intended Use

The data specified in this user manual is intended solely for the purpose of product description. No rep-

resentations or warranties, either express or implied, of merchantability, fitness for a particular purpose

©2021 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

Table of contents

Other Trinamic Computer Hardware manuals

Trinamic

Trinamic BB-100 User manual

Trinamic

Trinamic TMCM-1230 User manual

Trinamic

Trinamic TMCM-035 User manual

Trinamic

Trinamic TMCM-160 User manual

Trinamic

Trinamic TMCL TMCM-142 Use and care manual

Trinamic

Trinamic TMCM-1161 User manual

Trinamic

Trinamic TMCM-101 User manual

Trinamic

Trinamic PANdrive PD42-1- 1243-IOLINK Safety guide

Trinamic

Trinamic PD 108-28-SE-485 Series User manual

Trinamic

Trinamic TMCM-310 User manual