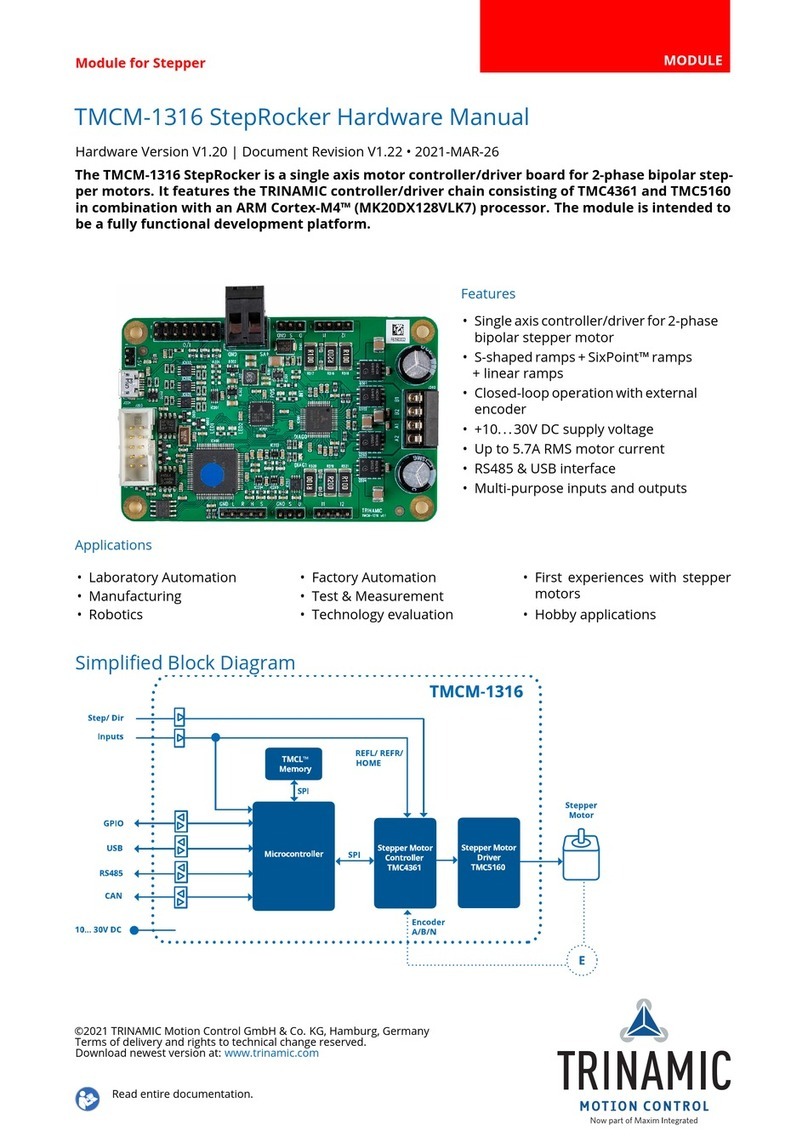

Trinamic TMCM-035 User manual

TMCM-035 Manual (V2.09 / February 27th, 2009) 2/18

Copyright © 2007-2009, TRINAMIC Motion Control GmbH & Co. KG

Table of Contents

1Features........................................................................................................................................................................................3

Life support policy.............................................................................................................................................................................4

2Electrical and Mechanical Interfacing..................................................................................................................................5

2.1 Dimensions ........................................................................................................................................................................5

2.2 Connecting the Module ..................................................................................................................................................6

3Operational Ratings..................................................................................................................................................................7

4Functional Description.............................................................................................................................................................7

4.1 Power Supply ....................................................................................................................................................................8

4.2 Motor Connection.............................................................................................................................................................8

4.3 Interfaces ............................................................................................................................................................................8

4.3.1 SPI ..................................................................................................................................................................................8

4.3.2 Analog ...........................................................................................................................................................................9

4.3.3 Step / Direction.........................................................................................................................................................11

4.4 Current setting ................................................................................................................................................................12

4.4.1 Fine current adjustment in SPI mode: ..............................................................................................................12

4.4.2 Standby current reduction for Step-/ Direction mode...................................................................................13

4.4.3 Continuous Current restrictions / Thermal conditions..................................................................................13

4.5 Mixed decay and slow decay ......................................................................................................................................14

4.6 Microstep resolution adjustments.............................................................................................................................14

4.6.1 Microstep resolution with step / direction interface.....................................................................................14

4.6.2 Increasing Microstep resolution with SPI interface ......................................................................................14

4.6.3 64 Microstep resolution with SPI interface since TMCM-035 V2.0 .............................................................15

5Hardware Revision..................................................................................................................................................................18

6Documentation Revision.......................................................................................................................................................18

7References .................................................................................................................................................................................18

List of Figures

Figure 2.1: Dimensions.....................................................................................................................................................................5

Figure 2.2: Pin order of the connector ........................................................................................................................................5

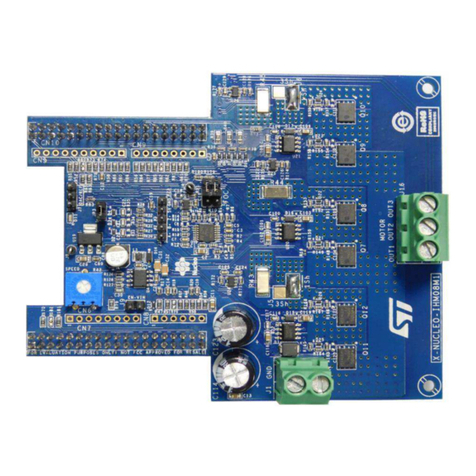

Figure 4.1: Main parts of the TMCM-035......................................................................................................................................7

Figure 4.2: How to connect the motor........................................................................................................................................8

Figure 4.3: Analog control.............................................................................................................................................................10

Figure 4.4: Step / Direction signal timing ................................................................................................................................11

Figure 4.5: SPI word assignment in 64 microstep mode ....................................................................................................15

Figure 4.6: Application with 3 TMCM-035 controlled by a TMCM-301...............................................................................16

Figure 4.7: Driver chain configuration for up to 3 TMCM-035 in use with TMCM-301.................................................17

Figure 4.8: Microstep table for 64 microsteps in use with TMCM-301 .............................................................................17

List of Tables

Table 1.1: Order codes......................................................................................................................................................................3

Table 2.1: Pinout 68-Pin Connector...............................................................................................................................................6

Table 3.1: Operational Ratings .......................................................................................................................................................7

Table 4.1: SPI interface connections ............................................................................................................................................8

Table 4.2: Connecting a TMCM-035 to a TMCM-301 ..................................................................................................................9

Table 4.3: Analog interface connections .....................................................................................................................................9

Table 4.4: Connecting a TMCM-035 to a TMCM-100 (analog) ...............................................................................................10

Table 4.5: Step / Direction interface connections...................................................................................................................11

Table 4.6: Connecting a TMCM-035 to a TMCM-100 (step / direction)...............................................................................11

Table 4.7: Current setting ..............................................................................................................................................................12

Table 4.8: Current fine adjustment with RSA and RSB.........................................................................................................13

Table 5.1: Hardware revision ........................................................................................................................................................18

Table 6.1: Documentation Revisions ..........................................................................................................................................18

TMCM-035 Manual (V2.09 / February 27th, 2009) 3/18

Copyright © 2007-2009, TRINAMIC Motion Control GmbH & Co. KG

1Features

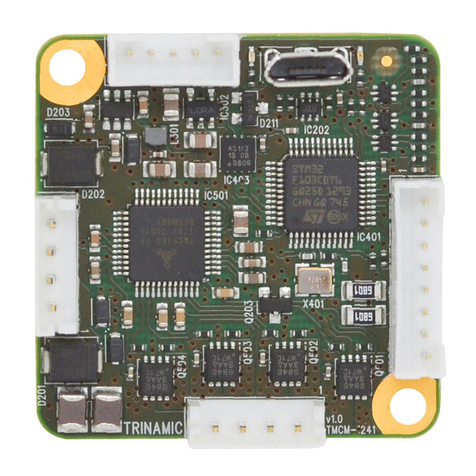

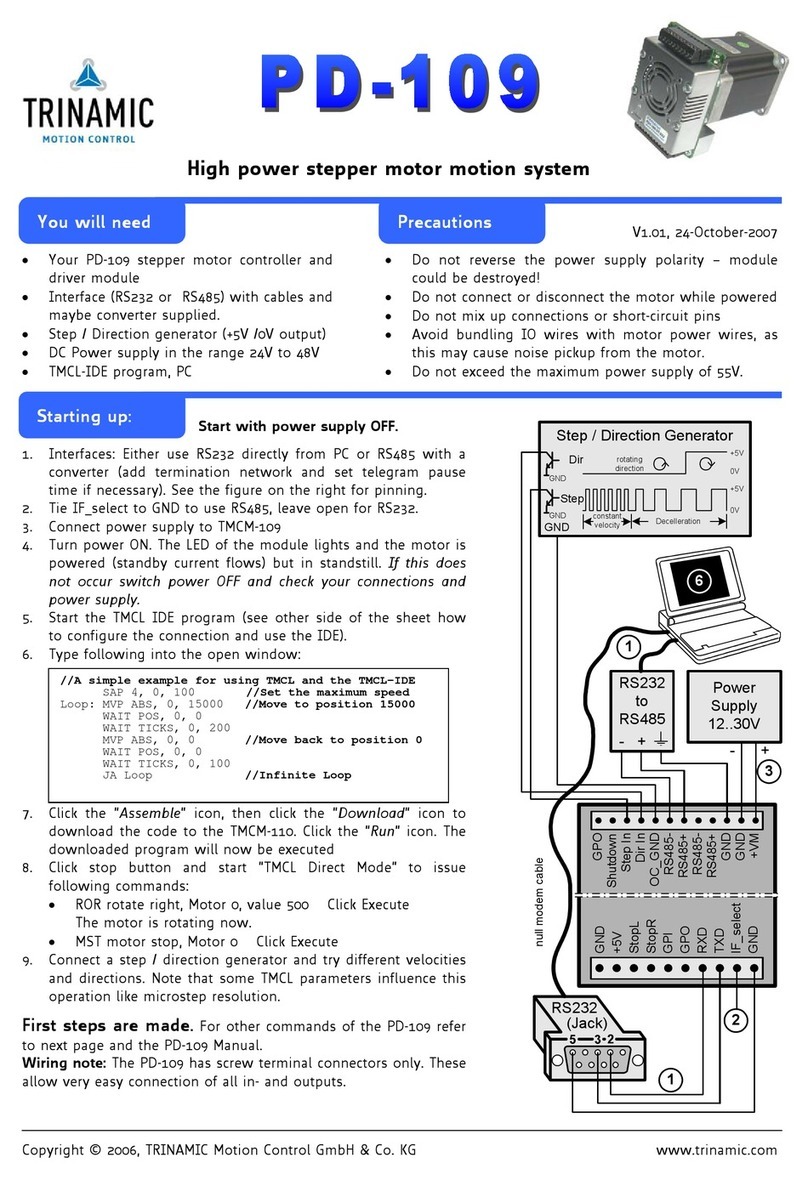

The TMCM-035 is a compact motor driver module for highly dynamic or high torque axis. It can be

combined with the driver-less modules TMCM-100, TMCM-301 or TMCM-302 or with any step / direction

controller. Its small size and low power dissipation, together with the variety of three different

control interfaces, make it an optimum solution for integration on any user board. The board can be

connected to a baseboard or customized electronics with a pin connector. Applications are consumer

and industrial controls, CNC power stages, lab automation, robotics, pick- and place machines

The TMCM-035 drives a two-phase bipolar stepping motor, with a maximum coil current of 5A and a

maximum voltage of 50V. It is based on the TMC239 or TMC249 stepper motor driver chip. The

interface between the control logic and the TMCM-035 module can be either Step / Direction, SPI or an

analogue interface. The maximum motor current can be selected via external inputs. Since the new

Version V2.0 of the board, the module has been extended from maximum 16 to 32 and 64 microsteps.

Applications

Driver module for a highly dynamic or high torque axis

Easy integration through three different control interfaces into any user board

Electrical Data

Up to 3.5A RMS coil current (5A peak)

14V to 50V DC motor supply voltage

5V DC logic supply voltage

Supported motors

two-phase bipolar motors with 0.3A to 3.5A coil current

Interface

Step / Direction input (TTL/CMOS signal)

SPITM interface

Classical analog interface

Highlights

Up 64 times microstepping, since version 2.0 (prev. versions up to 16)

Motor current settings via internal and / or external resistors

Up to 245kHz microstep frequency

TRINAMIC driver technology: No heat sink required

StallGuardTM optional for SPI operation

Standby reduction programmable

“mixed-decay” mode for good microstep performance mode

low EME design for ease of use

Other

68 pin connector carries all signals

RoHS compliant

Size: 80x50mm² (credit card)

Order code

Description

TMCM-035/SG (-option)

1-axis driver 3.5A / 50V with StallGuard

Related products

BB-035, BB-301

Option

-H

horizontal pin connector (standard)

-V

vertical pin connector (on request)

Table 1.1: Order codes

TMCM-035 Manual (V2.09 / February 27th, 2009) 4/18

Copyright © 2007-2009, TRINAMIC Motion Control GmbH & Co. KG

Life support policy

TRINAMIC Motion Control GmbH & Co. KG does not

authorize or warrant any of its products for use in life

support systems, without the specific written consent

of TRINAMIC Motion Control GmbH & Co. KG.

Life support systems are equipment intended to

support or sustain life, and whose failure to perform,

when properly used in accordance with instructions

provided, can be reasonably expected to result in

personal injury or death.

© TRINAMIC Motion Control GmbH & Co. KG 2009

Information given in this data sheet is believed to be

accurate and reliable. However no responsibility is

assumed for the consequences of its use or for any

infringement of patents or other rights of third

parties, which may result form its use.

Specifications are subject to change without notice.

TMCM-035 Manual (V2.09 / February 27th, 2009) 5/18

Copyright © 2007-2009, TRINAMIC Motion Control GmbH & Co. KG

2Electrical and Mechanical Interfacing

2.1 Dimensions

Horizontal

Connector: Header

Connector:

5

2 (PCB)

Note :

all dimensions in mm

6

C

C

2 (PCB)

2

2

68-Pin Connector

436.9

39.1

50

R1.1

46

2.2

4

977

80

77.8

R1.25

3.2

8.20

1.7

since V2.1

Figure 2.1: Dimensions

The size of the module (80x50mm) is the same as of the other Trinamic motion control modules. It

also uses the same connector.

The 68 pin connector has a 2.0mm pitch.

Bord outline changes since TMCM-035 V2.1

second notch (lower one) on each side for other type of plate holder

clearance in the board close to the 64 pin connector to allow easier mounting. The pins of a

horizontal connector are completely free and the opposite part wont abut against the board.

PCB

1

268

67

Figure 2.2: Pin order of the connector

TMCM-035 Manual (V2.09 / February 27th, 2009) 6/18

Copyright © 2007-2009, TRINAMIC Motion Control GmbH & Co. KG

2.2 Connecting the Module

The pin assignments of the connector are as follows:

Pin

Dir.

Description

Pin

Dir.

Description

1

In

+5VDC (+/- 5%) Imax=50mA

2

In

GND

3

In

+5VDC (+/- 5%)

4

In

GND

5

In

V_Motor (+14 to 50VDC)

6

In

GND

7

In

V_Motor (+14 to 50VDC)

8

In

GND

9

In

V_Motor (+14 to 50VDC)

10

In

GND

11

In

ENN (0 = enable driver)

12

In

Step/Dir mode: do not connect

SPI mode: TMC239 CLK signal

Analog mode:TMC239 MDBN signal

13

In

Step/Dir mode: do not connect

SPI mode: TMC239 CSN signal

Analog mode: TMC239 PHB signal

14

Out

Step/Dir mode: do not connect

SPI mode: TMC239 SDO signal

Analog mode: TMC239 ERR signal

15

-

n. c.

16

In

Step/Dir mode: do not connect

SPI mode: TMC239 SDI signal

Analog mode: TMC239 PHA signal

17

In

Reset (active low), leave open

18

In

Step In

19

In

SPE (0 = Analog mode,

1=SPI or Step/Dir mode)

20

In

Dir In

21

In

INA

22

In

SDEN: must be to 1 for Step/Dir

mode or 0 for SPI or Analog mode

23

In

INB

24

In

STEP16: Step/Dir mode only:

1 = 16 resp. 64 microsteps

0 = 8 resp. 32 microsteps

25

In

SPI mode: ANN (INA and INB provide

current reference if 0)

Step/Dir mode: do not connect

Analog Mode: TMC239 MDAN signal

26

In

USEMD: Set to 1 to use mixed decay

in Step/Dir mode

27

In

/STEP64EN: Leave open or tie to +5V

for 8 / 16 microsteps, tie to GND for

32 / 64 microstep resolution

28

In

OSC: leave open or supply external

chopper clock

29

-

n. c.

30

-

n. c.

31

-

n. c.

32

-

n. c.

33

-

n. c.

34

-

n. c.

35

-

n. c.

36

-

n. c.

37

Out

OB2

38

Out

OB2

39

Out

OB2

40

Out

OB2

41

Out

OB1

42

Out

OB1

43

Out

OB1

44

Out

OB1

45

In

RSB2

46

In

RSB2

47

In

RSB1

48

In

RSB1

49

Out

OA2

50

Out

OA2

51

Out

OA2

52

Out

OA2

53

Out

OA1

54

Out

OA1

55

Out

OA1

56

Out

OA1

57

In

RSA2

58

In

RSA2

59

In

RSA1

60

In

RSA1

61

In

GND

62

In

GND

63

-

n. c.

64

-

n. c.

65

-

n. c.

66

-

n. c.

67

-

n. c.

68

-

n. c.

Table 2.1: Pinout 68-Pin Connector

TMCM-035 Manual (V2.09 / February 27th, 2009) 7/18

Copyright © 2007-2009, TRINAMIC Motion Control GmbH & Co. KG

3Operational Ratings

The operational ratings show the intended / the characteristic range for the values and should be

used as design values. In no case shall the maximum values be exceeded.

Symbol

Parameter

Min

Typ

Max

Unit

VS

Power supply

14

50

V

V+5V

+5V DC input (max. 300mA)

4.75

5.0

5.25

V

ICOIL

Motor coil current for sine wave peak

(chopper regulated, adjustable via RSA /

RSB pins and software)

0

0.3 … 5

5

A

fCHOP

Motor chopper frequency

36.8

kHz

IS

Power supply current (per motor)

<< ICOIL

1.4 * ICOIL

A

fSTEP

Step frequency

245

kHz

tSPulse

Step pulse length

0.1

µs

tS2D

Direction hold time

2

µs

tD2S

Direction to step delay

0

µs

VANA

INx analog measurement range

0 ... 3

V

fSPI

SPI clock frequency

2

MHz

TBOARD

Recommended PCB temperature limit

+85

+105

°C

TENV

Environment temperature at rated current

(3.5A RMS), module mounted vertically

without forced cooling

-40

+40

°C

Environment temperature for up to

2.5A RMS, module mounted vertically

without forced cooling

-40

+60

°C

Table 3.1: Operational Ratings

4Functional Description

In Figure 4.1 the main parts of the TMCM-035 module are shown.

TMCM-035

high power

Driver

TMC239

5V DC

15..50V DC

Sequencer Step

Motor

MOSFET

Driver

Stage

SPI

Step/Dir

„classic“ analog

control

Figure 4.1: Main parts of the TMCM-035

TMCM-035 Manual (V2.09 / February 27th, 2009) 8/18

Copyright © 2007-2009, TRINAMIC Motion Control GmbH & Co. KG

4.1 Power Supply

The power supply for the TMCM-035 is 14V to 50V DC. The module is not protected against wrong

polarity. Also a +5VDC supply for module functionality is needed. Please use all listed pins for the

power supply inputs and ground parallel.

4.2 Motor Connection

Connect the motor to the OA and OB pins. Always use all the pins to connect the motor! Connect one

coil of the motor to the OA1 (53, 54, 55, 56) and OA2 (49, 50, 51, 52) pins and the other coil to the

OB1 (41, 42, 43, 44) and OB2 (37, 38, 39, 40) pins. Never connect or disconnect the motor while the

module is under power as this may damage the module.

M

OA1

OA2

OB1

OB2

Figure 4.2: How to connect the motor

4.3 Interfaces

The TMCM-035 has three different interfaces to fit in all applications. There is a SPI interface, a analog

interface and step / direction interface available. The classic analog interface provides very high

microstep resolutions but has compared to the SPI interface a disadvantage of poor diagnostics. SPI

on the other hand has all the diagnostics but is limited to 16x microstep resolution. Refer to 4.6.2 for

the possibility to increase microstep resolution to up to 64x for SPI.

4.3.1 SPI

The SPI interface pins of the connector are directly connected to the SPI pins of the TMC239. So, the

data that must be supplied via the SPI interface can be found in the TMC239 data sheet. The SPI data

can either be generated directly by a microcontroller or by a TMC428. To use the SPI interface you will

have to make the following connections:

Signal name

Pin number

Connection

SPE

19

High (can be left open, SPI enable)

SDEN

22

Connect to GND (to disable Step / Direction interface unit).

SDI

16

Connect to SPI bus

SDO

14

Connect to SPI bus

CSN

13

Connect to SPI bus

CLK

12

Connect to SPI bus

ANN

25

Set high (or leave open) for normal current settings or low to provide

the current reference via the INA and INB inputs (please see section

4.4.1 for details).

/STEP64EN

27

Leave open or connect to +5V to operate in 16 microstep mode, directly

using the 12 bits control shift register of the TMC239/249 (please refer to

the respective manuals)

Connect to GND for 64 microstep mode with 6 bit DAC. In this mode,

the SPI word is extended by an 8 bit shift register (see SPI table in

Figure 4.6).

Table 4.1: SPI interface connections

TMCM-035 Manual (V2.09 / February 27th, 2009) 9/18

Copyright © 2007-2009, TRINAMIC Motion Control GmbH & Co. KG

The SPI interface is mainly to be used to connect the TMCM-035 module to a TMCM-301 module. This

way, up to three TMCM-035 modules can be connected to one TMCM-301 module. The connection for

one module is shown in Table 4.2.

TMCM-035 pin number

TMCM-301 pin number

Signal name (TMCM-035)

1, 3

1, 3

+5V

2, 4, 6, 8, 10

2, 4, 6, 8, 10

GND

11

--

Enable, connect to GND

12

30

CLK

13

20

CSN

14

28

SDO

16

26

SDI

Table 4.2: Connecting a TMCM-035 to a TMCM-301

For operation with microstep resolution of 32 or 64 steps per fullstep refer to 4.6.2 Increasing

Microstep resolution with SPI interface

In SPI mode the LED on the board does not have any function and can be ignored.

4.3.2 Analog

The analog interface is mainly to be used to connect the TMCM-035 to a TMC453 chip or to a TMCM-

100 module (that contains a TMCM453 stepper motor controller chip).

The following pins are to be used in analogue mode:

Signal name

Pin number

Connection

SPE

19

Connect to GND (to enable analog interface unit)

SDEN

22

Connect to GND (to disable Step / Direction interface unit).

Enable

11

Connect to GND to enable or set high to disable the motor driver.

INA

21

Analog input which determines the current of phase A (0..3V).

INB

23

Analogue input which determines the current of phase B (0..3V).

PHA

16

Digital input which determines the polarity of phase A.

PHB

13

Digital input which determines the polarity of phase B.

MDAN

25

Set low to use mixed decay or high to use slow decay on phase A.

MDBN

12

Set low to use mixed decay or high to use slow decay on phase B.

Table 4.3: Analog interface connections

Please see Figure 4.3 for an explanation of the INA/INB/PHA/PHB signals.

Here is how to connect the TMCM-035 module to a TMCM-100 module:

TMCM-035 Manual (V2.09 / February 27th, 2009) 10/18

Copyright © 2007-2009, TRINAMIC Motion Control GmbH & Co. KG

TMCM-035 pin number

TMCM-100 pin number

Signal name (TMCM-035)

1, 3

1, 3

+5V

2, 4, 6, 8, 10

2, 4, 6, 8, 10

GND

19

--

SPE, connect to GND

11

--

Enable, connect to GND

22

--

SDEN, connect to GND

21

39

INA

23

41

INB

16

25

PHA

13

29

PHB

25, 12

--

MDAN/MDBN, connect to GND to use mixed

decay or leave open for slow decay.

Table 4.4: Connecting a TMCM-035 to a TMCM-100 (analog)

Please see section 4.4 for selecting the peak motor current.

In analog mode the LED shows the status of the module:

The LED is on when the motor is enabled and the supply voltage is high enough.

The LED is off when the motor is disabled due to pin 11 (Enable) set high or supply voltage to

low.

The LED flashes when there is an error :

Temperature too high: motor stops until temperature is acceptable (normally a few seconds)

Current too high (short circuit): motor is switched off until short circuit is corrected

Power supply too low for motor: motor is switched off, until power supply is sufficient.

Open load: motor is NOT switched off (occurs when a motor coil circuit is open or sometimes

at high velocities when the motors current limit is reached

90° 180° 270° 360°

INA

INB

PHA

PHB

Figure 4.3: Analog control

TMCM-035 Manual (V2.09 / February 27th, 2009) 11/18

Copyright © 2007-2009, TRINAMIC Motion Control GmbH & Co. KG

4.3.3 Step / Direction

To use the Step / Direction interface connect the inputs as follows:

Signal name

Pin number

Connection

SPE

19

high (+5V, can be left open alternatively)

SDEN

22

high (+5V, can be left open alternatively) , step / direction enable

STEP16

24

high for 16, low for 8 microsteps (STEP64EN is high)

high for 64, low for 32 microsteps (STEP64EN is low)

STEP64EN

27

high (can be left open) for 8/16 microsteps, low for 32/64 microsteps

available since version 2.0

USEMD

26

Set high (or leave open) to use mixed decay (recommended for most

applications), or low to use slow decay.

Step In

18

Connect your step signal here. The rising edge of the signal is a step

pulse.

Direction In

20

Connect your direction signal here.

ANN

25

Do not connect!

Table 4.5: Step / Direction interface connections

Note: Pins 12, 13, 14, 16 and 25 must not be connected in this mode!

The Step / Direction interface can also be used to connect the TMCM-035 module to a TMCM-100

module (however it results in a higher microstep resolution, if the analogue interface is used with the

TMCM-100). Here is how to do it:

TMCM-035 pin number

TMCM-100 pin number

Signal name (TMCM-035)

1, 3

1, 3

+5V

2, 4, 6, 8, 10

2, 4, 6, 8, 10

GND

11

--

Enable, connect to GND

18

20

STEP

20

19

DIR

Table 4.6: Connecting a TMCM-035 to a TMCM-100 (step / direction)

In step / direction mode the LED shows the status of the module:

The LED is on when the motor is enabled and the supply voltage is high enough.

The LED is off when the motor is disabled due to pin 11 (Enable) set high or supply voltage to

low.

The LED flashes when there is an error (please refer to chapter 4.3.2 for more information).

Step-Direction signal timing:

Step pulse

Direction

th tl

tS2D tD2S

2 steps CW CCW step

step

Figure 4.4: Step / Direction signal timing

Min

TS2D

2 µs

TD2S

0 µs

th

0.1µs

TMCM-035 Manual (V2.09 / February 27th, 2009) 12/18

Copyright © 2007-2009, TRINAMIC Motion Control GmbH & Co. KG

4.4 Current setting

The motor current setting can be selected by connecting the RSA and RSB pins to GND as shown in

the following table.

Note: In step-/direction mode the motor is without current until the first step impulse is given. The

same applies after a disable/enable cycle.

Caution: Never leave both, RSA/B1 and RSA/B2 pins, open!

peak coil current

RMS current

(microstep operation)

RSA1, RSB1

RSA2, RSB2

1.5 A

1 A

GND

open

3.4 A

2.5 A

open

GND

5.0 A

3.5 A

GND

GND

variable

peak current / 1.41

(external resistor from RSA/RSB to GND)

Table 4.7: Current setting

4.4.1 Fine current adjustment in SPI mode:

In SPI mode, the current values set via the sense resistors can be modified using the analog inputs

INA and INB. In this case the ANN input (pin 25) must be pulled low. The INA and INB inputs

supporting a voltage range of 0 to 3V can be used. Use a simple voltage divider on the 5V supply to

accomplish this, e.g. a 10K Potentiometer. A value of 2V corresponds to the currents given in the

table, i.e.

Current set value = (Value from Table 4.7) * (INA/INB-Voltage) / 2V

Please be careful with values of INA/INB > 2V since the maximum current of the module can be

exceeded (150% at 3V).

In 64 microstep mode the current adjustment via the analog inputs is limited. The voltage on INA and

INB should not exceed the range from 1.5 to 2.5 V in your application.

Following exemplary R/C filter gives an analog voltage range of about 0 to 2.1V.

Pin 2

Pin 30

Pin 32

Pin 34

Pin 36

Pin 38

Pin 40

Pin 68

TMCM-301

31

33

35

M

GND: Pin 2, 4, 6, 8

5V : Pin 1, 3

TMC249 /

TMCM-035

INB

OUTA1

OUTA2

OUTB1

OUTB2

PWM

47k

47k

470nF

INA

GND

GND

ANN

Figure 4.5: Application example for a TMCM-035 and TMCM-301 with analog current control

TMCM-035 Manual (V2.09 / February 27th, 2009) 13/18

Copyright © 2007-2009, TRINAMIC Motion Control GmbH & Co. KG

Another way of setting a different peak coil current is to connect the RSA pins to GND via an external

resistor and the RSB pin via the same size of resistor. The two resistors should be in the range

100mOhms to 1 Ohm. This possibility can also be used when the module is connected via its

analogue interface. However it is very important to use SMD resistors with low inductivity and very

short traces to GND for a stable operation in this configuration.

peak coil current

RMS current

(microstep operation)

RSA1, RSB1

RSA2, RSB2

1.0 A

0.7 A

open

each 0.22 R to GND

1.2 A

0.85 A

each 0.18R to GND

open

1.7 A

1.2 A

GND

each 1.5R to GND

2.1 A

1.5 A

GND

each 0.47R to GND

2.8 A

2.0 A

GND

each 0.15R to GND

4.2 A

3.0 A

each 0.27R to GND

GND

Table 4.8: Current fine adjustment with RSA and RSB

4.4.2 Standby current reduction for Step-/ Direction mode

In step / direction interface mode, the current control will switch to the INA and INB inputs when

there has been no step pulse for at least four seconds. Current control will switch back to the normal

value set via RSA/RSB pins when the next step pulse occurs. This way the standby current can be set

using the INA and INB pins (by applying a voltage between 0 (0%) and 2V (100%). The maximum

current while the motor is running must be set using the RSA/RSB pins.

The coil current should be reduced when the motor is standing still!

Power down current set value = Value from Table 4.7 * (INA/INB-Voltage) / 2V

4.4.3 Continuous Current restrictions / Thermal conditions

The module is designed as a microstepping module, with sine wave currents (sine and cosine) driving

both coils. The current peak of the sine wave can be as high as 5A, when the RMS current is set to

3.5A. The mean motor current (RMS) is calculated by dividing the peak current by 1.41.

The compact design of the module does not allow to continuously drive the full current unless forced

air cooling is used to keep the board temperature below 85°C, because of excessive heat generation.

On a short term basis, the board is allowed to reach 105°C, but it will shorten life time, if this occurs

in longer periods. However, since continuous maximum current operation also shortens the lifetime of

the motor, this is in most cases no restriction. The driver transistors on the module (8 transistors

labeled “4450” or similar) may heat up to 120°C at their surface - this is not critical!

The module provides a thermal protection, but this is only meant as a means against sudden

destruction, i.e. when a cooling blower fails and the module slowly overheats. The protection is not

meant to limit normal operation! It can not protect against all faults, since it is central in the TMC249

IC, and might react too slowly!

The following limits apply:

Maximum environment temperature for up to 3.5A RMS (= 5A peak) is 40°C, module mounted

vertically

Maximum environment temperature for up to 2.5A RMS (= 3.5A peak) is 60°C, module mounted

vertically

If the module is mounted horizontally, use forced air flow for current above 2.0A RMS.

The phase current should be reduced to a maximum of 70% of the above values while the motor

is standing

TMCM-035 Manual (V2.09 / February 27th, 2009) 14/18

Copyright © 2007-2009, TRINAMIC Motion Control GmbH & Co. KG

Maximum current for fullstep operation (both coils on) is 3.5A (peak value for fullstep is identical

to RMS value!)

For continuous operation above 2.5A RMS a forced cooling is mandatory. The module should not

be mounted in a horizontal position for continuous operation with coil currents above 2.5A RMS.

At a reduced supply voltage, heating will be less. The actual heat dissipation also depends on

the motor!

If the module will be operated near to these limits for extended periods of time, a measurement of

the board temperature in the final application / housing should be done in order to make sure, that

life time is not reduced by module operation near to / above the temperature limits.

4.5 Mixed decay and slow decay

When using the step / direction interface it is possible to switch to mixed decay by setting the USEMD

pin (pin 26) high or to switch to slow decay by pulling the USEMD pin low. When using the analogue

mode use the MDAN and MDBN pins to select between mixed decay and slow decay (pull

MDAN/MDBN low to use mixed decay). When using the SPI interface the mixed decay feature is

controlled by bit 11 and bit 5 of the SPI telegram (please see [TMC239] datasheet for details about the

structure of the SPI telegram).

The mixed decay setting especially at rotation velocities in the range of a few 10 steps per seconds to

several 100 steps per second improves motor behavior (less resonance). However, the actual

performance depends on the motor and mechanics. For supply voltages above 24V and for low

inductivity motors, best microstep behavior is reached when mixed decay setting is continuously on.

Mixed decay should be switched off when StallGuard operational in order to get usable results.

4.6 Microstep resolution adjustments

Step / direction and analog interface support high microstep resolutions. SPI is restricted to 16x

microstepping without external hardware additions described in [TMC236/239/246/249 FAQ] (Extending

the microstep resolution). Since hardware version V2.0 a 64 microstep resolution is possible without

additional hardware, refer to 4.6.2.

4.6.1 Microstep resolution with step / direction interface

When using the step / direction interface it is possible to select the microstep resolution of 8, 16, 32

or 64 microsteps per fullstep. The resolution is since hardware version 2.0 (some labeled TMCM-035 D)

pre-selected with Pin 27 “STEP64EN”. Pin 27 set high or left open selects low resolutions (8 or 16

microsteps), Pin 27 set low (to GND) selects high resolutions (32 or 64 microsteps). The final selection

has to be done by pin 24 “STEP16”, set high or left open the microstep resolution is either 16 or 64

depending on the setting of pin 27. Set low the microstep resolution is either 8 or 32. In former

hardware versions pin 24 sets the TMCM-035 to 8 or 16 microsteps only, and pin 27 has no function.

4.6.2 Increasing Microstep resolution with SPI interface

Even the 16 microstep version of the TMCM-035 can realize more than 16 microsteps via TMC428 SPI

control: Just program the TMC428 for 32 microstep mode. Due to the combination of two DACs driving

the two coils, this results in a resolution somewhere between 20 and 30 microsteps.

TMCM-035 Manual (V2.09 / February 27th, 2009) 15/18

Copyright © 2007-2009, TRINAMIC Motion Control GmbH & Co. KG

4.6.3 64 Microstep resolution with SPI interface since TMCM-035 V2.0

To get full 64 microsteps using the TMC428 with a user built electronics, please refer to the schematic

example in [TMC239] or [TMC249] and [TMC236/239/246/249 FAQ] (Extending the microstep resolution).

Please remark, that the lower two bits are inverted, and the values from 0 to 3 give a zero current.

This effectively results in a 60 level current resolution. A suitable microstep table is printed below.

The effect of this modified DAC behaviour is, that the TMC428 ramp-phase-dependent current scaling

function does not lead to a good result and should not be used! This could be improved by inverting

the additional DAC-Bits. Please be aware, that the module in 64 microstep mode can not be included

in SPI busses with multiple /CS lines.

For best microstep performance run the motors with mixed decay switched on continuously and

36kHz chopper.

To program the TMCM-035 for 64 microstep mode the pins 24 and 27 are used (refer to 4.6.1). It is

important to load the proper wave table as well as the proper SPI configuration. Both are available

on the TRINAMIC technical library. The following table depicts the SPI bit ordering. The bits are to be

shifted into the SPI chain from left (19) to right (0). The function of the bits is described in the

TMC239 / TMC249 manual and FAQ document.

Standard

function

Bit 12

TMC239 control word Additional 8 bits in 64 microstep mode

CB5

(MSB)

11

CB4

10

CB3

9

CB2

8

PHB

13

MXB

18

CA5

(MSB)

17

CA4

16

CA3

15

CA2

14

PHB

19

MXA

7

/CB1

6

/CB0

5

/CA1

4

/CA0

3

-

2

-

1

-

0

-

Figure 4.6: SPI word assignment in 64 microstep mode

Required TMC428 driver chain configuration for each TMCM-035 in 64 microstep mode:

0x11,0x05,0x04,0x03,0x02,0x06,0x11,0x0d,0x0c,0x0b,0x0a,0x0e,0x09,0x08,0x01,0x00,

0x10,0x10,0x10,0x30 // 4 unused bytes, last plus next motor bit

The suitable microstep table for 32 and 64 microstep with inverted LSBs (1/4 wave, like in TMC428):

0x00,0x07,0x05,0x04,0x0a,0x09,0x0f,0x0e,0x0c,0x13,0x11,0x10,0x17,0x15,0x14,0x1a,

0x19,0x18,0x1e,0x1d,0x1c,0x22,0x21,0x20,0x27,0x25,0x24,0x2b,0x2a,0x29,0x28,0x2f,

0x2e,0x2d,0x2c,0x33,0x32,0x31,0x30,0x37,0x36,0x35,0x35,0x34,0x3b,0x3a,0x3a,0x39,

0x39,0x38,0x38,0x3f,0x3f,0x3e,0x3e,0x3d,0x3d,0x3d,0x3d,0x3d,0x3c,0x3c,0x3c,0x3c

Since the wave table is modified (lower two bits, bit 0 and bit 1, are inverted), the current scaling

function of the TMC428 (IS_AGTAT, IS_ALEAT, IS_V0) should be switched off, i.e. these registers should

be set to zero (full current).

Hint for operation with TMC428 based controllers: The needs to read back the TMC249 bits for

operation of the StallGuard or for driver diagnostics. While the TMC428 can control driver chains with

up to 64 bits, it can read back a total of 48 bits only. Thus, when cascading three TMCM-035 in one

TMC428 driver chain and all modules are set to 64 microstep mode, the first 12 bits sent back from

the 60 bit long driver chain to the TMC428 can not be read back. These are all bits from the last

TMC249 in the chain, including its StallGuard bits. Thus, you should attach only two TMCM-035 in 64

microstep mode to a TMC428 based module. This brings also an advantage for the reachable motor

velocity. If you need all StallGuard bits in a three driver chain, switch at least two modules in the

chain to 16 microstep mode.

TMCM-035 Manual (V2.09 / February 27th, 2009) 16/18

Copyright © 2007-2009, TRINAMIC Motion Control GmbH & Co. KG

Example: Up to three TMCM-035 with 64 microsteps in use with a TMCM-301

Pin 2

Pin 20

Pin 22

Pin 24

Pin 26

Pin 28

Pin 30

Pin 68

TMCM-301

GND: Pin 2, 4, 6, 8

5V : Pin 1, 3

M

CSN

SDO

SDI

SCK

OUTA1

OUTA2

OUTB1

OUTB2

M

CSN

SDO

SDI

SCK

OUTA1

OUTA2

OUTB1

OUTB2

M

CSN

SDO

SDI

SCK

OUTA1

OUTA2

OUTB1

OUTB2

TMC249

TMC249

TMC249

3x TMCM-035 driver

Figure 4.7: Application with 3 TMCM-035 controlled by a TMCM-301

The microstep configuration of the three TMCM-035 drivers (digital pins 24 and 27) can be controlled

by the I/O ports of the TMCM-301, so that each driver is configured directly.

Fill in the Driver Chain and set global parameters according to Figure 4.8. CS_COMM_IND has to be

deactivated for cascaded TMCM-035 modules. LSMD defines the number of motors used (2 for 3

motors). After loading or filling in the driver chain press “Set” to program the TMCM-301.

TMCM-035 Manual (V2.09 / February 27th, 2009) 17/18

Copyright © 2007-2009, TRINAMIC Motion Control GmbH & Co. KG

Figure 4.8: Driver chain configuration for up to 3 TMCM-035 in use with TMCM-301

Now it is time to program the TMCM-301 with the following microstep table (Figure 4.9) by pressing

“Set”. Please use the 64 microstep table to get the smoothest operation.

Figure 4.9: Microstep table for 64 microsteps in use with TMCM-301

Mixed decay has to be switched on constantly, SAP 203 has to be set to 2048 for all used motors. This

values can be saved with STAP 203 to the EEPROM of the TMCM-301 for each motor.

TMCM-035 Manual (V2.09 / February 27th, 2009) 18/18

Copyright © 2007-2009, TRINAMIC Motion Control GmbH & Co. KG

5Hardware Revision

Version

Since

Description

1.0

2003

Initial version

2.0

Mar.2006

Labelled TMCM-035-D V1.0.

The module has been extended from maximum 16 to 32 and 64 microsteps

New function of connector pin 27 (activates 64 microsteps)

2.1

Jan 2007

Bord outline changes (please refer to 2.1):

second notch on each side for other type of plate holder

clearance close to the 64 pin connector to allow easier mounting.

Table 5.1: Hardware revision

6Documentation Revision

Version

Date

Author

Description

1.00

08-Jan-04

OK

Initial version

1.01

20-Apr-04

OK

Minor error corrections

1.02

01-Oct-04

OK

Address corrected

1.03

28-Oct-04

BD

Maximum step rate increased

1.04

13-Feb-04

OK

Ordering information added

2.00

20-Jun-06

BD

64 microstep version info added

2.01

14-Jul-06

HC

Major revision

2.02

21-Aug-06

HC

Additions to 64 microstep version info

2.03

29-Nov-06

BD

Comments on maximum component temperature

2.04

10-Jan-07

HC

Addition to 4.4; step-/Dir: motor currentless before first step

2.05

21-Feb-07

HC

Added 2.0mm pitch connector info

2.06

25-May-07

HC

Hardware revision and new dimensions for version 2.1 added

2.07

13-Jun-07

HC

Additions to 4.4.1 Fine current adjustment in SPI mode:

2.08

28-Nov-07

HC

Additions to errors indicated by LED in analog mode (4.3.2)

2.09

27-Feb-09

OK

Step/Dir connections (Table 4.5) corrected

Table 6.1: Documentation Revisions

7References

[TMC239] TMC239 manual (see http://www.trinamic.com)

[TMC249] TMC249 manual (see http://www.trinamic.com)

[TMC236/239/246/249 FAQ] TMC239/249 FAQ (see http://www.trinamic.com)

[TMCM-301] TMCM-301 manual (see http://www.trinamic.com)

[TMCM-100] TMCM-100 manual (see http://www.trinamic.com)

Table of contents

Other Trinamic Computer Hardware manuals

Trinamic

Trinamic TMCM-101 User manual

Trinamic

Trinamic TMCM-1633 User manual

Trinamic

Trinamic TMCL TMCM-142 Use and care manual

Trinamic

Trinamic PD 108-28-SE-485 Series User manual

Trinamic

Trinamic CANopen User manual

Trinamic

Trinamic PANdrive PD42-1- 1243-IOLINK Safety guide

Trinamic

Trinamic BB-100 User manual

Trinamic

Trinamic PD-109 User manual

Trinamic

Trinamic TMCM-1316 StepRocker User manual

Trinamic

Trinamic TMCM-351 Use and care manual