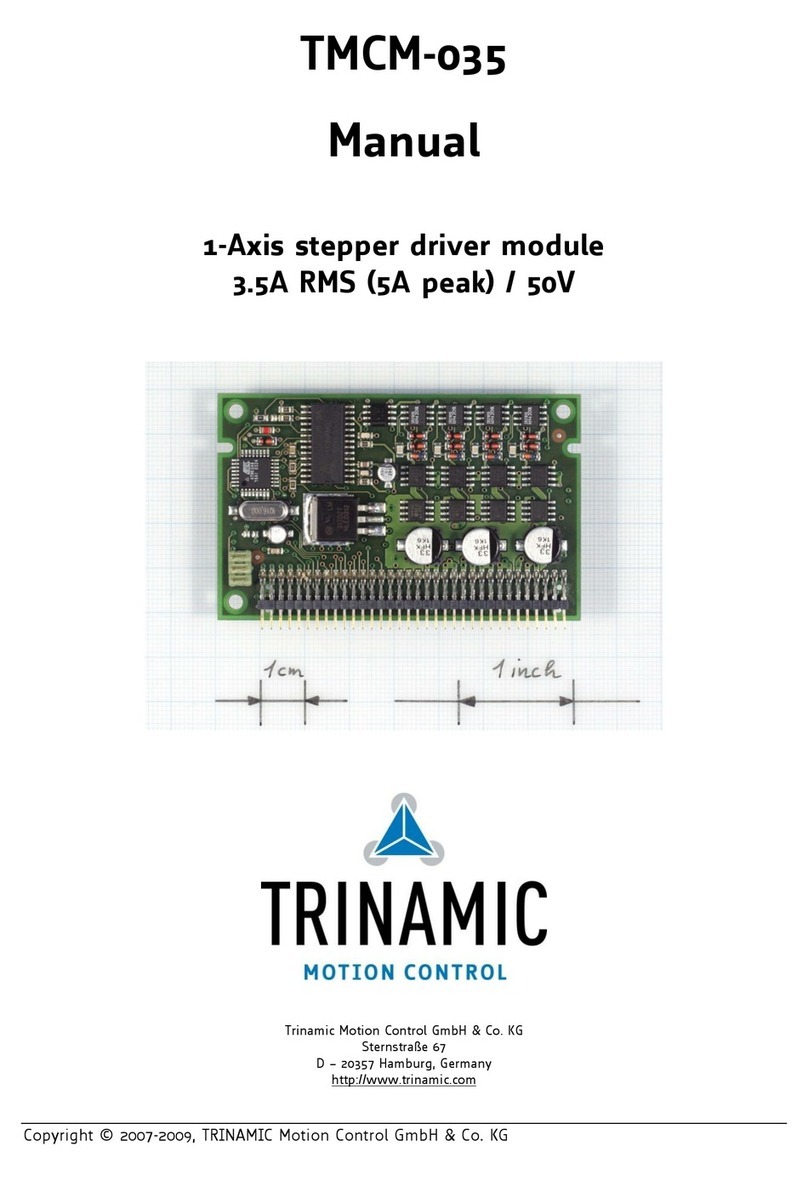

Trinamic TMCM-351 User manual

TMCM-351 Manual (V1.01 / May 25nd, 2009) 2

Copyright © 2008, TRINAMIC Motion Control GmbH & Co. KG

Table of Contents

1Life support policy ....................................................................................................................................................... 3

2Features........................................................................................................................................................................... 4

3Order codes.................................................................................................................................................................... 5

4Mechanical and Electrical Interfacing ..................................................................................................................... 6

4.1 Board size and mounting holes...................................................................................................................... 6

4.2 Connectors............................................................................................................................................................. 7

4.2.1 Power connector............................................................................................................................................ 8

4.2.2 Motor connector............................................................................................................................................. 8

4.2.3 Reference connector ..................................................................................................................................... 9

4.2.4 Analogue input connector .......................................................................................................................... 9

4.2.5 USB connector ..............................................................................................................................................10

4.2.6 RS232 connector ..........................................................................................................................................10

4.2.7 CAN connector..............................................................................................................................................10

4.2.8 RS485 connector ..........................................................................................................................................11

4.2.9 SPI connector ............................................................................................................................................... 11

4.2.10 I/O connector................................................................................................................................................11

4.2.11 Encoder_0/1/2 connector ...........................................................................................................................12

4.3 Jumpers.................................................................................................................................................................13

4.3.1 J1: RS485 bus termination.........................................................................................................................13

4.3.2 J2: RS232 / RS485 interface selection.....................................................................................................13

4.3.3 J3: CAN bus termination ............................................................................................................................13

4.3.4 J4 –J12: Encoder input termination.......................................................................................................13

5Operational Ratings ...................................................................................................................................................14

6Revision History ..........................................................................................................................................................15

6.1 Document Revision ...........................................................................................................................................15

6.2 Hardware Revision ............................................................................................................................................15

TMCM-351 Manual (V1.01 / May 25nd, 2009) 3

Copyright © 2008, TRINAMIC Motion Control GmbH & Co. KG

1Life support policy

TRINAMIC Motion Control GmbH & Co. KG does not

authorize or warrant any of its products for use in life

support systems, without the specific written consent of

TRINAMIC Motion Control GmbH & Co. KG.

Life support systems are equipment intended to support or

sustain life, and whose failure to perform, when properly

used in accordance with instructions provided, can be

reasonably expected to result in personal injury or death.

© TRINAMIC Motion Control GmbH & Co. KG 2005

Information given in this data sheet is believed to be

accurate and reliable. However no responsibility is assumed

for the consequences of its use nor for any infringement of

patents or other rights of third parties, which may result

form its use.

Specifications subject to change without notice.

TMCM-351 Manual (V1.01 / May 25nd, 2009) 4

Copyright © 2008, TRINAMIC Motion Control GmbH & Co. KG

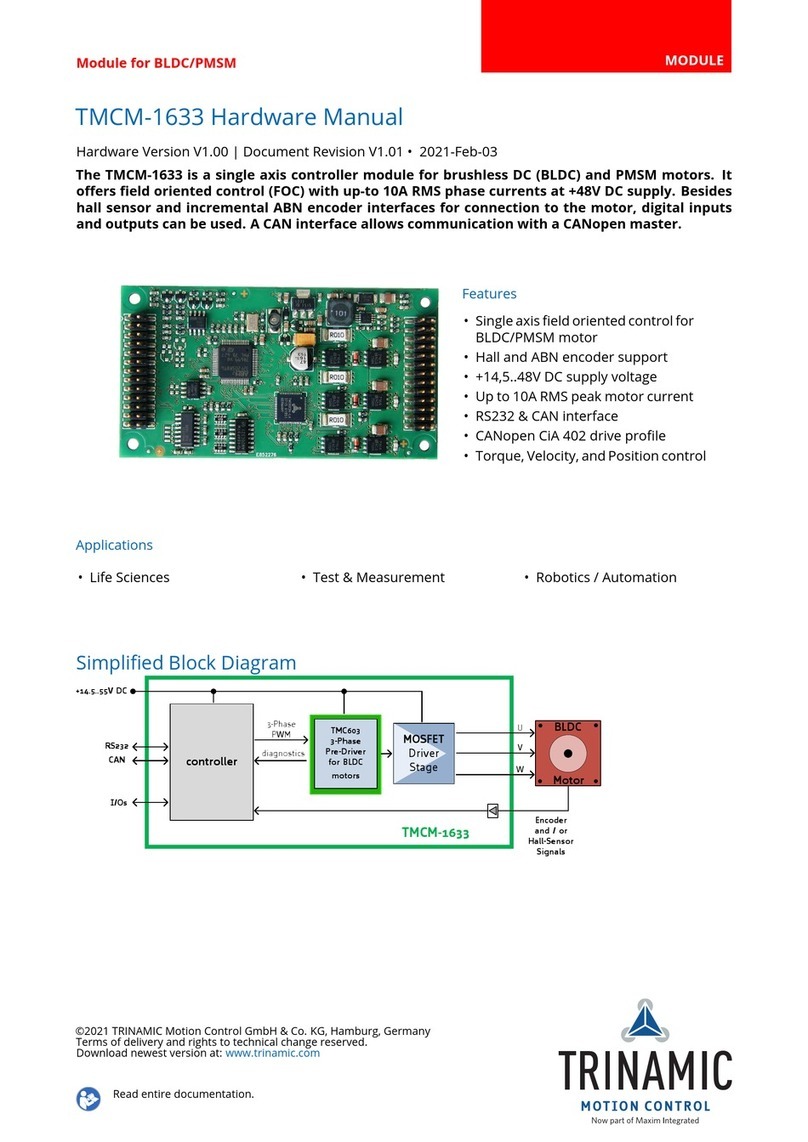

2Features

The TMCM-351 is a powerful three axes bipolar stepper motor controller / driver board with optional encoder

interface for all three axes and a large number of general purpose digital and analogue input / outputs.

Several different serial communication interfaces are available.

Electrical data

Supply voltage: +24V DC nominal (28.5V DC max.)

Motor current: up-to 2.8A RMS per axis (programmable)

Stepper motor data

two phase bipolar stepper motors with up-to 2.8A RMS coil current

optional incremental encoder interface (a/b/n), accepts differential or single ended input signals

Interfaces

2 reference switch inputs per motor axis (6 altogether, internal pull-up resistors, +24V compatible)

8 general purpose inputs (+24V compatible)

8 general purpose outputs incl. two power outputs (all open-collector)

1 shutdown input (enable / disable driver stage in hardware)

4 dedicated analogue inputs (programmable 3.3V / 10V input range)

SPI connector with three chip select signals for I/O extension

RS-232, RS-485, CAN and USB serial communication interfaces

Features

High-efficient operation, low power-dissipation (TMC249 stepper driver with external MOSFETs)

Dynamic current control

Integrated Protection

On the fly alteration of motor parameters (e.g. position, velocity, acceleration)

Motion profile calculation in real-time (TMC428 motion controller)

Each axis individually and independently programmable

Supports up-to 64 microsteps per fullstep

Integrated stallGuardTM for motor stall detection (e.g. elimination of end switches)

Closed-loop operation with TMCL possible (when using the optional incremental encoder interface)

Software

TMCL remote (direct mode) or stand-alone operation (memory for 2048 TMCL commands)

Fully supported by TMCL-IDE (PC based integrated development environment)

Optional CANopen firmware

TMCM-351 Manual (V1.01 / May 25nd, 2009) 5

Copyright © 2008, TRINAMIC Motion Control GmbH & Co. KG

3Order codes

The TMCM-351 is available with optional encoder interface and with standard TMCL firmware or CANopen

firmware:

Order code

Description

Dimensions [mm2]

TMCM-351

TMCM-351 without encoder interface with TMCL firmware

160mm x 100mm

TMCM-351-CANopen

TMCM-351 without encoder interface with CANopen firmware

160mm x 100mm

TMCM-351-E

TMCM-351 with encoder interface and TMCL firmware

160mm x 100mm

TMCM-351-E-CANopen

TMCM-351 with encoder interface and CANopen firmware

160mm x 100mm

Table 3.1: Order codes

TMCM-351 Manual (V1.01 / May 25nd, 2009) 6

Copyright © 2008, TRINAMIC Motion Control GmbH & Co. KG

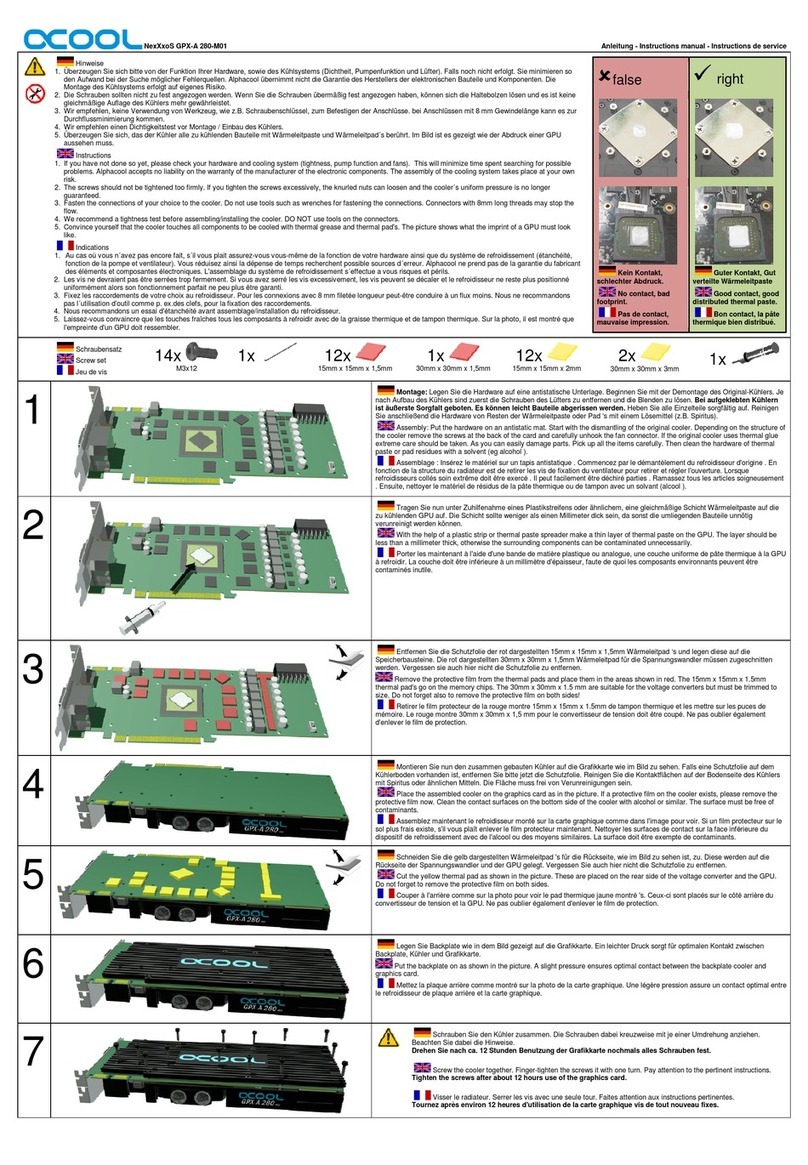

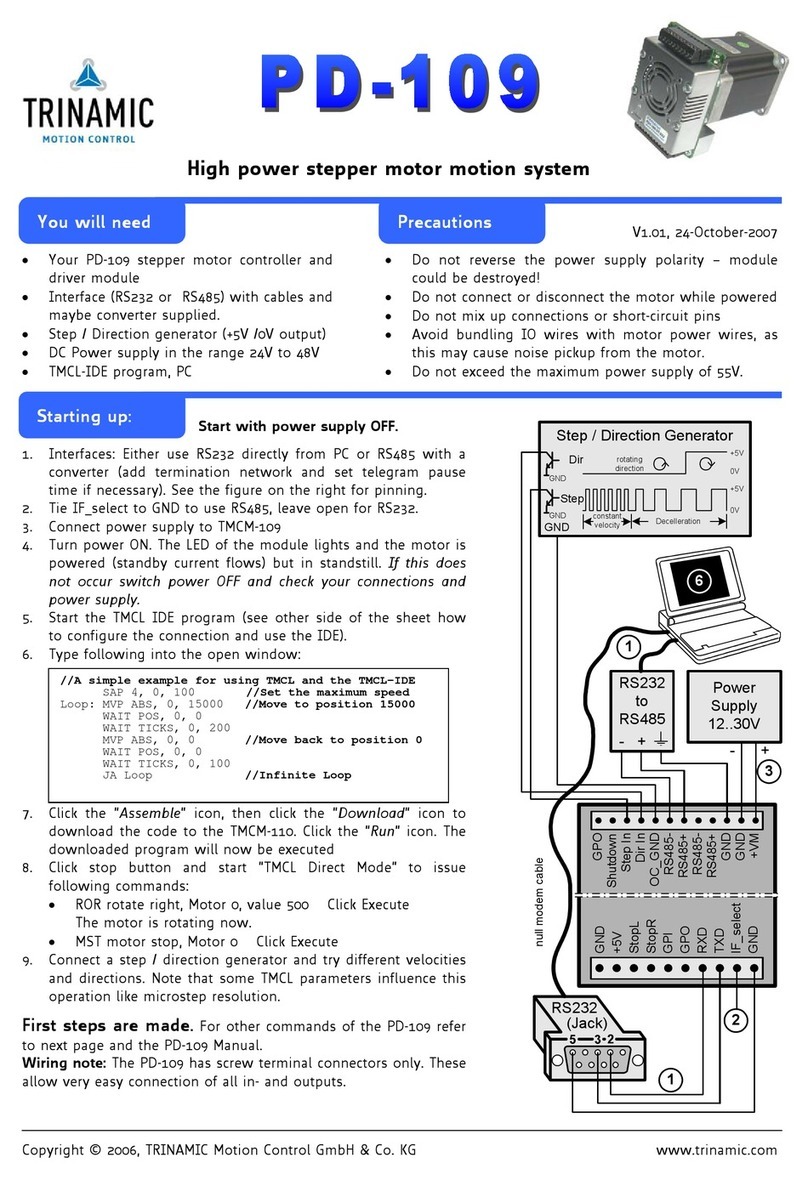

4Mechanical and Electrical Interfacing

4.1 Board size and mounting holes

The TMCM-351 three axes controller driver board has a board size of 160mm x 100mm (standard euro board

format). There are four mounting holes altogether for M3 screws placed at a distance of 4mm from each

corner of the board (Figure 4.1).

4mm

4mm

160mm

100mm

4mm

4mm

4mm

4mm

4mm

4mm

R3.2mm R3.2mm

R3.2mm

R3.2mm

Figure 4.1 TMCM-351 controller / driver board

TMCM-351 Manual (V1.01 / May 25nd, 2009) 7

Copyright © 2008, TRINAMIC Motion Control GmbH & Co. KG

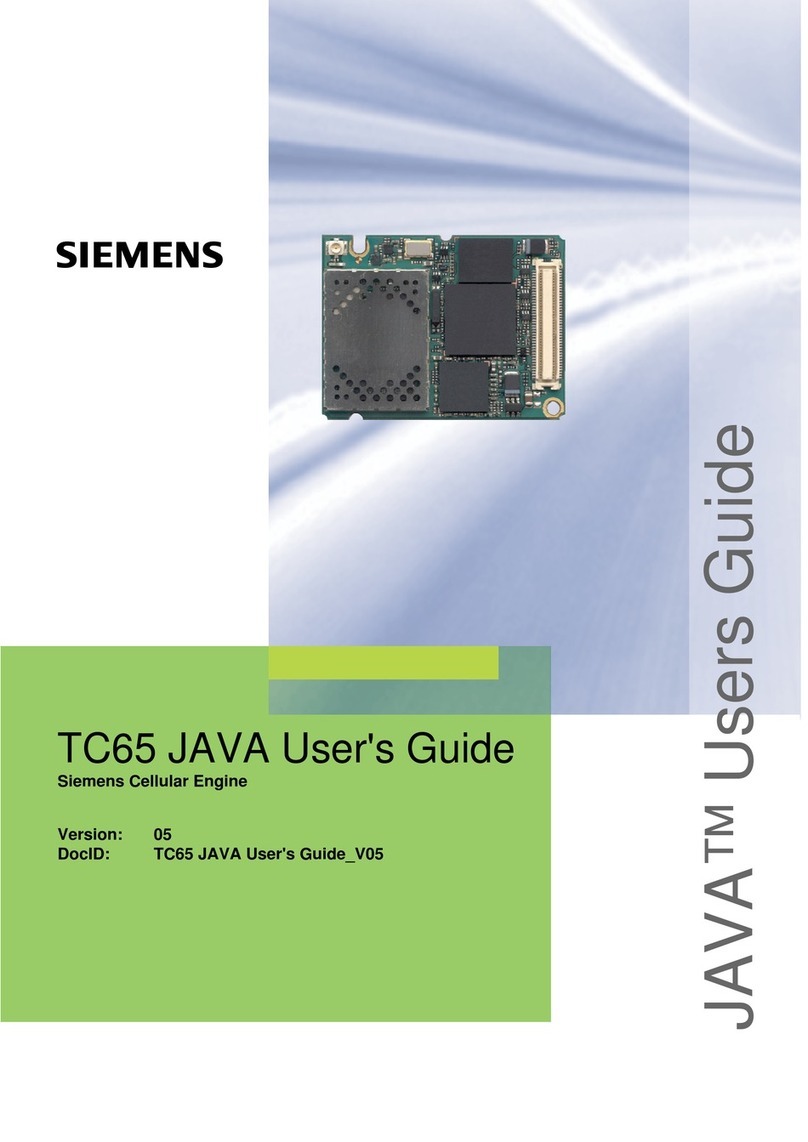

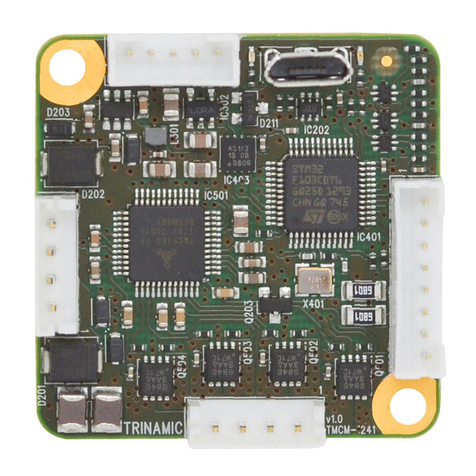

4.2 Connectors

The TMCM-351 has connectors for three motors, related reference switches, three encoders (only with

encoder option), analogue and digital inputs and outputs and several serial interfaces (RS232, RS485, CAN

and USB).

Analog input 0 / 1

connector

Encoder_0

connector

Encoder_1

connector

Encoder_2

connector

I/O

connector

SPI

connector

CAN

connector

RS232

connector

USB

connector

Reference

connector

Motor

connector

Power

connector

RS485

connector

J1: RS485 bus termination

J2: RS232 / RS485 selection

J3: CAN bus termination

Analog input 2 / 3

connector

J4 - J12: Encoder input termination

Figure 4.2 TMCM-351 connectors

TMCM-351 Manual (V1.01 / May 25nd, 2009) 8

Copyright © 2008, TRINAMIC Motion Control GmbH & Co. KG

4.2.1 Power connector

A 2-pin detachable screw connector is used for power supply.

12

Pin

Label

Description

1

GND

Module ground (power supply and signal ground)

2

VDD

Power supply input, nom. +24V DC (+7 .. +28.5V DC)

Table 4.1: Power connector

4.2.2 Motor connector

For the three motors there are two connector options: either one detachable screw connector (for

prototyping, smaller series) or three separate crimp connectors (for higher volume series).

112

Pin

Label

Description

1

Motor_0_B-

Motor 0, coil B

2

Motor_0_B+

Motor 0, coil B

3

Motor_0_A-

Motor 0, coil A

4

Motor_0_A+

Motor 0, coil A

5

Motor_1_B-

Motor 1, coil B

6

Motor_1_B+

Motor 1, coil B

7

Motor_1_A-

Motor 1, coil A

8

Motor_1_A+

Motor 1, coil A

9

Motor_2_B-

Motor 2, coil B

10

Motor_2_B+

Motor 2, coil B

11

Motor_2_A-

Motor 2, coil A

12

Motor_2_A+

Motor 2, coil A

Table 4.2: Motor connector (detachable screw connector)

1 4

Pin

Label

Description

1

Motor_0/1/2_B-

Motor 0/1/2, coil B

2

Motor_0/1/2_B+

Motor 0/1/2, coil B

3

Motor_0/1/2_A-

Motor 0/1/2, coil A

4

Motor_0/1/2_A+

Motor 0/1/2, coil A

Table 4.3: Motor connector (crimp connector)

TMCM-351 Manual (V1.01 / May 25nd, 2009) 9

Copyright © 2008, TRINAMIC Motion Control GmbH & Co. KG

4.2.3 Reference connector

For the reference switch inputs (two reference switch inputs are supported for each motor) there are two

connector options: either one detachable screw connector (for prototyping, smaller series) or three separate

crimp connectors (for higher volume series).

112

Pin

Label

Description

1

REF_0_R

Motor 0, right reference / stop switch input

2

REF_0_L

Motor 0, left reference / stop switch input

3

GND

System / module ground

4

+5V

+5V supply output for active switches

5

REF_1_R

Motor 1, right reference / stop switch input

6

REF_1_L

Motor 1, left reference / stop switch input

7

GND

System / module ground

8

+5V

+5V supply output for active switches

9

REF_2_R

Motor 1, right reference / stop switch input

10

REF_2_L

Motor 1, left reference / stop switch input

11

GND

System / module ground

12

+5V

+5V supply output for active switches

Table 4.4: Reference connector (detachable screw connector)

1 4

Pin

Label

Description

1

REF_0/1/2_R

Motor 0/1/2, right reference / stop switch input

2

REF_0/1/2_L

Motor 0/1/2, left reference / stop switch input

3

GND

System / module ground

4

+5V

+5V supply output for active switches

Table 4.5: Reference connector (crimp connector)

4.2.4 Analogue input connector

The board has four dedicated analogue inputs with programmable input range (either 0..+3.3V or 0..+10V).

There are two connectors with two analogue inputs connected to each connector

1 4

Pin

Label

Description

1

Analogue_0/2

Analogue input 0 / 2

2

GND

System / module ground

3

Analogue_1/3

Analogue input 1/3

4

GND

System / module ground

Table 4.6: Analogue input connector

TMCM-351 Manual (V1.01 / May 25nd, 2009) 10

Copyright © 2008, TRINAMIC Motion Control GmbH & Co. KG

4.2.5 USB connector

The board includes a USB interface for serial communication. A standard USB type B connector is used for

this purpose. USB is one out of four different interfaces available for communication with the board.

1

2

4

3

Pin

Label

Description

1

+5V

Board is self-powered –just use to detect availability

of attached host system (e.g. PC)

2

USB-

Differential USB bus

3

USB+

Differential USB bus

4

GND

System / module ground

Table 4.7: USB connector

4.2.6 RS232 connector

The board includes an RS232 interface for serial communication. A standard DSUB 9-pin female connector is

used for this purpose. RS232 is one out of four different interfaces available for communication with the

board.

5 1

9 6

Pin

Label

Description

2

RS232_TxD

RS232 transmit serial data

3

RS232_RxD

RS232 receive serial data

5

GND

System / board ground

1, 4, 6, 7, 8, 9

n.c.

Pins not used / not connected

Table 4.8: RS232 connector

Attention: please verify setting of J2 (selection of RS232 / RS485 interface) for proper operation of the

RS232 connection.

4.2.7 CAN connector

The board includes a CAN interface for serial communication. A standard DSUB 9-pin male connector is used

for this purpose. CAN is one out of four different interfaces available for communication with the board.

1 5

6 9

Pin

Label

Description

2

CAN_L

CAN differential bus

7

CAN_H

CAN differential bus

3, 6

GND

System / board ground

n.c.

Pins not used / not connected

Table 4.9: CAN connector

Attention: please verify setting of J3 (CAN bus termination) for proper operation of the CAN connection.

TMCM-351 Manual (V1.01 / May 25nd, 2009) 11

Copyright © 2008, TRINAMIC Motion Control GmbH & Co. KG

4.2.8 RS485 connector

The board includes an RS485 interface for serial communication. A 4-pin detachable screw connector is used

for this purpose. RS485 is one out of four different interfaces available for communication with the board.

1

4

Pin

Label

Description

1

RS485+

RS485 differential bus (connected to pin 3)

2

RS485-

RS485 differential bus (connected to pin 4)

3

RS485+

RS485 differential bus (connected to pin 1)

4

RS285-

RS485 differential bus (connected to pin 2)

Table 4.10: RS485 connector

Attention: please verify settings of J1 (RS485 bus termination) and J2 (selection of RS232 / RS485

interface) for proper operation of the RS485 connection.

4.2.9 SPI connector

For extension of the available inputs and outputs an SPI interface is available. A standard 2.54mm pitch two

row header is used as connector for the external SPI interface.

1

2

9

10

Pin

Label

Pin

Label

1

SPI_MOSI

2

GND

3

SPI_MISO

4

GND

5

SPI_CLK

6

GND

7

SPI_SEL0

8

SPI_SEL2

9

SPI_SEL1

10

+5V_output

Table 4.11: SPI connector

4.2.10 I/O connector

The I/O connector offers 8 digital and analogue inputs and 8 digital outputs. All inputs are +24V compatible.

All outputs offer open collector driver stages. OUT_0/1/2/3/4/5 can sink up-to 100mA, OUT_6/7 are more

powerful and can drive up-to 2A. A standard 2.54mm pitch two row header is used for this connector.

Attention: /Shutdown input pin has to be connected to supply voltage in order to enable driver stages

for all three stepper motor axes. A jumper between pin 19 and pin 20 can be used to permanently

enable drivers (see picture on front page).

1

2

20

19

Pin

Label

Pin

Label

1

OUT_0

2

OUT_1

3

OUT_2

4

OUT_3

5

OUT_4

6

OUT_5

7

OUT_6

8

OUT_7

9

+5V_output

10

GND

11

IN_0

12

IN_1

13

IN_2

14

IN_3

15

IN_4

16

IN_5

17

IN_6

18

IN_7

19

/Shutdown

20

VDD

Table 4.12: I/O connector

TMCM-351 Manual (V1.01 / May 25nd, 2009) 12

Copyright © 2008, TRINAMIC Motion Control GmbH & Co. KG

4.2.11 Encoder_0/1/2 connector

These three connectors (one encoder interface connector per axis) will be available only for boards with

assembled encoder option. A standard 2.54mm pitch two row header is used for connecting an encoder.

Differential and single ended incremental encoders with / without zero / index channel are supported.

1

2

9

10

Pin

Label

Pin

Label

1

GND

2

GND

3

Encoder_0/1/2_N+

4

Encoder_0/1/2_N-

5

Encoder_0/1/2_A+

6

Encoder_0/1/2_A-

7

+5V_output

8

+5V_output

9

Encoder_0/1/2_B+

10

Encoder_0/1/2_B-

Table 4.13: Encoder connector

TMCM-351 Manual (V1.01 / May 25nd, 2009) 13

Copyright © 2008, TRINAMIC Motion Control GmbH & Co. KG

4.3 Jumpers

Most settings of the board are done through the software. Nevertheless, a few jumpers are available for

configuration.

4.3.1 J1: RS485 bus termination

The board includes a 120 Ohm resistor for proper bus termination of the RS485 interface. When this jumper

is closed, the resistor will be placed between the two differential bus lines RS485+ and RS485-.

4.3.2 J2: RS232 / RS485 interface selection

This 3-pin single row header is used for selecting one of two desired serial interfaces: RS232 or RS485 using

a jumper:

RS232 interface

selection

RS485 interface

selection

4.3.3 J3: CAN bus termination

The board includes a 120 Ohm resistor for proper bus termination of the CAN interface. When this jumper is

closed, the resistor will be placed between the two differential bus lines CAN_H and CAN_L.

4.3.4 J4 –J12: Encoder input termination

For enhanced reliability differential encoder signals should be terminated properly. The board offers

termination resistors (120 Ohm) for all three encoder interface signals (a/b/n) for all three encoders. By

setting jumpers, these resistors will be placed between the differential encoder signals. Do not set these

jumpers in case encoders with single ended signals are used.

Place jumpers for

proper temrination

TMCM-351 Manual (V1.01 / May 25nd, 2009) 14

Copyright © 2008, TRINAMIC Motion Control GmbH & Co. KG

5Operational Ratings

The operational ratings shown below should be used as design values. In no case should the maximum

values been exceeded during operation.

Symbol

Parameter

Min

Typ

Max

Unit

VDD

Power supply voltage for operation

7

24

28.5

V

ICOIL_peak

Motor coil current for sine wave

peak (chopper regulated, adjustable

via software)

0

4

A

ICOIL_RMS

Continuous motor current (RMS)

0

2.8

A

ISUPPLY

Power supply current

<< ICOIL

1.4 * ICOIL

A

TENV

Environment temperature at rated

current (no forced cooling required)

-20

+40

°C

Environment temperature at 80% of

rated current or 50% duty cycle

(no forced cooling required)

-20

+60

°C

Table 5.1: General operational ratings of the module

TMCM-351 Manual (V1.01 / May 25nd, 2009) 15

Copyright © 2008, TRINAMIC Motion Control GmbH & Co. KG

6Revision History

6.1 Document Revision

Version

Date

Author

Description

1.00

2008-10-22

GE

Initial version

1.01

2009-05-25

OE

Encoder input pinning corrected

Table 6.1: Document Revision

6.2 Hardware Revision

Version

Date

Description

1.00

2008-08-25

First prototypes

Table 6.2: Hardware Revision

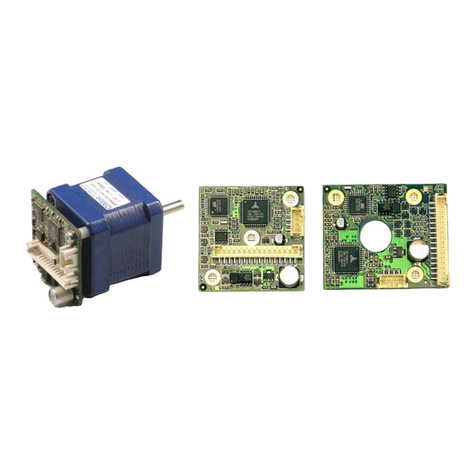

Other manuals for TMCM-351

4

Table of contents

Other Trinamic Computer Hardware manuals

Trinamic

Trinamic PANdrive PD013-42 User manual

Trinamic

Trinamic BB-100 User manual

Trinamic

Trinamic TMCM-035 User manual

Trinamic

Trinamic PANdrive PD42-1- 1243-IOLINK Safety guide

Trinamic

Trinamic TMCM-1161 User manual

Trinamic

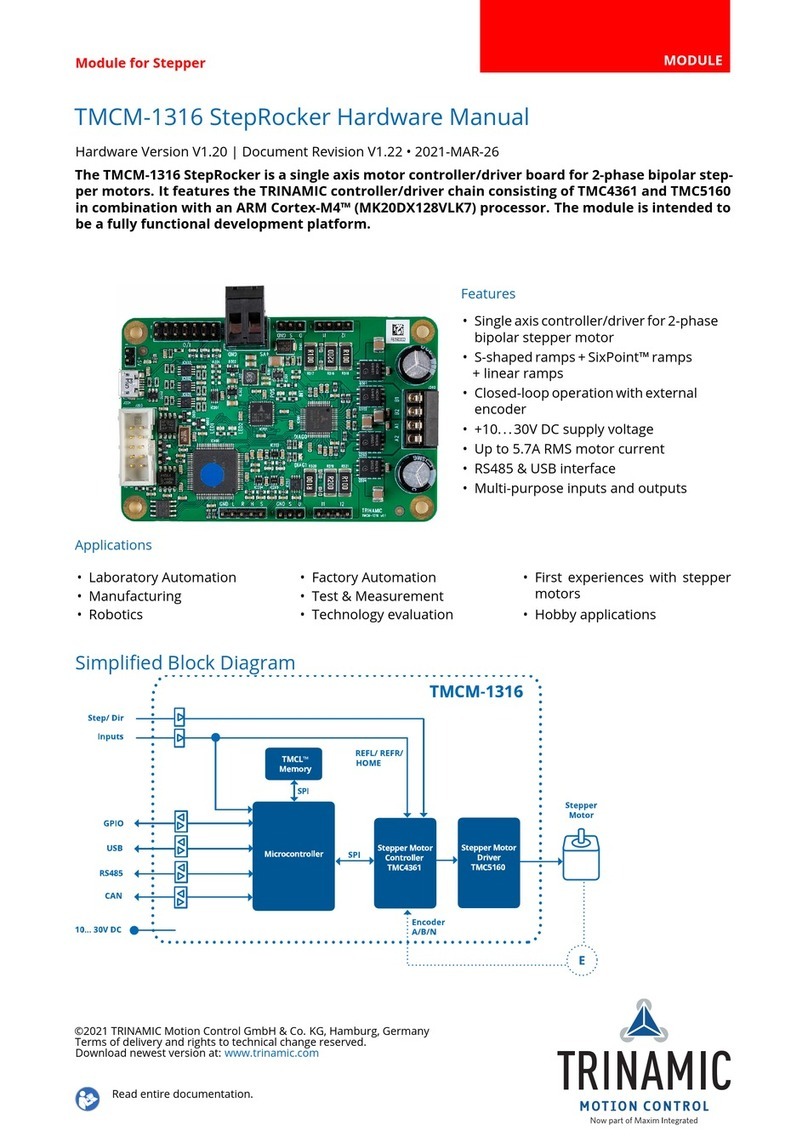

Trinamic TMCM-1316 StepRocker User manual

Trinamic

Trinamic TMCL TMCM-142 Use and care manual

Trinamic

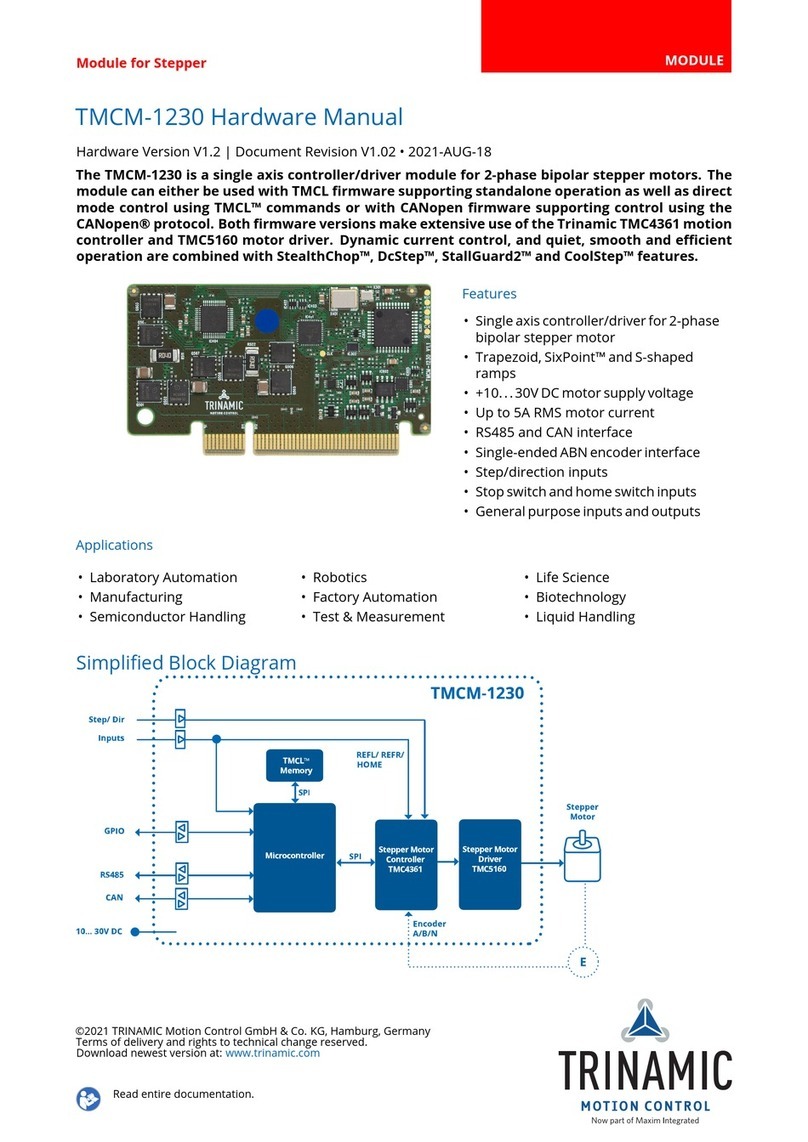

Trinamic TMCM-1230 User manual

Trinamic

Trinamic PD-109 User manual

Trinamic

Trinamic CANopen User manual