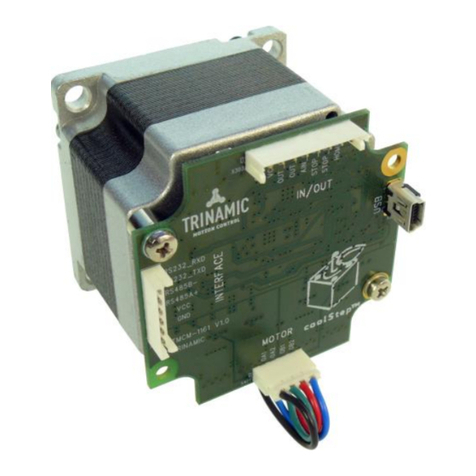

Trinamic PANdrive PD-1021 User manual

MECHATRONIC DRIVE WITH STEPPER MOTOR PANdrive

TRINAMIC Motion Control GmbH & Co. KG

Hamburg, Germany

www.trinamic.com

Hardware Version V1.2

HARDWARE MANUAL

++PD-1021

+ +

UNIQUE FEATURES:

Stepper Motor with

Controller / Driver

0.06 - 0.12Nm / 24V

sensOstep™Encoder

RS485 Interface

PD-1021 V1.2 Hardware Manual (Rev. 1.01 / 2013-JUL-23)2

www.trinamic.com

Table of Contents

1Features........................................................................................................................................................................... 3

2Order Codes ................................................................................................................................................................... 5

3Mechanical and Electrical Interfacing..................................................................................................................... 6

3.1 Dimensions ........................................................................................................................................................... 6

3.1.1 Dimensions of PD28-1-1021 ....................................................................................................................... 6

3.1.2 Dimensions of PD28-3-1021 ....................................................................................................................... 7

3.2 Motor Characteristics .......................................................................................................................................... 8

3.3 Connectors............................................................................................................................................................. 9

3.3.1 Power, Communication and I/O Connector ........................................................................................ 10

3.3.2 Motor Connector.......................................................................................................................................... 11

3.4 Power Supply ..................................................................................................................................................... 12

3.5 Communication .................................................................................................................................................. 13

3.5.1 RS485 .............................................................................................................................................................. 13

3.6 Inputs and Outputs .......................................................................................................................................... 14

3.6.1 Digital Inputs IN_0, IN_1, IN_2, IN_3 .................................................................................................... 14

3.6.2 Outputs OUT_0, OUT_1 ............................................................................................................................... 15

4Reset to Factory Defaults......................................................................................................................................... 16

5On-board LED............................................................................................................................................................... 16

6Operational Ratings ................................................................................................................................................... 17

7Torque Curves ............................................................................................................................................................. 18

8Functional description .............................................................................................................................................. 19

9Life Support Policy..................................................................................................................................................... 20

10 Revision History.......................................................................................................................................................... 21

10.1 Document Revision ........................................................................................................................................... 21

10.2 Hardware Revision ............................................................................................................................................ 21

11 References .................................................................................................................................................................... 21

PD-1021 V1.2 Hardware Manual (Rev. 1.01 / 2013-JUL-23)3

www.trinamic.com

1Features

The PANdrive™ PD-1021 is a full mechatronic extremely small and compact solution with state of the art

feature set. It is highly integrated and offers a convenient handling. The PD-1021 includes a stepper

motor, controller/driver electronics, and TRINAMICs sensOstep™ encoder. It can be used in many

decentralized applications and has been designed for 0.06… 0.12 Nm max. holding torque and 24V DC

nominal supply voltage. With its high energy efficiency from TRINAMIC’s coolStep technology cost for

power consumption is kept down. The TMCL™ firmware allows for standalone operation and direct

mode.

MAIN CHARACTERISTICS

Highlights

-Motion profile calculation in real-time

-On the fly alteration of motor parameters (e.g. position, velocity, acceleration)

-High performance microcontroller for overall system control and serial communication protocol

handling

-For position movement applications, where larger motors do not fit and higher torques are not

required

Bipolar stepper motor driver

-Up to 256 microsteps per full step

-High-efficient operation, low power dissipation

-Dynamic current control

-Integrated protection

-stallGuard2 feature for stall detection

-coolStep feature for reduced power consumption and heat dissipation

-ready for dcStep

Encoder

-sensOstep magnetic encoder (max. 1024 increments per rotation) e.g. for step-loss detection under

all operating conditions and positioning supervision

Interfaces

-Up to 4 multi-purpose inputs (2 shared with outputs)

-2 general purpose outputs

-RS485 2-wire communication interface

Software

-TMCL: standalone operation or remote controlled operation,

program memory (non volatile) for up to 876 TMCL commands, and

PC-based application development software TMCL-IDE available for free.

Electrical and mechanical data

-Supply voltage: +24V DC nominal (9… 28V DC)

-Motor current: up to 0.7A RMS (programmable)

-0.06 or 0.12Nm max. holding torque (depends on motor)

Refer to separate TMCL Firmware Manual, too.

PD-1021 V1.2 Hardware Manual (Rev. 1.01 / 2013-JUL-23)4

www.trinamic.com

TRINAMICS UNIQUE FEATURES –EASY TO USE WITH TMCL

stallGuard2™stallGuard2 is a high-precision sensorless load measurement using the back EMF on the

coils. It can be used for stall detection as well as other uses at loads below those which

stall the motor. The stallGuard2 measurement value changes linearly over a wide range

of load, velocity, and current settings. At maximum motor load, the value goes to zero or

near to zero. This is the most energy-efficient point of operation for the motor.

Load

[Nm]

stallGuard2

Initial stallGuard2

(SG) value: 100%

Max. load

stallGuard2 (SG) value: 0

Maximum load reached.

Motor close to stall.

Motor stalls

Figure 1.1 stallGuard2 load measurement SG as a function of load

coolStep™coolStep is a load-adaptive automatic current scaling based on the load measurement via

stallGuard2 adapting the required current to the load. Energy consumption can be

reduced by as much as 75%. coolStep allows substantial energy savings, especially for

motors which see varying loads or operate at a high duty cycle. Because a stepper motor

application needs to work with a torque reserve of 30% to 50%, even a constant-load

application allows significant energy savings because coolStep automatically enables

torque reserve when required. Reducing power consumption keeps the system cooler,

increases motor life, and allows reducing cost.

0

0,1

0,2

0,3

0,4

0,5

0,6

0,7

0,8

0,9

0 50 100 150 200 250 300 350

Efficiency

Velocity [RPM]

Efficiency with coolStep

Efficiency with 50% torque reserve

Figure 1.2 Energy efficiency example with coolStep

PD-1021 V1.2 Hardware Manual (Rev. 1.01 / 2013-JUL-23)5

www.trinamic.com

2Order Codes

The combination of motor and motor mounted controller/driver electronic is currently available with two

stepper motors (different length and holding torque).

The length of the PANdrives™ is specified without the length of the axis. For the overall length of the

product please add 21 mm.

Order code

Description

Size of unit [mm3]

PD28-1-1021-option

PANdrive 0.06Nm max. holding torque*)

28 x 28 x 43 max.

PD28-3-1021-option

PANdrive 0.12Nm max. holding torque*)

28 x 28 x 62 max.

Table 2.1 Order codes

The following options are currently available:

Firmware option

Description

Order code example:

-TMCL

Module pre-programmed with TMCL firmware

PD28-1-1021-TMCL

Table 2.3 PD-1021 firmware options

A cable loom set is available for this module:

Order code

Description

PD-1021-CABLE

Cable loom for PD-1021

1x cable loom for power, communication and I/O connector (length 200mm)

Table 2.5 Cable loom order code

PD-1021 V1.2 Hardware Manual (Rev. 1.01 / 2013-JUL-23)6

www.trinamic.com

3Mechanical and Electrical Interfacing

The PD-1021 consists of a 28mm / NEMA 11 stepper motor with controller/driver electronics mounted to

the back of the motor.

Note:

In order to make proper use of the integrated sensOstep encoder (the sensor IC is placed on the bottom

of the pcb) the electronics should not be removed/moved relative to the motor. In case this encoder

feature is not used, the electronics may be mounted according to different application requirements.

3.1 Dimensions

Currently, there is a choice between two 28mm stepper motors of different lengths and different torques.

The board with the controller/driver electronics has an overall size of 28mm x 28mm in order to fit on

the back side of a NEMA11 (28mm flange size) stepper motor. The printed circuit board outline is marked

green in the following figure.

Please also refer to the manuals of the related stepper motors QSH2818-32-07-006 and QSH2818-51-07-

012.

3.1.1 Dimensions of PD28-1-1021

28

2

22-0.05

20±1

5

4.5

43 max

15±0.2

28

28

25.5

25.5 2.5

23

26

R 2

ø2.6

R 2.5

Rear view

28

23±0.2

23±0.2 28

Front view

M2.5

deep 4.5 22-0.05

5

30+1

32

Figure 3.1 PD28-1-1021 dimensions

PD-1021 V1.2 Hardware Manual (Rev. 1.01 / 2013-JUL-23)7

www.trinamic.com

3.1.2 Dimensions of PD28-3-1021

2

22-0.05

20±1

5

4.5

15±0.2

28

28

25.5

25.5 2.5

23

26

R 2

ø2.6

R 2.5

Rear view

28

23±0.2

23±0.2 28

Front view

M2.5

deep 4.5 22-0.05

5

28 30+1

62 max

51

Figure 3.2 PD28-3-1021 with 2-phase 28mm stepper motor QSH2818-51-07-012

PD-1021 V1.2 Hardware Manual (Rev. 1.01 / 2013-JUL-23)8

www.trinamic.com

3.2 Motor Characteristics

Main characteristics of the two different motors available as part of the PD-1021:

Specifications

Parameter

Units

QSH2818

-32-07-006

-51-07-012

Rated Voltage

VRATED

V

3.8

6.2

Rated Phase Current

IRMS_RATED

A

0.67

0.67

Phase Resistance at 20°C

RCOIL

Ω

5.6

9.2

Phase Inductance (typ.)

mH

3.4

7.2

Holding Torque (typ.)

Ncm

6

12

oz in

8.5

17.0

Detent Torque

Ncm

Rotor Inertia

g cm2

9

18

Weight (Mass)

Kg

0.11

0.2

Insulation Class

B

B

Insulation Resistance

Ω

100M

100M

Dialectic Strength (for one minute)

VAC

500

500

Connection Wires

N°

4

4

Step Angle

°

1.8

1.8

Step angle Accuracy (max.)

%

5

5

Flange Size (max.)

mm

28.0

28.0

Motor Length (max.)

LMAX

mm

32

51

Axis Diameter

mm

5.0

5.0

Axis Length (typ.)

mm

20.0

20.0

Shaft Radial Play (450g load)

mm

0.02

0.02

Shaft Axial Play (450g load)

mm

0.08

0.08

Maximum Radial Force

(20 mm from front flange)

N

28

28

Maximum Axial Force

N

10

10

Ambient Temperature

°C

-20…+50

-20…+50

Temp Rise (rated current, 2phase on)

°C

max. 80

max. 80

Related PANdrive

type

PD28-1-1021

PD28-3-1021

Table 3.1 NEMA 11 / 28mm technical motor data

PD-1021 V1.2 Hardware Manual (Rev. 1.01 / 2013-JUL-23)9

www.trinamic.com

3.3 Connectors

The PD-1021 has two connectors, an 8-pin power and input/output connector and a 4-pin motor

connector (used to connect the attached motor).

1

1

Power / Communication / IOs

Motor

Figure 3.3 PD-1021 connectors

Overview of connector and mating connector types:

Label

Connector type

Mating connector types

Power,

communication

and I/O

CI0108P1VK0-LF

CVIlux CI01 series, 8pins, 2mm

pitch

Connector housing CVIlux: CI01085000-A

Contacts CVIlux: CI01T011PE0-A

or

Connector housing JST: PHR-8

Contacts JST: SPH-002T-P0.5S

Wire: 0.22mm2

Motor

CI0104P1VK0-LF

CVIlux CI01 series, 4 pins, 2mm

pitch

Connector housing CVIlux: CI01045000-A

Contacts CVIlux: CI01T011PE0-A

or

Connector housing JST: PHR-4

Contacts JST: SPH-002T-P0.5S

Wire: 0.22mm2

Table 3.2 Connectors and mating connectors, contacts and applicable wire

PD-1021 V1.2 Hardware Manual (Rev. 1.01 / 2013-JUL-23)10

www.trinamic.com

3.3.1 Power, Communication and I/O Connector

An 8-pin CVIlux CI0108P1VK0-LF 2mm pitch single row connector is used for power supply, RS485 serial

communication and additional multi-purpose inputs and outputs.

Pin

Label

Direction

Description

1

GND

Power (GND)

GND

2

VDD

Power (Supply)

VDD (+9V…+28V)

3

RS485+

Bidirectional

RS485 interface, diff. signal (non-inverting)

4

RS485-

Bidirectional

RS485 interface, diff. signal (inverting)

5

IN_0

Input

Digital input (+24V compatible)

Alternate function 1: step input

Alternate function 2: left stop switch

6

IN_1

Input

Digital input (+24V compatible)

Alternate function 1: direction input

Alternate function 2: right stop switch

7

OUT_0 / IN_2

Output / Input

Open drain output with freewheeling diode

(max. 100mA)

Alternate function 1:

digital input (+24V compatible)

Alternate function 2:home switch

8

OUT_1 / IN_3

Output / Input

Open drain output with freewheeling diode

(max. 100mA)

Alternate function 1: digital input

(+24V compatible)

Alternate function 2: analog input

Table 3.3 Power, communication and I/O connector

PD-1021 V1.2 Hardware Manual (Rev. 1.01 / 2013-JUL-23)11

www.trinamic.com

3.3.2 Motor Connector

A 4-pin CVIlux CI0104P1VK0-LF 2mm pitch single row connector is used for connecting the four motor

wires to the electronics.

Pin

Label

Direction

Description

1

OB2

Output

Pin 2 of motor coil B

2

OB1

Output

Pin 1 of motor coil B

3

OA2

Output

Pin 2 of motor coil A

4

OA1

Output

Pin 1 of motor coil A

Table 3.4 Motor connector

PD-1021

QSH2818 Motor

Motor connector pin

Cable colour

Coil

Description

1

Blue

B-

Motor coil B pin 2

2

Red

B

Motor coil B pin 1

3

Green

A-

Motor coil A pin 2

4

Black

A

Motor coil A pin 1

CAUTION!

Keep the electronics free of (metal) particles!

The integrated sensOstep™ encoder uses a magnet at the end of the motor axis in order

to monitor position. The magnet naturally attracts especially tiny metal particles. These

particles might be held on the top side of the PCB and even worse –start moving in

accordance with the rotating magnetic field as soon as the motor starts moving. This

might lead to shorts of electronic contacts / wires on the board and totally erratic

behavior of the module! Use compressed air for cleaning the module if necessary.

M

black

green

red

blue

A

B

PD-1021 V1.2 Hardware Manual (Rev. 1.01 / 2013-JUL-23)12

www.trinamic.com

3.4 Power Supply

For proper operation care has to be taken with regard to power supply concept and design. Due to space

restrictions the PD-1021 includes just about 20µF/35V of supply filter capacitors. These are ceramic

capacitors which have been selected for high reliability and long life time. The module includes a 28V

suppressor diode for over-voltage protection.

CAUTION!

Add external power supply capacitors!

It is recommended to connect an electrolytic capacitor of significant size (e.g.

470µF/35V) to the power supply lines next to the TMCM-1021!

Rule of thumb for size of electrolytic capacitor:

In addition to power stabilization (buffer) and filtering this added capacitor will also

reduce any voltage spikes which might otherwise occur from a combination of high

inductance power supply wires and the ceramic capacitors. In addition it will limit

slew-rate of power supply voltage at the module. The low ESR of ceramic-only filter

capacitors may cause stability problems with some switching power supplies.

Do not connect or disconnect motor during operation!

Motor cable and motor inductivity might lead to voltage spikes when the motor is

disconnected / connected while energized. These voltage spikes might exceed voltage

limits of the driver MOSFETs and might permanently damage them. Therefore, always

disconnect power supply before connecting / disconnecting the motor.

Keep the power supply voltage below the upper limit of 28V!

Otherwise the driver electronics will seriously be damaged! Especially, when the

selected operating voltage is near the upper limit a regulated power supply is highly

recommended. Please see also chapter 6, operating values.

There is no reverse polarity protection!

The module will short any reversed supply voltage due to internal diodes of the driver

transistors.

PD-1021 V1.2 Hardware Manual (Rev. 1.01 / 2013-JUL-23)13

www.trinamic.com

3.5 Communication

3.5.1 RS485

For remote control and communication with a host system the PD-1021 provides a two wire RS485 bus

interface. For proper operation the following items should be taken into account when setting up an

RS485 network:

1. BUS STRUCTURE:

The network topology should follow a bus structure as closely as possible. That is, the

connection between each node and the bus itself should be as short as possible. Basically, it

should be short compared to the length of the bus.

c:> node

1

node

n- 1

node

n

Host Slave Slave Slave

RS485

termination

resistor

(120 Ohm)

termination

resistor

(120 Ohm)

}

keep distance as

short as possible

Figure 3.5 Bus structure

2. BUS TERMINATION:

Especially for longer busses and/or multiple nodes connected to the bus and/or high

communication speeds, the bus should be properly terminated at both ends. The PD-1021 does

not integrate any termination resistor. Therefore, 120 Ohm termination resistors at both ends of

the bus have to be added externally.

3. NUMBER OF NODES:

The RS485 electrical interface standard (EIA-485) allows up to 32 nodes to be connected to a

single bus. The bus transceiver used on the PD-1021 units (SN65HVD3082ED) has just 1/8th of the

standard bus load and allows a maximum of 256 units to be connected to a single RS485 bus.

4. NO FLOATING BUS LINES:

Avoid floating bus lines while neither the host/master nor one of the slaves along the bus line is

transmitting data (all bus nodes switched to receive mode). Floating bus lines may lead to

communication errors. In order to ensure valid signals on the bus it is recommended to use a

resistor network connecting both bus lines to well defined logic levels. In contrast to the

termination resistors this network is normally required just once per bus. Certain RS485 interface

converters available for PCs already include these additional resistors (e.g. USB-2-485).

node

n- 1

node

n

Slave Slave

termination

resistor

(120 Ohm)

+5V

GND

pull-up (1k)

pull-down (1k)

RS485- / RS485B

RS485+ / RS485A

Figure 3.6 Bus lines with resistor network

PD-1021 V1.2 Hardware Manual (Rev. 1.01 / 2013-JUL-23)14

www.trinamic.com

3.6 Inputs and Outputs

3.6.1 Digital Inputs IN_0, IN_1, IN_2, IN_3

The eight pin connector of the PD-1021 provides four general purpose inputs IN_0, IN_1, IN_2 and IN_3.

The first two inputs have dedicated connector pins while the other two share pins with two general

purpose outputs.

All four inputs are protected using voltage resistor dividers together with limiting diodes against

voltages below 0V (GND) and above +3.3V DC (see figure below).

+3.3V

IN_0

IN_1

IN_2

IN_3

microcontroller

and TMC262

10k

10k

1nF

GND GND GND

Figure 3.7 General purpose inputs

The four inputs have alternate functionality depending on configuration in software. The following

functions are available:

Label

(connector pin)

Default Function

Alternate function 1

Alternate function 2

IN_0 (5)

Digital input

Step signal input

(connected to TMC262 step

input)

Left stop switch

IN_1 (6)

Digital input

Direction signal input

(connected to TMC262

direction input)

Right stop switch

OUT_0 / IN_2 (7)

Output

Digital input

Home switch

OUT_1 / IN_3 (8)

Output

Digital input

Analog input

(0… +6.6V, 12bit resolution)

Table 3.5 Multipurpose inputs / alternate functions

All four inputs are connected to the on-board processor and can be used as general purpose digital

inputs.

Using the alternate functionality of IN_0 and IN_1 it is possible to control the on-board stepper motor

driver with the help of an external stepper motor controller using step and direction signals. For the step

and direction signals the signal levels are the same as for the general purpose digital inputs.

IN_3 can be used as analog input, also. A 12bit analog to digital converter integrated in the

microcontroller will convert any analog input voltage between 0 and +6.6V to a digital value between 0

and 4095 then.

PD-1021 V1.2 Hardware Manual (Rev. 1.01 / 2013-JUL-23)15

www.trinamic.com

3.6.2 Outputs OUT_0, OUT_1

The eight pin connector of the PD-1021 provides two general purpose outputs. These two outputs are

open-drain outputs and can sink up to 100mA each. The outputs of the N-channel MOSFET transistors are

connected to freewheeling diodes each for protection against voltage spikes especially from inductive

loads (relais etc.).

Both outputs OUT_0 and OUT_1 share pins with two of the four inputs (IN_2 resp. IN_3).

Please take into account the 20k (2x 10k in series) resistance to ground (transistor not active) of the input

voltage divider (figure 4.8) when designing the external “load” circuit.

VDD

OUT_0 / IN_2

OUT_1 / IN_3

microcontroller

GND

+3.3V

microcontroller

10k

10k

1nF

GND GND GND

Figure 3.8 General purpose outputs

PD-1021 V1.2 Hardware Manual (Rev. 1.01 / 2013-JUL-23)16

www.trinamic.com

4Reset to Factory Defaults

It is possible to reset the PD-1021 to factory default settings without establishing a communication link.

This might be helpful in case communication parameters of the preferred interface have been set to

unknown values or got accidentally lost.

For this procedure two pads on the bottom side of the board have to be shortened (see Figure 4.1).

Please perform the following steps:

1. Power supply off

2. Short two pads as marked in Figure 4.1

3. Power up board

4. Wait until the on-board green LED start flashing fast (this might take a while)

5. Power-off board (disconnect USB cable)

6. Remove short between pads

7. After switching on the power-supply all permanent settings have been restored to factory

defaults

Short these two pads

Figure 4.1 Reset to factory default settings

5On-board LED

The board offers one LED in order to indicate board status. The function of the LED is dependent on the

firmware version. With standard TMCL firmware the green LED flashes slowly during operation.

When there is no valid firmware programmed into the board or during firmware update the green LED is

permanently on.

Green LED

Figure 5.1 On-board LED

PD-1021 V1.2 Hardware Manual (Rev. 1.01 / 2013-JUL-23)17

www.trinamic.com

6Operational Ratings

The operational ratings show the intended or the characteristic ranges and should be used as design

values.

In no case shall the maximum values be exceeded!

Symbol

Parameter

Min

Typ

Max

Unit

VDD

Power supply voltage for operation

9

12… 24

28

V

ICOIL

Motor coil current for sine wave peak (chopper

regulated, adjustable via software)

0

1000*)

mA

IMC

Continuous motor current (RMS)

0

700*)

mA

IS

Power supply current

<< ICOIL

1.4 * ICOIL

A

TENV

Environment temperature at rated current (no

forced cooling required)

-35

tbd

+60

°C

Table 6.1 General operational ratings of module

*) maximum setting for prototype and first versions of TMCL firmware. Will be adapted in firmware for

series version.

Symbol

Parameter

Min

Typ

Max

Unit

VOUT_0/1

Voltage at open collector output

0

+VDD

V

IOUT_0/1

Output sink current

100

mA

VIN_digital 0/1/2/3

Input voltage for IN_0, IN_1, IN_2, IN_3 when used

as digital input

0

+VDD

V

VIN_digital_L 0/1/2/3

Low level voltage for GPI0 and GPI1 when used as

digital input

0

1.2

V

VIN_digital_L 0/1/2/3

High level voltage for GPI0 and GPI1 when used as

digital input

4

+VDD

V

VIN_analog 3

Measurement range for IN_3 when used as

analogue input

0

+6.6

V

Table 6.2 Operational ratings of multipurpose I/Os

Symbol

Parameter

Min

Typ

Max

Unit

NRS485

Number of nodes connected to single RS485

network

256

Table 6.3 Operational ratings of RS485 interface

PD-1021 V1.2 Hardware Manual (Rev. 1.01 / 2013-JUL-23)18

www.trinamic.com

7Torque Curves

The following figures show the curve of each PANdrive.

Figure 7.1 PD28-1-1021 torque vs. speed 24V / 0.7 A, 256 µsteps

Figure 7.2 PD28-3-1021 torque vs. velocity 24V / 0.7 A, 256µsteps

0,00

0,01

0,02

0,03

0,04

0,05

0,06

0,07

0,08

0,09

0,10

10 100 1000 10000

torque[Nm]

speed[rpm]

PD21-1-1021 - 0.7A RMS Phase Current, 256 uSteps

0,00

0,02

0,04

0,06

0,08

0,10

0,12

0,14

0,16

0,18

0,20

10 100 1000 10000

torque[Nm]

speed[rpm]

PD28-3-1021 - 0.7A RMS Phase Current, 256 uSteps

PD-1021 V1.2 Hardware Manual (Rev. 1.01 / 2013-JUL-23)19

www.trinamic.com

8Functional description

The PD-1021 is a highly integrated mechatronic device which can be controlled via RS485 serial interface.

Communication traffic is kept low since all time critical operations, e.g. ramp calculations are performed

on board. Nominal supply voltage of the unit is 24V DC. The PANdrive is designed for both: direct mode

and standalone operation. Full remote control of device with feedback is possible. The firmware of the

module can be updated via any of the serial interfaces.

Figure 8.1 the main parts of the PD-1021 are shown:

-the microprocessor, which runs the TMCL operating system (connected to TMCL memory),

-the motion controller, which calculates ramps and speed profiles internally by hardware,

-the power driver with stallGuard2 and its energy efficient coolStep feature,

-the MOSFET driver stage,

-the QSH stepper motor, and

-the sensOstep encoder with resolutions of 10bit (1024 steps) per revolution.

9… 28V DC

TMCL™

Memory

4

add.

I/Os

Step

Motor

RS485 MOSFET

Driver

Stage

Energy Efficient

Driver

TMC262

Power

Driver

TMC262

with

coolStep™

sensOstep™

Encoder

SPI

PD-1021

S/D

SPI

I2C

µC

TMCM-1021

Figure 8.1: Main parts of PD-1021

The PD-1021 comes with the PC based software development environment TMCL-IDE for the Trinamic

Motion Control Language (TMCL). Using predefined TMCL high level commands like move to position a

rapid and fast development of motion control applications is guaranteed.

Please refer to the PD-1021 Firmware Manual for more information about TMCL commands.

PD-1021 V1.2 Hardware Manual (Rev. 1.01 / 2013-JUL-23)20

www.trinamic.com

9Life Support Policy

TRINAMIC Motion Control GmbH & Co. KG does not

authorize or warrant any of its products for use in life

support systems, without the specific written consent

of TRINAMIC Motion Control GmbH & Co. KG.

Life support systems are equipment intended to

support or sustain life, and whose failure to perform,

when properly used in accordance with instructions

provided, can be reasonably expected to result in

personal injury or death.

© TRINAMIC Motion Control GmbH & Co. KG 2013

Information given in this data sheet is believed to be

accurate and reliable. However neither responsibility is

assumed for the consequences of its use nor for any

infringement of patents or other rights of third parties,

which may result from its use.

Specifications are subject to change without notice.

All trademarks used are property of their respective

owners.

Other manuals for PANdrive PD-1021

2

Table of contents

Other Trinamic Engine manuals