1.4

Section 1

Safety and General Information

Oil Recommendations

Using the proper type and weight of oil in the

crankcase is extremely important. So is checking oil

¢ȱȱȱȱ¢ǯȱȱȱȱȱ

correct oil, or using dirty oil, causes premature engine

wear and failure.

Oil Type

Use high-quality detergent oil of ȱǻȱ

ȱǼȱȱȱȱȱ. Select

the viscosity based on the air temperature at the time

of operation as shown in the following table.

Refer to Section 6, Lubrication System for detailed

procedures on checking the oil, changing the oil and

ȱȱȱęǯ

Fuel Recommendations

WARNING: Explosive Fuel!

ȱȱ¡¢ȱĚȱȱȱȱȱ¡ȱ

if ignited. Before servicing the fuel system, make sure there

ȱȱǰȱȱĚȱȱȱȱȱȱ

nearby as these can ignite gasoline vapors. Disconnect and

ground the spark plug leads to prevent the possibility of

sparks from the ignition system.

General Recommendations

Purchase gasoline in small quantities and store

in clean, approved containers. A container with a

¢ȱȱŘȱȱȱȱȱȱȱȱȱ

recommended. Such a container is easier to handle

and helps eliminate spillage during refueling.

ȱȱȱȱĞȱȱȱȱȱǰȱ

to minimize gum deposits in your fuel system and to

ensure easy starting.

Do not add oil to the gasoline.

ȱȱęȱȱȱǯȱȱȱȱȱȱȱ

expand.

Fuel Type

ȱȱǰȱȱ¢ȱǰȱǰȱȱ

gasoline with a pump sticker octane rating of 87 or

higher. In countries using the Research method, it

should be 90 octane minimum.

Unleaded gasoline is recommended as it leaves

less combustion chamber deposits and reduces

harmful exhaust emissions. Leaded gasoline is not

recommended.

Gasoline/Alcohol blends

Gasohol (up to 10% ethyl alcohol, 90% unleaded

gasoline by volume) is approved as a fuel for Kohler

engines. Other gasoline/alcohol blends are not

approved.

Gasoline/Ether blends

Methyl Tertiary Butyl Ether (MTBE) and unleaded

gasoline blends (up to a maximum of 15% MTBE by

volume) are approved as a fuel for Kohler engines.

Other gasoline/ether blends are not approved.

NOTE: Using other than service class SJ or higher oil

or extending oil change intervals longer than

recommended can cause engine damage.

DZȱ ¢ȱȱȱȱȱęȱ

may be used with oil changes performed

at the recommended intervals. However, to

allow piston rings to properly seat, a new or

rebuilt engine should be operated for at least

50 hours using standard petroleum based oil

before switching to synthetic oil.

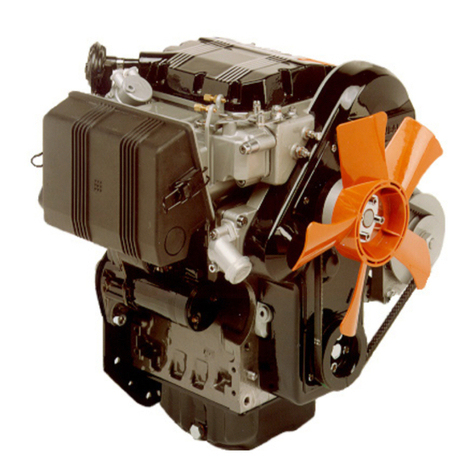

ȱȱȱ¢ȱȱȱȱęȱȱȱ

ȱȱȱȱ¢ȱǯȱȱȱŗȬřǯ

Figure 1-3. Oil Container Logo.

5W-20, 5W-30

RECOMMENDED SAE VISCOSITY GRADES

10W-30

Kohler 10W-30

°F -20 0 20 32 40 60 80 100

°C -30 -20 -10 0 10 20 30 40

TEMPERATURE RANGE EXPECTED BEFORE NEXT OIL CHANGE

* Use of synthetic oil having 5W-20 or 5W-30 rating is acceptable,

up to 4°C (40°F)

** Synthetic oils will provide better starting in extreme cold below

23°C (-10°F)

** *

SAE

10W-30

A

P

I

S

E

R

V

I

C

E

S

J