Trinity Amps TriFly User manual

TrinityAmps TriFly PCB Builders Guide v1.docx

- 1 -

The Trinity Amps

TriFly

TriFlyTriFly

TriFly

PCB Builder's Guide

For the sole personal use of Trinity Amps Customers.

February 2017, Version 1.1

Parts © Trinity Amps 2005 2016

www.trinityamps.com

TrinityAmps TriFly PCB Builders Guide v1.docx

Page - 2 -

TrinityAmps TriFly PCB Builders Guide v1.docx

Page - 3 -

Table of Contents

Table of Contents ......................................................................................................................................................... 3

Introduction ................................................................................................................................................................... 6

Acknowledgements ....................................................................................................................................................... 6

WARNING ................................................................................................................................................................... 7

Please Read this Information Carefully ............................................................................................................. 7

Version Control ............................................................................................................................................................. 8

Product Overview and Specs ................................................................................................................................. 11

Guitar Amplifier Basics .............................................................................................................................................. 12

Distortion ................................................................................................................................................................. 13

General Amplifier Operation ................................................................................................................................ 15

Some DO NOTS .................................................................................................................................................... 15

Some DOs ................................................................................................................................................................ 15

Introduction to Vacuum Tubes and Common Terms .......................................................................................... 16

Introduction ............................................................................................................................................................. 19

Switches and wire .................................................................................................................................................... 19

Physical layout .......................................................................................................................................................... 19

Grounding ................................................................................................................................................................ 19

Insulated jacks .......................................................................................................................................................... 20

Minimizing transformer interference .................................................................................................................... 20

Wiring ........................................................................................................................................................................ 20

Assembling the amp ................................................................................................................................................... 21

Before You Begin .................................................................................................................................................... 21

Tools .......................................................................................................................................................................... 21

Soldering ................................................................................................................................................................... 21

Making a Voltage Measurement ............................................................................................................................ 22

Wiring ........................................................................................................................................................................ 23

Tube Pin Numbering .............................................................................................................................................. 23

Potentiometer Pin Numbering .............................................................................................................................. 23

Assembly Steps Summary .......................................................................................................................................... 24

1. Install Transformers ............................................................................................................................................... 24

2. Install IEC, Power Switch, Tube Sockets and Output Jacks ........................................................................... 25

3. Wire up and test the Power Transformer and Power Switch .......................................................................... 26

Grounding Scheme ................................................................................................................................................. 26

4. Build sub assemblies Volume Control and Input Jack ..................................................................................... 28

5. Build sub assembly Printer Circuit Board (PCB) ............................................................................................... 29

6. Install sub assembly PCB ...................................................................................................................................... 30

7. Install LED in V1 tube socket .............................................................................................................................. 31

8. Output Transformer Connection and Power Transformer Connection ....................................................... 31

9. Wire up the Heaters; Check Wiring ..................................................................................................................... 32

10. Start Up .................................................................................................................................................................. 34

Trinity TRIFLY Voltage Chart ................................................................................................................................. 36

TrinityAmps TriFly PCB Builders Guide v1.docx

Page - -

WARNING ................................................................................................................................................................. 36

Please Read this Information Carefully ........................................................................................................... 36

Troubleshooting .......................................................................................................................................................... 37

Hum ........................................................................................................................................................................... 37

Volume Test ............................................................................................................................................................. 37

Faulty tube ................................................................................................................................................................ 37

Severely unmatched output tubes in a push pull amplifier ............................................................................... 38

Faulty power supply filter caps .............................................................................................................................. 38

Faulty bias supply in fixed bias amplifiers ........................................................................................................... 39

Unbalanced or not ground referenced filament winding .................................................................................. 39

Defective input jack ................................................................................................................................................ 39

Poor AC grounding ................................................................................................................................................. 39

Induced hum ............................................................................................................................................................ 39

Poor internal wire routing ...................................................................................................................................... 39

Poor AC Chassis Ground at Power Transformer .............................................................................................. 40

Defective internal grounding ................................................................................................................................. 40

Hiss ............................................................................................................................................................................ 40

Metal Film Resistor Substitutions ......................................................................................................................... 40

Squealing/Feedback ................................................................................................................................................ 41

Radio Interference ................................................................................................................................................... 41

Scratchy Sounds on Potentiometer(s) .................................................................................................................. 41

Amp Buzz or Rattle When Installed in Cabinet ................................................................................................. 41

Appendix 1 Tone Tweaking ................................................................................................................................... 44

More Tips for fine tuning your amp ..................................................................................................................... 45

Appendix 2 How to read Resistor Color Codes .................................................................................................. 46

First the code ....................................................................................................................................................... 46

How to read the Color Code ............................................................................................................................ 46

Appendix 3 How to read Capacitor Codes .......................................................................................................... 47

Appendix 4 TriFly PCB Bill of Materials .............................................................................................................. 50

Appendix 5 FAQ ...................................................................................................................................................... 51

TrinityAmps TriFly PCB Builders Guide v1.docx

Page - 5 -

Thank You

Thank you for purchasing your TriFly kit from Trinity Amps. We truly hope that you enjoy

building it and that it will be enjoyed for many years. If you have any questions please do not

hesitate to contact us and. Please be sure to check the package contents in case there are any

missing items.

We are always looking for feedback form our Customers on our products. We have checked

the build instructions over thoroughly and are confident in our product. However, mistakes

do happen so our advice is that as you connect each wire and part according to the layout,

cross check against the schematic. If you find any inconsistencies, or have any concerns,

please let us know. Do not hesitate to contact us! We want this build to be successful for

you and for Trinity Amps!

We’re confident that you will like our product and our support and when you’re completed,

we’d appreciate your comments posted on any of the internet forums such as

thegearpage.net

, 18watt.com, AX84.com or trinityamps.com. You will find some extra

business cards in the package. Please keep one and pass the rest around.

We know you have a choice in suppliers and do appreciate your business. If there is any

other product we can provide to you or your associates, please get in touch and we will be

happy to discuss requirements.

Sincerely,

Stephen Cohrs,

Trinity Amps

Web site: www.trinityamps.com

email: stephen@trinityamps.com

TrinityAmps TriFly PCB Builders Guide v1.docx

Page - 6 -

ntroduction

This guide has been prepared for builders of Trinity Amps Kits. It is always being improved

and we would appreciate your feedback and comments to:

stephen@trinityamps.com

Accordingly, content and specifications are subject to change without notice.

We do try to make it as accurate as possible, but it is sometimes hard to keep up with the

changes. Therefore, if you do find an error, please let us know about it and we will correct it.

Suggestions are welcome so if you have one, please get in touch with us.

Sources of help.

Forums: Please use the various forums to get help. They are an excellent resource and can

be found at trinityamps.com, AX84.com, the Gear Page etc..

Color assembly pictures and the latest drawings, tips, techniques are all in the Trinity Amps

Forum, in the Resources Forum. To view the Resources, you need to sign up so go to

www.trinityamps.com

and click on the Forum button.

Email: We can’t help with every problem but if you can not get your problem resolved, email

us and we’ll do our best to help.

Phone Call: If your problem can’t be solved, email for a phone appointment.

Acknowledgements

Much of the content in this document is original. Rather than reinvent content, some parts

are based on content from other excellent sources and are hereby acknowledged.

R.G. Keen’s site

www.geofex.com

Tube Amp FAQ, Tube Amp Debugging

AX84.com site

www.AX84.com

Gary Anwyl's P1 construction guide version 1.0

GM Arts website

http://users.chariot.net.au/~gmarts/index.html

Guitar Amp

Basics

www.18watt.com

website for various content and diagrams – Richie TMB

Aron from diystompboxes.com

Parts © Trinity Amps 2005. No part of this document may be copied or reprinted without

written permission of Trinity Amps or contributing authors listed above.

TrinityAmps TriFly PCB Builders Guide v1.docx

Page - 7 -

WARN NG

Please Read this Information Carefully

The projects described in these pages utilize POTENT ALLY FATAL H GH

VOLTAGES. If you are in any way unfamiliar with high voltage circuits or are

uncomfortable working around high voltages, DO NOT R SK YOUR L FE BY

BU LD NG THEM. Seek help from a competent technician before building any

unfamiliar electronics circuit. While efforts are made to ensure accuracy of these circuits, no

guarantee is provided, of any kind!

USE AT YOUR OWN RISK: TRINITY AMPS EXPRESSLY DISCLAIM ALL LIABILITY FOR

INJURY OR PROPERTY DAMAGE RESULTING FROM THIS INFORMATION! ALL

INFORMATION IS PROVIDED 'AS-IS' AND WITHOUT WARRANTY OF ANY KIND

REMEMBER: NEVER OPERATE YOUR AMP W THOUT A LOAD. YOU

W LL RU N YOUR OUTPUT TRANSFORMER!

TrinityAmps TriFly PCB Builders Guide v1.docx

Page - 8 -

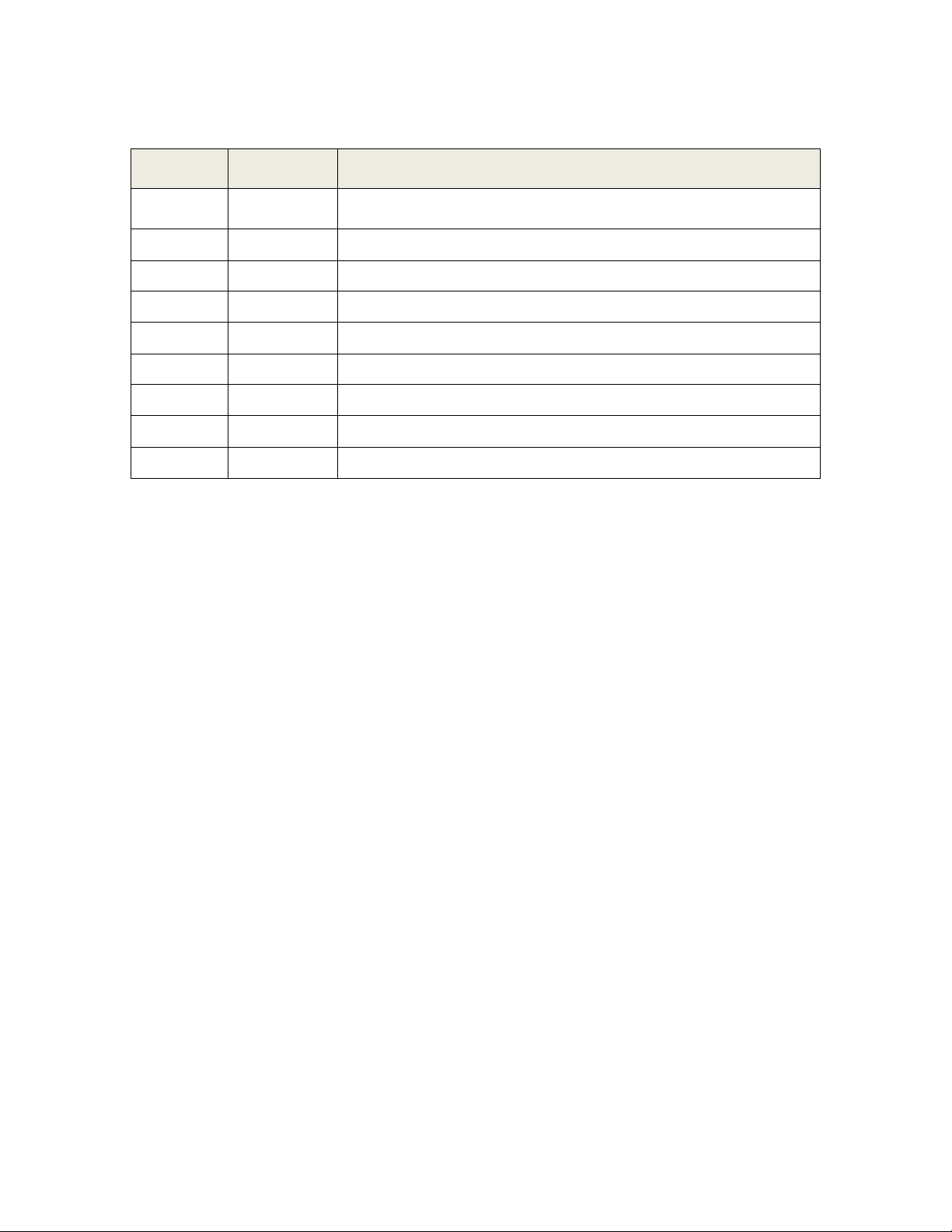

Version Control

Version Date Change

1.0 28Dec16 First release

1.1 1Feb17 Clarified input jack wiring

TrinityAmps TriFly PCB Builders Guide v1.docx

Page - 9 -

TrinityAmps TriFly PCB Builders Guide v1.docx

Page - 10 -

TriFly Description

The design of the TriFly began with an inspiring customer call "Please make me a small,

higher gain amp that I can play but that my ears can tolerate".. His ears were suffering from

an illness and he could not withstand any loud sounds. Yet he still wanted to play his guitar

like his old JCM 800 .

So the research began. Our design criteria were:

low and high gain modes but not too loud.

cost effective iron and parts

compact

minimal controls (possible tone control by the guitar tone).

Printed Circuit Board manufacture an option.

Able to use it in our Amp Camp Training program – build it in a day.

use traditional power supply not complicated circuitry.

use readily available off the shelf tubes such as 12AX7s.

We did a lot of research and in doing so, learned about the Phillips Self Split design which

eliminates the need for a Phase Inverter (PI). It is less efficient than a true Push Pull design

but would help meet our design goals. It was invented by Phillips and was used in some

budget amps of the day.

We also learned about a public domain amp called the Firefly that used this concept and

since we had all the parts, that became our first attempt at a low power amp.

The final design while unique retains some of the Firefly heritage. Once again we settled on

a Heyboer output transformer since in studio listening tests it proved the best. Surprisingly,

the output tube we chose was a 12BH7 rather than the expected ECC99 because he tone

was more like a Marshall. While we tried various preamp tubes, we did settle on the

ubiquitous and readily available 12AX7. We tried a tone control that was quite uncommon

and was used in Gibson and Garnet amps. It was a low loss control that at extremes subtly

boosts treble and gain or filters out treble. We also tried a Master Volume. In the end, we

went with ONE knob since most of the testers thought it was perfect that way. . So the

current design has Power, Volume and Input on the front panel.

We spent several hours in the SlyFi Chapel studio. Shawn Dore played while settings were

changed, tweaked, recorded, commented. We noted that the TriFly takes pedals so well; you

can get pretty well anything you want out of the TriFly. And we know players who like

pedals! If you want over the top distortion, this is the way to go.

After all was said and done, everyone agreed the TriFly was ready for prime time!! It really

shone and the best example was when using the Ash body Tele, on the neck pick up. Under

TrinityAmps TriFly PCB Builders Guide v1.docx

Page - 11 -

the vast majority of situations, this arrangement would be very hard to listen to, yet the

TriFly made it sound nice! With the Gretsch Country Gentlemen you could hear the detail

of the hollow body in the sound. it was quite glorious!

We were aiming for a great tone at a low power in a compact package and we definitely

achieved that.

Product Overview and Specs

The TriFly is a one channel input with a single Volume control.

12AX7 Preamp tube.

12BH7 dual Triode high current

Power tube, in self split push pull mode , running a little “hot” to deliver more symmetrical

clipping.

The 12BH7 sounded like a Marshall which was a BIG surprise. It had better dynamics and

feel but a little less headroom in a good way. An ECC99 can be substituted if desired.

Self Split drive design is an arrangement where the power tubes also function as it’s own

Phase Invertor. The first triode drives the second one through the common cathode

connection.

Volume sets the overall listening level.

Heyboer M 27 steel output transformer with 4,8 and 16 (unused) ohm taps. This

transformer gave the TriFly an excellent bottom end with a thicker sound and also it had

fantastic clean tone at low levels.

A Conjunctive filter is incorporated into the output stage to tame some fizz and smooth out

the response.

The eyelet board / PCB for the TriFly is a new approach. Wanting to keep this design

compact, we went for a layout that located the tubes in the middle of the chassis with holes

through to feed the components directly to the tube pins and we used regular tube sockets.

The tubes are aligned so the heater connections are closest to each other. This is a very

compact and very quiet design!

TrinityAmps TriFly PCB Builders Guide v1.docx

Page - 12 -

Guitar Amplifier Basics

Electric guitarists can be fairly criticized for their reluctance to change to new ideas

and technologies; however, there is no doubt that a classic 1950’s guitar and tube

amplifier in good condition still sounds great in modern recordings. This is a

testament to good design from the start. What has improved today is consistency,

and the cost benefits of production line manufacturing. This is offset by the rarity of

good guitar wood (it makes a huge difference, even on an electric guitar), increased

labour costs for both guitars and amplification equipment, and the availability of good

and consistent quality tubes.

There is also an element of nostalgia, with memories of many of the great players of

years gone by, and the desire to use the same types of instruments and equipment to

recapture the magic. Vintage instruments and equipment have also become valuable

collectors items (some with very inflated prices) which adds further to the desirability

of older tools of the trade. There has been a recent trend by many companies to re

market their original instruments and equipment; new guitars can even be bought now

‘pre aged’!

This desire for vintage equipment is also related to guitarists’ reluctance to part with

tube amplification, and there are many reasons why tube and solid state amplifiers

behave differently. Quite simply, if players prefer the sound of tubes, they will

continue to buy and use them. Below are some fundamentals.

nput mpedance

Typically 1M, 500K minimum (humbucking pickup guitars

have volume pots up to 500K, single coil pickup guitars typically of 250K) .

Tone Controls

Magnetic guitar pickups are inductive, and require

compensation, although this opportunity is also used for tone enhancement, not just

correction. Without compensation, they have a strong low middle emphasis and

little high frequency response overall a very muddy and muffled sound. This is

why typical hi fi Baxandall treble & bass controls are unsuitable.

To hear the natural sound of a pickup, use a typical guitar amp with the middle set to

full, and bass and treble on 0. This is actually sets a flat response in the amp (see

below). Expect to hear a muffled and muddy sound. And that's the whole point of

these tone controls providing compensation for the natural sound of a pickup the

middle control simply boosts the pickup's normal ‘middley’ sound. The treble and

bass controls do the opposite they boost higher and lower frequency levels, leaving

TrinityAmps TriFly PCB Builders Guide v1.docx

Page - 13 -

a notch in between for middle cut (see the Fender/Marshall comparison below). So

with typical settings of a bit of bass, middle and treble, the overall tone equalization

complements the natural pickup sound for a balanced response of lows, mids and

highs.

Distortion

The overdriven sound of a tube power amplifier is highly desirable, with many different

output stage designs to produce the variety of trademark sounds heard on modern

recordings. The only problem is that a tube power amplifier is only capable of producing

this sound at one volume (usually, fairly loud!).

There are probably 3 distinctly identifiable types of tube power amplifiers used:

Leo Fender's classic early designs used 6V6 tubes, and later, the higher powered 6L6's. This

gave a characteristic full and punchy sound, suitable for many styles of the day, and later.

Steel and country players like the chime like clean sounds, and blues players were quick to

discover the classic way it breaks up when pushed hard. At really high overdrive, though,

the sound becomes quite dirty, with bass in particular sounding flabby.

Marshall designs started as Fender copies, but soon switched to EL34 output tubes, possibly

for local supply reasons. Anyway, the rest is history. These tubes exhibit a softer overdrive

transition, and maintain clarity even at high overdrive levels. They also have a limited

middle response, giving rise to the famous Marshall crunch sound. The lower powered

EL84 tubes have similar characteristics.

Vox AC30 (and the more popular top boost model) uses a Class AB power amplifier design,

with the tubes biased ‘hot’, so while this operates in class A at lower levels, it is a class AB

design. There's no negative feedback in the power amp either, so this gives a different

sound, often described as a sweeter overdrive. Listen to Brian May's sounds for plenty of

good examples.

The Fender and Marshall designs use class AB for their output designs, biased with the

tubes almost off with no signal. This is more efficient (more watts per tube), and better for

tube life. When you play, tubes take turns handling each half of the signal. This leads to

some (unwanted) distortion as the tubes cross over. Class A designs are rare in medium to

high power guitar amps, but true class A has the tubes operating at half power, with no

signal applied. When you play, the tube fluctuates between full and no power, so there is no

switching to add unwanted distortion. This is a very superficial explanation; please read

elsewhere on the Internet for more detailed descriptions.

Wide Dynamic Range

A plucked guitar string requires a wide dynamic range

to handle the initial peak, and then cleanly amplify the decaying string

vibrations. Some poor designs do not have this capability in their preamp stages, let

alone the power amp to handle this. Pre amplifier stages need generous power rails,

TrinityAmps TriFly PCB Builders Guide v1.docx

Page - 1 -

and should not have gain stages which cause the initial plucked part of the string

sustain envelope to be clipped.

nstrument Speakers

Unlike hi fi speakers, which are designed to keep the

coil entirely within the magnetic field to maximize linearity, instrument speakers are

designed to have the coil partially leave the magnetic field at the extremes of cone

travel. This is partly to protect the speaker, but also produces a ‘soft clipping’ effect

which is desirable with guitar amplifiers. It is also therefore important to match

speaker power ratings reasonably closely with the power of the amplifier. Popular

instrument speakers are available from Tone Tubby, Celestion, Jensen and others.

Note: If you were to use two cabinets hooked directly into the amp, be sure to set

the amp at half the impedance of the cabinets. For example, if your cabinets are 8

ohms each, set the impedance selector to 4 ohms.

Durability

Most musical styles will require the amplifier to be overdriven for

extended periods of time, and the amplifier must be designed to provide this without

duress on any components. Common non guitar design principles assume that

circuitry will be designed to avoid overdrive, and technicians working in this field

have to ‘un learn’ many basic assumptions. Popular circuits have evolved through

trial and error, due to a general lack of documented knowledge in the field of non

linear amplification.

Road Worthiness

Musical equipment of this type needs both physical and

electrical protection. A band often has its equipment transported and set up by a

road crew with little guarantee of physical care. Likewise, an assumption should be

made that the output stage will at times be inadvertently shorted, so most

professional equipment is designed to handle this contingency, preferably

electronically, and at the very least without fuses inside the chassis.

TrinityAmps TriFly PCB Builders Guide v1.docx

Page - 15 -

General Amplifier Operation

Some DO NOTS

•

Never, Never, Never run the amp without a speaker plugged in.

This can cause

major damage.

• Do not flip the power switch off, and then back on rapidly. This can cause

power supply damage.

• Never replace a burned out fuse with a bigger amperage one. Remember

there was a reason the first one burned out, usually protecting something

more expensive. Putting a bigger fuse in will just ratchet up the power level

until something really vital burns out. If the second equal rating fuse pops,

turn it off and get a tech to look at it.

• Never ignore signs of high heat inside a wisp of smoke or a burning smell is

NOT normal.

• Your amp produces lots of heat, and will continue to do so even if you block

the fresh air vents. Blocking the vents will overheat the amp and you may

have to get some very expensive repairs done.

• Never ignore a red glow other than the small orange ends of the filaments. A

red glow over a large part of the internal plates of the output tubes means

they're about to melt. If you notice this, shut it down and get a tech to help

you find out what is wrong.

Some DOs

Add another speaker into the "external speaker" jack; a mismatched speaker load

won't kill it, while an open circuit (disconnected speakers) may do so.

Overdrive the stuffing out of it. Tubes are very forgiving of massive overdrives,

unlike solid state gear. As long as they tubes don't overheat for long periods, it's not

fatal.

TrinityAmps TriFly PCB Builders Guide v1.docx

- 16 -

ntroduction to Vacuum Tubes and Common Terms

Reprinted with permission from Aron from diystompboxes.com

Here are a few terms that you may see online when referencing tube schematics. Like distortion

pedals, tube circuits seemingly have their own language! I present this knowledge in the hopes that

it may help you decipher the interesting life of tubes! : ) Below, is a picture and a very simplistic

view of a tube stage.

As you can see above, in this tiny snippet

of a tube schematic, the terms you commonly see are there in this triode stage example.

Plate the plate is usually connected to a plate resistor which is usually connected to the B+ or

power supply voltage. Typical Plate Resistor values are 100K, 150K, 220K. Larger values equal

more gain.

The Grid is where the signal enters the tube.

The Cathode is usually connected to a cathode resistor which usually goes to ground. The cathode

resistor, along with the Plate resistor, control the gain of the tube stage. Typical values are

anywhere from 100 ohms to 10K. Smaller values = more gain.

It is common to see a cathode bypass cap connected in parallel with the cathode resistor. By

altering the values of the cathode resistor and cathode bypass cap, it is possible to roll off various

degrees of bass with this triode stage. The cathode resistor and plate resistor control the biasing of

the tube. The cathode bypass cap also gives the stage more gain.

Sometimes you see a capacitor in parallel with the plate resistor, much like the cathode resistor

bypass cap. It is usually a small value (i.e. .001uF) and it rolls off highs in the stage. Sometimes you

see a high frequency roll off cap going from the plate pin to the cathode pin 350pf >500pf in

value.

TriFly PCB Builders Guide Version 1.0 Page 17

You will also see a coupling cap in

between triode stages. The coupling cap controls the bass and rolls off bass between stages and

blocks DC from entering the next stage which could throw off the bias on the next tube stage.

As usual, smaller values roll off more bass, larger values retain more bass between stages.

Another modification you may see is a Grid Stopper Resistor, this can also control gain between

stages and also interacts with the tube to roll off highs. Values can be 1.5K >100K. Larger values

roll off more highs and reduce gain between stages. The Grid Stopper Resistor works best when

mounted directly or as close as possible to the grid pin.

"Complete" typical tube preamp stage:

TriFly PCB Builders Guide Version 1.0 Page 18

The grid ("leak") resistor, typically sets the impedance of the stage and biasing. It is interesting

because it and the previous stage's plate resistor form a voltage divider on the signal. What this

means to you is that the grid leak resistor can be used to control the level into the stage. Low grid

leak values will attenuate the signal into the tube stage. If you look at different tube amp

schematics, you can see where they control the level into the stage by using different values for the

grid leak resistor. There is a maximum value that you need to adhere to. Check the datasheet for

the tube you are using to see the typical value of the grid leak resistor. This particular circuit is

called cathode bias which you can read about here.

In summary, the cathode resistor, plate resistor and grid resistor, determine the biasing of the tube

stage. The cathode bypass cap controls the degree of bass reduction generally 25uF passes all

frequencies commonly used in Fender amps, 1uF an 0.68uF are used in Marshall amps. A

capacitor can be placed in parallel with the plate resistor to roll off highs and you see this in bass

channels of amps sometimes. The plate receives the voltage from the power supply through a plate

resistor, the grid receives the AC signal as input and the cathode is grounded through a cathode

resistor.

TriFly PCB Builders Guide Version 1.0 Page 19

Building an Amp

Warning: Do not attempt to build a guitar amp unless you know how to work safely with the

dangerous voltages present in a tube amp. These can exceed 700 volts.

ntroduction

If you have purchased your Trinity Amp as a kit, this guide will help you build a tube guitar

amplifier. It is oriented towards someone who knows a little about electronics but is new to do it

yourself amps. It outlines a simple path to getting a quality amp build.

Switches and wire

Use standard UL approved switches with a 125V/3A rating for the Power and Standby switches.

Use 20 or 22 Gauge insulated solid wire with a 600V rating. It is good to get a variety of colors so

you can color code your wiring.

Physical layout

Make sure the jacks, sockets and pots mounted along the edge won't interfere with parts mounted

on the underside of the chassis. Imagine how chassis will be mounted in the cabinet and make sure

there is enough clearance for the speaker and mounting brackets. Trinity amp chassis are laid out

with serviceability and neatness in mind.

Grounding

It is recommended that you follow the layout provided with your Trinity Amp. It has been tested

and has proven reliable. If you choose to deviate, consider the following information.

Amps traditionally use the chassis for signal ground. This is not the best choice since it can create

ground loops and bad ground connections may develop over time. It is better to use star

grounding in which all of the local grounds are collected at a single ‘star ground’ point. With star

grounding there is only one connection between the chassis and signal ground.

Here are some rules for laying out a star ground. More information on grounding can be found in

the Tube Amp FAQ and the Tech Info page of Aiken Amplification.

(1) Connect the power transformer center tap directly to the negative terminal of the first power

supply filter capacitor (cap) then run a separate wire from the negative terminal to the star ground

point.

(2) Collect the ground points of each tube and its associated resistors and capacitors to a local

ground point that is not connected to the chassis. Run one wire to the star ground point from each

collection.

(3) Run exactly one wire from the star ground point to chassis.

(4) Insulate the input and output jacks from the chassis.

TriFly PCB Builders Guide Version 1.0 Page 20

The safety ground wire from the mains is separate from the signal ground. Run a wire from the

AC ground to the chassis near where the AC power enters the chassis.

nsulated jacks

To insulate the input and output jacks either use plastic insulated jacks or metal jacks with

insulating washers. Some people prefer the increased durability of metal jacks. Insulating a metal

jack requires a shoulder washer with a 3/8’ internal hole that fits a ½’ panel hole.

Minimizing transformer interference

To minimize coupling between the power transformer and output transformer orient them so their

plates are at right angles. If possible, place them at opposite ends of the chassis.

Keep the input stage wiring short and away from the output stages. This minimizes the possibility

of oscillations caused by coupling of the output signal into the input.

Mount the grid resistors as physically close to the grid pins as possible.

Use a twisted pair of wires for the tube filament wiring. Route it away from AC lines and close to

the chassis.

Wiring

The traditional method of constructing amps involved mounting the components on tag board or

fiberboard. This is the technique that is used for Trinity Amplifiers and is the recommended

approach for service and reliability.

Table of contents

Other Trinity Amps Amplifier manuals

Trinity Amps

Trinity Amps Tramp User manual

Trinity Amps

Trinity Amps TRIWATT User manual

Trinity Amps

Trinity Amps Tube Effects Loop User manual

Trinity Amps

Trinity Amps TRIP TOP User manual

Trinity Amps

Trinity Amps OSD User manual

Trinity Amps

Trinity Amps THOR User manual

Trinity Amps

Trinity Amps Triton User manual

Trinity Amps

Trinity Amps Trinity Tweed Amp User manual