Trion Heremidifier Dual Pneumatic User manual

TRION®| www.trioniaq.com

Dual Pneumatic

Atomizing System

READ & SAVE THESE INSTRUCTIONS

Dual Pneumatic

Installation, Operation & Service Manual

2www.trioniaq.com

TABLE OF CONTENTS

I. Warranty ............................................................................................................................................ 3

II. System Operations ..........................................................................................................................4

III. System Components .......................................................................................................................4

IV. System Layout/Installation Guidelines.............................................................................................8

V. Start-Up Procedures.........................................................................................................................10

VI. Operating Instructions .....................................................................................................................11

VII. Maintenance Instructions ...............................................................................................................12

VIII. Troubleshooting Instructions ......................................................................................................... 12

IX. Parts List .........................................................................................................................................15

X. Typical Layouts.................................................................................................................................16

XI. Wiring Diagram................................................................................................................................ 17

IMPORTANT

It is of vital importance that the procedures outlined in this booklet be followed completely. All foreign matter must be

ushed from air and water lines supplying the atomizing heads before the head valves are opened and heads used.

If foreign matter reaches the interior of the heads, each head must be disassembled and thoroughly cleaned - a very

tedious and time-consuming process.

DON’T TAKE SHORTCUTS!

Properly installed and maintained, this system will provide for years of trouble-free service with minimal attention.

Following the steps in the Maintenance section will ensure this. Please read and understand this section. The system

is designed for direct humidication of an area. DO NOT install in duct or air handling systems. Contact TRION for

information on our Herrmidicool system if direct humidication is not possible.

Dual Pneumatic

Installation, Operation & Service Manual

3

www.trioniaq.com

I. WARRANTY

Limited 2-Year Warranty

1. TRION warrants to the buyer or any user during the duration of the Warranty that the TRION/HERRMIDIFIER humidier

described in this manual will be free from defects of material and workmanship for a period of two (2) years.

2. For this Warranty to be effective, this humidier must be installed, operated and maintained in accordance with the Installation

Instructions, Operations and Service Manual(s) supplied with the humidier.

3. In the event of a defect or malfunction in this product during the Warranty Period, user may contact their TRION/HERRMIDIFIER

Representative or TRION Customer Service Department for a Return Material Authorization number. Items tagged with this

number may be returned to the TRION Factory Repair Department for complete reconditioning without charge to the user

for parts or labor. Incidental expenses such as cost of transporting the part/unit to TRION shall be borne by the user. Upon

completion of the reconditioning, the humidier will be returned at no cost to the user. In an effort to keep equipment on line,

TRION may elect to send items out and use the RMA to return alleged defective parts for examination. Credit consideration will

be given upon return and conrmation of improper performance. In either case, items returned without an RMA number will not

be accepted!

4. This Warranty does not cover eld labor for repairs to this humidier or any special, indirect or consequential damages. Some

states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation may not apply to you.

5. If, after a reasonable number of attempts to do so, TRION is unable to remedy any defects or malfunctions in this humidier,

then the user may elect either a replacement of such product or part which may be defective without charge or a refund at the

buyer’s original purchase price.

6. This Warranty gives you specic legal rights, and you may also have other rights, which vary from state to state.

Dual Pneumatic

Installation, Operation & Service Manual

4www.trioniaq.com

II. SYSTEM OPERATION

The Dual Pneumatic atomizing system operates with air and

water under pressure - air at approximately 30 psi and water

at approximately 32 - 38 psi. Air consumption is gured at

.12 SCFM per lbs. of water atomized per hour. A safety

factor of 20% should be added for any potential line losses.

Operation is fully automatic and controlled by humidistats.

When the relative humidity (RH) level drops below the

setting on the control humidistat, the contacts on the control

humidistat close the circuit, opening the solenoid valve on the

air control section. As soon as pressure builds up sufciently

to atomize, the air pressure switch closes the circuit to the

water solenoid valve, starting water ow. Water can not ow

without adequate air pressure. All valves close if there is a

power failure. The water solenoid will close if there is an air

compressor failure.

When the desired level of RH is reached, the humidistat

breaks the circuit, and all solenoid valves close, shutting

off ow of air and water to the heads. The three-way water

solenoid bleeds off the water pressure instantly, allowing the

water valve seat in the head to close immediately, preventing

any chance of dripping or spitting. At the end of each cycle,

the air pressure is allowed to fall gradually to zero through

the heads, blowing all water from the mixing chamber of the

heads. The stainless steel cleaning needle connected to the

diaphragm cleans the water orice of the heads at the end

of each ON cycle. By completely drying the mixing chamber

of each head, mineral build-up is prevented. This cleaning

is so effective that YEARLY maintenance is typically all that

is required!

III. SYSTEM COMPONENTS

A Dual Pneumatic atomizing system consists of atomizing

nozzles, control sections, humidistats, and an adequate air

and water supply.

Atomizing Heads

Atomizing heads are available in capacities of 6, 8, 10, 12, or

15 lbs. of water per hour.

The proper head capacity for a given project is selected on

the basis of installed height of the head above the oor, clear

area available for spray patterns to evaporate, and conditions

to be maintained in the humidied space.

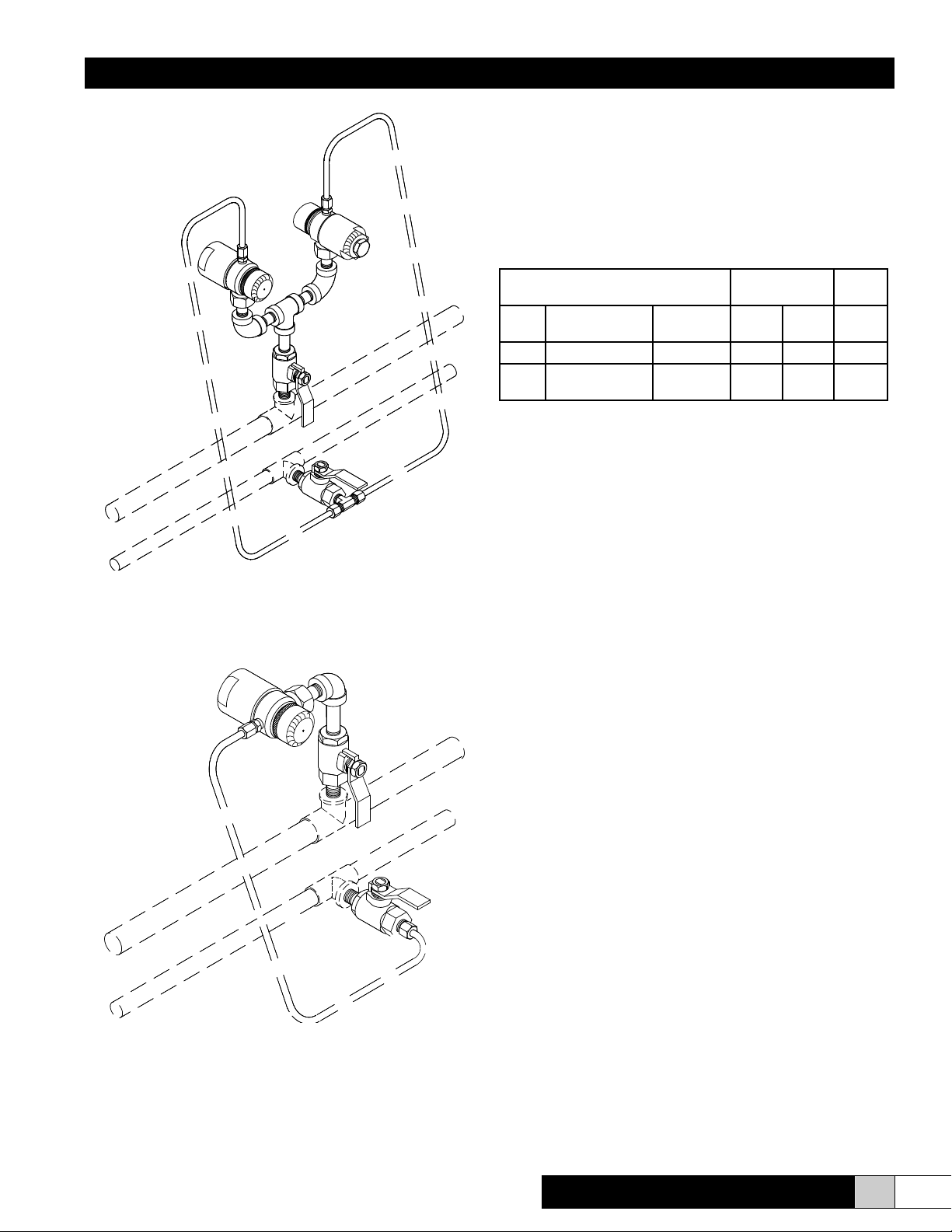

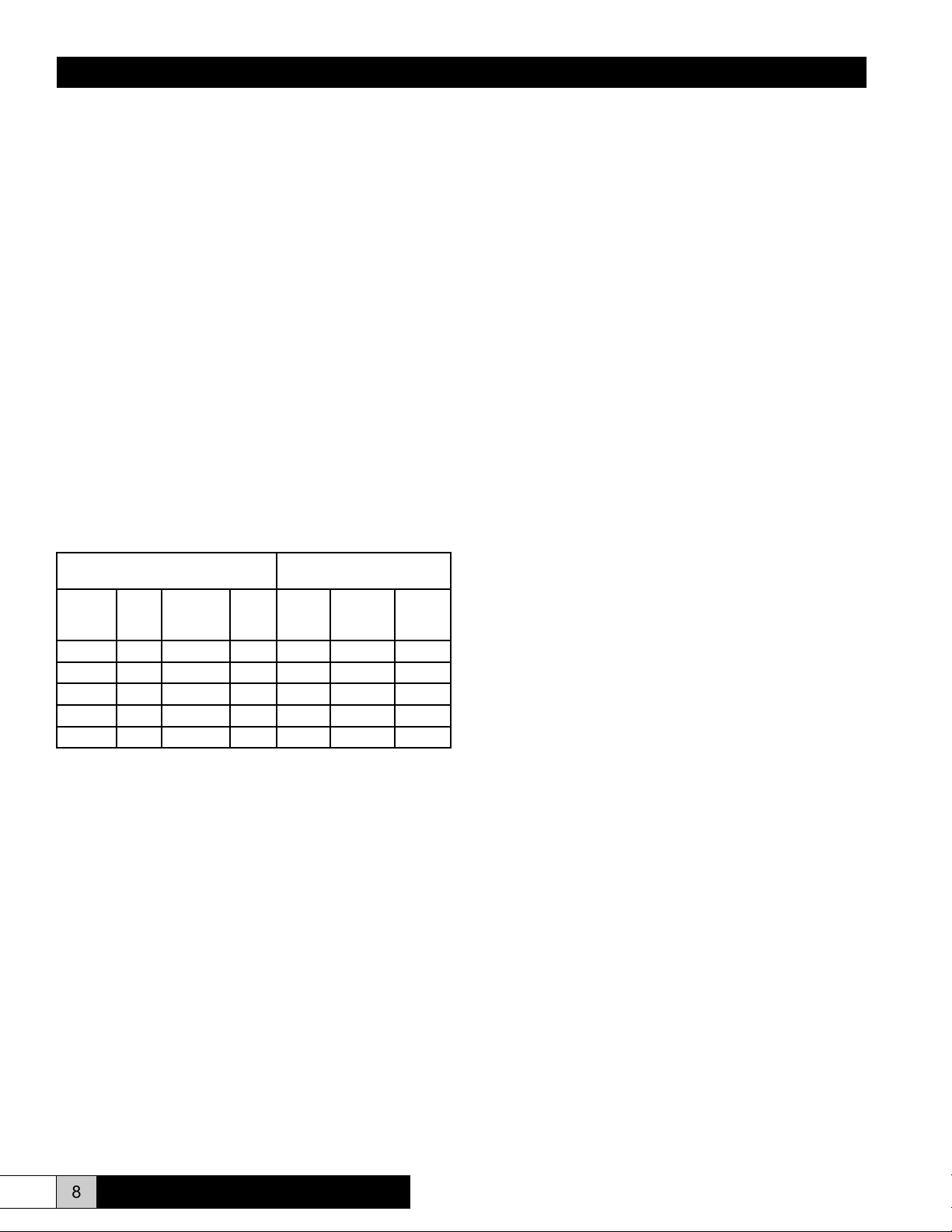

Atomizing head assemblies are available in three versions.

The A-17 assembly (Figure 1) consists of two identical

capacity heads spraying in opposite directions and is

used when areas are clear of obstacles in both directions

and where distances shown in installation section can be

observed.

The B-13 assembly (Figure 2) consists of two identical

capacity head assemblies discharging in the variable

directions of discharge.

Figure 1. A-17 Head Assembly

Dual Pneumatic

Installation, Operation & Service Manual

5

www.trioniaq.com

The A-33 assembly (Figure 3) is a single head assembly for

use in restricted areas.

Control Sections

The control sections provide the following features:

• Regulate plant air and water to desired operating pressures

• Monitor the ow of air and water to the heads via

solenoid valves

• Air pressure switch prevents ow of water to heads until

there is sufcient air pressure for atomization

• Dripless operation and automatic purging of minerals

from heads during system cycling

The standard air control sections are available in two

different sizes, and the water control section is available in

one size (see pages 6-7).

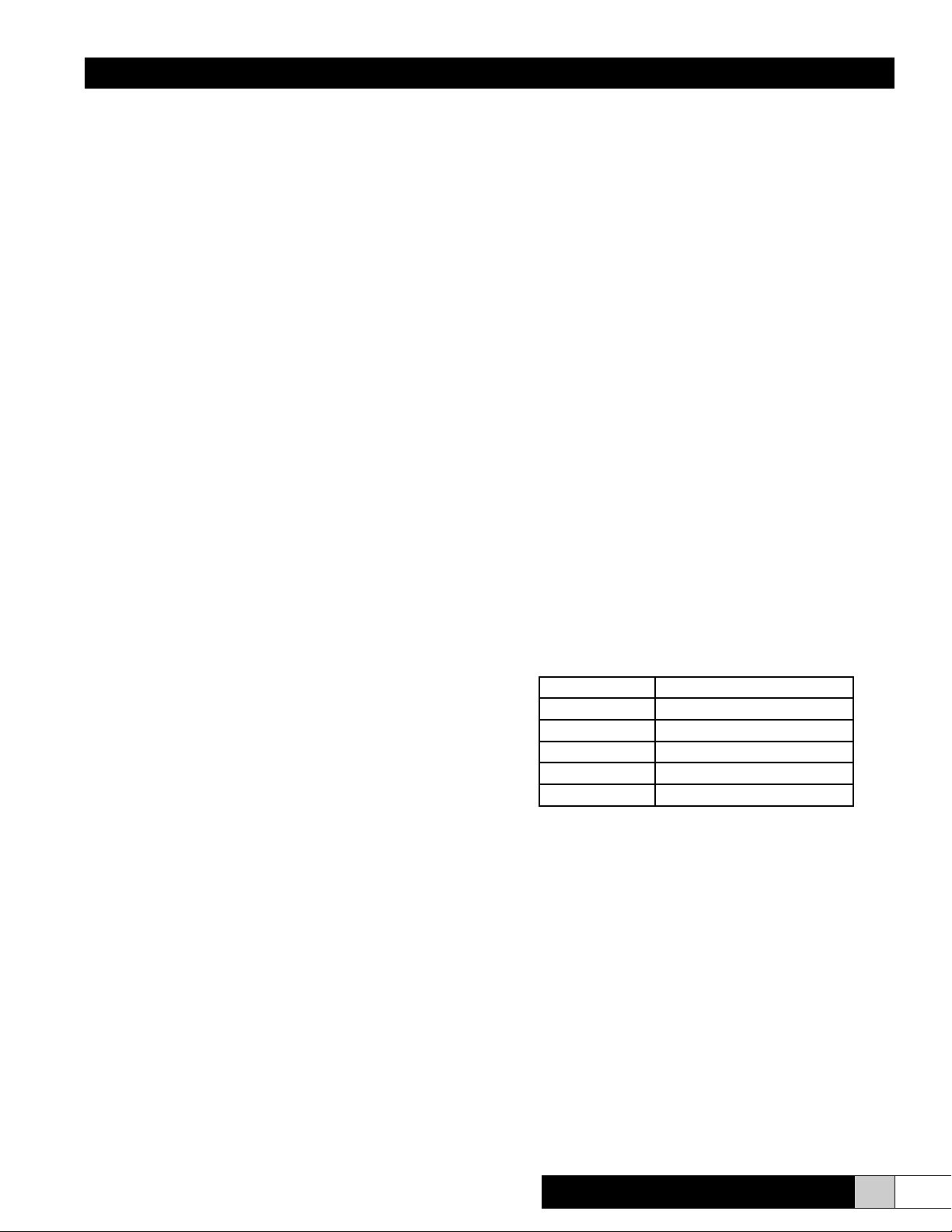

Minimum Pipe

Size to Heads

Size Pipe

Connections

Max.

Capacity Air Water Water

Drain

1/2” 1/2” FPT 240 lbs/hr 3/4” 1/2” 1/2”

3/4” 3/4” FPT Air

1/2” FPT Water 500 lbs/hr 3/4” 1/2” 1/2”

Controls

The standard Dual Pneumatic atomizing system requires

ON-OFF humidistats for operation. Controls may be

provided by others, in which case, consultation with TRION

is essential to ensure proper operation.

Several control options are available from TRION. The

standard system consists of a control humidistat and high-

limit (safety) humidistat. (A hygrometer is optional with any

Dual Pneumatic system.)

For critical applications where extreme tolerances or

temperature and humidity requirement demand it, an

electronic humidistat may be required.

Air Supply

Plant air can be used if supply is adequate. All heads use

12 SCFM of air per 100 pounds of atomized water delivered.

However, a safety factor of 20% should be added for line losses.

Air should run through a minimum of a cyclone type moisture

separator and a 0.5 micron coalescing lter (supplied by

others) to ensure that it is dry and oil-free before it reached

the air control section and the heads.

An air compressor used only for humidication can be

operated at 60-70 psi. No need to run at 125-150 psi, as

this would waste energy.

Water Supply

With any air/water atomization system, any solids in the

water will be distributed into the air during atomization.

Always check the water quality before installing an air/water

atomization system. TRION, or your local lab, can perform

this test for you. The Dual Pneumatic atomizing system is

available for raw and demineralized water supplies. With

your water analysis, you and your TRION/HERRMIDIFIER

representative can determine what, if any, water treatment

is required.

Figure 2. B-13 Head Assembly

Figure 3. A-33 Head Assembly

Dual Pneumatic

Installation, Operation & Service Manual

6www.trioniaq.com

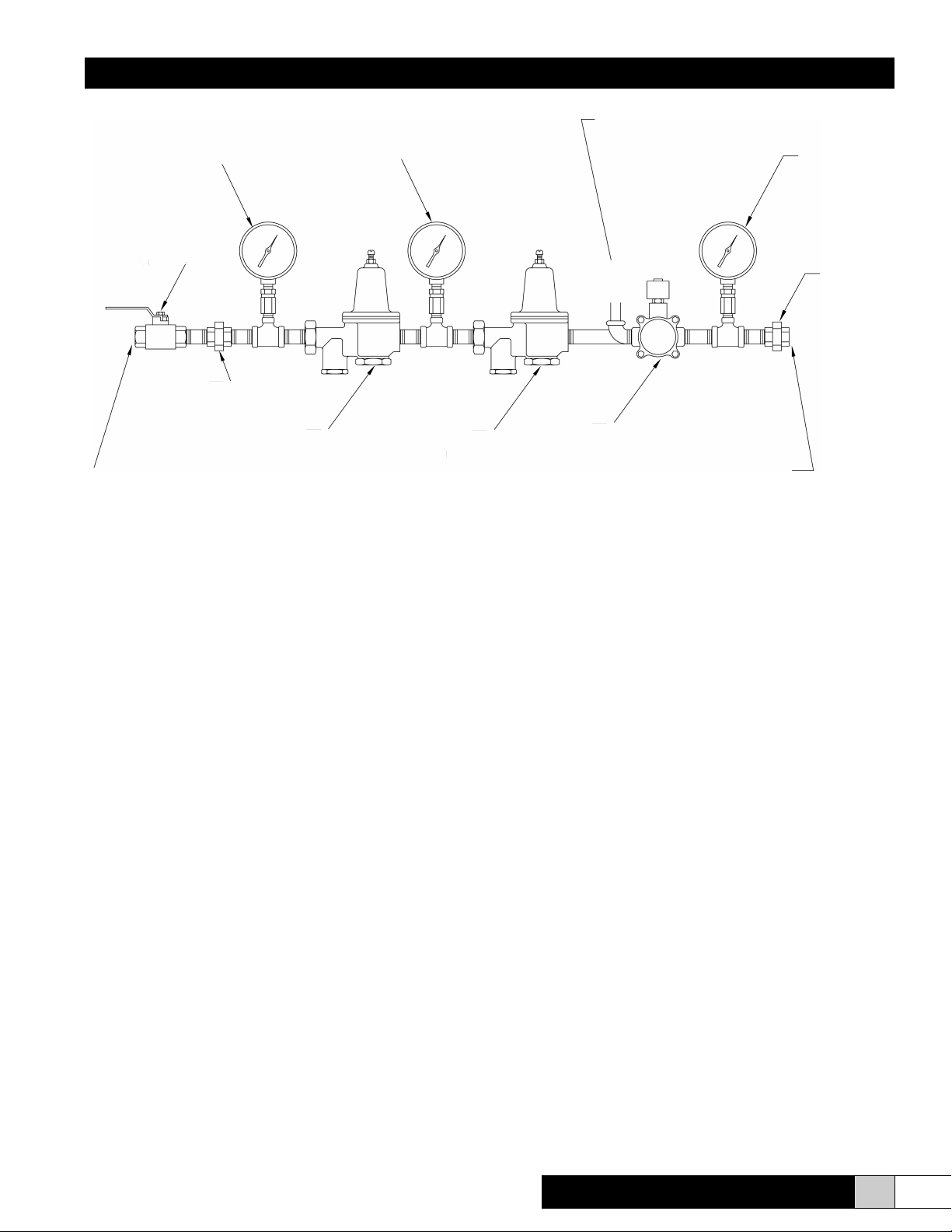

Figure 4. AH-1020 - Air Control Section

For System Capacities up to 240 lbs./hr.

Approximate Measurements: 23” L x 6” H

Figure 5. AH-1050 - Air Control Section

For System Capacities up to 500 lbs./hr.

Approximate Measurements: 32” L x 10” H

Dual Pneumatic

Installation, Operation & Service Manual

7

www.trioniaq.com

OVERALL DIMENSIONS

33"L x 8"H

n

THREE-WAY

WATER VALVE

Figure 6. AH-1021 - Water Control Section

To be Used with AH-1020 or AH-1050 Air Control Sections

Approximate Measurements: 33” L x 8” H

Dual Pneumatic

Installation, Operation & Service Manual

8www.trioniaq.com

IV. SYSTEM LAYOUT AND INSTALLATION

Be sure all parts are used in the system in their proper order

and direction of ow. DO NOT leave out any parts because

they have a different function in the operating system.

Layout of Head Assemblies

1. Be sure all ttings are in their proper place in all head

assemblies. (Reference drawings on the next page).

Do not add parts to these assemblies without permis-

sion from TRION. Head assemblies for systems using

demineralized water supplies will have the same com-

ponents as shown on this page. However, their materi-

als may be different, e.g. PVC or stainless steel.

2. The smallest spray pattern is experienced at low levels

of relative humidity and high temperatures, and the

largest pattern at the high levels of relative humidity and

low temperatures. If the head discharges directly into a

warm air stream that is moving in the same direction as

the head spray discharge, any size head can be used.

(This is found when heads are located at discharge

grilles of an air handling system.) The chart below is a

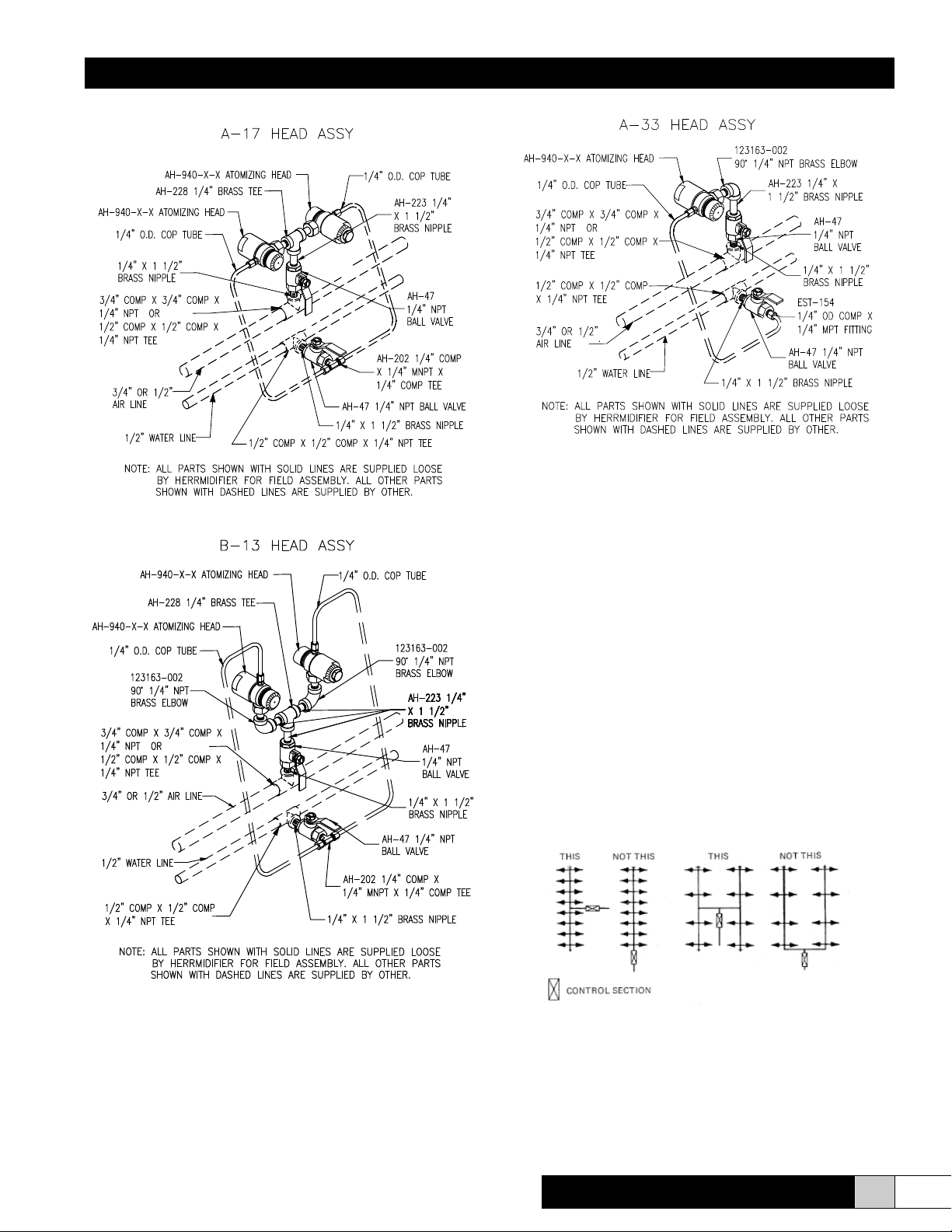

good guide to follow in selecting proper head capacity.

Spray Visible to This Point

from Hd in Med

Head

Cap.

Inst.

Hgt.

Use w/

RH Lvls

Max.

Spray

Dia.

Low

(<45%)

RH

Med

(45-60%)

RH

High

(>60%)

RH

6 lbs/hr Any Any 2.5 ft 10 ft 13 ft 16 ft

8 lbs/hr 12 ft+ Any 2.5 ft 10 ft 13 ft 16 ft

10 lbs/hr 14 ft+ Up to 85% 3 ft 11 ft 14 ft 17 ft

12 lbs/hr 16 ft+ Up to 75% 3.5 ft 12 ft 15 ft 18 ft

15 lbs/hr 18 ft+ Up to 65% 4 ft 13 ft 17 ft 21 ft

Note: The above table applies to installations at normal temperatures

(68°-75° F) and with no forced air movement in the area.

For temperatures 50°-67° F, use rst smaller head size. For

temperatures 32°-49° F, use second smaller head size. For example:

18 ft installed height @ 70° - 65% RH: Select 15 lb/hr head

@ 55° - 65% RH: Select 12 lb/hr head

@ 36° - 65% RH: Select 10 lb/hr head

Important: Obstructions such as columns, stacks of materials, etc. may

indicate that even a lower capacity head might be preferred. Good

air movement in the space results in more rapid evaporation of the

atomized water into the vapor state with shorter spray patterns being

visible. However, very high air movement can carry droplets causing

them to impinge on objects - especially at high levels of RH.

3. The number of head assemblies required should be

calculated and then properly arranged to provide

uniform coverage.

4. Do not locate heads in a manner where the spray will

contact a wall, machine, unit heater, pipes, columns,

conveyer, lights, wires, or obstructions. Distance from

such obstructions should not be less than the maximum

visible spray pattern length. (See chart above.)

5. Heads should be located so that the discharge is away

from personnel to ensure that droplets and evaporative

cooling will not cause discomfort.

6. Do not locate heads in such a manner that they

discharge directly towards one another, unless they

are further apart than twice the maximum distance the

spray pattern is visible. (See chart above.)

7. In all cases, the heads can be further apart than the

maximum visible spray pattern. Due to Dalton’s Law

of Partial Pressures, the water vapor travels throughout

the area very rapidly, and a uniform level of relative

humidity will be attained and maintained automatically.

8. Pipe runs should be kept as short as possible.

9. Head assemblies must have less than 100 feet of pipe

run between the control section and the farthest head

assembly.

10. Head assemblies A-17 and A-33 should be a minimum

of 4 ft. apart on air and water pipes. Head assembly

B-13 should be mounted a minimum of 8 ft. apart.

11. It is recommended that the heads be located above

the air and water lines. However, if this is not practical

for installation or aesthetic reasons, the heads may be

hung below the air and water lines. In this case, the 3/4”

air lines should be run on the bottom and the 1/2” water

line run on top. Air and water takeoffs must always

come of the top of the lines regardless of the position of

the heads. The heads may NEVER be positioned more

than 18” vertically from the air and water lines.

12. Heads installed near a wall with the spray directed away

from the wall should be kept at least one foot away (from

the wall) to allow for start-up adjustment on the heads.

13. Use ONLY copper or plastic air and water lines. DO NOT

USE IRON, STEEL, OR GALVANIZED PIPE, as these

types are especially susceptible to scaling and aking,

which can cause jamming of the head mechanism. If

iron, steel, or galvanized piping must be used before

the system, a lter MUST be installed at the transition.

14. Air and water lines MUST be located so that a straight

level run can be maintained from the control section

to the heads. Avoid excessive curves and NEVER

allow loops in the piping, as these will trap air and

debris. ALL HEADS MUST BE LEVEL AND AT THE

SAME ELEVATION. If loops are unavoidable in routing

piping, air vents must be installed at the high point of

the vertical drop.

15. Hose bibs, supplied by others, must be used on the

ends of ALL water and air lines for each in maintaining

the system.

Dual Pneumatic

Installation, Operation & Service Manual

9

www.trioniaq.com

Control Sections

1. Control sections should be placed where they are easily

accessible and protected from trafc damage.

2. Control sections should be located level with or below air

and water lines, never above. Where heads are located

high, it is advisable to locate the control section at a

height that is accessible with a small ladder. The 1/2”

and 3/4” control sections can be mounted a maximum of

30’ below the height of the heads. If the control sections

are mounted at a level different from the heads, it is

recommended that air and water gauges be placed on

the lines at the height of the heads because the pressure

readings at the control sections and heads will differ.

3. Always be sure the drain from the 3-way solenoid extends

a minimum of 3” above the heads, pipe run, or control

sections. It is advisable to place a union on the drain line

near the control section. If the drain loop is not used,

water will siphon out of the system and allow air into the

water lines causing system malfunction.

4. Feed lines from the control section to heads should be

placed at the midpoint of the pipe run to equalize pressure

and ow in the system.

Control Location

Humidistats are to be at a protected location, on a column or

inside wall. They should be located so they are not affected

by the discharge from the heads, heaters, or air conditioners,

and they should be protected from direct sunlight. There

must, however, be sufcient clearance around the humidistats

Dual Pneumatic

Installation, Operation & Service Manual

10 www.trioniaq.com

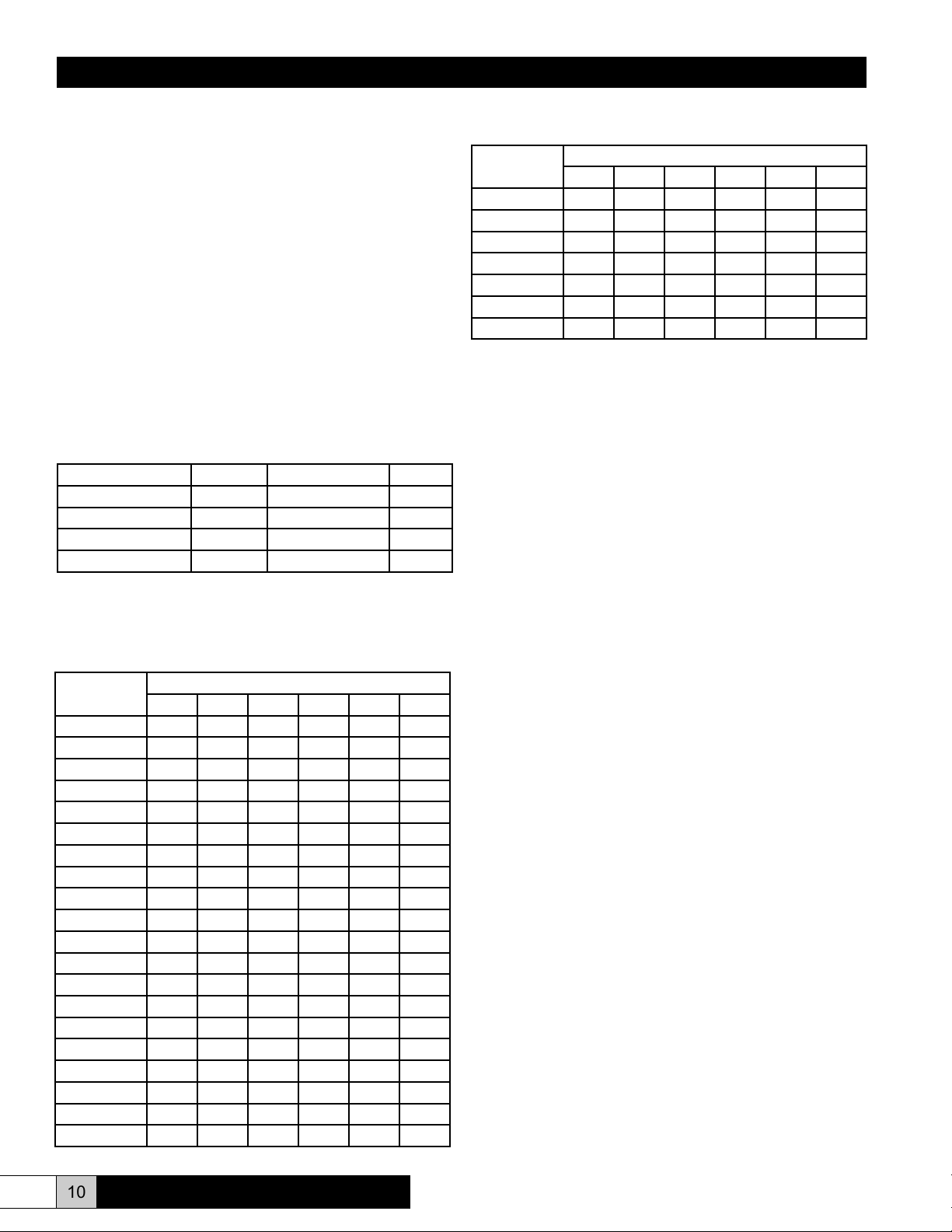

Loss of Water Pressure Due to Friction

in psi per 100 ft. of Type “K” copper tube at 60 PSIG

Flow Gals.

per Min.

Pipe Size

1/2” 3/4” 1” 1 1/4” 1 1/2” 2”

1 1.30 0.25 0.05 - - -

2 4.50 0.85 0.23 0.07 - -

3 9.00 1.70 0.45 0.15 0.063 -

4 15.00 2.80 0.75 0.25 0.10 -

5 22.00 4.20 1.10 0.36 0.16 0.042

6 31.00 5.80 1.50 0.50 0.22 0.058

7 40.00 7.50 2.00 0.65 0.28 0.073

For longer or shorter lengths of pipe,the friction loss is

proportional to the length.

Example: AIR LINE 500 ft. One half of the above

4,000 ft. Four times the above

WATER LINE 50 ft. One half the above

400 ft. Four times the above

5. Follow start-up procedure EXACTLY. Repeat the start-up

procedure every time the system is drained or cleaned.

V. START-UP PROCEDURES

1. CHECK INSTALLATION WITH THE LAYOUT

DRAWING. Be sure that the equipment has been

installed exactly as laid out on the system drawing

- location of head assemblies, control sections,

humidistats, etc. and that the proper size pipe has

been used on all air and water supply lines as well as

drain lines. (Frictional losses and pressure drops were

considered in making the layout.)

2. CLOSE ALL AIR AND WATER VALVES AT EACH

HEAD ASSEMBLY. It is vitally important that no foreign

matter in the supply lines - air and water - gets into the

heads.

3. CLEAN MAIN SUPPLY LINES TO CONTROL

SECTIONS. Close air and water valves on the incoming

side of all control sections. Start the air compressor.

Open the main valves at the air compressor and water

source. Break the unions just ahead of the incoming air

and water pressure gauges of the control sections. AIR

MAIN LINE: Put on safety glasses. Place a cloth over the

open air line to catch any ying debris. Place a bucket

over the end of the air line. Slowly open the valve and

let the air line blow until clean. DO NOT LOOK INTO

THE BUCKET WHILE THE AIR IS BLOWING. Close the

valve and retighten the union securely. WATER MAIN

LINE: Repeat the above procedure for the water line.

Clean lines to all control sections as described above.

4. CHECK ELECTRICAL WIRING OF CONTROLS. Set

the SAFETY humidistat to maximum. Set the CONTROL

humidistat to 20%. NOTE: If only one humidistat is used,

set to 20% or switch it to OFF. Open air valve ONLY to

feed air to control section. Do NOT open water valve.

to properly sense the relative humidity of the surrounding air.

(See Wiring Diagram on page 17.)

Other Considerations

1. Air must be free of oil and water. It is wise to place lters

on both the air and water feed lines ahead of the control

sections. TRION recommends the use of a moisture

separator and trap and a coalescing lter on the air line.

2. To prevent condensation on uncovered cold water pipes

in the system, it is advisable to consider using aftercooler

water from the air compressor in the humidication

system. If this is not practical, a heater for the system’s

water supply may be used.

3. If the water supply pressure uctuates and doesn’t

maintain 50 psi at the highest level of a head assembly,

it will be necessary to supply a water pressure booster

pump or bladder tank for the system. Consult TRION for

assistance in sizing pump and tank.

4. With extremely large systems, supply piping should be

sized as follows:

System Cap. - Water MIN. Water System Req. - Air Min. Air

Up to 1,000 lbs/hr 1/2” 10 - 24 CFM 3/4”

1,000 to 2,000 lbs/hr 3/4” 24 - 45 CFM 1”

2,000 - 3,000 lbs/hr 1” 45 - 70 CFM 1 1/4”

Over 3,000 lbs/hr 1 1/4” 70 - 100 CFM 1 1/2”

Supply piping should be sized to control sections so as to

minimize pressure drop in accordance with table below.

Cu. Ft. Free

Air per Min.

Pipe Size

1/2” 3/4” 1” 1 1/4” 1 1/2” 2”

10 6.50 0.99 0.28 - - -

20 23.90 3.90 1.31 0.25 0.11 -

30 58.50 9.01 2.51 0.57 0.26 -

40 - 16.00 4.45 1.03 0.46 -

50 - 25.10 6.96 1.61 0.71 0.19

60 - 36.20 10.00 2.32 1.02 0.28

70 - 49.30 13.70 3.16 1.40 0.37

80 - 64.50 17.80 4.14 1.83 0.49

90 - 82.80 22.00 5.23 2.32 0.62

100 - - 27.90 6.47 2.86 0.77

125 - - 48.60 10.20 4.49 1.19

150 - - 62.80 14.20 6.43 1.72

175 - - - 19.80 8.72 2.38

200 - - - 25.80 11.40 3.06

250 - - - 40.40 17.90 4.78

300 - - - 58.20 25.80 6.85

350 - - - - 35.10 9.36

400 - - - - 45.80 12.10

450 - - - - 58.00 15.40

500 - - - - 71.60 19.20

Loss of Air Pressure Due to Friction

in psi per 1000 ft of pipe at 100 PSIG

Dual Pneumatic

Installation, Operation & Service Manual

11

www.trioniaq.com

Adjust air pressure regulator of control section to 30 psi.

Slowly move the CONTROL humidistat to a higher RH

until you hear a “click” indicating the 2-way solenoid valve

on the air control section has opened. NOTE: If only one

humidistat is used, follow above procedure slowly raising

RH setting, or if switch is used, turn to ON. Reduce the

setting on the SAFETY humidistat until you hear a click

indicating the 3-way solenoid on the water line has closed.

(If no safety humidistat is used, skip this step.) Open the

AIR valve ONLY on one pair of heads. There should be a

constant ow of air from the heads with no ow of water.

This will indicate that the controls for the control section

are properly wired. Make any corrections needed. Close

the air valve after determining wiring is correct. Repeat

the above at each control section in the system.

5. CLEAN DISTRIBUTION LINES FROM CONTROL

SECTIONS TO HEAD ASSEMBLIES. IMPORTANT:

Be sure all air and water valves at head assemblies are

closed (Step 2). AIR LINES: Put on safety glasses. With

CONTROL humidistat ON and air valve at control section

open, place bucket and cloth over hose bib at end of each

air line and slowly open the hose bib and allow line to

blow clean. DO NOT LOOK INTO BUCKET WHILE AIR

IS BLOWING. Close hose bib. Repeat on all air lines

from each control section. WATER LINES: (Air valve at

control section should be open.) Set SAFETY humidistat

at maximum and CONTROL humidistat ON. Open water

valve at control section. Place bucket or hose on ends

of water lines and slowly open hose bibs. Allow water to

ow until clean. Throttle valve to avoid splashing. Close

hose bib. Close air and water valves at control section.

Repeat on all water lines from each control section.

6. STARTING THE SYSTEM. Close air and water valves

at all control sections. Open air valves only at all head

assemblies. Set humidistats high enough to assure

system operation. Open AIR valve at control section.

With air owing through heads, adjust primary air

pressure regulator (or compressor) to maintain 55 psi.

Adjust control section air pressure regulator to 30 psi.

With water valve open at water source, open the control

section water valve and the water valve of the ONE

head assembly located the GREATEST distance from

the control section. Adjust the primary water pressure

reducer to provide 45-50 psi to the control section.

Adjust control section water valve to provide 32-38 psi

to heads. Open the water valve at each head assembly,

checking and correcting for air and water leaks as you

go. CAUTION: Never let water pressure get below

air pressure as air will then get into water lines and

necessitate bleeding of lines. Repeat procedure on all

control sections and primary reducers. Normally, with all

heads operating, it will be necessary to again adjust the

primary water pressure reducer to 45-50 psi and control

section water pressure regulator to 32-38 psi. Tighten

the locknut on all WATER pressure regulators - primary

and control section. All further adjustments will be made

on air controls and at heads. With the entire system in

full operation, check for leaks in all air and water lines,

ttings, connections, valves, control sections, and head

assemblies. Correct as required.

7. FINAL ADJUSTMENTS TO HEADS. Remove cap

(253206-00X) of each head. This cap is at the non-

discharge end of the head and covers the head adjusting

“spring tension nut” (253207-00X). Slowly turn this

adjusting nut in a clockwise direction until no water is

discharged by the head. Use care to avoid damage to

the valve seat. Then, back off this adjusting nut TWO full

turns counter clockwise. This may result in an excessively

heavy spray, but this will be adjusted later in the control

section. Replace cap. Repeat this operation on every

head on the system. NOTE: Maintain air pressure at 30

psi and water pressure at 32 - 38 psi. Do NOT let air

pressure exceed water pressure.

8. BALANCING THE SYSTEM. The nal and most

important adjustment will be made at the air pressure

regulator of each control section. Adjust the air regulator

to 30 psi; adjust water pressure for proper head capacity.

Increasing the air pressure to the heads results in smaller

droplet size in discharge pattern - and vice versa. Spray

pattern should be visible to at least 10’ from the head to

assure rated capacity. With the system in full operation,

adjust the safety humidistat to 10% above the desired

level. Remove the cover of this humidistat and set the

low and high limit stops to the RH setting so the setting

cannot be changed. Replace cover. Move the CONTROL

humidistat setting alternately lower and higher to cycle

the system OFF and ON several times until all gauges

become repetitive in action and readings.

Water Pressure Settings

Head Capacity Water Pressure Setting (PSI)

6 32

8 38

10 33

12 35

15 37

Note: A new system may require some adjustment until all parts are

properly seated during break-in. This period may last about two weeks.

After that, adjustments may not be required but should be checked on a

regular schedule. Set the humidistat at the desired level.

CAUTION:

1. Do not balance the system by adjusting individual heads. Each

head has been adjusted to provide its design capacity.

2. Do not throttle any valves at control sections or head assemblies to

get nal adjustment.

VI. OPERATING INSTRUCTIONS

The Dual Pneumatic Atomizing System utilizes air and water

under pressure to atomize the water into tiny droplets (2-

15 microns with an average of 7.5). These droplets rapidly

evaporate to a gaseous state to raise the level of relative

humidity.

Dual Pneumatic

Installation, Operation & Service Manual

12 www.trioniaq.com

Each Dual Pneumatic Atomizing System is custom designed

for each application to maintain the level of relative humidity

desired under the conditions to be maintained with the

equipment as it exists in the area at the time. If ANY

conditions change, the demand load for humidication can

be affected.

Once the system is installed, checked out, and started in

accordance with the instructions contained in this manual,

operation is completely automatic to maintain the level

of relative humidity. With air and water supplied to the

equipment, the system cycles ON and OFF as needed.

Set the desired level of RH on the control humidistat, 10%

more on the safety humidistat, and you can walk away and

forget it.

If there is a POWER FAILURE, the system automatically

shuts off.

If there is an AIR COMPRESSOR FAILURE, the system

automatically shuts off.

If there is a FAILURE OF THE WATER SUPPLY, the heads

will blow air.

If the water supply PRESSURE is lost or reduced, the heads

will “sputter”.

If the CONTROL humidistat fails to shut off the system, the

SAFETY humidistat will shut off the water to the heads at 10%

above the desired level of RH. You cannot over-humidify to

any greater extent than the 10%.

The atomizing heads operate drip free and are self-cleaning

and self-purging at the end of every ON cycle. The system

is designed to go ON and OFF. Without this cycling, the

cleaning and purging action is lost.

The system can be started and stopped by merely operating

the control humidistat.

All humidication equipment needs periodic maintenance.

The procedure for the Dual Pneumatic System is spelled out

in that section of this manual. Otherwise, the operation is

fool-proof and dependable.

VII. MAINTENANCE INSTRUCTIONS

The Dual Pneumatic Atomizing System requires little

maintenance to keep it operating properly. In hard water

areas and dusty atmospheres, more frequent attention will

be required.

NORMAL MAINTENANCE required is as follows.

• AIR COMPRESSOR: Follow the air compressor

manufacturer’s instructions.

• ATOMIZING HEADS: Clean dust and debris from the

OUTSIDE of the heads as required to keep the spray

pattern adequate. At least ONCE A YEAR, remove the

atomizer nozzles (AH-941-X-X). Clean these nozzles in

a weak acid solution. Do NOT use a wire or other object

that will score the nozzle or its orice.

• AIR & WATER LINES: Blow out all supply lines at least

ONCE A YEAR using the procedures covered under

start-up of the system in this manual. Check all joists

and valves for leaks ONCE A YEAR.

• STRAINERS: Strainers on air and water controls (both

primary regulators and control section regulators) should

be cleaned ONCE A YEAR and replaced as required.

Strainer screens (AH-21) in the strainer union assembly

(AH-17) of each head should be cleaned ONCE A YEAR.

If air strainers are dirty or oily, it may be necessary to

install an air dryer or after cooler on the compressor or a

separator on the air line.

• HUMIDISTATS: Calibration should be checked with a

dependable psychrometer at least ONCE A YEAR and

adjusted as needed.

• HYGROMETERS: (RH indicators) Use psychrometer to

check for accuracy.

• PRESSURE REGULATORS: Air and water (primary

and control sections) - check operation at least ONCE A

YEAR to be sure regulation to desired pressures is being

maintained properly.

• SOLENOID VALVES: Air and water (control sections) -

check operation at least ONCE A YEAR to be sure their

operation is proper and valves do not leak.

After the removal and re-installation of heads and control

sections, ALWAYS follow the start-up procedure to be sure

all foreign matter is ushed from the lines and none reaches

the heads.

Your system will last indenitely if properly maintained.

VIII. TROUBLESHOOTING

HEAVY SPRAY PATTERN (Droplets too large)

ALL HEADS served by one control section: either this is

caused by too low a setting on the air pressure regulator of

the air control section, which calls for slightly increasing the

air pressure - or too high a setting on the water regulator

of the water control section, which requires decreasing the

water setting slightly.

NEVER LETAIR PRESSURE EXCEED WATER PRESSURE.

INDIVIDUAL HEADS: These heads are not getting enough air.

1. Foreign matter may be clogging the screen (AH-21) in

the air strainer union (AH-17) of the head.

2. One or more heads served by the same control section

may have been IMPROPERLY ADJUSTED by throttling

the valves at the head assembly. No valves should ever

be throttled!

3. Water nozzle (AH-942-X) orice may have been enlarged

due to bent cleaning needle on diaphragm (AH-10).

Dual Pneumatic

Installation, Operation & Service Manual

13

www.trioniaq.com

Replace parts as required.

4. Atomizer nozzle (AH-941-X-X) orice may have been

enlarged due to improper cleaning or dirty air. (See

Maintenance section.) Replace parts as required.

SPRAY PATTERN TOO LIGHT

ALL HEADS served by one control section: either this is

caused by too high a setting on the air pressure regulator of

the air control section, which calls for slightly decreasing the

air pressure - or too low a setting on the water regulator of

the water control section, which requires increasing the water

setting slightly.

INDIVIDUAL HEADS: Heads are not getting enough water.

1. Water valve at head may have been throttled. No valves

should ever be throttled! Adjust head and shown in Step

7 of start-up procedure.

2. Foreign matter may be restricting water ow in the water

nozzle (AH-942-X). Shut off air and water valves at head

assembly. Remove atomizer nozzle (AH-941-X-X) and

water nozzle (AH-942-X) with wrench. DO NOT use wire

or hard object that will score inside.

SPUTTERING HEADS

ALL HEADS served by one control section: air pressure at

heads exceeds water pressure at heads.

• Adjust air and/or water pressure at control section so that

air pressure is about 2 psi lower than water pressure.

• Three-way solenoid on water control section may be

malfunctioning to allow water to leak down drain port

when system is operating. This may be caused by dirt

under the drain valve seat or a bad valve seat on the

drain side of the three-way solenoid. NOTE: The drain

side of the three-way solenoid should open only when

the system shuts off. Approximately one cup of water

should be drained from the system between cycles. A

greater amount may be a sign of air trapped in the water

line. Review start up procedure.

INDIVIDUAL HEADS:

1. Water valve supplying head assembly has been throttled.

No valves should ever be throttled.

2. Head improperly adjusted. Follow Step 7 of start-up

procedure.

3. Part malfunctioning inside head. Check diaphragm (AH-

10), spring (AH-8), and valve disk (AH-16). Correct as

required.

INOPERATIVE HEADS (No air or water)

ALL HEADS served by one control section:

1. These heads shut down because control humidistat is

satised.

2. If proper RH level has not been attained, check calibration

of the control humidistat and adjust if required. Use a

dependable psychrometer.

3. Air and water valves serving the control section are not

open.

4. Electric current not owing to central section. Check

wiring and supply lines.

5. Compressed air is not reaching the control section.

Possible compressor failure.

INDIVIDUAL HEADS:

1. Be sure air and water valves at head assembly are

fully open.

2. Indicates diaphragm (AH-10) may be ruptured or

leaking OR water and air ports clogged. Close air and

water valves at head assembly. Remove rear part of

head (Bonnet, 253209-00X) with a wrench. Examine

the diaphragm (AH-10), spring (AH-7), and valve disc

(AH-16). Replace any bad parts. If these parts are

OK, reassemble the head. CAUTION: Use care in

reassembling so that cleaning needle is not damaged.

Remove atomizer nozzle (AH-941-X-X) and water nozzle

(AH-942-X). Clean these nozzle ports with air pressure

or as recommended under maintenance. DO NOT use

a wire or any object that will score the inside or port of

the nozzles. Reassemble the head, open the air valve

of the head assembly, then the water valve of the head

assembly and adjust spray pattern. (See Step 7 of the

start-up procedure.)

AIR WITHOUT WATER

ALL HEADS served by one control section: be sure water

valve at control section is open. RH exceeds that set on the

SAFETY humidistat. This shuts off water to all heads but

allows air to ow. Correct this condition by:

1. Set SAFETY humidistat higher than CONTROL

humidistat.

2. Make sure CONTROL humidistat is functioning to start

and stop system.

3. Check calibration of BOTH humidistats with a dependable

psychrometer.

4. Check the setting on the air pressure switch and be sure

that the switch is cutting in at 26 psi and out at 20 psi of

air pressure. Adjust accordingly by setting high end rst

at 26 psi and then turning low end up against it.

INDIVIDUAL HEADS:

1. Water cut-off at valve at head assembly.

2. Water nozzle (AH-942-X) plugged with foreign matter.

Correct as above under “Spray Pattern Too Light”.

HUMIDITY LEVEL TOO LOW

1. Be sure CONTROL humidistat is set at desired RH.

2. Check calibration of CONTROL humidistat and

HUMIDITY INDICATOR with dependable psychrometer

and adjust as required.

3. Be sure humidistat is not being “inuenced” by the spray

pattern of a head coming too close to it. Correct as

required.

4. Be sure humidistat is not being “inuenced” by a cold air

stream blowing directly on it. Correct as required.

5. The temperature of the air in the area being humidied

may be different for than that for which the system was

designed. If so, AND this changed temperature will now

Dual Pneumatic

Installation, Operation & Service Manual

14 www.trioniaq.com

be maintained, additional humidication equipment will

now be required. Call your TRION/HERRMIDIFIER

representative.

6. Exhaust, make-up air, or cooling equipment may have

been added to the area since the system was designed.

These add to the maximum demand load, and additional

humidication equipment will now be required. Call your

TRION/HERRMIDIFIER representative.

HUMIDITY LEVEL TOO HIGH

1. Be sure CONTROL humidistat is set at desired RH (and

SAFETY humidistat about 10% higher than control).

2. Check calibration of CONTROL and SAFETY humidistats

as well as the RH indicator with a dependable

psychrometer and adjust as required.

3. Be sure humidistat is not being “inuenced” by a hot air

stream blowing directly on it. Correct as required.

EXCESSIVE AIR CONSUMPTION

Dual Pneumatic Atomizing Systems consume a maximum of

12 CFM of free air delivery per 100 lbs. of water atomized

per hour.

1. Check ALL air line joints, valves, and valve stems

throughout entire compressed air system (not just the

Dual Pneumatic system) for leaks and correct as required.

2. Air compressor may not be delivering rated capacity

because of maintenance work needed.

3. Other air operated equipment in plant may be consuming

more air than it should because of maintenance work

needed.

4. Air operated equipment may have been added to the

plant which caused the total air consumption needed to

exceed rated capacity of the air compressor.

Dual Pneumatic

Installation, Operation & Service Manual

15

www.trioniaq.com

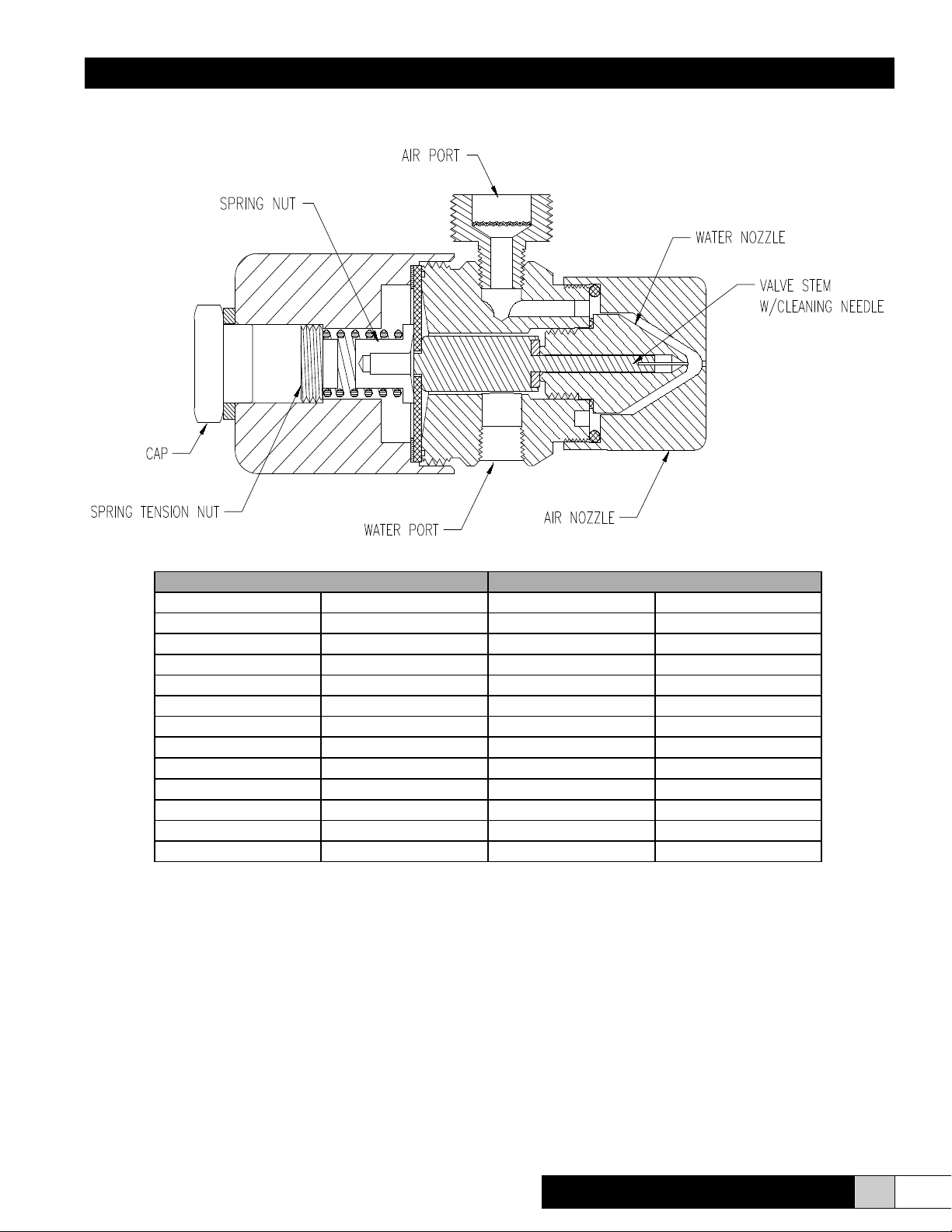

IX. PARTS LIST

Brass Nozzle Consists of: SS Nozzle Consists of:

Part # Description Part # Description

253205-001 Nozzle Body 253205-002 Nozzle Body

253209-001 Bonnet 253209-002 Bonnet

AH-941-1-”X” Air Nozzle AH-941-2-”X” Air Nozzle

AH-942-1(R) Water Nozzle AH-942-2(R) Water Nozzle

253206-001 Cap 253206-002 Cap

253207-001 Spring Tension Nut 253207-002 Spring Tension Nut

253208-001 Spring Nut 253208-002 Spring Nut

AH-12(R) Valve Stem w/ Needle AH-12(R)-SS Valve Stem w/ Needle

AH-19A Air Port AH-19ASS Air Port

AH-18A Union Tail Piece AH-18ASS Union Tail Piece

AH-20 Union Nut AH-20SS Union Nut

AH-1RK (Note 1) Rebuild Kit AH-1RK Rebuild Kit

“X” Denotes nozzle rating in pounds/hour (6, 8, 10, 12 or 15 lb/hr).

Notes:

1. AH-1RK Kit includes: Diaphragm, AH-122 “O” Ring, AH-14 Air Nozzle Gasket, AH-15 Water Nozzle

Gasket, AH-16 Valve Disk, AH-21 Strainer Screen, AH-23 Diaphragm Washer, AH-8 Spring, FV-17-

1 Union Washer

2. Always specify nozzle rating in lbs/hr on any nozzle parts order.

3. The notation for (R) is used when capacity of head is 6 or 8 lbs/hr.

Dual Pneumatic

Installation, Operation & Service Manual

16 www.trioniaq.com

X. TYPICAL LAYOUTS

Dual Pneumatic

Installation, Operation & Service Manual

17

www.trioniaq.com

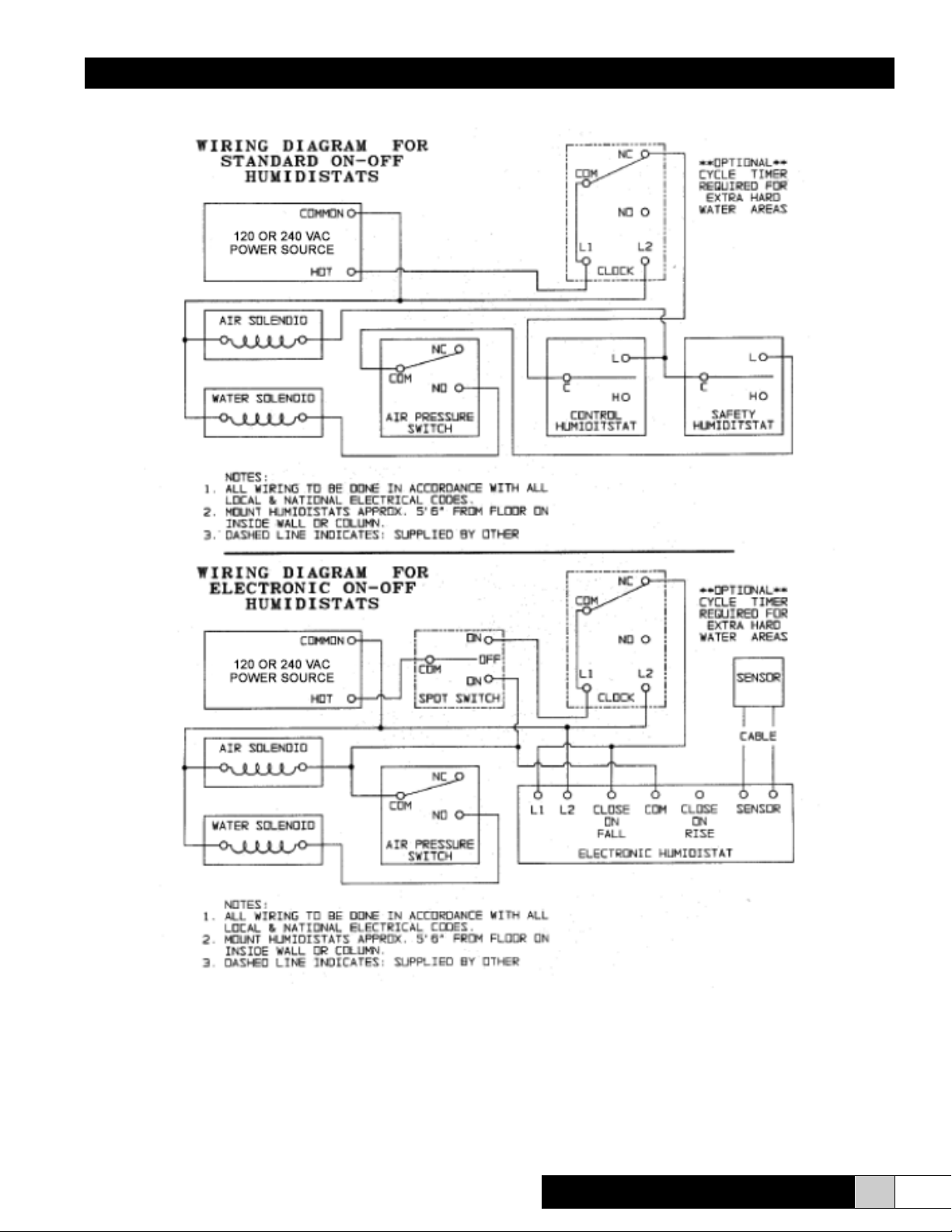

XI. WIRING DIAGRAMS

© 2018 TRION. All Rights Reserved.

TRION®

101 McNeill Rd. | Sanford, NC 27330

Form No. AH-22 Rev. 06/18

Table of contents