triOS Dissolved Oxygen User manual

Dissolved Oxygen

OPERATING INSTRUCTIONS

1

TABLE OF CONTENTS

Table of Contents

1 General Information 2

1.1 Introduction 2

1.2 Health and Safety Information 3

1.3 Warnings 4

1.4 Users and Operating Requirements 4

1.5 Intended Use 4

1.6 Disposal Information 5

1.7 Certicates and Approvals 5

2 Introduction 6

2.1 Product Identication 6

2.2 Scope of Delivery 7

2.3 Measurement Principle and Design 7

3 Commissioning 8

3.1 Electrical Installation 8

3.1.1 Fixed Cable with M12 Industrial Plug 8

3.2 Interfaces 8

3.2.1 Serial Interface 8

4 Use 9

4.1 Normal Operation 9

4.2 Bypass Installation 9

4.3 Support Tube Installation 10

5 Calibration 12

5.1 Two-Point Calibration 12

5.1.1 Oset Calibration 12

5.1.2 Slope Calibration 12

5.2 One-Point Calibration 13

5.3 Measurement Properties 13

5.3.1 Inuences on the measurement 13

5.3.2 Temperature Compensation 13

5.3.3 Atmospheric pressure 13

5.3.4 Salinity 13

6 Malfunction and Maintenance 14

6.1 Cleaning and Upkeep 14

6.2 Maintenance and Inspection 14

6.2.1 Changing the Membrane Cap 15

6.3 Troubleshooting 15

6.3.1 Implausible Values 15

6.4 Returns 15

7 Technical Data 16

7.1 Technical Specications 16

7.2 External Dimensions 17

8 Accessories 18

8.1 TriBox 3 18

8.2 TriBox Mini 18

9 Warranty 19

10 Customer Service 20

11 Contact 21

12 Keyword Index 22

Annex 24

2D01-903en201912 Manual Dissolved Oxygen

General Information // Dissolved Oxygen

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

1 General Information

1.1 Introduction

Welcome to TriOS.

We are glad that you have chosen to purchase the Dissolved Oxygen sensor.

The Dissolved Oxygen sensor is based on luminescent optical technology. With only low calibration requirements and thanks

to an ultra low power technology, the sensor meets the demands of eld works and short or long term campaigns. Without

oxygen consumption, this technology allows you an accurate measure in all situations and especially in very low oxygen con-

centrations. The “smart” Oxygen sensor stores calibration and history data within the sensor. This allows you a “plug and play”

system without re-calibration.

In this manual, you will nd all of the information you will need to commission the Dissolved Oxygen sensor. Technical speci-

cations, detection limits and dimensions can be found in chapter 7.

Please note that the user is responsible for complying with local and national regulations on the installation of electronic de-

vices. Any damage caused by incorrect use or unprofessional installation will not be covered by the warranty. All sensors and

accessories supplied by TriOS Mess- und Datentechnik GmbH must be installed and operated in accordance with the speci-

cations provided by TriOS Mess- und Datentechnik GmbH. All parts were designed and tested in accordance with international

standards for electronic instruments. The device meets the requirements of the international regulations on electromagnetic

compatibility. Please use only original TriOS accessories and cables to ensure reliable and correct operation of the devices.

Before using the device, read the manual carefully, and keep this manual on hand so it can be used later. Before commissioning

the sensor, please make sure that you have read and understood the following safety precautions. Always make sure that the

sensor is operated correctly. The safety precautions described on the following pages should ensure the reliable and correct

operation of this device and any additional associated devices and should prevent injuries to yourself or other persons and

damage to other equipment.

If the translation is at all dierent from the original German text, the German version is binding.

Copyright Notice

All of the content in this manual, including texts, photographs and graphics, are protected by copyright. Unless expressly

stated otherwise, TriOS Mess- und Datentechnik GmbH is the owner of the copyright. Violations of this copyright will be pun-

ishable according to section 106 of the German Copyright Act. The violator will be warned at his own expense and must pay

compensation.

NOTICE

3

D01-903en201912 Manual Dissolved Oxygen

Dissolved Oxygen // General Information

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

1.2 Health and Safety Information

This manual contains important information about health and safety rules. This information is labelled according to the in-

ternational specications of ANSI Z535.6 (“Product safety information in product manuals, instructions and other collateral

materials”) and must be followed strictly. The distinction is made between the following categories:

Tip / Useful Information

Can result in damage to property

Warning / may lead to serious injury or death

Caution / may cause moderate injury

Electromagnetic Waves

Devices that radiate strong electromagnetic waves can inuence the measurement data or result in a malfunction of the sen-

sor. Avoid using the following devices in the same room as the TriOS sensor: mobile phones, cordless phones, transmitters/

receivers and other electrical devices that produce electromagnetic waves.

Reagents

Follow the safety and operating instructions of the manufacturer when using reagents. Observe the valid Hazardous Materials

Ordinance for reagents (German GefStoV)!

Biological Safety

Liquid waste may be a biohazard. Therefore, you should always wear gloves when working with such materials. Please observe

the current biological material ordinance (German BioStoV)!

Waste

When handling liquid waste, observe the regulations on water pollution, drainage and waste disposal.

Danger warning / will lead to serious injury or death

DANGER

WARNING

CAUTION

NOTICE

4D01-903en201912 Manual Dissolved Oxygen

General Information // Dissolved Oxygen

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

1.3 Warnings

• This sensor has been developed for use in industry and science. It should only be used for the measurement of

aqueous solutions, e.g. process waste water, river water or sea water.

• Sensors made from stainless steel must be cleaned immediately after coming into contact with salt water or other

corrosive substances (e.g. acids, alkalis and chlorine-based connections.)

• The material resistance should be checked after every use.

• Do not cut, damage or change the cord. Make sure there are no heavy objects on the cord and that the cord is not

folded. Make sure that the cord is not placed near hot surfaces.

• If the sensor cord is damaged, it must be replaced with an original part by the customer service of TriOS Mess- und

Datentechnik GmbH or by an authorized TriOS workshop.

• Stop operation of the sensor if excessive heat develops (i.e. if it is hot to the touch). Switch o the sensor immediately

and unplug the power cord from the power supply. Please contact your dealer or TriOS customer service.

• Never try to disassemble or modify a part of the sensor if such a procedure is not explicitly described in this manual.

Inspections, modications and repairs may only be done by the dealer or by qualied experts authorized by TriOS.

Devices from TriOS Mess- und Datentechnik GmbH meet the highest safety standards. Repairs to the device that involve the

replacement of the connecting cable must be done by TriOS Mess- und Datentechnik GmbH or a workshop authorized by

TriOS. Faulty, improper repairs can result in accidents and injuries.

Stainless steel sensors are not intended for use in sea water or in high chloride concentrations (corro-

sion). Only sensors made of titanium can be used in these cases.

1.4 Users and Operating Requirements

The Dissolved Oxygen sensor was developed for use in industry and science. The target group for the operation of the Dis-

solved Oxygen sensor is technically skilled sta in plants, sewage treatment plants, water plants and institutes. Operating this

device often requires the handling of hazardous substances. We assume that the operating personnel are familiar with dealing

with dangerous substances based on their professional training and experience. Operating personnel must be able to correctly

understand and implement the safety labels and information on the packaging and in the package inserts of the test kits.

1.5 Intended Use

The Dissolved Oxygen sensor is designed exclusively to take oxygen measurements as described in this manual. For this pur-

pose, the sensor is an immersion sensor, to be used underwater or with ow cells. Please note the technical data of the acces-

sory parts. Other uses do not comply with the intended use.

NOTICE

TriOS does not guarantee the plausibility of measurement values. The user is responsible for

monitoring and interpreting the values.

DANGER

5

D01-903en201912 Manual Dissolved Oxygen

Dissolved Oxygen // General Information

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

The compact and robust stainless steel or titanium sensor is particularly well suited to the following typical areas of application:

• Industrial and municipal sewage treatment plants

• Wastewater management (nitrication and de-nitrication)*

• Surface water monitoring

• Fish farming, aquaculture

• Drinking water monitoring

The use of other media can damage the sensor. For the use of the Dissolved Oxygen sensor in media other than those specied

this manual, please contact the customer service of TriOS Mess- und Datentechnik GmbH ([email protected]).

According to current scientic knowledge, the device is safe to use when it is handled according to the instructions in this

user manual.

1.6 Disposal Information

At the end of the device’s life or use, the device and its accessories can be returned to the manufacturer for environmentally

friendly disposal for a fee. (See address below.)The preceding professional decontamination of the device must be proven with

a certicate. Please contact us for more information before you send the device back.

Address of the manufacturer:

TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D-26180 Rastede

Germany

Telephone: +49 (0) 4402 69670 - 0

Fax: +49 (0) 4402 69670 – 20

1.7 Certicates and Approvals

This product meets all of the requirements of the harmonized European standards. It therefore meets the legal requirements

of the EU guidelines. TriOS Mess- und Datentechnik GmbH conrms the successful testing of the product by axing the CE

marking. (See Annex.)

Avoid touching the membrane, because it can become scratched or dirty. If this happens, the func-

tionality of the device can no longer be guaranteed.

NOTICE

6D01-903en201912 Manual Dissolved Oxygen

Introduction // Dissolved Oxygen

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

2 Introduction

2.1 Product Identication

There is a rating plate on the sensor with the following information that you can use to uniquely identify the product:

Serial number

Product type

Power supply

Interface

In addition to the product bar code, the rating plate includes the TriOS Mess- und Datentechnik GmbH logo and the quality

label.

Please note that the specications given here are for illustration purposes only and may be dierent depending on the version

of the product.

The Dissolved Oxygen sensor applies the luminescence-based optical measurement technology and measures reliably and

accurately. With low consumables and maintenance required, the Dissolved Oxygen sensor gives an immediate return on the

investment. The only intervention required is to replace the Membrane Cap every two years.

The sensor can even be used in applications with very weak ow of water.

The sensor oers the following advantages:

• Low operating costs due to reduced maintenance work (no electrolyte changes)

• Greater calibration intervals due to low drift behaviour

• No polarization voltage required

• High measuring accuracy, even for low concentrations

• Rapid response times

• No minimum inow (no oxygen consumption)

The sensor features excellent interference immunity thanks to the integrated preamplier and digital signal processing. The

measured value for dissolved oxygen is automatically compensated with the temperature, air pressure, and salinity (salt con-

tent), and transferred without interference to the connected display unit and controller via a digital interface. The membrane

cap is easy to replace, meaning the sensor is very easy to maintain. The current calibration data is saved directly in the sensor

electronics. As a result, the Plug and Play function of the system is enabled without the need for recalibration. The sensor also

includes a log book containing the last ten successful calibrations in the form of a ring buer.

Assembled

in Europe

Serial No 903-17-A7135

Type DO VA 2m

Sensor Power

12 VDC

Sensor Interface

Modbus RTU

TriOS eCHEM Serie

903-17-A7135

7

D01-903en201912 Manual Dissolved Oxygen

Dissolved Oxygen // Introduction

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

2.2 Scope of Delivery

The shipment contains the following components:

Sensor

Operating Instructions

Accessories (if applicable)

Keep the original packaging in case the device needs to be returned for maintenance or repairs.

2.3 Measurement Principle and Design

Stainless steel membrane

cap

Membrane cap seal

Cable bushing

8D01-903en201912 Manual Dissolved Oxygen

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

AccessoriesUseCommissioning

Commissioning // Dissolved Oxygen

3 Commissioning

This chapter deals with the commissioning of the sensor. Please pay particular attention to this section and follow the safety

precautions to protect the sensor from damage and yourself from injury.

Before the sensor is put into operation, it is important to ensure that it is securely attached and all of the connections are

connected correctly.

3.1 Electrical Installation

3.1.1 Fixed Cable with M12 Industrial Plug

Ensure correct polarity of the operating voltage or otherwise the sensor may be damaged.

1. RS-485 A

2. RS-485 B

6. Power 12 VDC

7. Ground (Power + Ser. Interface)

NOTICE

The sensor is ready for initial startup once it is connected to your terminal, settled in its accessory of assembly and the param-

eterization has been carried out on the display unit.

The sensor must be operated with 12 VDC.

NOTICE

3.2 Interfaces

3.2.1 Serial Interface

The sensors serial interface is RS-485.

For the RS-485, voltages of –5 V to +5 V with respect to the ground are possible. RS-485 uses a dierential signal where the

sign-negative potential of the A line is put on the B line. The A-B dierence is decisive where the transmission is most resistant

to interactive interference signals.

The used protocol is Modbus RTU. A detailed description of the Modbus protocol commands can be found in the Annex.

9

D01-903en201912 Manual Dissolved Oxygen

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

Use Commissioning

Dissolved Oxygen // Use

4 Use

The Dissolved Oxygen sensor can be operated with any of the TriOS controllers. Instructions for correct installation can be

found in the controller manual.

4.1 Normal Operation

Once the sensor is connected to your Controller, the sensor is settled in its accessory of assembly and the parameterization has

been carried out on the display unit, the sensor is ready for initial startup.

Remove the black cap of protection (by holding the sensor head downward and by unscrewing the hood towards the right).

The sensor is delivered dry and the Membrane Cap must be rehydrated so that the measures are optimized. After dry storage,

rehydrate the membrane for a 12 hours period (one night) in clear water.

Standard operation of the sensor is carried out by immersing it into the medium. The sensor can either hang freely or be

mounted at 45°.

For measurement, you must eliminate bubbles trapped under the membrane. Presence of chlorine will distort the measure

(overestimation of dissolved oxygen level).

During the introduction of the sensor to the measurement environment, wait for the sensor’s temperature stabilization before

starting a measurement. To optimize a sustainable functioning of your probe, we recommend you to respect a frequency of

measurements above 10 seconds.

Optical oxygen sensors do not carry out any continuous measurements. To extend the operating life of the optical membrane,

the measurement interval can be set to a value superior to 10 seconds.

4.2 Bypass Installation

TriOS oers a compact modular FlowCell System to install the sensor into your application. This system allows exible adaption

to the application and the possibility to expand your range of sensors.

The membrane is vulnerable to chemicals (organic solvents, acids, peroxide) and mechanical treat-

ments (impact, abrasion, tearing).

NOTICE

10 D01-903en201912 Manual Dissolved Oxygen

Use // Dissolved Oxygen

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

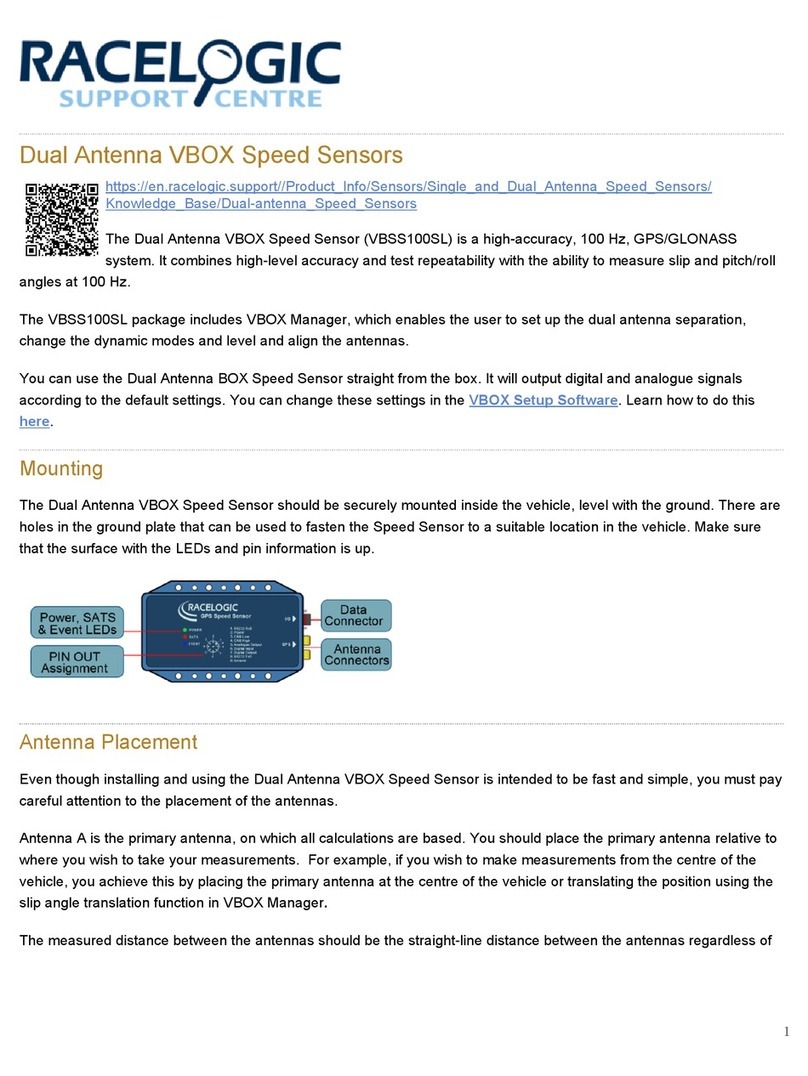

4.3 Support Tube Installation

TriOS provides two adapter pieces for installing the TpH-D sensor in existing tube systems:

• NPT1 adapter ZM12 (incl. cap nut ZM13)

• G1 adapter ZM11 (incl. cap nut ZM13)

1

1

2

2

3

3

4

4

A A

B B

C C

D D

E E

F F

TriOS GmbH

Tel. 04402-69670-0

DIN ISO 2768-f (Oberfl.) Maßstab: DIN A4 (Gewicht) 1 kg

(Werkstoff, Halbzeug)

G1-Adapter Ponsel O2

Name

Witte

Datum

25.01.2018Bearb.

Änder.

Ursprung:

TriOS GmbH

Bgm.-Brötje-Str. 25

26180 Rastede ZM101710

Ersatz für: Ersatz durch:

Blatt

1 von

1

ENTWICKLUNG

Freig.

iProperties - Übersicht - Kommentar:

In der Zeichnung:

iProperties - Übersicht - Kommentar:

Im Modell

Weitergabe sowie Vervielfältigung dieses Dokuments, Verwertung und Mitteilung seines Inhalts sind verboten,

soweit nicht ausdrücklich gestattet. Zuwiderhandlungen verpflichten zu Schadenersatz. Alle Rechte vorbehalten.

The reproduction, distribution and utilization of this document as well as the communication of its contents to others

without express authorization is prohibited. Offenders will be held liable for the payment of damages. All rights reserved.

ZM131710

Mechanik

OR 25x2,5 NBR

00B00 4136

ZM111710

Mechanik

Halterohr

Assembly process

1

1

2

2

3

3

4

4

A A

B B

C C

D D

E E

F F

TriOS GmbH

Tel. 04402-69670-0

DIN ISO 2768-f (Oberfl.) Maßstab: DIN A4 (Gewicht) 1 kg

(Werkstoff, Halbzeug)

G1-Adapter Ponsel O2

Name

Witte

Datum

25.01.2018Bearb.

Änder.

Ursprung:

TriOS GmbH

Bgm.-Brötje-Str. 25

26180 Rastede ZM101710

Ersatz für: Ersatz durch:

Blatt

1 von

1

ENTWICKLUNG

Freig.

iProperties - Übersicht - Kommentar:

In der Zeichnung:

iProperties - Übersicht - Kommentar:

Im Modell

Weitergabe sowie Vervielfältigung dieses Dokuments, Verwertung und Mitteilung seines Inhalts sind verboten,

soweit nicht ausdrücklich gestattet. Zuwiderhandlungen verpflichten zu Schadenersatz. Alle Rechte vorbehalten.

The reproduction, distribution and utilization of this document as well as the communication of its contents to others

without express authorization is prohibited. Offenders will be held liable for the payment of damages. All rights reserved.

ZM131710

Mechanik

OR 25x2,5 NBR

00B00 4136

ZM111710

Mechanik

Halterohr

9

Version 1.1

Update: January 2016

AQUALABO CONTROLE

35 Rue Michel Marion –56850 CAUDAN, FRANCE

Tel.: +33(0)2 97 89 25 30 –Fax: +33(0)2 97 76 55 72

Short pole

Long pole

The long poles are available in elbow version, for installations in aeration basin, and straight, for

applications in open channel. Every pole is equipped with an elbowed shutter and with waterproofness

joints. The lower part includes a nozzle which is adapted to the sensor what assures its mechanical

support.

Elbowed shutter

Ring shutter

Nozzle

The short pole is available in 2 versions :

- version with elbowed shutter. The nozzle of support is included in

the offer.

PF-ACC-C-00266

STRAIGHT SHORT POLE

FOR OPTOD SENSOR (1495

mm, ELBOWED SHUTTER)

PF-ACC-C-00267

STRAIGHT SHORT POLE

FOR PHEHT SENSOR (1495

mm, ELBOWED SHUTTER)

PF-ACC-C-00268

STRAIGHT SHORT POLE

FOR C4E/NTU SENSOR

(1495 mm, ELBOWED

SHUTTER)

- version with shutter for mounting with chain The nozzle of

support is included in the offer.

PF-ACC-C-00269

STRAIGHT SHORT POLE

FOR OPTOD SENSOR (1550

mm, RING SHUTTER)

PF-ACC-C-00270

STRAIGHT SHORT POLE

FOR PHEHT SENSOR (1550

mm, RING SHUTTER)

PF-ACC-C-00271

STRAIGHT SHORT POLE

FOR C4E/NTU SENSOR

(1550 mm, RING SHUTTER)

- Elbowed pole with elbowed shutter

PF-ACC-C-00230

90° ELBOW LONG POLE FOR

OPTOD SENSOR (2955 mm,

ELBOWED SHUTTER)

PF-ACC-C-00261

90° ELBOW LONG POLE FOR

PHEHT SENSOR (2955 mm,

ELBOWED SHUTTER)

PF-ACC-C-00262

90° ELBOW LONG PERCH

FOR C4E/NTU SENSOR (2955

mm, ELBOWED SHUTTER)

- Straight long pole with elbowed shutter

PF-ACC-C-00263

STRAIGHT LONG POLE FOR

OPTOD SENSOR (2745 mm,

ELBOWED SHUTTER)

PF-ACC-C-00264

STRAIGHT LONG POLE FOR

PHEHT SENSOR (2745 mm,

ELBOWED SHUTTER)

PF-ACC-C-00265

STRAIGHT LONG POLE FOR

C4E/NTU SENSOR (2745 mm,

ELBOWED SHUTTER)

Elbowed

shutter

1. Guide the sensor cable from the side through the adapter, onto which the screw cap is later screwed (short thread).

Support tube

Adapter ZM11/ZM12

O-Ring

Cap nut ZM13

11

D01-903en201912 Manual Dissolved Oxygen

Dissolved Oxygen // Use

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

2.Pull the complete cable through.

3. Fix the sensor with the mounting cap.

4. The sensor and adapter can now be installed in the support tube.

12 D01-903en201912 Manual Dissolved Oxygen

Calibration // Dissolved Oxygen

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

5 Calibration

The sensor is calibrated to specication at the factory. The manufacturer does not recommend calibration unless due to specic

local regulations. If calibration is required, let the sensor come to equilibrium with the measurement process before calibration.

Do not calibrate the sensor at setup.

After the membrane cap is replaced, calibration should always be carried out.

It is also advisable to regularly clean the sensor in a water-sulphite solution with a sulphite concentration of < 2 %, and to

subsequently check the zero point (0 % saturation).

If the zero point is moved, a complete two-point calibration must be carried out.

5.1 Two-Point Calibration

With two-point calibration, the zero point (0% - oset) and slope (100 %)of the sensor are calibrated. This calibration method

oers the greatest possible level of accuracy and is particularly recommended for measurements of small oxygen concentra-

tions.

It is carried out as follows:

5.1.1 Oset calibration

The sensor must be cleaned before calibration (see chapter 6). Immerse the sensor in a water-sulphite solution (sulphite con-

centration < 2 %) in order to determine the zero point (0 % saturation). Mix the solution with the sensor so that the saturation

in oxygen decreases more quickly (The oxygen xed to the Membrane Cap must be consumed).

After calibration, clean the sensor with clear water and carefully dry it.

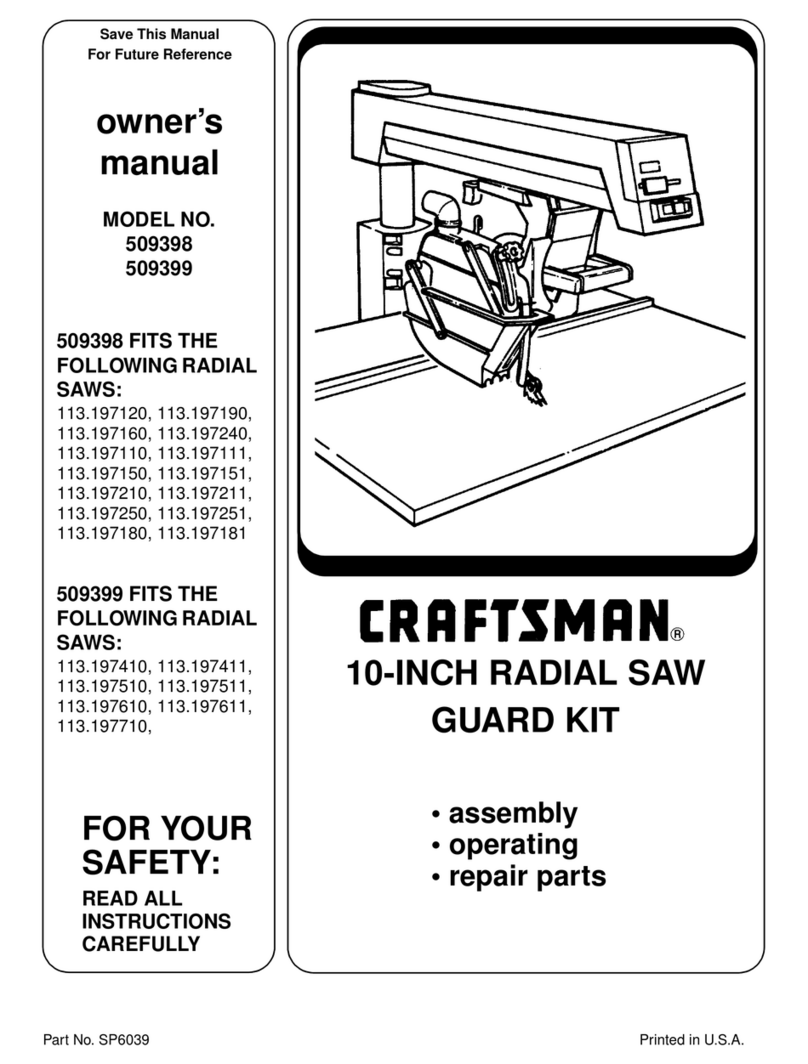

5.1.2 Slope calibration

Sensor slope is determined by positioning in oxygen-saturated environment (100 % saturation). The slope of the sensor is

calibrated beyond the dened state of 100 % oxygen saturation. This state can in principle be achieved in two ways:

1. By positioning the sensor in water vapor-saturated air (for example, directly over a water surface, see picture on

following page).

2. By positioning the sensor in air-saturated water (air is directed through water until the water is saturated with it).

The sensor can be damaged by chemicals. A damaged membrane can lead to incorrect measurement

results. The sensor membrane must not be in contact with the sulphite solution for longer than 15

minutes.

NOTICE

The sensor must be kept dry during the calibration process. Drops of water adhering to the sensor mem-

brane could distort the measurement.

The air pressure and temperature must remain constant during the calibration.

13

D01-903en201912 Manual Dissolved Oxygen

Dissolved Oxygen // Calibration

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

5.2 One-Point Calibration

The calibration in one point consists in propping up a 100% point : please consult chapter 5.1.2 (slope calibration).

5.3 Measurement Properties

5.3.1 Inuences on the measurement

The oxygen measurement is dependent on the following parameters:

• The temperature of the measurement medium

• The air pressure (atmospheric pressure)

• The salinity of the measurement medium

The degree of solubility of oxygen in water is dependent on the temperature, the salinity, and the air pressure.This dependency

is stored in the sensor's measurement electronics in the form of functions. The sensor can therefore determine the oxygen

concentration of the measurement medium, in order to digitally transmit the inuencing factors above, in compensated form,

to the transmitter/controller.

5.3.2 Temperature compensation

The temperature compensation is automatically managed by the sensor via the integrated temperature sensor (NTC).

5.3.3 Atmospheric pressure

With the most frequently used calibration method – end value calibration of the sensor in water vapor-saturated air – the air

pressure must be taken into account. For this purpose, the air pressure can, for example, be transmitted to the sensor by your

controller, where it is saved.

The default value of the atmosphere used for the compensation is 1013 hPa.

5.3.4 Salinity

The value for the salinity of the measurement medium could be transmitted to the sensor by your terminal.

The default value of the salinity used for the compensation is 0 g/Kg.

(1) Positioning in water vapor-saturated air

14 D01-903en201912 Manual Dissolved Oxygen

Malfunction and Maintenance // Dissolved Oxygen

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

6 Malfunction and Maintenance

The maintenance schedule shows minimum intervals for regular maintenance tasks. Perform maintenance tasks more fre-

quently for applications that cause electrode fouling.

• The sensor must always be kept clean, particularly in the area around the optical membrane. The presence of a biolm on

the membrane cap can lead to measuring errors.

• A dirty membrane should be cleaned with warm, soapy water. A soft sponge should be used for cleaning (not an abrasive

scouring sponge).

• If the sensor is put out of operation, it should be rinsed prior to being stored, and the protective cap should be tted with

the protective case and a moist absorbent surface (like cotton).

6.1 Cleaning and Upkeep

Rinse meticulously the sensor and the membrane with clear water. If deposits like biolm or mud persist, wipe the membrane

gently with a sweet cloth or an absorbent paper.

NO

Do not disassemble the probe for maintenance or cleaning.

NOTICE

Avoid touching the membrane, because it can become scratched or dirty. If this happens, the func-

tionality of the device can no longer be guaranteed.

NOTICE

6.2 Maintenance and Inspection

It is advisable to regularly clean the sensor in a water-sulphite solution with a sulphite concentration of < 2 %, and to subse-

quently check the zero point (0 % saturation).

If the zero point is moved, a complete two-point calibration must be carried out.

For the Titanium version clean the body of the sensor by means of acetone (do not use methylated

spirit, ethanol or methanol).

NOTICE

15

D01-903en201912 Manual Dissolved Oxygen

Dissolved Oxygen // Malfunction and Maintenance

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

6.2.1 Changing the Membrane Cap

1. Unscrew the Membrane Cap from the sensor body. When doing so, ensure that the front part of the sensor is not touched.

2. Remove the replacement Membrane Cap from the opaque protective bag and screw slowly onto the sensor body. When

screwing on, ensure that the membrane of the sensor is not touched.

3. Rehydrate the membrane for a 12 hours period and recalibrate the sensor in 2 points (chapter 5.1).

Do only unscrew the Cap for changing it.

NOTICE

After the membrane cap is replaced, calibration should be carried out.

6.4 Returns

Please observe the following procedure for your returns.

If returning a sensor, please contact customer service rst. To ensure a smooth return and to avoid incorrect deliveries, each

return package must rst be reported to the customer service. You will then receive a numbered RMA form, which you need

to ll out completely, check and send back to us. Please attach the form with the number so it is clearly visible on the outside

of the return package or write it in large numbers on the packaging. This is the only way your return package can be correctly

allocated and accepted.

Please make sure that the sensor is cleaned and disinfected before shipping. In order to ship the goods undamaged, use the

original packaging. If this is not on hand, make sure that safe transport is guaranteed and the sensor is safely packed using

enough packing material.

Caution! Return shipments without an RMA number cannot be accepted and processed!

6.3 Troubleshooting

6.3.1 Implausible Values

After every reboot, the sensor will show „9998,0“ as a placeholder value for every measurement, as long as no actual measure-

ment values are avaible.

The average life time of the Membrane Cap is of 2 years. In case of deterioration of the cap or of diculty on the processes of

calibration, the membrane cap will be to change (see chapter 5).

16 D01-903en201912 Manual Dissolved Oxygen

Technical Data // Dissolved Oxygen

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

7 Technical Data

7.1 Technical Specications

Measurement principle Luminescence

Parameter Dissolved Oxygen

Measurement range

0...20 mg/L

0...20 ppm

0...200 %

Measurement accuracy

± 0.1 mg/L

± 0.1 ppm

± 1 %

Resolution 0.01

Response time 90 % of the value in less than 60 seconds

Measurement interval > 5 s

Inow Velocity no movement necessary

Temperature Compensation Via NTC (compensation active for temperature lower than 0 °C)

Measurement range

(temperature) 0...+50 °C

Resolution (temperature) 0.01 °C

Accuracy (temperature) 0.5 °C

Membrane Cap

No cross-sensitivity with : pH 1 – 14 ; CO2, H2S, SO2

Cross-sensitivity to Organic solvents, such as acetone, toluene, chloroform or methylene

chloride Chlorine gas

Material

Standard Version in passivated Stainless steel 316L body, strainer and screw,

For Seawater application Version in Titanium body, strainer and screw,

Cable : polyurethane jacket

Steam gland : Polyamide

Patch with active material (black) – Membrane : Optical isolation silicon

Dimensions (L x Ø) 146 mm x 25 mm ~ 5.7˝ x 1˝

Weight stainless steel ~ 450 g ~ 1 lbs

titanium ~ 300 g ~ 0.7 lbs

Interface RS-485 (Modbus RTU)

Power consumption 1 W

Power supply 12 V (± 10 %)

Sensor cable 2 m and 10 m

17

D01-903en201912 Manual Dissolved Oxygen

Dissolved Oxygen // Technical Data

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

Calibration/maintenance

interval 2 years

Warranty 1 year (EU& US: 2 years) on electronics; All wearing parts are not included in the

warranty

INSTALLATION

Max. pressure 5 bar ~ 72.5 psig

Protection type IP68 NEMA 6P

Sample temperature 0...+50 °C ~ +32 °F... +122 °F

Ambient temperature 0...+50 °C ~ +32 °F... +122 °F

Storage temperature -10...+60 °C ~ +14 °F... +140 °F

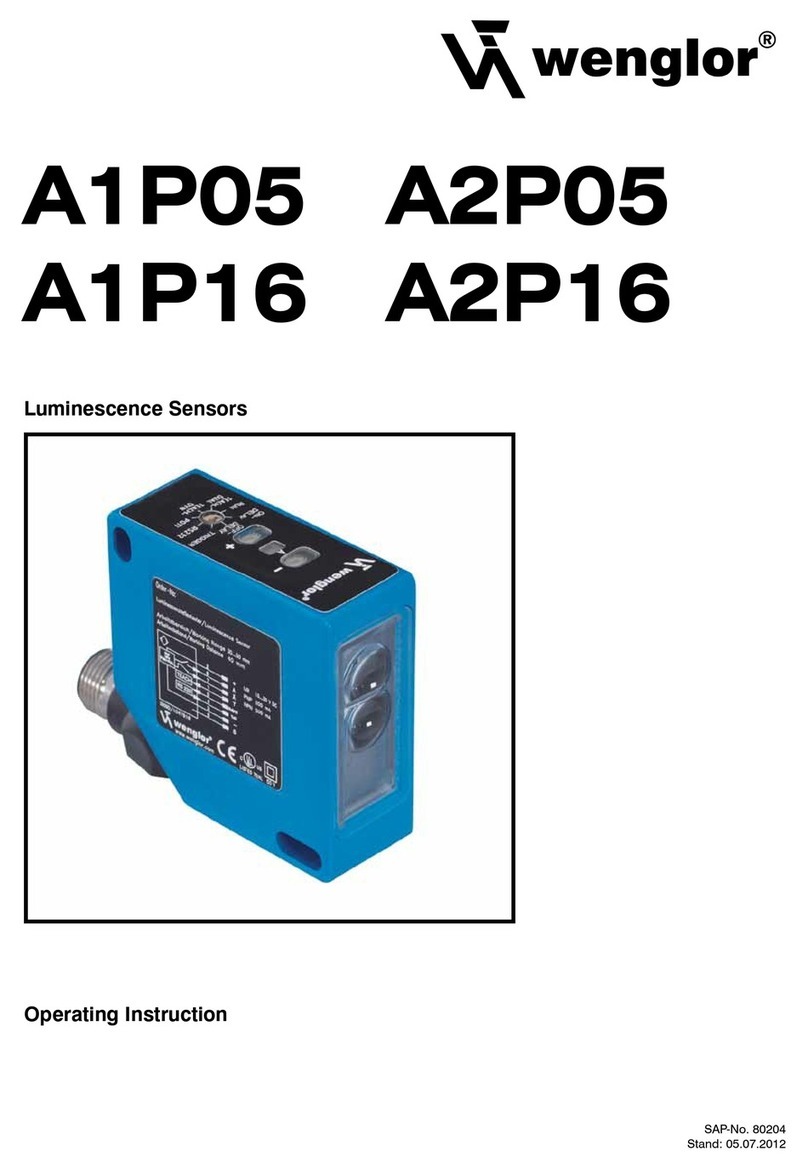

Polyamid gland

Sensor body

Membrane Cap

7.2 External Dimensions

All dimensions are indicated in mm.

18 D01-903en201912 Manual Dissolved Oxygen

Accessories // Dissolved Oxygen

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

8 Accessories

8.1 TriBox3

Digital, 4-channel display and control unit with

integrated solenoid valve for compressed-air con-

trol

TriBox3 is a measurement and control system for all TriOS sen-

sors. The device has 4 sensor channels with selectable RS-232

or RS-485 function. In addition to the Modbus RTU, various

other protocols are available. A built-in valve allows the use

of compressed-air cleaning for the sensors. The TriBox3 also

has various interfaces, including an IEEE 802.3 Ethernet inter-

face, an IEEE 802.11 b/g/n interface, a USB connection and 6

analog outputs (4...20 mA). An integrated relay can trigger

alarms or control external devices. Features such as low pow-

er consumption, a robust aluminium housing and a range of

interfaces make it suitable for all applications associated with

environmental monitoring, drinking water, wastewater treat-

ment plants and many other areas.

8.2 TriBox mini

Digital 2-channel controller

Mini controller with two digital sensor inputs and two

4...20mA outputs. All of the measured values and diagnostics

data that are saved can be selected using an integrated web

browser.

Table of contents

Other triOS Accessories manuals