triOS TpH User manual

TpH

OPERATING INSTRUCTIONS

1

TABLE OF CONTENTS

Table of Contents

1 General Information 2

1.1 Introduction 2

1.2 Health and safety information 3

1.3 Warnings 4

1.4 Users and Operating Requirements 4

1.5 Intended use 4

1.6 Proper disposal 5

1.7 Certicates and Approvals 5

2 Introduction 6

2.1 Product Identication 6

2.2 Scope of delivery 7

2.3 Measurement Principle and Design 7

3 Commissioning 8

3.1 Electrical installation 8

3.1.1 Fixed Cable with M12 Industrial Plug 8

3.2 Interfaces 8

3.2.1 Serial Interface 8

4 Use 9

4.1 Normal operation 9

4.2 Bypass Installation 9

4.3 Support Tube Installation 10

4.4 Storage 10

5 Calibration 11

5.1 pH Calibration 11

5.2 Measurement properties 13

5.2.1 Inuences on the Measurement 13

5.2.2 Temperature compensation 13

6 Malfunction and Maintenance 14

6.1 Cleaning and Upkeep 14

6.2 Maintenance and Inspection 14

6.2.1 Temperature Calibration 14

6.2.2 Replacing the sensor at TriBox3 15

6.3 Returns 15

7 Technical Data 16

7.1 Technical specications 16

7.2 External Dimensions 17

8 Accessories 18

8.1 TriBox3 18

8.2 TriBox mini 18

8.3 FlowCell for eCHEM sensors 19

8.4 pH Buer Set 19

9 Warranty 20

10 Customer service 20

11 Contact 21

12 Keyword Index 22

Annex 24

2D01-068en201913 Manual TpH

General Information // TpH

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

1 General Information

1.1 Introduction

Welcome to TriOS.

We are glad that you have chosen to purchase our TpH pH sensor.

The TpH is based on the electrochemical measuring method with a measuring electrode and a reference electrode. This intel-

ligent sensor stores calibrations internally. This enables a "plug-and-play" system without recalibration when the location or

measuring transducer is changed.

In this manual, you will nd all the information you will need to commission the pH sensor. Technical specications as well as

detection limits and the dimensions can be found in chapter 7.

Please note that the user is responsible to comply with local and state regulations for the installation of electronic equipment.

Any damage caused by incorrect use or unprofessional installation will not be covered by the warranty. All sensors and ac-

cessories supplied by TriOS Mess- und Datentechnik GmbH must be installed and operated in accordance with the specica-

tions provided by TriOS Mess- und Datentechnik GmbH. All parts were designed and tested in accordance with international

standards on electronic instruments. The device meets the requirements of the international standards on electromagnetic

compatibility. Please use only original TriOS accessories and cables to ensure smooth and professional use of the devices.

Read this manual carefully before using the equipment and save this manual for future reference. Before commissioning the

sensor, please make sure that you have read and understood the following safety precautions. Always make sure that the

sensor is operated correctly. The safety precautions noted on the following pages are intended to provide a simple and correct

operation of the instrument and all its accessories to prevent harm from coming to you, other people or devices.

Copyright Notice

All content in this manual, i.e. texts, photographs and graphics, are protected by copyright. Unless expressly stated otherwise,

TriOS Mess- und Datentechnik GmbH is the owner of the copyright. Persons who violate the copyright shall be liable pursuant

to § 106 et seq of the German copyright law, they will be warned at their own expense and must pay compensation.

In case of inconsistence, the German original version shall prevail.

NOTICE

3

D01-068en201913 Manual TpH

TpH // General Information

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

1.2 Health and safety information

This manual contains important information on health and safety rules.This information is labelled according to the internatio-

nal specications of ANSI Z535.6 ("Product safety information in product manuals, instructions and other collateral materials")

and must be strictly followed. A distinction is made between the following categories:

Tip / Useful Information

Can result in damage to property

Warning / may lead to serious injury or death

Caution / may cause moderate injury

Electromagnetic Waves

Devices that radiate strong electromagnetic waves can inuence the measurement data or result in a malfunction of the sen-

sor. Avoid using the following devices in the same room as the TriOS sensor: mobile phones, cordless phones, transmitters/

receivers and other electrical devices that produce electromagnetic waves.

Reagents

Follow the safety and operating instructions of the manufacturer when using reagents. Observe the valid Hazardous Materials

Ordinance for reagents (German GefStoV)!

Biological Safety

Liquid waste may be biologically dangerous. Therefore, you should always wear gloves when working with such materials.

Please observe the currently valid biological agents regulation!

Waste

When handling liquid waste, the regulations on water pollution, drainage and waste disposal must be observed.

Danger warning / will lead to serious injury or death

DANGER

WARNING

CAUTION

NOTICE

4D01-068en201913 Manual TpH

General Information // TpH

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

1.3 Warnings

• this sensor has been developed for use in industry and science. It should only be used for the measurement of

aqueous solutions, e.g. process waste water, river water or sea water.

• The material resistance should be checked after every use.

• Do not cut, damage or change the cord. Make sure that no heavy objects are placed on the cord and that the cord is

not folded. Make sure that the cord is not run near hot surfaces.

• If the sensor cable is damaged, it must be replaced with an original part by the customer service of TriOS Mess- und

Datentechnik GmbH.

• Stop operation of the sensor in the event of excessive heat development (i.e. if it is hot to the touch).

Switch o the sensor immediately and remove the cable from the power supply. Please contact your dealer

or the TriOS customer service.

• Never try to disassemble or modify a part of the sensor if such a procedure is not explicitly described in this manual.

Inspections, modications and repairs may only be carried out by the dealer or by qualied experts authorized by

TriOS.

Devices from TriOS Mess- und Datentechnik GmbH meet the highest safety standards. Repairs to the device (which involve the

replacement of the connecting cable) must be carried out by TriOS Mess- und Datentechnik GmbH or by a workshop authori-

zed by TriOS. Defective, improper repairs can lead to accidents and injuries.

1.4 Users and Operating Requirements

The TpH sensor has been developed for use in industry and science. The target group for the operation of the TpH sensor is

technically skilled sta in plants, sewage treatment plants, water plants and institutes. The use of this device often requires the

handling of hazardous substances. We assume that operators are familiar with dealing with hazardous substances due to their

professional training and experience. The operating personnel must be able to correctly understand and implement the safety

labels and information on the packaging and in the package inserts of the test kits.

1.5 Intended use

The purpose of the TpH sensor is exclusively to measure pH values in aqueous solutions, as described in this manual. In this

respect, the TpH sensor is an immersion sensor used under water or in conjunction with ow cells. Please note the technical

data of the accessory parts. Any other use is not considered to be in compliance with the intended use.

TriOS does not guarantee the plausibility of the measured values. The user is always responsib-

le for the monitoring and interpretation of the measured values.

DANGER

5

D01-068en201913 Manual TpH

TpH // General Information

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

The compact and robust sensor is particularly suitable for the following areas of application:

• Industrial and municipal sewage treatment plants

• Wastewater management

• Monitoring of surface waters

• Aquaculture and sh farming

• Drinking water monitoring

Use in other media can damage the sensor. For the use of the TpH sensor in other media than those specied in this manual,

According to current scientic knowledge, the device is safe to use when it is handled according to the instructions in this

user manual.

1.6 Proper disposal

At the end of its service life, the device and its accessories may be returned for environmentally friendly disposal.The preceding

professional decontamination must be proven with a certicate. Please contact us for more details before you send the device

back.

Shipping address:

TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

26180 Rastede

Germany

Tel.: +49 (0) 4402 69670 - 0

Fax: +49 (0) 4402 69670 – 20

1.7 Certicates and Approvals

This product meets all the requirements of the harmonized European standards. It therefore meets the legal requirements

of the EC guidelines. TriOS Mess- und Datentechnik GmbH conrms the successful testing of the product by axing the CE

marking (see annex).

6D01-068en201913 Manual TpH

Introduction // TpH

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

2 Introduction

The TpH is based on the electrochemical measuring method with a measuring electrode and a reference electrode. This intel-

ligent sensor stores calibrations internally. This enables a "plug-and-play" system without recalibration when the location or

measuring transducer is changed.

Built-in encapsulated preamplier for reliability

The encapsulated design protects the sensor's built-in preamplier from moisture and humidity, ensuring reliable sensor ope-

ration. The preamplier produces a strong signal so that the sensor can be located up to 300m away from the controller.

2.1 Product Identication

All TriOS Mess- und Datentechnik GmbH products have a label, which clearly shows the product designation.

There is also a rating plate on the sensor with the following information that you can use to uniquely identify the product:

Serial number

Product type

Power supply

Electric

In addition to the product bar code, the rating plate includes the TriOS Mess- und Datentechnik GmbH logo and

the quality label.

Please note that the specications given here are for illustration purposes only and may deviate depending on the version of

the product.

Assembled

in Europe

Serial No 068XXXXX

Type TpH 2m

Sensor Power

12...24 VDC

Sensor Interface

Modbus RTU

TriOS eCHEM Serie

068XXXXX

7

D01-068en201913 Manual TpH

TpH // Introduction

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

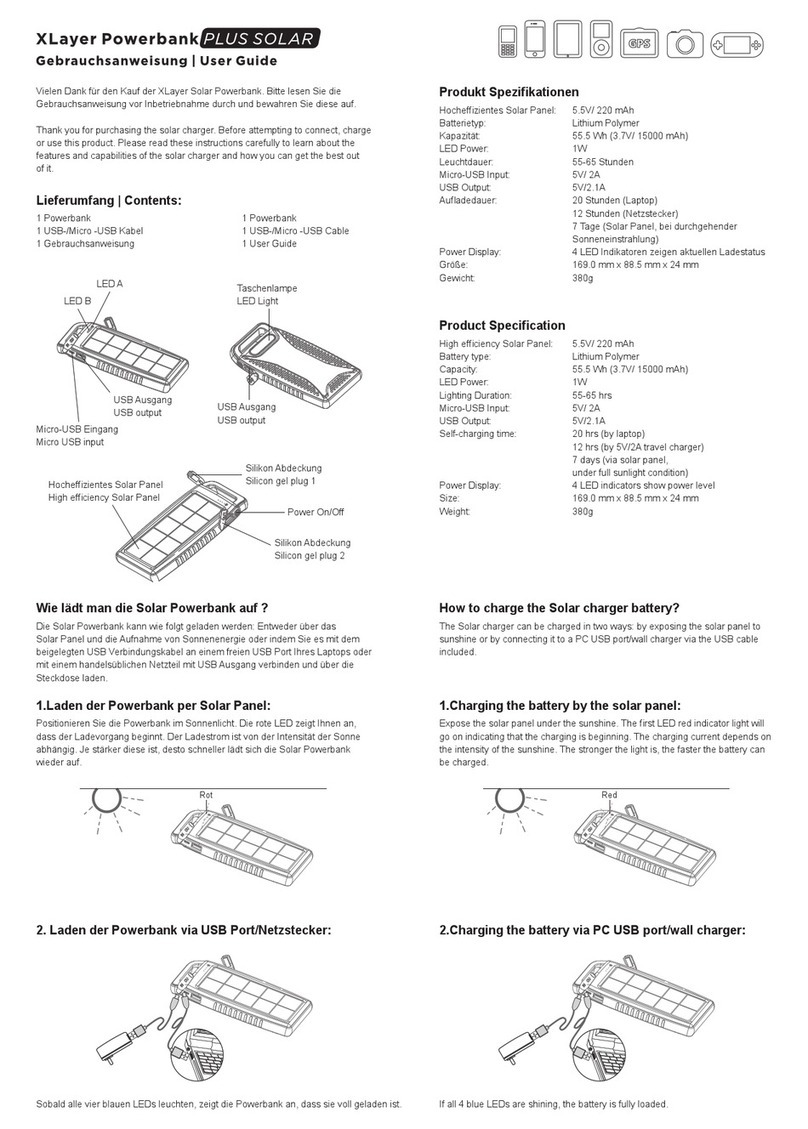

2.2 Scope of delivery

The delivery contains the following components:

Sensor

Operating Instructions

Accessories (if applicable)

Keep the original packaging of the device in case it needs to be returned for maintenance or repairs.

2.3 Measurement Principle and Design

Cable bushing

Porous reference compound (HDPE*)

Flat pH glass

* High-density polyethylene.

8D01-068en201913 Manual TpH

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

AccessoriesUseCommissioning

Commissioning // TpH

3 Commissioning

This chapter deals with the commissioning of the sensor. Please pay particular attention to this section and follow the safety

precautions to protect the sensor from damage and yourself from injury.

Before the sensor is put into operation, it is important to ensure that it is securely attached and all connections are connected

correctly.

3.1 Electrical installation

3.1.1 Fixed Cable with M12 Industrial Plug

The sensor can be operated with 12...24 VDC.

1. RS-485 A

2. RS-485 B

3. Not assigned

4. Not assigned

5. Not assigned

6. Not assigned

7. Ground (Power + Ser. Interface)

8. Power 12...24 VDC

Ensure correct polarity of the supply voltage, because otherwise the sensor may be damaged.

The sensor is ready for commissioning as soon as the installation of accessories is complete, it is connected to your control

device and the conguration is complete.

3.2 Electric

3.2.1 Serial Interface

The serial interface of the sensor is RS-485 (9600/8-N-1).

With RS-485, voltages from -5V to +5 V to ground are possible. RS-485 uses a dierential signal with the sign-negative potential

of the A line is put on the B line. The dierential value between lines A and B is the decisive factor for the transmission robust-

ness against conducted noise signals.

The protocol used is Modbus RTU. A detailed description of the Modbus RTU protocol for TpH can be found in the annex.

NOTICE

NOTICE

9

D01-068en201913 Manual TpH

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

Use Commissioning

TpH // Use

4 Use

The TpH sensor can be operated with all TriOS controllers. Instructions for correct installation can be found in the relevant

controller manual.

4.1 Normal operation

The sensor is ready for commissioning as soon as the installation of accessories is complete, it is connected to your control

device and the conguration is complete.

Remove the black protective cap by holding the sensor vertically downwards and unscrewing the cap. The sensor is supplied

with a lled protective cap containing a solution of pH4 buer and potassium chloride. Therefore, the sensor does not need to

be activated in order to achieve optimum measurements. Please note the minimum immersion depth up to the ring.

The sensor is now immersed in the measuring medium. The black sensor head should be completely surrounded by the medi-

um. Otherwise, measurement uctuations may occur.

Before a measurement, all air bubbles under the membrane must rst be removed by light shaking.

As soon as the sensor is connected to the power supply, it starts to measure. This is indicated by the green light in the upper

sensor area. To obtain stable and safe measurements, please wait for temperature stabilisation after introducing the sensor

into the measuring environment.

The TpH sensor should be calibrated at regular intervals. The intervals depend on the respective application. If the TpH is

used in the highly alkaline range, the calibration intervals should be as close as possible. For information on calibration, see

Chapter 5.

The TpH are classied as consumables and therefore have a limited service life, depending on the user's application. Under

normal conditions, the typical life span is about one year. The service life of the TpH can be extended by regular cleaning.

4.2 Bypass Installation

A suitable TriOS ow cell is available to integrate the sensor into a bypass installation. The ow cell is designed according to a

modular system and makes it possible to adapt or extend the system as required.

If the sensor is dry, it must rst be conditioned in pH4 buer for 24 hours.

NOTICE

10 D01-068en201913 Manual TpH

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

AccessoriesCalibrationUse

Use // TpH

4.3 Support Tube Installation

TriOS provides two adapter pieces for installing the TpH sensor in existing tube systems:

• NPT1 adapter ZM46 (incl. cap nut ZM13)

• G1 adapter ZM41 (incl. cap nut ZM13)

Assembly process

9

Version 1.1

Update: January 2016

AQUALABO CONTROLE

35 Rue Michel Marion –56850 CAUDAN, FRANCE

Tel.: +33(0)2 97 89 25 30 –Fax: +33(0)2 97 76 55 72

Short pole

Long pole

The long poles are available in elbow version, for installations in aeration basin, and straight, for

applications in open channel. Every pole is equipped with an elbowed shutter and with waterproofness

joints. The lower part includes a nozzle which is adapted to the sensor what assures its mechanical

support.

Elbowed shutter

Ring shutter

Nozzle

The short pole is available in 2 versions :

- version with elbowed shutter. The nozzle of support is included in

the offer.

PF-ACC-C-00266

STRAIGHT SHORT POLE

FOR OPTOD SENSOR (1495

mm, ELBOWED SHUTTER)

PF-ACC-C-00267

STRAIGHT SHORT POLE

FOR PHEHT SENSOR (1495

mm, ELBOWED SHUTTER)

PF-ACC-C-00268

STRAIGHT SHORT POLE

FOR C4E/NTU SENSOR

(1495 mm, ELBOWED

SHUTTER)

- version with shutter for mounting with chain The nozzle of

support is included in the offer.

PF-ACC-C-00269

STRAIGHT SHORT POLE

FOR OPTOD SENSOR (1550

mm, RING SHUTTER)

PF-ACC-C-00270

STRAIGHT SHORT POLE

FOR PHEHT SENSOR (1550

mm, RING SHUTTER)

PF-ACC-C-00271

STRAIGHT SHORT POLE

FOR C4E/NTU SENSOR

(1550 mm, RING SHUTTER)

- Elbowed pole with elbowed shutter

PF-ACC-C-00230

90° ELBOW LONG POLE FOR

OPTOD SENSOR (2955 mm,

ELBOWED SHUTTER)

PF-ACC-C-00261

90° ELBOW LONG POLE FOR

PHEHT SENSOR (2955 mm,

ELBOWED SHUTTER)

PF-ACC-C-00262

90° ELBOW LONG PERCH

FOR C4E/NTU SENSOR (2955

mm, ELBOWED SHUTTER)

- Straight long pole with elbowed shutter

PF-ACC-C-00263

STRAIGHT LONG POLE FOR

OPTOD SENSOR (2745 mm,

ELBOWED SHUTTER)

PF-ACC-C-00264

STRAIGHT LONG POLE FOR

PHEHT SENSOR (2745 mm,

ELBOWED SHUTTER)

PF-ACC-C-00265

STRAIGHT LONG POLE FOR

C4E/NTU SENSOR (2745 mm,

ELBOWED SHUTTER)

Elbowed

shutter

1. Guide the sensor cable from the side through the adapter, onto which the screw cap is later screwed

(short thread).

2. Pull the complete cable through and push the sensor into the adapter as far as it will go

(up to the guide obstacle).

3. Fix the sensor with the mounting cap.

4. The sensor and adapter can now be installed in the support tube.

Support tube

Adapter ZM46/ZM41

O-ring 23x2.5 NBR

Cap nut ZM13

4.4 Storage

Never store the sensor dry. Always keep the protective cap and reuse it for storage in a solution of pH4 buer and potassium

chloride or a 3 molar KCl solution.

Never store the TpH sensor dry.

If a sensor or the electrode of the sensor should nevertheless have dried out, the hydrated layer on the electrode must form

anew. The sensor must be immersed in a 3 molar KCl solution for several hours (>12h).

Never store the TpH sensor in distilled water!

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

TriOS GmbH

Tel. 04402-69670-0

DIN ISO 2768-f

(Oberfl.) Maßstab: DIN A3 (Gewicht) 1,0 kg

(Werkstoff, Halbzeug)

G1-Adapter TpH

Name

Witte

Datum

07.06.2018Bearb.

Änder.

Ursprung:

TriOS GmbH

Bgm.-Brötje-Str. 25

26180 Rastede ZM401802

Ersatz für: Ersatz durch:

Blatt

1 von

1

1:2

ENTWICKLUNG

Freig.

iProperties - Übersicht - Kommentare im Modell:

iProperties - Übersicht - Kommentare In der Zeichnung:

Weitergabe sowie Vervielfältigung dieses Dokuments, Verwertung und Mitteilung seines Inhalts sind verboten,

soweit nicht ausdrücklich gestattet. Zuwiderhandlungen verpflichten zu Schadenersatz. Alle Rechte vorbehalten.

The reproduction, distribution and utilization of this document as well as the communication of its contents to others

without express authorization is prohibited. Offenders will be held liable for the payment of damages. All rights reserved.

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

TriOS GmbH

Tel. 04402-69670-0

DIN ISO 2768-f

(Oberfl.) Maßstab: DIN A3 (Gewicht) 1,0 kg

(Werkstoff, Halbzeug)

G1-Adapter TpH

Name

Witte

Datum

07.06.2018Bearb.

Änder.

Ursprung:

TriOS GmbH

Bgm.-Brötje-Str. 25

26180 Rastede ZM401802

Ersatz für: Ersatz durch:

Blatt

1 von

1

1:2

ENTWICKLUNG

Freig.

iProperties - Übersicht - Kommentare im Modell:

iProperties - Übersicht - Kommentare In der Zeichnung:

Weitergabe sowie Vervielfältigung dieses Dokuments, Verwertung und Mitteilung seines Inhalts sind verboten,

soweit nicht ausdrücklich gestattet. Zuwiderhandlungen verpflichten zu Schadenersatz. Alle Rechte vorbehalten.

The reproduction, distribution and utilization of this document as well as the communication of its contents to others

without express authorization is prohibited. Offenders will be held liable for the payment of damages. All rights reserved.

NOTICE

NOTICE

11

D01-068en201913 Manual TpH

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

Calibration Use

TpH // Calibration

5 Calibration

TpH sensors that have not been used for a long time or that are new should be calibrated before measurement. Calibration

should then be repeated at regular intervals. The calibration intervals depend on the type of application. Checks with standard

solutions are recommended to determine the intervals.TriOS oers suitably bottled buer solutions pH4 and pH7 (see chapter

8).

Calibration is possible both on the controllers (see chapter 8) and via Modbus. The calibrations performed are stored internally

by the sensor. Thus, the current calibration is always present.

5.1 pH Calibration

With the calibration, the zero value (pH7) and the scaling factor (pH4) are calibrated. For calibration, select pH buer solutions

with an accuracy of +/- 0.01pH and observe the temperature. Fresh or newly prepared solutions must be used for each calibra-

tion! TriOS oers an ideal set for the TpH calibration with a sensor holder and buer solutions for 6 calibrations.

Do not wipe the electrode.

NOTICE

Procedure:

• Since the pH value is temperature-dependent, it is recommended to check the temperature with a reference

thermometer before the rst pH calibration.

• If the temperature measured by the sensor deviates more than 1°C from the one measured by the reference

thermometer, a calibration of the temperature oset is necessary.

• Rinse the sensor with distilled water.

• Immerse the TpH in pH7 buer solution, the sensor head (black) should be immersed as completely as possible

(the picture on the next page shows the immersion depth in the beaker with the buer solution as a red line).

Otherwise, measurement uctuations may occur.

Buer Solution pH7

6 x 25 ml

Buer Solution pH4

6 x 25 ml

Do not stir the sensor in the buer solution

NOTICE

12 D01-068en201913 Manual TpH

Calibration // TpH

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

The pH value depends on temperature!

NOTICE

• Rinse the sensor again with distilled water.

• Immerse the TpH in pH4 buer solution, the sensor head (black) should be immersed as completely as possible

(the picture below shows the immersion depth in the beaker with the buer solution as a red line). Otherwise,

measurement uctuations may occur.

• Allow the sensor to warm up for approx. 5 minutes and then calibrate to pH4 (or pH10). Observe the temperature!

• Rinse the sensor with distilled water.

• You can now begin your measurements.

• Dispose the buer solutions after use.

• Immerse the sensor slowly into the small buer solution and move it slightly so the membrane is wetted by the

buer solution.

• Allow the sensor to warm up for approx. 5 minutes and then calibrate to pH7. Observe the temperature!

Optimum immersion depth in applica-

tion with TriOS buer solution.

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

Name: TpH

Date: 23.02.2018 Rev.: TP101711

Note: Dimensions in mm

Document: D10-068en201805

TriOS Mess- und Datentechnik GmbH ●Bgm.-Brötje-Str. 25 ●26180 Rastede ●Germany

fon: +49 4402 / 69 67 0 - 0 ●fax: - 20 ●web: http://www.trios.de ●e-mail: info@trios.de

Dimension Drawing: TpH

Weitergabe sowie Vervielfältigung dieses Dokuments, Verwertung und Mitteilung seines Inhalts sind verboten,

soweit nicht ausdrücklich gestattet. Zuwiderhandlungen verpflichten zu Schadenersatz. Alle Rechte vorbehalten.

The reproduction, distribution and utilization of this document as well as the communication of its contents to others

without express authorization is prohibited. Offenders will be held liable for the payment of damages. All rights reserved.

Page 1 of 1

Note: iProperty -> Übersicht -> Kommentar

Preliminary: iProperty -> Status -> Status

Titel: iProperty -> Übersicht -> Titel

23

~

27

~

138~ 36,5~

AF = across flats

178~

Position Material

sensor body Polyethylene Terephthalate (PET)

Polyphenylene Sulfide (PPS)

sealings Nitrile Butadiene Rubber (NBR)

pH Stem pH Sensing Glass

13

D01-068en201913 Manual TpH

TpH // Calibration

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

5.2 Measurement Properties

5.2.1 Inuences on the Measurement

• The pH measurement depends on the following parameters:

• High temperatures of the measuring medium accelerate the ageing of the electrode.

• Note the immersion depth: a too shallow immersion depth can lead to uctuating measured values.

• Air bubbles on the sensor can cause measurement errors.

• Alkali error: at pH values above pH12, alkali ions (Li+, Na+) can cause lower pH values to be displayed, as the

alkaliions are detected in addition to the H+ ions.

• Flow can inuence the measured value.

5.2.2 Temperature Compensation

Temperature compensation is performed automatically by the integrated temperature sensor (Pt1000).

14 D01-068en201913 Manual TpH

Malfunction and Maintenance // TpH

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

6 Malfunction and Maintenance

6.1 Cleaning and Upkeep

The sensor requires only minimal maintenance. In applications which cause heavy soiling of the sensor, the sensor should be

serviced more often.

• The sensor should always be kept clean. If there is a biolm on the sensors, this can lead to measurement

errors.

• A dirty sensor should be cleaned with buer solution.

• If possible, mechanical inuences on the glass membrane should be avoided.

• For stubborn soiling, a very soft brush or a soft sponge can be used carefully.

• For more solid deposits, the sensor can be immersed in a diluted HCl solution or a base. Pepsin can also be used in

the case of organic deposits.

If the sensor is taken out of operation, it should be cleaned before being stored. The protective cap must be lled with

a 3-molar KCl solution.

6.2 Maintenance and Inspection

The average lifetime of a TpH sensor is about 1 year. If diculties occur during calibration, the sensor probably has to be

replaced.

Do not disassemble the sensor for cleaning and maintenance.

Avoid touching the sensors, as they could be damaged. If this is the case, the functionality of the

sensor can no longer be guaranteed.

After cleaning, always rinse the sensor and the sensor system carefully with distilled water.

NOTICE

NOTICE

NOTICE

6.2.1 Temperature calibration

Since the pH value is temperature-dependent, it is recommended to check the temperature with a reference thermometer

before the rst pH calibration. If the temperature measured by the sensor deviates more than 1°C from the one measured by

the reference thermometer, a calibration of the temperature oset is necessary.

1. If you need calibrate the temperature sensor, set the controller to Maintenance mode:“Options”“Service mode”

2. Select the TpH sensor under “Sensor” and the corresponding port (COM port).

3. Press the“Calibrate”button and select the temperature.

4. The following calibration wizard will guide you through the next steps:

• Enter the measured temperature (reference thermometer) as the setpoint and press“Next”

• Then initiate a measurement by pressing“Measurement”

• Wait until“Continue” is active and then press it.

5. At the end you will be asked if you want to save the calibration. By pressing“Next”, the new calibration is saved in

the sensor; “Cancel” restores the previous calibration.

15

D01-068en201913 Manual TpH

TpH // Malfunction and Maintenance

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

6.3 Returns

Please observe the following instructions when returning items.

If returning a sensor, please contact customer service rst. To ensure a smooth return and to avoid incorrect deliveries, each

return package must rst be reported to the customer service. You will then receive a numbered RMA form, which you need

to ll out completely, check and send back to us. Please attach the form with the number so it is clearly visible on the outside

of the return package or write it in large numbers on the packaging. This is the only way your return package can be correctly

allocated and accepted.

Please make sure that the sensor is cleaned and disinfected before shipping. In order to ship the goods undamaged, use the

original packaging. If this is not on hand, make sure that safe transport is guaranteed and the sensor is safely packed using

enough packing material.

Caution! Return shipments without an RMA number can not be accepted and processed!

6.2.2 Replacing the sensor at TriBox3

1. If you need to replace your sensor, set the controller to Maintenance mode:“Options” „Service mode”

2. Remove the sensor from the FlowCell / tube system. At this point you should also check whether the O-rings are

still perfect. Replace the O-rings if necessary.

3. Commissioning the new sensor:

Connect the new sensor to the TriBox3. Press “Sensor Scan”. After a short time, the TriBox3 should have recog-

nized the new sensor.

Display:

“Display” select the display click on the window(s) for TpH “Current value” select the value to be dis-

played.

Automatic measurements:

In the„Sensor“ menu, click on the TpH sensor (blue button).

Select “Automatic measurement” “Automatic measurement” or “Burst mode”(as required).

For setting the automatic measurements (if not burst mode), select „Options“ „Automatic measurements“

„Raster“ Set the selection of the measuring interval as required.

Set Modbus Address:

“Sensor” menu click on the TpH sensor button “Modbus server settings” “Slave address” change the

address.

Set Analog output:

“Options” “Analog outputs” select the previous analog output where the old sensor was set “Measure-

ment value used” select the new sensor from the drop down list set scaling information.

Post-processing:

If you want to keep previous post-processing settings, you can set them with “Sensor” “pH” here you can

congure the sensor settings as required.

If you need to replace the sensor, the controller settings for the new sensor need to be congured

again.

NOTICE

16 D01-068en201913 Manual TpH

Technical Data // TpH

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

7 Technical Data

7.1 Technical specications

Measurement technology pH electrode

Measurement principle Potentiometry

Parameter pH value, temperature

measuring range pH 0...14 pH

Temperature 0...+65 °C

resolution pH 0.01 pH

Temperature 0.1 °C

precision pH ± 0,06 pH

Temperature ± 0.5 °C

Intrinsic error

pH1 ± 0.05 pH

pH7 ± 0.05 pH

pH13 ± 0.35 pH

Linearity measurement error ± 0.1 pH

Repeatability

pH1 ± 0.1 pH

pH7 ± 0.05 pH

pH13 ± 0.1 pH

Output signal uc-

tuation

pH7 ± 0.025 pH

pH4 ± 0.05 pH

Warm-up time < 5 min

Drift Short-term drift 24 h ≤ 0.03 pH

Long-term drift 1 week ≤ 0.05 pH

10% time and

90% time

T10 ascending < 2 s

T10 falling < 2 s

T90 ascending ≤ 5 s

T90 falling ≤ 5 s

Temperature compensation Pt1000

Measurement interval 2 s

Housing material PPS / PET / NBR

Dimensions (L x Ø) ~ 180 x 27 mm ~ 7.1˝ x 1.1˝

Weight 110 g ~ 0.2 lbs

Interface RS-485, Modbus RTU

Power consumption 0.2 W

17

D01-068en201913 Manual TpH

TpH // Technical Data

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

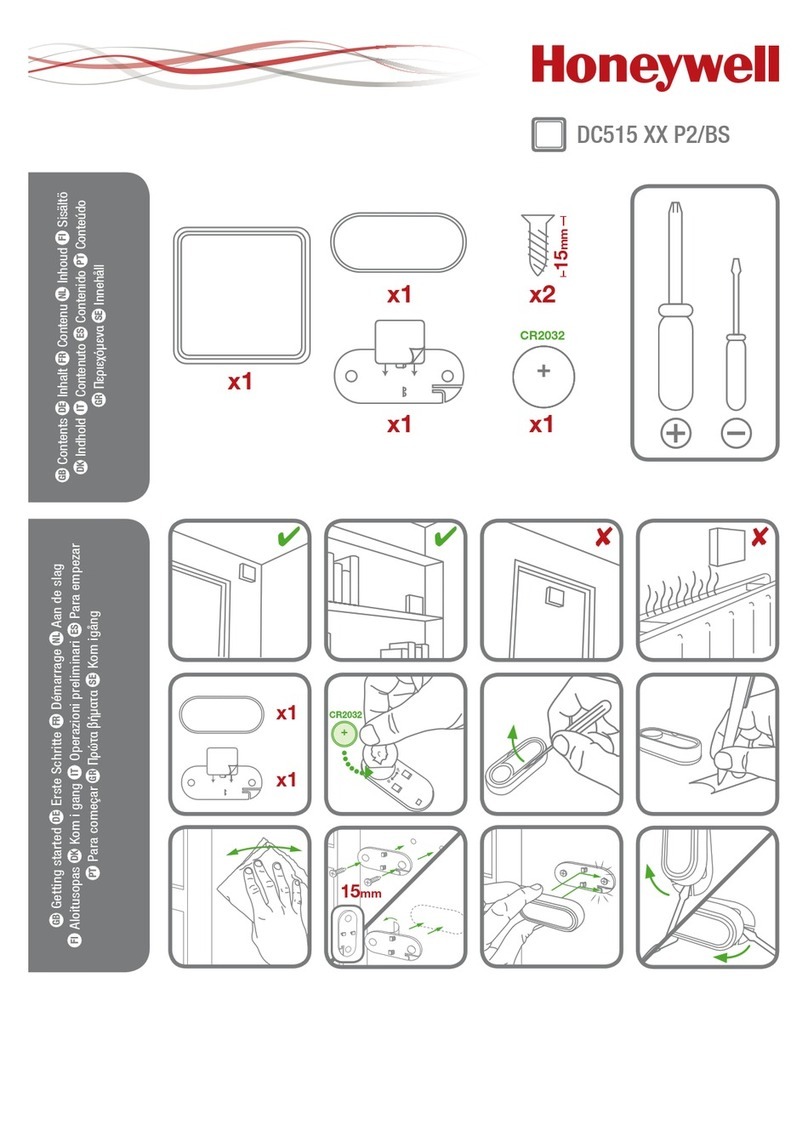

7.2 External Dimensions

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

Name: TpH

Date: 23.02.2018 Rev.: TP101711

Note: Dimensions in mm

Document: D10-068en201805

TriOS Mess- und Datentechnik GmbH ●Bgm.-Brötje-Str. 25 ●26180 Rastede ●Germany

fon: +49 4402 / 69 67 0 - 0 ●fax: - 20 ●web: http://www.trios.de ●e-mail: info@trios.de

Dimension Drawing: TpH

Weitergabe sowie Vervielfältigung dieses Dokuments, Verwertung und Mitteilung seines Inhalts sind verboten,

soweit nicht ausdrücklich gestattet. Zuwiderhandlungen verpflichten zu Schadenersatz. Alle Rechte vorbehalten.

The reproduction, distribution and utilization of this document as well as the communication of its contents to others

without express authorization is prohibited. Offenders will be held liable for the payment of damages. All rights reserved.

Page 1 of 1

Note: iProperty -> Übersicht -> Kommentar

Preliminary: iProperty -> Status -> Status

Titel: iProperty -> Übersicht -> Titel

23

~

27

~

138~ 36,5~

AF = across flats

178~

Position Material

sensor body Polyethylene Terephthalate (PET)

Polyphenylene Sulfide (PPS)

sealings Nitrile Butadiene Rubber (NBR)

pH Stem pH Sensing Glass

Power supply 12...24 VDC (± 10 %)

Connection 8-pin M12 plug

Sensor cable 2 m and 10 m

Required supervision Typically ≤ 0.5 h/month

Calibration / maintenance interval Typically 4 weeks

System compatibility Modbus RTU

Warranty

1 year (EU: 2 years) on electronics;

wearing parts are excluded

from the warranty

Max. pressure with xed cable 3 bar ~ 43.5 psig

in ow cell 1 bar, 2...4 L/min ~ 14.5 psig, 0.5 to 1 gpm

Protection type IP68 NEMA 6P

Sample temperature +2...+40 °C ~ +36 °F to +104 °F

Ambient temperature -5...+55 °C ~ +23 °F to +131 °F

Storage temperature 0...+80 °C ~ +32 °F to +176 °F

Inow velocity 0...3 m/second ~ 0...10 fps

18 D01-068en201913 Manual TpH

Accessories // TpH

Use

Use

Calibration

Calibration

Malfunction &

Maintenance

Malfunction &

Maintenance

Commissioning

Commissioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ Technical Data

Technical Data

Warranty

Warranty

Customer

Service

Customer

Service

Contact

Contact

Keyword Index

Keyword Index

Accessories

Accessories

8 Accessories

8.1 TriBox 3

Digital 4-channel display and control unit

with integrated solenoid valve for pneumatic con-

trol

TriBox3 is a measurement and control system for all TriOS sensors.

The device provides 4 sensor channels with selectable RS-232

or RS-485 function. In addition to the Modbus RTU, various

other protocols are available. A built-in valve allows the use of

compressed-air cleaning for the sensors The TriBox3 also oers

TCP/IP and WLAN networks, USB connection and 6 analog

outputs (4...20 mA). An integrated relay can be used to trigger

alarms or to control external devices. Features such as low po-

wer consumption, a robust aluminium housing and a range of

interfaces make it suitable for all applications that have to do

with environmental monitoring, drinking water, wastewater tre-

atment plants and many other areas.

Firmware version 1.4.11 or higher.

8.2 TriBox Mini

Digital 2-channel controller

Mini controller with two digital and serial sensor channels

and two 4...20mA outputs. All measurement data and diag-

nostic data can be read out via a built-in web browser.

Firmware version 1.2.0 or higher.

Table of contents

Other triOS Accessories manuals