triOS eCHEM 90S220000 User manual

Chlorine Dioxide

OPERATING INSTRUCTIONS

1

TABLE OF CONTENTS

Table of Contents

1 General Information 2

1.1 Introduction 2

1.2 Health and safety information 3

1.3 Warnings 4

1.4 Users and Operating Requirements 4

1.5 Intended use 5

1.6 Disposal Information 5

1.7 Certicates and Approvals 5

2 Introduction 6

2.1 Product Identication 6

2.2 Scope of Delivery 7

2.3 Measurement Principle and Design 7

3 Commissioning 8

3.1 Preparation of the Sensor for Commissioning 8

3.2 Electrical installation 10

3.3 Interfaces 11

3.4 Measurement 11

4 Use 12

4.1 Installation with retaining ring in the ow cell 13

5 Calibration 14

5.1 Manufacturer Calibration 14

5.2 Customer calibration 14

5.3 Measurement properties 15

6 Malfunction and Maintenance 16

6.1 Cleaning and Upkeep 16

6.2 Maintenance and inspection 16

6.2.1 Electrolyte Replacement 17

6.2.2 Membrane cap replacement 17

6.2.3 Sensor Check 18

6.2.4 Storage 18

6.3 Troubleshooting 18

6.3.1 General Troubleshooting 19

6.3.2 Special Troubleshooting on the Sensor 22

6.4 Returns 25

7 Technical Data 26

8 Accessories 27

8.1 Controller 27

8.1.1 TriBox3 27

8.1.2 TriBox mini 27

9 Warranty 28

10 Customer service 29

11 Contact 28

12 Keyword Index 32

Annex 34

2

Use

Use

Calibration

Calibration

Malfunction and

Maintenance

Malfunction and

Maintenance

Comm-

issioning

Comm-

issioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ

Technical

Data

Technical

Data

Warranty

Warranty

Customer

service

Customer service

Contact

Contact

Keyword

Index

Keyword

Index

Accessories

Accessories

D01-915en201911 Manual eCHEM Chlorine Dioxide

General Information // Chlorine Dioxide

1.1 Introduction

Welcome to TriOS.

We are glad that you have chosen to purchase our chlorine dioxide sensor.

The chlorine dioxide sensor from the eCHEM sensors product range is an electrochemical sensor for measuring the chlorine

dioxide concentration in water. The range of application of the sensor covers almost all water qualities and treatments (e.g.

bottle washing machine, CIP system, rinser). It can also be used in seawater. Thanks to a special membrane system, the sensor

is particularly resistant to chemicals and surfactants.

In this manual, you will primarily only nd information you will need to commission the eCHEM chlorine dioxide sensor. Tech-

nical specications can be found in chapter 7. The corresponding operating instructions of the peripheral devices must be

observed.

Please note that the user is responsible to comply with local and state regulations for the installation of electronic equipment.

Any damage caused by incorrect use or unprofessional installation will not be covered by the warranty. All sensors and ac-

cessories supplied by TriOS Mess- und Datentechnik GmbH must be installed and operated in accordance with the specica-

tions provided by TriOS Mess- und Datentechnik GmbH. All parts were designed and tested in accordance with international

standards on electronic instruments. The device meets the requirements of the international standards on electromagnetic

compatibility. Please use only original TriOS accessories and cables to ensure reliable and correct operation of the devices.

Before using the device, read the manual carefully, and keep this manual on hand for future reference. Before commissioning

the sensor, please make sure that you have read and understood the following safety precautions. Always make sure that the

sensor is operated correctly. The safety precautions described on the following pages should ensure the reliable and correct

operation of this device and any additional associated devices and should prevent injuries to yourself or other persons and

damage to other equipment.

1 General Information

If the translation is at all dierent from the original German text, the German version is binding.

Copyright Notice

All of the content in this manual, including texts, photographs and graphics, are protected by copyright. Unless expressly

stated otherwise, TriOS Mess- und Datentechnik GmbH is the owner of the copyright. Persons who violate the copyright shall

be liable pursuant to § 106 et seq of the copyright law, they will be warned at their own expense and must pay compensation.

NOTICE

3

Use

Use

Calibration

Calibration

Malfunction and

Maintenance

Malfunction and

Maintenance

Comm-

issioning

Comm-

issioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ

Technical

Data

Technical

Data

Warranty

Warranty

Customer

service

Customer service

Contact

Contact

Keyword

Index

Keyword

Index

Accessories

Accessories

D01-915en201911 Manual eCHEM Chlorine Dioxide

Chlorine Dioxide // General Information

1.2 Health and safety information

This manual contains important information about health and safety rules. This information is labelled according to the in-

ternational specications of ANSI Z5356 ("Product safety information in product manuals, instructions and other collateral

materials") and must be strictly followed. The following are distinct categories:

Electromagnetic waves

Devices that radiate strong electromagnetic waves can inuence the measurement data or result in a malfunction of the sen-

sor. Avoid using the following devices in the same room as the TriOS sensor: mobile phones, cordless phones, transmitters/

receivers and other electrical devices that produce electromagnetic waves.

Reagents

Follow the safety and operating instructions of the manufacturer when using reagents. Observe the valid Hazardous Materials

Ordinance for reagents (German GefStoV)!

Biological safety

Liquid waste may be a biohazard. Therefore, you should always wear gloves when working with such materials. Please observe

the currently valid biological agents regulation! (German BioStoV)

Waste

When handling liquid waste, observe the regulations on water pollution, drainage and waste disposal.

Tip / Useful Information

Can result in damage to property

Warning / may lead to serious injury or death

Caution / may cause moderate injury

Danger warning / will lead to serious injury or death

DANGER

WARNING

CAUTION

NOTICE

4

Use

Use

Calibration

Calibration

Malfunction and

Maintenance

Malfunction and

Maintenance

Comm-

issioning

Comm-

issioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ

Technical

Data

Technical

Data

Warranty

Warranty

Customer

service

Customer service

Contact

Contact

Keyword

Index

Keyword

Index

Accessories

Accessories

D01-915en201911 Manual eCHEM Chlorine Dioxide

General Information // Chlorine Dioxide

1.3 Warnings

• The sensor should only be used in drinking water, swimming pool water or sea water, other water qualities should

be tested.

• Any other use is considered improper. In the event of improper use, all warranty claims are void and liability is

excluded.

• The sensor may only be used to determine and control the chlorine dioxide concentration.

• The sensor is not suitable for checking the absence of chlorine dioxide.

• The material resistance should be tested for each application.

• Do not cut, damage or change the cable. Make sure that no heavy objects are placed on the cable and that the

cable is not kinked. Make sure that the cable is not run near hot surfaces.

• Do not place any unsuitable objects near the measuring head as long as the measurement process is running,

as this can cause damage to the membrane or incorrect measurement results.

• Stop operation of the sensor in the event of excessive heat development (i.e. if it is hot to the touch). Switch

o the sensor immediately and remove the cable from the power supply. Please contact your dealer

or the TriOS customer service.

• Never try to disassemble or modify the electrode body of the sensor if such a procedure is not explicitly

described in this manual. Inspections, modications and repairs may only be carried out by the dealer or

by qualied experts authorized by TriOS.

• If the associated cable is damaged, it must be replaced with an original part by the customer service of

TriOS GmbH.

• When installing the sensor outside Germany, the relevant national regulations must be

observed.

• No liability is assumed for personal injury or damage to property resulting from non-observance of these

operating instructions, modication of the sensor or its improper use.

• Devices from TriOS Mess- und Datentechnik GmbH meet the highest safety standards. Repairs to

the device (which involve the replacement of the connecting cable) must be carried out by

TriOS Mess- und Datentechnik GmbH or by a workshop authorized byTriOS. Defective, improper repairs can lead to

accidents and injuries.

Do not touch the electrode nger or otherwise contaminate it! Do not remove the coating of the

electrode nger!

1.4 User and Operating Requirements

The chlorine dioxide sensor has been developed for use in industry and science.The implementation of chlorine dioxide deter-

mination with test kits often requires the handling of hazardous substances.

We assume that the operating personnel are familiar with dealing with dangerous substances based on their professional

training and experience. The operating personnel must be able to correctly understand and implement the safety labels and

information on the packaging and in the package inserts of the test kits.

TriOS does not guarantee the plausibility of the measured values. The user is always responsib-

le for the monitoring and interpretation of the measured values.

NOTICE

DANGER

5

Use

Use

Calibration

Calibration

Malfunction and

Maintenance

Malfunction and

Maintenance

Comm-

issioning

Comm-

issioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ

Technical

Data

Technical

Data

Warranty

Warranty

Customer

service

Customer service

Contact

Contact

Keyword

Index

Keyword

Index

Accessories

Accessories

D01-915en201911 Manual eCHEM Chlorine Dioxide

Chlorine Dioxide // General Information

1.5 Intended use

The purpose of the eCHEM chlorine dioxide sensor is exclusively to measure the chlorine dioxide

concentration as described in this manual. The chlorine dioxide sensor should only be used in conjunction with a ow cell.

Please note the technical data of the accessory parts. Other uses do not comply with the intended use.

The sensor may only be used for the measurement of chlorine dioxide in aqueous uids such as drinking water, swimming

pool water or sea water. Use in other media can damage the sensor. For the use of the chlorine dioxide sensor in other media

than those specied in this manual, please contact the customer service of TriOS Mess- und Datentechnik GmbH (support@

trios. de).

According to current scientic knowledge, the device is safe to use when it is handled according to the instructions in this

user manual.

Avoid any contact with the membrane that could scratch or dirty it. This would no longer guarantee

the functionality of the device.

1.6 Disposal Information

At the end of the device’s life or use, the device and its accessories can be returned for environmentally friendly disposal for a

fee (see addressbelow). The preceding professional decontamination of the device must be proven with a certicate. Please

contact us for more details before you send the device back.

Address of the dealer:

TriOS Mess- und Datentechnik GmbH

Bürgermeister-Brötje-Str. 25

D-26180 Rastede

Germany

Telephone: +49 (0) 4402 69670 - 0

Fax: +49 (0) 4402 69670 – 20

1.7 Certicates and Approvals

This product meets all of the requirements of the harmonised European standards. It therefore meets the legal requirements

of the EU guidelines. TriOS Mess- und Datentechnik GmbH conrms the successful testing of the product by axing the CE

marking. (See Annex.)

NOTICE

6

Use

Use

Calibration

Calibration

Malfunction and

Maintenance

Malfunction and

Maintenance

Comm-

issioning

Comm-

issioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ

Technical

Data

Technical

Data

Warranty

Warranty

Customer

service

Customer service

Contact

Contact

Keyword

Index

Keyword

Index

Accessories

Accessories

D01-915en201911 Manual eCHEM Chlorine Dioxide

Introduction // Chlorine Dioxide

2 Introduction

2.1 Product Identication

All TriOS Mess- und Datentechnik GmbH products have a label, which clearly shows the product designation.

There is also a rating plate on the sensor with the following information that you can use to uniquely identify the product:

Serial number

Product type

Power supply

Interface

In addition to the product bar code, the rating plate includes the TriOS Mess- und Datentechnik GmbH logo and the quality

label.

Please note that the specications given here are for illustration purposes only and may be dierent depending on the version

of the product.

7

Use

Use

Calibration

Calibration

Malfunction and

Maintenance

Malfunction and

Maintenance

Comm-

issioning

Comm-

issioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ

Technical

Data

Technical

Data

Warranty

Warranty

Customer

service

Customer service

Contact

Contact

Keyword

Index

Keyword

Index

Accessories

Accessories

D01-915en201911 Manual eCHEM Chlorine Dioxide

Chlorine Dioxide // Introduction

2.2 Scope of Delivery

The shipment contains the following components:

- Sensor with membrane cap M10.1N

- 100 ml gel electrolyte ECD4/W*ECD7/W

- Fine sandpaper S2

- 1 G-holder with O-ring

- Tweezers

- Operating instructions

Keep the original packaging of the device in case it needs to be returned for repairs.

2.3 Measurement Principle and Design

The chlorine dioxide sensor is a membrane-covered am-

perometric 2-electrode sensor. The measuring electrode is

covered by a membrane and, together with the combined

counter and reference electrode, is located in an electrolyte

chamber separated from the sample water, which contains a

special gel electrolyte.

In this measuring method, chlorine dioxide diuses from the

sample water through the membrane. When the chlorine

dioxide combines with the electrolyte at the measuring elec-

trode, an electrical signal is triggered. This signal is proporti-

onal to the chlorine dioxide concentration and is amplied

by the sensor electronics. Due to an integrated temperature

compensation, the measuring signal is independent of the

temperature of the sample water. Surfactants are tolerated

as far as possible.

8

Use

Use

Calibration

Calibration

Malfunction and

Maintenance

Malfunction and

Maintenance

Comm-

issioning

Comm-

issioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ

Technical

Data

Technical

Data

Warranty

Warranty

Customer

service

Customer service

Contact

Contact

Keyword

Index

Keyword

Index

Accessories

Accessories

D01-915en201911 Manual eCHEM Chlorine Dioxide

Commissioning // Chlorine Dioxide

3 Commissioning

This chapter deals with the commissioning of the chlorine dioxide sensor. Please pay particular attention to this section and

follow the safety precautions to protect the sensor from damage and yourself from injury. Prior to electrical installation (chap-

ter 3.2) of the sensor, it must rst be lled with gel electrolyte as described in chapter 3.1.

Before the sensor can be put into operation, it must be ensured that the sensor is securely attached and all connections are

correctly made.

The following installation requirements must be met:

• Permanent power supply and presence of sample water

• Flow rate according to data sheet

• Constant ow rate

• Disinfectant must be present in the sample water.

• Galvanic isolation of the electrical connection (if not present in the sensor)

• The sample water must not outgas at the measuring point.

3.1 Preparation of the Sensor for Commissioning

Some electrolytes contain diluted acids. Therefore, observe the warning notices on the

electrolyte bottle. Do not swallow the gel electrolyte. In case of skin or eye contact with the

electrolyte, rinse the aected areas thoroughly with water. Consult an ophthalmologist if the

eyes are reddened.

Gel electrolytes must not be shaken and must be stored upside down or on the sealing cap after

opening.

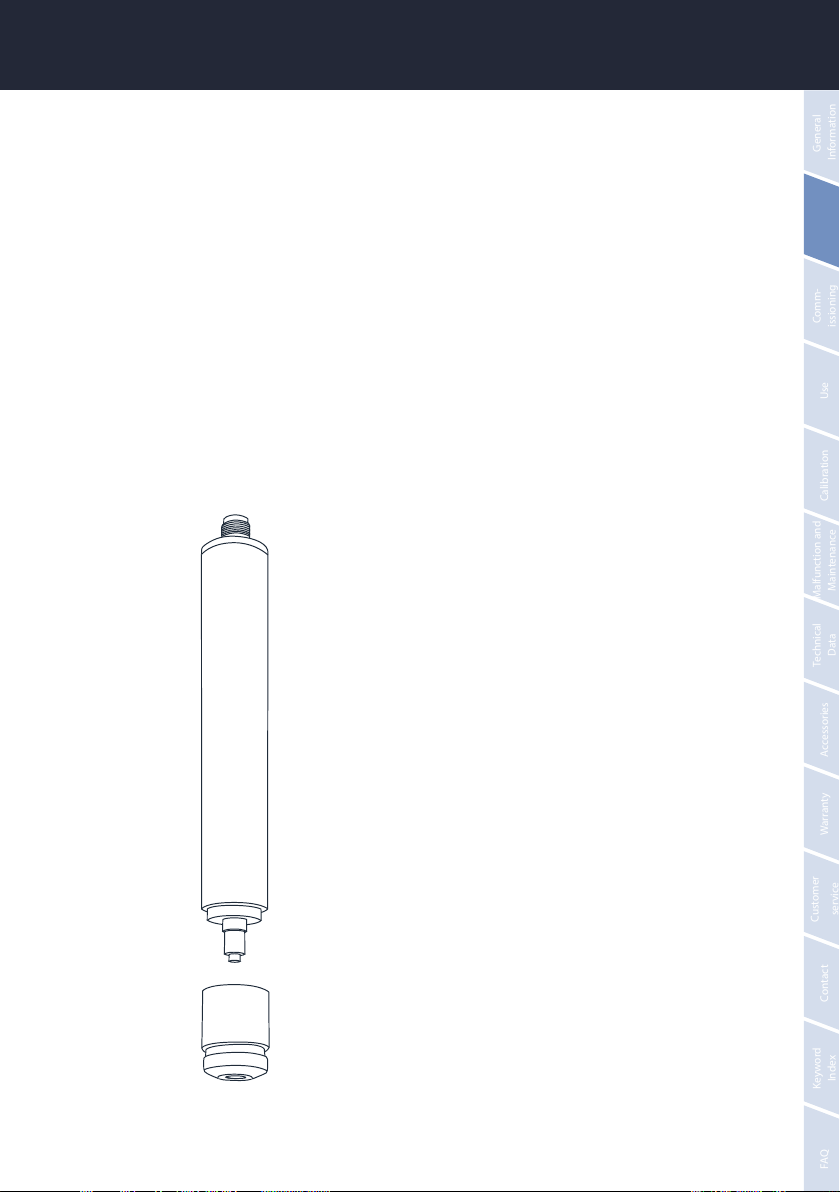

Remove the protective cap [3] from the membrane

cap [2].

Unscrew the membrane cap [2] from the sensor

body [1].

1

2

3

2.

1.

NOTICE

CAUTION

9

Use

Use

Calibration

Calibration

Malfunction and

Maintenance

Malfunction and

Maintenance

Comm-

issioning

Comm-

issioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ

Technical

Data

Technical

Data

Warranty

Warranty

Customer

service

Customer service

Contact

Contact

Keyword

Index

Keyword

Index

Accessories

Accessories

D01-915en201911 Manual eCHEM Chlorine Dioxide

Chlorine Dioxide // Commissioning

Place the membrane cap on a clean surface and ll to the rim

with gel electrolyte.

Place the G-holder on a clean surface with the fabric facing

down and moisten the G-holder with gel electrolyte.

Use the tweezers [1] to grasp the G-holder [2] with the fabric

facing down and place the G-holder centrally on the memb-

rane in the membrane cap [3].

Carefully pull the tweezers out of the membrane cap again.

The G-holder is now placed in the membrane cap.

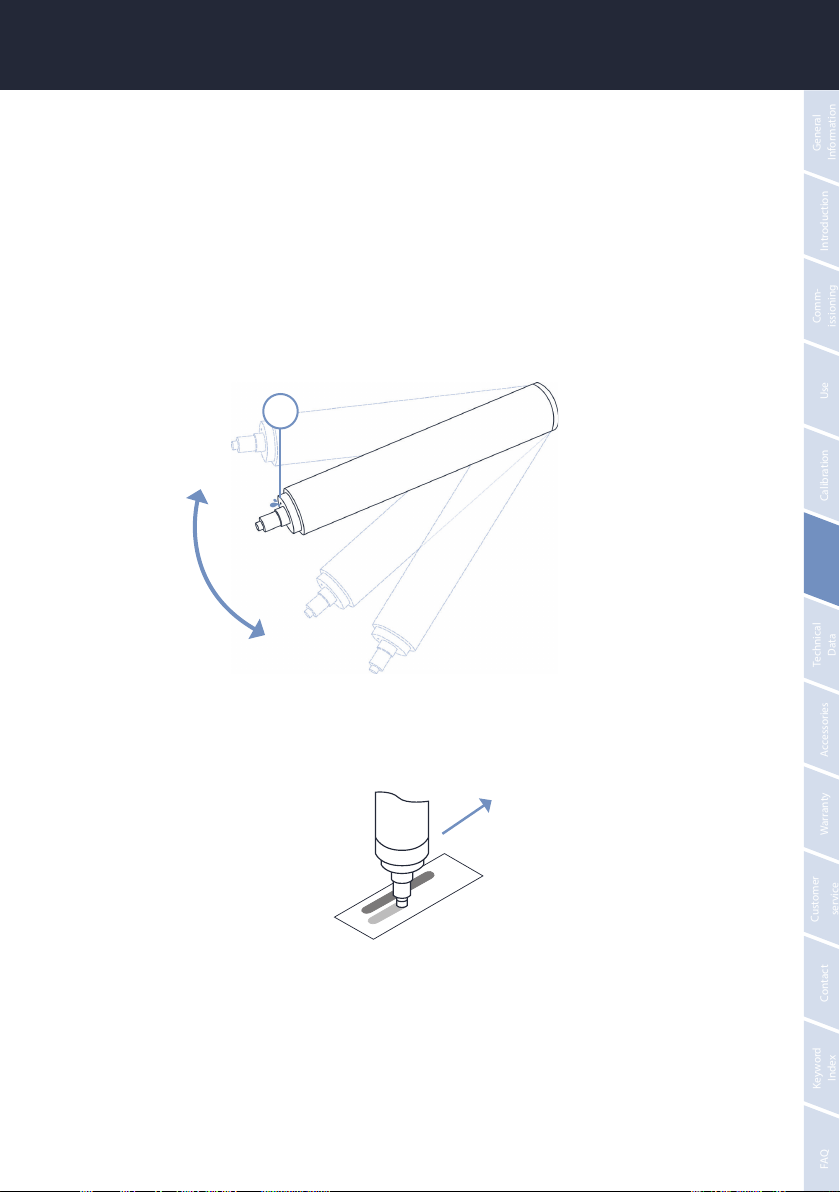

Place the sensor body [1] upright on the membrane cap [2]

and turn it counterclockwise until the thread is engaged.

Slowly screw the sensor body into the membrane cap.

Make sure that the membrane cap is completely screwed onto the sensor body, i.e. as far as it will go.

Neither touch nor strike the membrane!

The sensor is ready for commissioning.

1

2

3

1

2

Rinse o electrolyte residues adhering to the outside of the

sensor with tap water.

NOTICE

10

Use

Use

Calibration

Calibration

Malfunction and

Maintenance

Malfunction and

Maintenance

Comm-

issioning

Comm-

issioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ

Technical

Data

Technical

Data

Warranty

Warranty

Customer

service

Customer service

Contact

Contact

Keyword

Index

Keyword

Index

Accessories

Accessories

D01-915en201911 Manual eCHEM Chlorine Dioxide

Commissioning // Chlorine Dioxide

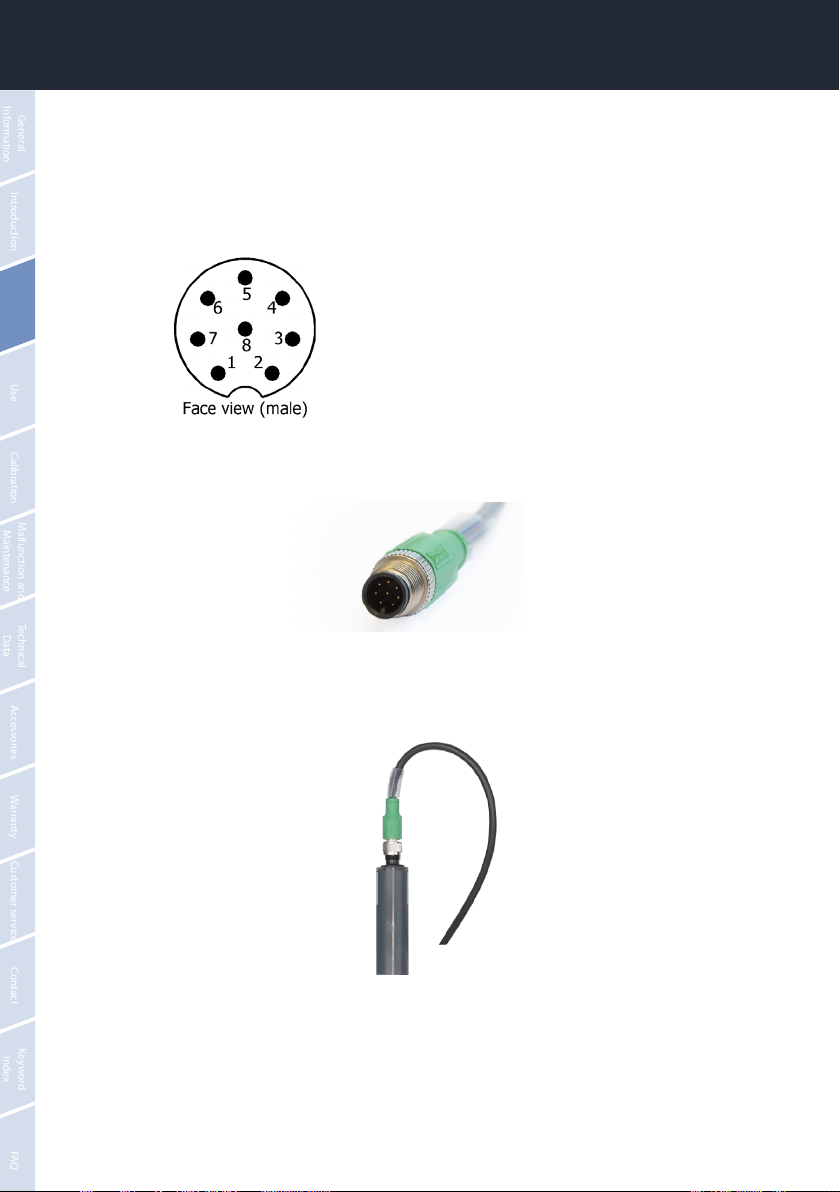

3.2 Electrical installation

The chlorine dioxide sensor is equipped with an 8-pin M12 screw connector for electrical commissioning. The following gure

shows the pin assignment of the connector:

1. RS-485 A (commands)

2. RS-485 B (data)

3. Not assigned

4. Not assigned

5. Not assigned

6. Not assigned

7. Ground (Power + Ser. Interface)

8. Power (9...30 VDC)

Insert the connector into one of the suppliedTriOS cables. Connect the male end of the cable into the connector on the sensor

by making the pins align with the slots of the cable. The next step is to turn the locking sleeve clockwise to secure the end of

the connector.

The sensor may only be operated with the specied supply voltage.

Make sure that the supply voltage of the controller is constant! A supply voltage that is too low causes an incorrect measured

value and can lead to dangerous over-metering in a control loop. The sensors must be operated potential-free. There must be

no current ow between the sensors and the measuring medium. Measuring and control devices must therefore have galvanic

isolation.

11

Use

Use

Calibration

Calibration

Malfunction and

Maintenance

Malfunction and

Maintenance

Comm-

issioning

Comm-

issioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ

Technical

Data

Technical

Data

Warranty

Warranty

Customer

service

Customer service

Contact

Contact

Keyword

Index

Keyword

Index

Accessories

Accessories

D01-915en201911 Manual eCHEM Chlorine Dioxide

Chlorine Dioxide // Commissioning

3.3 Interfaces

The chlorine dioxide sensor with digital signal processing has a digital Modbus RTU interface (RS-485). The pin assignment has

already been explained in more detail in chapter 3.

The interface must be congured as follows:

• Baud rate: 9600 bps

• Data bits: 8

• Stop bits: 1

• Parity: none

• Flow control: none

A detailed description of the Modbus protocol commands can be found in the Annex.

3.4 Measurement

The sensor must be used for measurements in the ow cell type FLC (see chapter 4). The use of the sensor in other ow cells

must be approved byTriOS GmbH. Otherwise, no warranty will be given for the proper functioning of the sensor or for resulting

damage to property or personal injury.

The maximum permissible operating pressure of the sensor is 1.0 bar (with retaining ring). The permissible temperature ope-

rating range of the sensor is 0 to <50 °C. The sensor may only be used to determine and control the chlorine dioxide concen-

tration.

As soon as the sensor is supplied with power, it starts measuring automatically. The measured values can be displayed, conver-

ted or stored using a TriOS controller.

Please also refer to the corresponding controller manuals! If the sensor is not recognized by the controller, the conguration of

the interface should be checked directly (see chapter 3.3).

12

Use

Use

Calibration

Calibration

Malfunction and

Maintenance

Malfunction and

Maintenance

Comm-

issioning

Comm-

issioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ

Technical

Data

Technical

Data

Warranty

Warranty

Customer

service

Customer service

Contact

Contact

Keyword

Index

Keyword

Index

Accessories

Accessories

D01-915en201911 Manual eCHEM Chlorine Dioxide

Use // Chlorine Dioxide

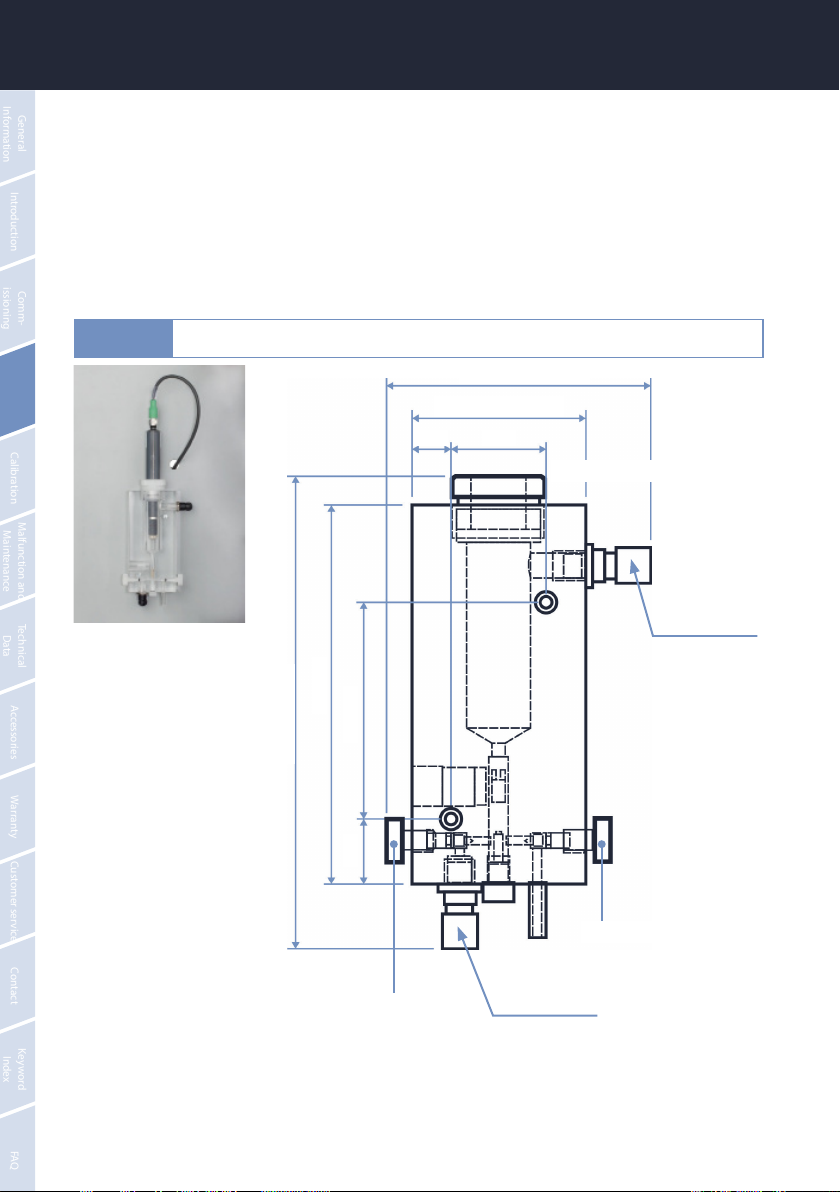

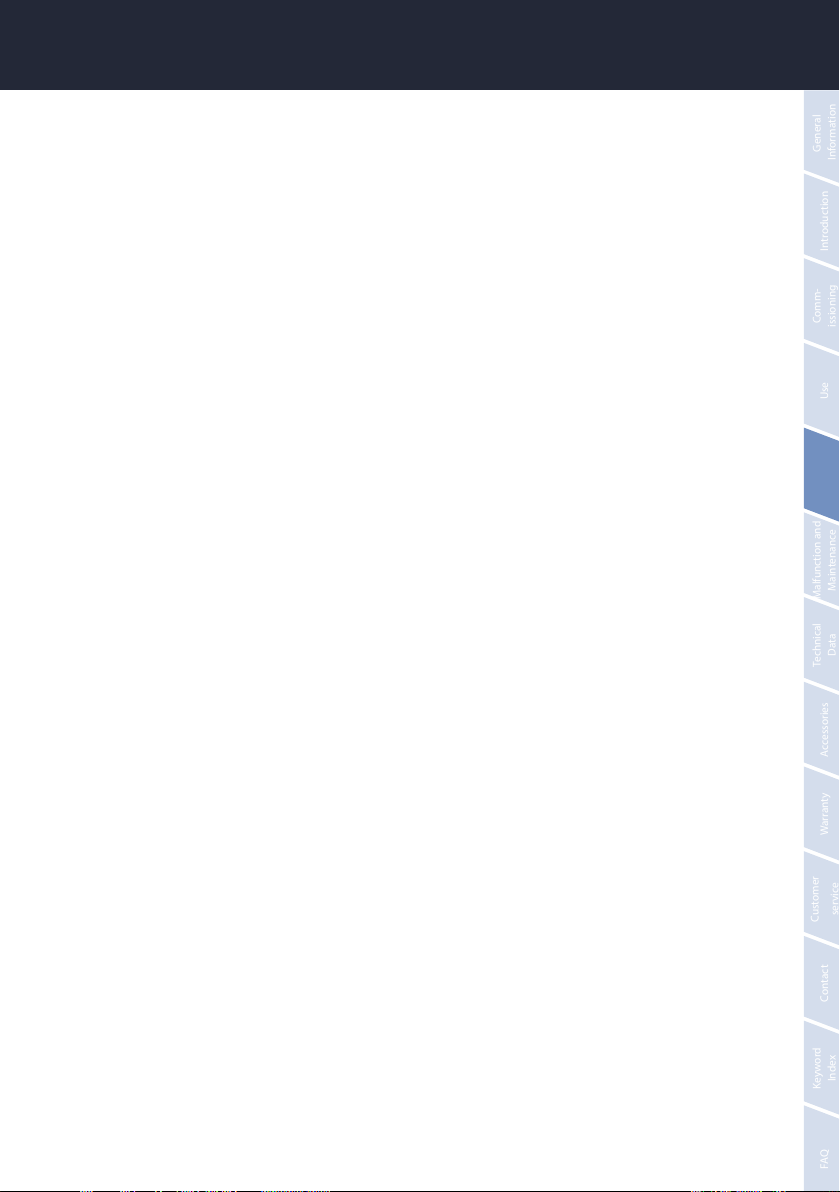

4 Use

The chlorine dioxide sensor can be operated with all TriOS controllers. Instructions for correct installation can be found in the

relevant controller manual.

A bypass installation of the sensor is essential for correct results. Therefore we strongly recommend to use the sensor in the

ow cell type FLC for permanent use.

Before installing the sensor in the ow cell type FLC, make sure that there is no pressure in the system. Close the shut-o valves

upstream and downstream of the ow-through tting. Push the sensor slowly into the ow-through tting. The sensor must

not be pushed against the bottom of the tting.

The use of the sensor without ow cell is not recommended and can lead to loss of warranty.

Screw connection 1 1/4”

Approx. 122

80.00

Dimensions in mm

18.00 44.00

OUT

IN

30.00 100.00

175.00

Approx. 220

Flow control

Sampling

6/8 mm hose

6/8 mm hose

NOTICE

13

Use

Use

Calibration

Calibration

Malfunction and

Maintenance

Malfunction and

Maintenance

Comm-

issioning

Comm-

issioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ

Technical

Data

Technical

Data

Warranty

Warranty

Customer

service

Customer service

Contact

Contact

Keyword

Index

Keyword

Index

Accessories

Accessories

D01-915en201911 Manual eCHEM Chlorine Dioxide

Chlorine Dioxide // Use

A sudden failure of the sensor can lead to dangerous over-metering. Take appropriate precautions in

this case! Check system for odour, check water for abnormal discolouration. In case of strong over-

metering, the DPD-1 measurement can remain colourless because the dye is bleached by the chlorine

present.

4.1 Installation with retaining ring in the ow cell

For installation in a ow cell, you need the sensor for chlorine dioxide measurement on the one hand and the ow cell on the

other.

1. To install the sensor in the ow cell, you must rst remove the screw connections on the ow cell FLC.

2. Push the slide ring from the FLC under the retaining ring of the sensor.

3. Push the 25x2.5 O-ring (silicone) underneath the slidw ring over the sensor (see gure).

Make sure that the sensor is prepared as described in chapter 3.

Make sure that the 30x2.6 O-ring (Viton) is still in the ow cell at the insertion edge.

4. Now slowly insert the prepared sensor into the ow cell as shown in the gure.

5. Carefully slide the screw connection over the sensor and screw it tight, otherwise leaks may occur!

6. Open the sample water drain.

7. Slowly open the sample water inlet.

Avoid installations where air bubbles can form in the sample water.

Operating mode Flow-through tting Max. operating

pressure

Max. operating tempe-

rature Flow rate

Sensor operation with

retaining ring FLC 1.0 bar (10 mH2O) 50 °C 15-30 L/h

IMPORTANT Observe and adhere to the max. permitted operating pressure / operating temperature of the

sensor!

Anschlußbuchse

connector

Elektrodenschaft mit

integrierter Elektronik

electrode shaft

with amplifier

Sicherungsring, retaining ring

Gleitring, slide ring

O-Ring

1_17_02_ZB.skd

Connection socket M12 plug

Electrode shaft

with integrated

electronics

Retaining ring

Slide ring

O-ring

Sensor

Screw connection 1 1/4“

Retaining ring

Slide ring

O-ring 25x2.5 (silicone)

O-ring holder

O-ring 30x2.6 (Viton)

FLC

NOTICE

14

Use

Use

Calibration

Calibration

Malfunction and

Maintenance

Malfunction and

Maintenance

Comm-

issioning

Comm-

issioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ

Technical

Data

Technical

Data

Warranty

Warranty

Customer

service

Customer service

Contact

Contact

Keyword

Index

Keyword

Index

Accessories

Accessories

D01-915en201911 Manual eCHEM Chlorine Dioxide

Calibration // Chlorine Dioxide

5 Calibration

5.1 Manufacturer Calibration

No manufacturer calibration is performed due to application-related changes in measured values (pH, inow velocity, etc.)The

sensors are only tested under standard conditions (concentration, pH, inow velocity etc.) in an endurance test.

5.2 Customer calibration

A customer calibration using the DPD-1 method ("chlorine dioxide") must be carried out in the application. The installation and

other conditions must match the nal application.

Recommendation: Weekly control, if necessary more frequently. In case of a necessary recalibration, operation with a TriOS

controller is recommended. An integrated wizard guides the user step by step through a calibration menu. The value determi-

ned analytically in parallel by the DPD method is set as the reference value in the controller.

Please note the following explanations for direct Modbus access:

Calibration

The values for zero point (X_Null), slope (X_Span) and then date and time are written to the sensor. The sensor electronics

accepts the new calibration data if the date stamp is sent within approx. 5 seconds following the values. If the date diers from

that of the last calibration, the new values are stored in the history memory and the oldest values are overwritten.

Date / Time stamp

• Data type: unsigned long

• 232 = 4294967296

• Year: (20)42, Month: [94], Day [96], Hour [72], Min: [96]

• Last possible date: 31.12.2042, 23:59

The determination of chlorine dioxide is also possible with a photometer for chlorine if the result is multiplied

by the factor 1.9.

15

Use

Use

Calibration

Calibration

Malfunction and

Maintenance

Malfunction and

Maintenance

Comm-

issioning

Comm-

issioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ

Technical

Data

Technical

Data

Warranty

Warranty

Customer

service

Customer service

Contact

Contact

Keyword

Index

Keyword

Index

Accessories

Accessories

D01-915en201911 Manual eCHEM Chlorine Dioxide

Chlorine Dioxide // Calibration

5.3 Measurement properties

The following instructions must be observed when operating the sensor:

• The sensor must be operated in an upright position so that the incoming ow of sample water comes from

below up against the membrane.

• Outgassing sample water interferes with the measurement. During unpressurised operation with free outow

of the sample water gas bubbles have no disturbing eect as long as they do not cover the membrane. Gas

bubbles in front of the membrane prevent the chlorine dioxide from entering the gel electrolyte, which falsies

the measuring signal.

• A minimum inow velocity (>15 L/h) is required. The ow rate must be constant.

• The service life of the membrane is typically 1 year, but it depends very much on the water quality. Heavy soiling

of the membrane must be avoided.

• The supply voltage of the sensor must not be switched o during interval operation of the measuring

system. The sensor must be permanently connected to the supply voltage. The sensor must not stand dry.

• The sensor must not be operated for a longer period of time (>1 day) in chlorine dioxide free water. There is a risk

that deposits/soiling (e.g. biological) will form on the membrane, which makes later chlorine dioxide

measurement impossible. After operating the sensor in chlorine-dioxide-free water, longer stabilization times

must be expected. If required, re-dosing should take place with a time delay. If no chlorine dioxide is expected

over a longer period of time, the sensor must be separated from the controller, removed and stored in a dry place.

• The presence of reducing and oxidizing agents as well as corrosion inhibitors can interfere with the

measurement.

16

Use

Use

Calibration

Calibration

Malfunction and

Maintenance

Malfunction and

Maintenance

Comm-

issioning

Comm-

issioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ

Technical

Data

Technical

Data

Warranty

Warranty

Customer

service

Customer service

Contact

Contact

Keyword

Index

Keyword

Index

Accessories

Accessories

D01-915en201911 Manual eCHEM Chlorine Dioxide

Malfunction and Maintenance // Chlorine Dioxide

6 Malfunction and Maintenance

To ensure error-free and reliable measurement, the chlorine dioxide sensor should be cleaned and serviced at regular intervals.

When carrying out maintenance and in the event of a malfunction, the entire system from the extraction point to the drain

must always be taken into account. The system usually consists of:

• Chlorine dioxide sensor

• Electrical wiring and connections

• Flow-through ttings and connections

• Measuring and / or control device

• Dosing device

• Analysis kit

Before removing the sensor, downstream controllers should be switched o or switched to manual operation. If the sensor is

removed, an incorrect measured value may occur at the input of the controller and lead to uncontrolled dosing in a control

loop. Shut o the sample water inlet and outlet. Remove the electrical connection.

6.1 Cleaning and Upkeep

To ensure a long service life of the chlorine dioxide sensor, it should be checked regularly for contamination. Carefully rinse

o any soiling on the outside with water. In case of heavy soiling it is recommended to change the gel electrolyte and/or the

membrane cap. A detailed description on how to change the gel electrolyte and the membrane cap is given in the following

chapter 6.2.

If you have further questions on this topic, we would be pleased to help you. Please contact our customer service at support@

trios.de.

6.2 Maintenance and inspection

The sensor should be checked regularly for contamination, fouling and bubbles on the outside of the membrane. Avoid con-

tamination of the membrane with particles, condensation etc. as far as possible. Bubbles on the outside of the membrane can

be eliminated by briey increasing the ow rate.

After a membrane cap or electrolyte change, a slope adjustment must be carried out.

The use of warm water is recommended for rinsing o the gel electrolyte residues on the electrode nger

and in the membrane cap.

The coating of the electrode nger must not be sanded down. Do not unscrew the membrane disc

holder from the membrane cap, as the membrane may be damaged and the adjustment may be lost!

NOTICE

17

Use

Use

Calibration

Calibration

Malfunction and

Maintenance

Malfunction and

Maintenance

Comm-

issioning

Comm-

issioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ

Technical

Data

Technical

Data

Warranty

Warranty

Customer

service

Customer service

Contact

Contact

Keyword

Index

Keyword

Index

Accessories

Accessories

D01-915en201911 Manual eCHEM Chlorine Dioxide

Chlorine Dioxide // Malfunction and Maintenance

6.2.1 Electrolyte Replacement

It is recommended to replace the gel electrolyte at least twice a year or when an adjustment is no longer possible due to

readings that are unstable or too low.

Carry out the following steps one after the other:

1. Unscrew the membrane cap.

2. Use the tweezers to remove the G-holder from the membrane cap.

3. Empty the gel electrolyte from the membrane cap.

4. Rinse the electrode nger with tap water.

5. Shake the sensor body dry several times so that the pressure equalization opening [1] is emptied (see gure).

6.2.2 Membrane cap replacement

It is recommended to replace the membrane cap once a year or when an adjustment is no longer possible due to readings that

are unstable or too low.

The new membrane cap is supplied with the G-holder. To replace the membrane cap, please follow the commissioning proce-

dure (see chapter 3.1).

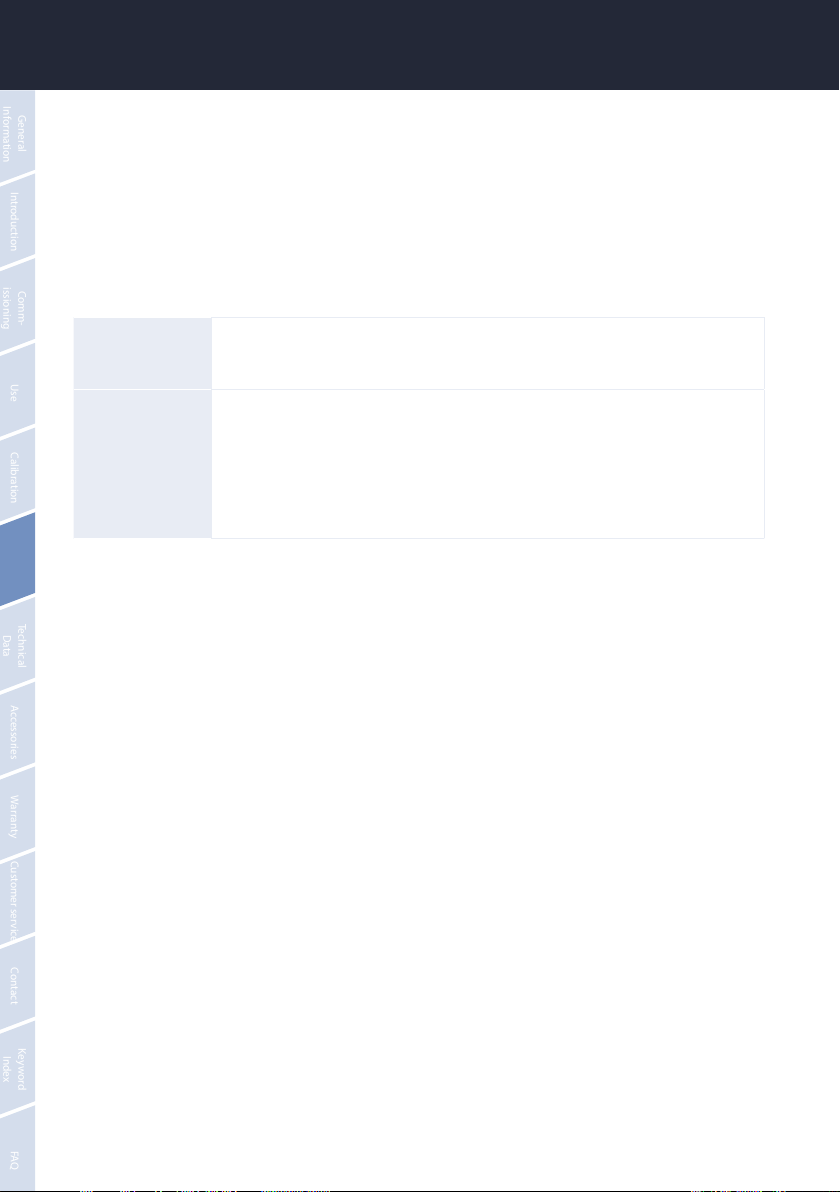

6. Place the special sandpaper on a paper towel.

7. Hold the sensor upright.

8. Hold the special sandpaper and run the tip of the working electrode at least twice over it. Use a new surface of sandpaper

each time (see gure).

1

18

Use

Use

Calibration

Calibration

Malfunction and

Maintenance

Malfunction and

Maintenance

Comm-

issioning

Comm-

issioning

Introduction

Introduction

General

Information

General

Information

FAQ

FAQ

Technical

Data

Technical

Data

Warranty

Warranty

Customer

service

Customer service

Contact

Contact

Keyword

Index

Keyword

Index

Accessories

Accessories

D01-915en201911 Manual eCHEM Chlorine Dioxide

Malfunction and Maintenance // Chlorine Dioxide

6.2.3 Sensor Check

An adjustment or a check of the sensor according to the DPD-1 method should be carried out regularly at specic intervals,

depending on the requirements.

Recommendation: Weekly control, if necessary more frequently.

It is recommended to replace the electrolyte at least twice a year.

Sensors with digital internal signal processing

The mounting of the socket on the sensor is transparent. Two light emitting diodes (green and orange) are visible:

Green LED

Continuous light: Power supply is correct. Program in the processor is running.

Flickering or no light: Indicates low voltage and resulting processor malfunction.

Orange LED

No light: (all correct) Sensor signal has the right polarity.

Continuous light: indicates wrong polarity of the sensor signal. Multiply the displayed output

signal by -1.

Regular ashing: The chlorine sensor is overloaded. Cause: Chlorine dioxide concentrations too

high. (Due to the dierent sensitivities/slopes of the chlorine dioxide sensors, an overdrive may

occur even if the maximum measuring range is not reached yet.)

6.2.4 Storage

To store the sensor, unscrew the membrane cap, rinse the membrane cap and electrode holder with clean water and dry in a

dust-free place. The dry membrane cap is then screwed loosely onto the electrode shaft to protect the electrode nger. The

membrane must not be in contact with the measuring electrode.

When the electrode is put back into operation, clean the electrode tip with special sandpaper and use a new membrane cap

(see section 6.2.2).

Used membrane caps, which were once in operation, cannot be stored and reused again.

6.3 Troubleshooting

For a targeted error analysis, the entire system from the extraction point to the drain must always be taken into account. The

system usually consists of:

• Sensor

• Electrical wiring and connections

• Flow-through ttings and connections

• Measuring and / or control device

• Dosing device

• Analysis kit

In most cases, a faulty measurement is corrected by cleaning the electrode, replacing the electrolyte or changing the memb-

rane cap. In the case of electronic faults, there is no possibility of repairing the electrode body adequately on site. The chlorine

dioxide sensor must be sent back to the manufacturer for troubleshooting. When returning a sensor, always follow the proce-

dure described in chapter 6.4, including provision of the RMA number.

In the following, detailed troubleshooting instructions are given, which are intended to enable a clear assessment of the fault

and to provide appropriate guidance. A distinction is made between general troubleshooting (chapter 6.3.1) and special trou-

bleshooting on the sensor (chapter 6.3.2).

Table of contents

Other triOS Accessories manuals