triOS 02A100 8 Series User manual

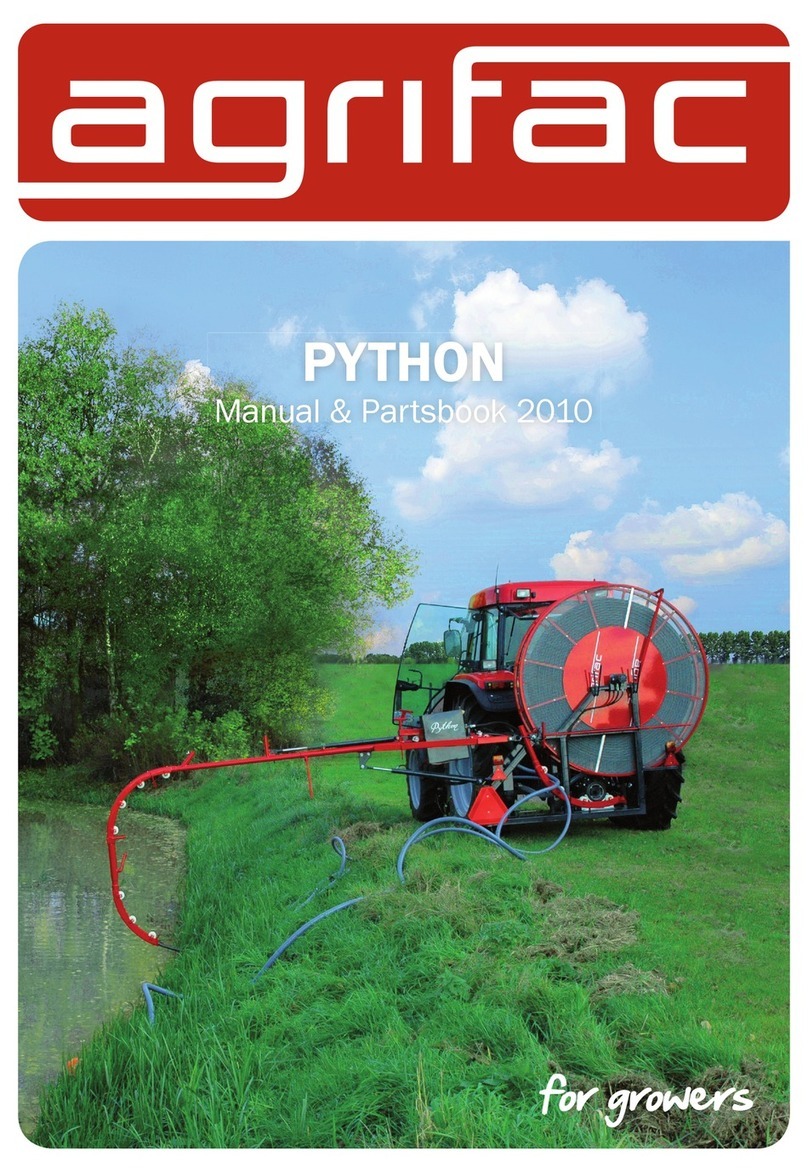

Wiper W55 V2

1

TriOS Mess- und Datentechnik GmbH · Bürgermeister-Brötje-Str. 25 · D-26180 Rastede · Germany

fon: +49 (0) 4402 69670 - 0 · fax: +49 (0) 4402 69670 - 20 · [email protected] · www.trios.de

D04-067en202111 Quick Guide Wiper W55 V2

Wiper W55 V2

02A100XX8

Technical Specications

Path lengths 2 mm, 5 mm, 10 mm

Control port

4-pin M8-plug

A suitable M8 connection cable with open end is included in the scope of

delivery.

Trigger input 5-24 VDC (±10% )

Power consumption

trigger input 2...15 mA

Operating time (max.) 3 Seconds

Dimensions L x Ø 175 mm x 80 mm

Weight 0.52 kg

Material NBR, POM, TPE (PP, EPDM), Titanium or V4A

Power supply 12-24 VDC (± 10 %)

Power consumption approx. 2-6 W in operation; max. 0.75 W in standby

Maintenance eort ≤ 0.5 h/month typical

Maintenance interval depending on application

Warranty 1 year (EU & USA : 2 years)

Max. Pressure 1 bar

Protection Type IP68

Inow velocity up to 10 m/s

Operating temperature +2...+40 °C

Storage temperature -10 °C...+70 °C

The TriOS Wiper W55 V2 provides an additional cleaning option for all TriOS photometers with path lengths

up to 10 mm. The wiper housing can be mounted on the sensor in just a few steps and provides reliable

cleaning of the measurement windows. The new magnetic axis lock allows quick and easy wiper blade re-

placement, without any tools.

The new version of the wiper now features blockage detection and removal, and a service mode that increas-

es the life of the wiper through regular use. The accessory can also be used in seawater up to a depth of 10m.

2

D04-067en202111 Quick Guide Wiper W55 V2

TriOS Mess- und Datentechnik GmbH · Bürgermeister-Brötje-Str. 25 · D-26180 Rastede · Germany

fon: +49 (0) 4402 69670 - 0 · fax: +49 (0) 4402 69670 - 20 · [email protected] · www.trios.de

Wiper W55 V2 // Quick Guide

Quick Guide

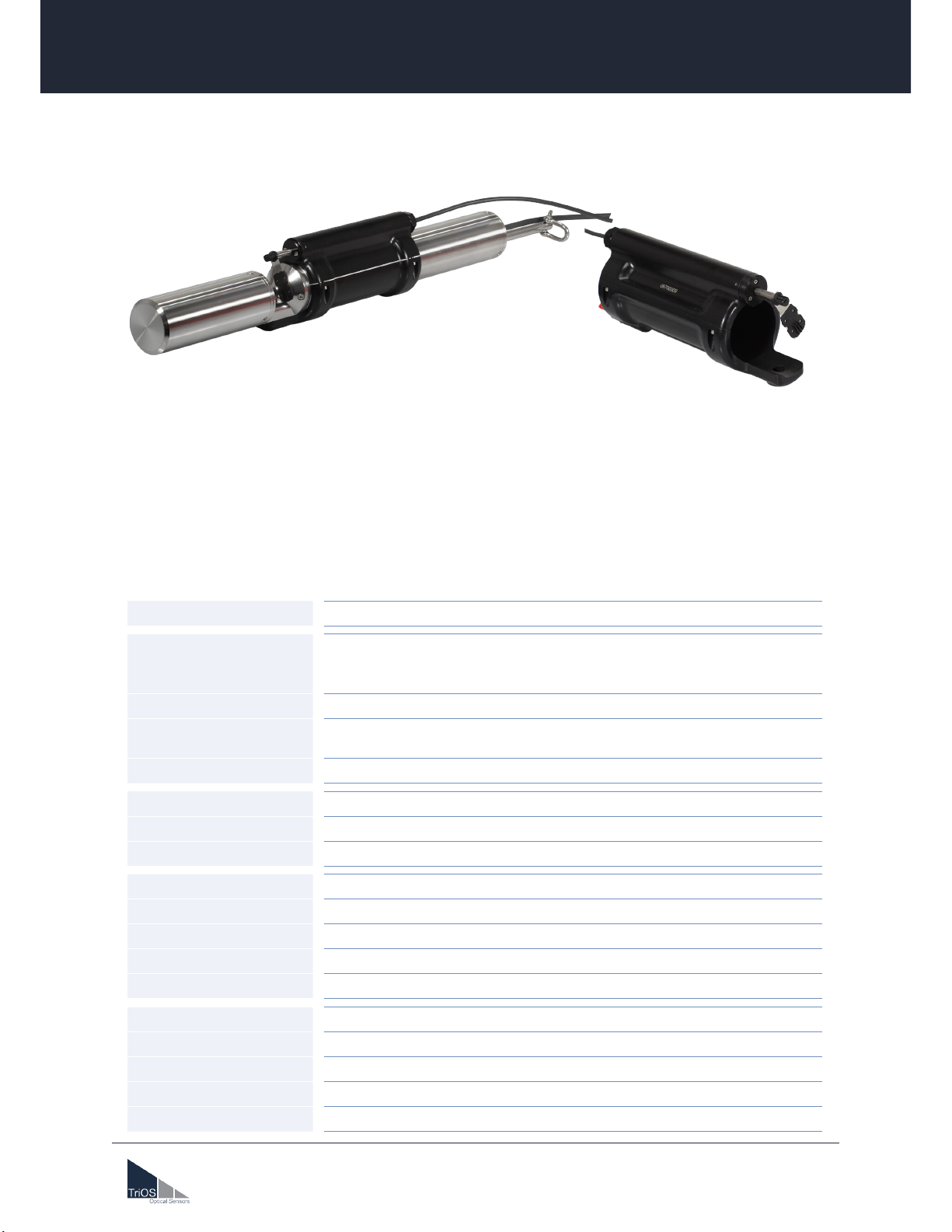

1 Scope of Delivery

02A100008

1x Wiper

1x M8 open end cable

1x adjustment screw with o-ring

1x compressed air tting incl. sealing plug

1x magnet

02A100X18

5x wiper blades 2, 5 or 10 mm path

1x axis for 2, 5 or 10 mm path

1x grease

Optional (recommended)

1x protective cage

1x hexagonal oset screwdriver 5 mm

00P100010

The wiper blades and the axis are not included in the scope of delivery of the wiper housing, as these must

be selected depending on the path length of the sensor. A set of wiper blades contains ve wiper blades and

an axis of the appropriate size incl. grease.

Item number

02A100008 Wiper W55 V2

02A100218 Set with wiper blades for 2 mm path

02A100518 Set with wiper blades for 5 mm path

02A100618 Set with wiper blades for 10 mm path

2 Inserting / changing the wiper blade

If there are larger particles or objects in the sample water, you should always use

a protective cage to avoid damaging the wiper gear (see p. 9 for installation).

NOTICE

We recommend replacing the wiper blades every 4-5 weeks. The axis should be

changed every 5-6 months (new box).

NOTICE

3

D04-067en202111 Quick Guide Wiper W55 V2

TriOS Mess- und Datentechnik GmbH · Bürgermeister-Brötje-Str. 25 · D-26180 Rastede · Germany

fon: +49 (0) 4402 69670 - 0 · fax: +49 (0) 4402 69670 - 20 · [email protected] · www.trios.de

Wiper W55 V2 // Quick Guide

1. First place the wiper blade on the axis. To do this, push the wiper blade onto the axis until you hear a click.

2. Slightly grease the O-ring on the axis and insert the axis into the spring in the wiper housing. The axis

groove is magnetically tightened and must be inserted as far as it will go and, if necessary, turned slightly

until the correct position engages.

Wiper blades and axis must always be selected to match the path length of the

sensor, otherwise the measuring windows may be damaged.

NOTICE

The wiper axis is not seated correctly until the O-ring is no longer visible and the

axis can no longer rotate.

NOTICE

Never immerse the wiper in water without the axis installed! Since no other seal

is installed, unrepairable damage will occur which is not covered by the warranty.

NOTICE

4

D04-067en202111 Quick Guide Wiper W55 V2

TriOS Mess- und Datentechnik GmbH · Bürgermeister-Brötje-Str. 25 · D-26180 Rastede · Germany

fon: +49 (0) 4402 69670 - 0 · fax: +49 (0) 4402 69670 - 20 · [email protected] · www.trios.de

Wiper W55 V2 // Quick Guide

If the wiper gets stuck in the light path or is jammed by an object, we recommend removing the wiper com-

pletely from the sensor to prevent damage to the transmission. To do this, loosen the four screws on the wiper

housing and remove the wiper from the sensor.

Alternatively, only the axis can be pulled out. It is held magnetically and can simply be pulled out in the direc-

tion of the axis. Please remember to remove the wiper blade beforehand.

It is recommended to replace the O-ring and axis every 5-6 months.

1. Remove the axis with the wiper and the sealing ring.

2. Slightly grease the O-ring of the new axis and attach the new wiper blade.

3. Insert the new axis with wiper blade and O-ring into the spring in the wiper housing. The axis groove is

magnetically tightened and must be inserted as far as it will go and, if necessary, turned slightly until the

correct position engages.

3 Change housing seal (O-ring) and axis

4 Installation on the sensor

1. Place the lower housing of the wiper against the sensor and align it with the screw hole. Now tighten the

positioning screw.

positioning screw

lower housing

wiper housing

1.

2.

3. To change the wiper blade, it can be easily removed by lifting the upper part of the cover slightly and

pulling off the blade.

External mechanical loads, such as turning the wiper or the axis by hand, can

damage the gear unit!

NOTICE

Attention, the axis is held magnetically and must be pulled out in the direction of

the axis. Do not attempt to unscrew the axis under any circumstances.

Please make absolutely sure that there is an O-ring on the adjustment screw.

NOTICE

NOTICE

2. Place the upper part of the wiper housing on top and fasten with the four screws. At first only screw the

screws in very slightly and then tighten them one by one in a symmetrical order.

lower housing

wiper housing

positioning screw with o-ring

5

D04-067en202111 Quick Guide Wiper W55 V2

TriOS Mess- und Datentechnik GmbH · Bürgermeister-Brötje-Str. 25 · D-26180 Rastede · Germany

fon: +49 (0) 4402 69670 - 0 · fax: +49 (0) 4402 69670 - 20 · [email protected] · www.trios.de

Wiper W55 V2 // Quick Guide

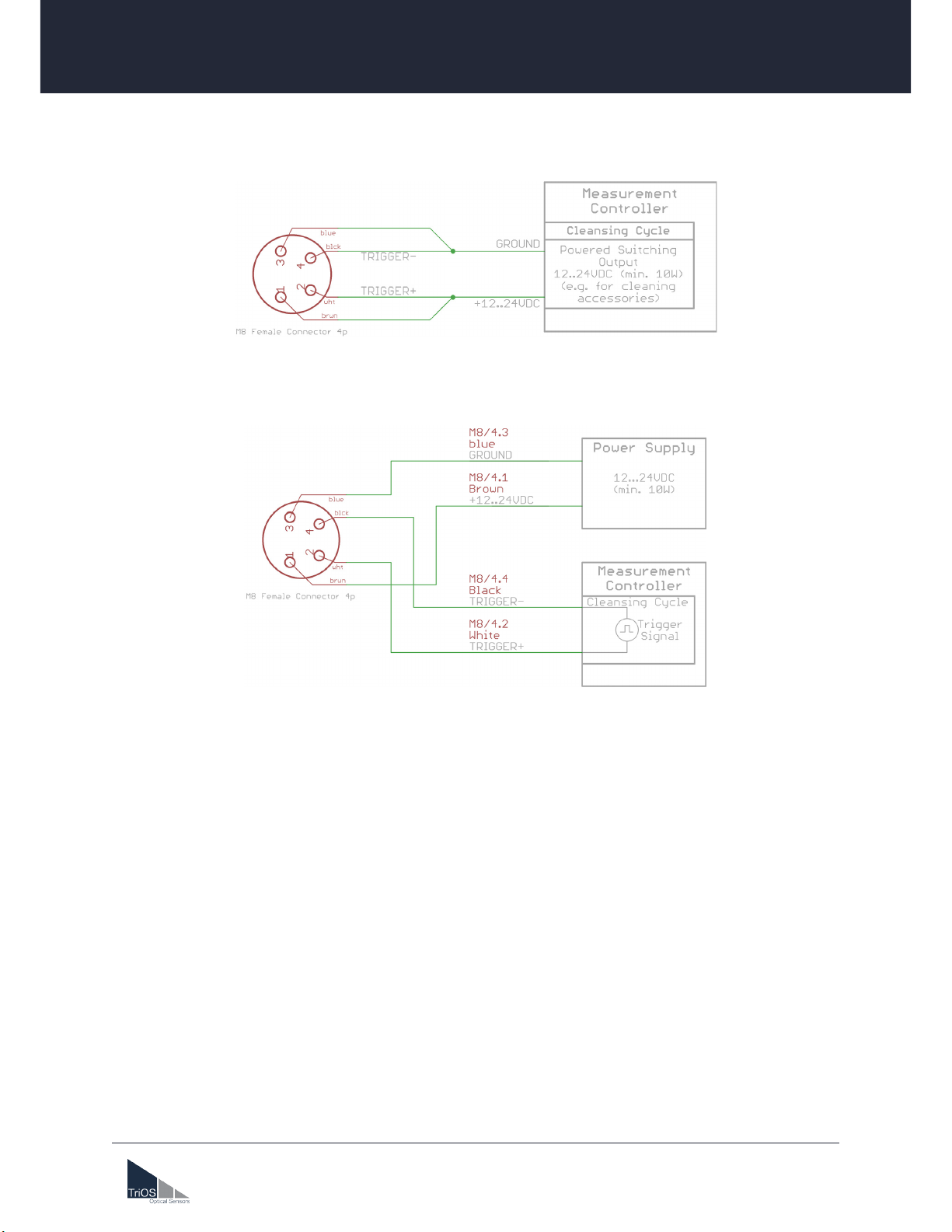

If the wiper is connected using the supplied M8 connection cable (see option 1), the cleaning process is au-

tomatically started after the supply voltage of 12 – 24 VDC has been applied. This lasts approx. 2-3 seconds

(two wiping cycles) – then the wiper stops in the parking position. For further wiping operations, the power

supply must be interrupted for at least one second and then reconnected.

IMPORTANT: The supply voltage must remain switched on until the end of the wiping process (reaching the

parking position), otherwise the wiper may stop at an undened point. In the worst case, it then covers the

light path and faulty measurements occur!

For an alternative connection where power supply and cleaning control (triggering) are separate, the open

end of the M8 line can be disconnected (see option 2). Remove the twin ferrules and equip the individual

cores with single ferrules. Now the wiper can be connected to a suitable DC voltage source according to the

connection diagram shown in the Option 2 gure. The trigger line in turn can be connected to a controller

which controls the cleaning cycle. The wiping process is started by a voltage signal (5 – 24 V; min. duration:

100 ms) on the trigger line. Here, too, two wiping cycles are carried out, which require approx. 2-3 seconds.

A new wiping process can then be started by re-triggering (pause between the intervals ≥ 1 second).

IMPORTANT: Even with this circuit option, it must be ensured that the supply voltage remains switched on

during the wiping process!

Option 1: M8 connection cable with open end, trigger is connected parallel to the supply voltage (included in

delivery).

Option 2: M8 connection cable with open end, trigger and power supply are separate.

5 Commissioning

6

D04-067en202111 Quick Guide Wiper W55 V2

TriOS Mess- und Datentechnik GmbH · Bürgermeister-Brötje-Str. 25 · D-26180 Rastede · Germany

fon: +49 (0) 4402 69670 - 0 · fax: +49 (0) 4402 69670 - 20 · [email protected] · www.trios.de

Wiper W55 V2 // Quick Guide

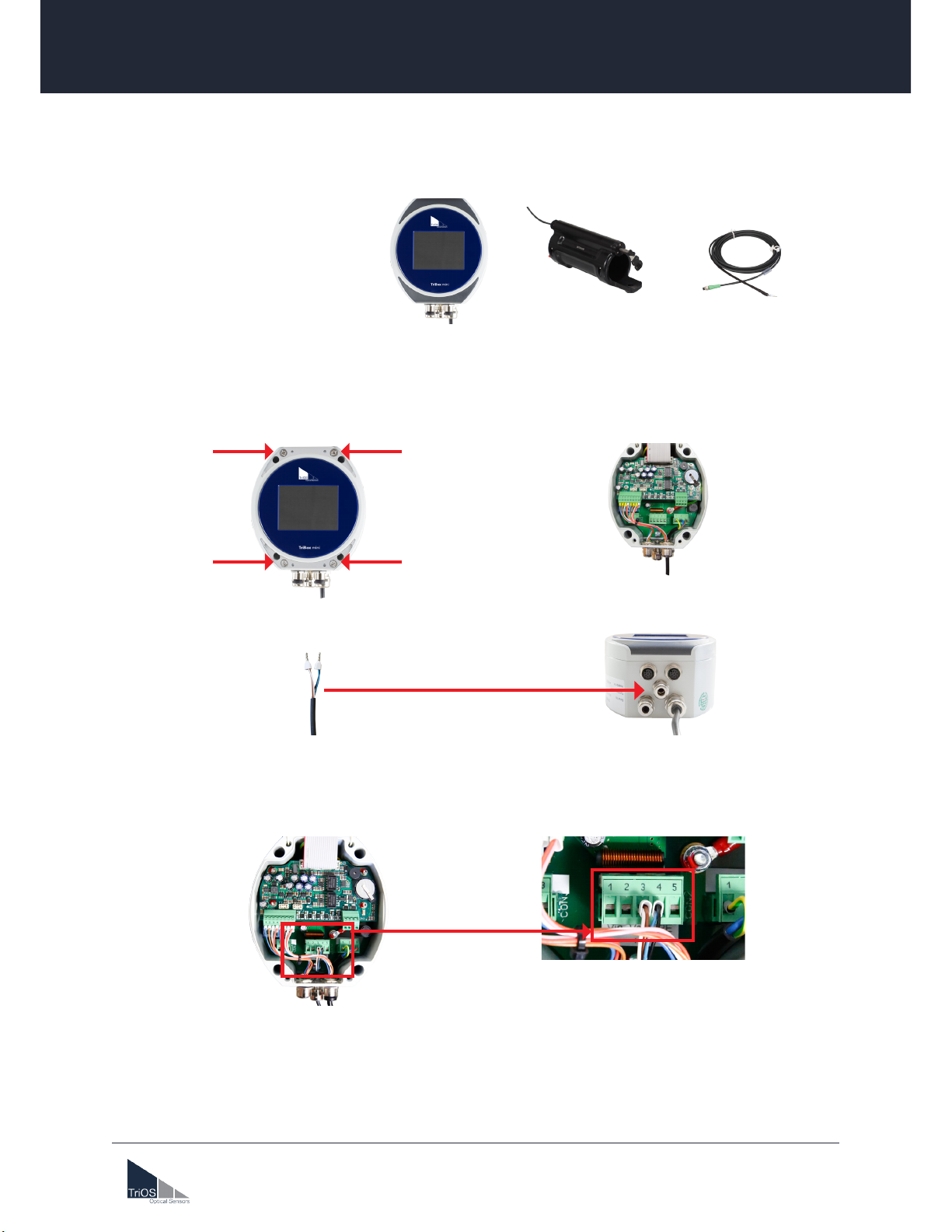

6 Connecting the wiper to the TriBox mini

Necessary components

TriBox mini Wiper Open End Cable

Connection

1. Open the lid of the TriBox mini by removing the dark grey covers and unscrewing the four screws under-

neath.

2. Place the wiper cable through the cable guide of the TriBox mini and tighten the cable guide.

3. Connect the blue-black wire of the wiper cable to the CON2 connector, pin 4 (VOUT-) and the brown-

white wire to the CON2 connector, pin 3 (VOUT+). Make sure that the screws are tightened.

4. Close the TriBox mini lid, tighten the four screws and place the grey covers on the TriBox mini.

5. The wiper settings can now be adjusted in the TriBox mini menu under “Measurement & Cleaning”. Un-

der “Cleaning Settings”, the cleaning duration should be at least 10 seconds and set to “active”.

7

D04-067en202111 Quick Guide Wiper W55 V2

TriOS Mess- und Datentechnik GmbH · Bürgermeister-Brötje-Str. 25 · D-26180 Rastede · Germany

fon: +49 (0) 4402 69670 - 0 · fax: +49 (0) 4402 69670 - 20 · [email protected] · www.trios.de

Wiper W55 V2 // Quick Guide

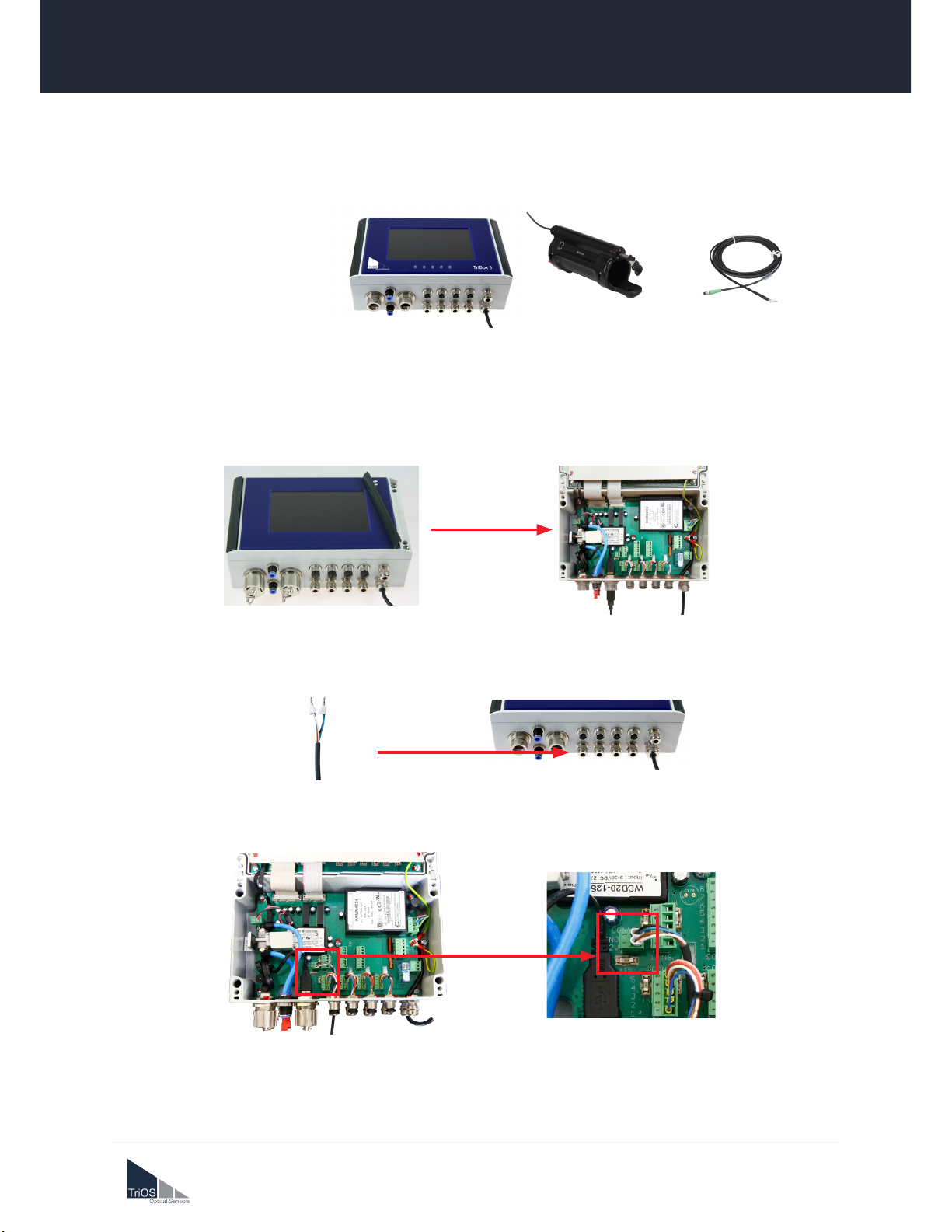

7 Connecting the wiper to the TriBox 3

Necessary components

Connection

1. Open the lid of the TriBox3 by removing the dark grey covers and unscrewing the screws underneath.

TriBox3 Wiper Open End Cable

2. Place the wiper cable through the TriBox3 cable guide and tighten the cable guide on the wider part of

the cable.

3. Connect the blue-black wire of the wiper cable to the CON15 connector, pin 2 and the brown-white wire

to the CON15 connector, pin 1. Make sure the screws are tightened.

4. Close the TriBox3 lid, tighten the screws and place the grey covers on the TriBox3.

5. The wiper settings can now be adjusted in the TriBox3 menu under “Cleaning”. Cleaning time should be

at least 10 seconds and the valve must be activated.

8

D04-067en202111 Quick Guide Wiper W55 V2

TriOS Mess- und Datentechnik GmbH · Bürgermeister-Brötje-Str. 25 · D-26180 Rastede · Germany

fon: +49 (0) 4402 69670 - 0 · fax: +49 (0) 4402 69670 - 20 · [email protected] · www.trios.de

Wiper W55 V2 // Quick Guide

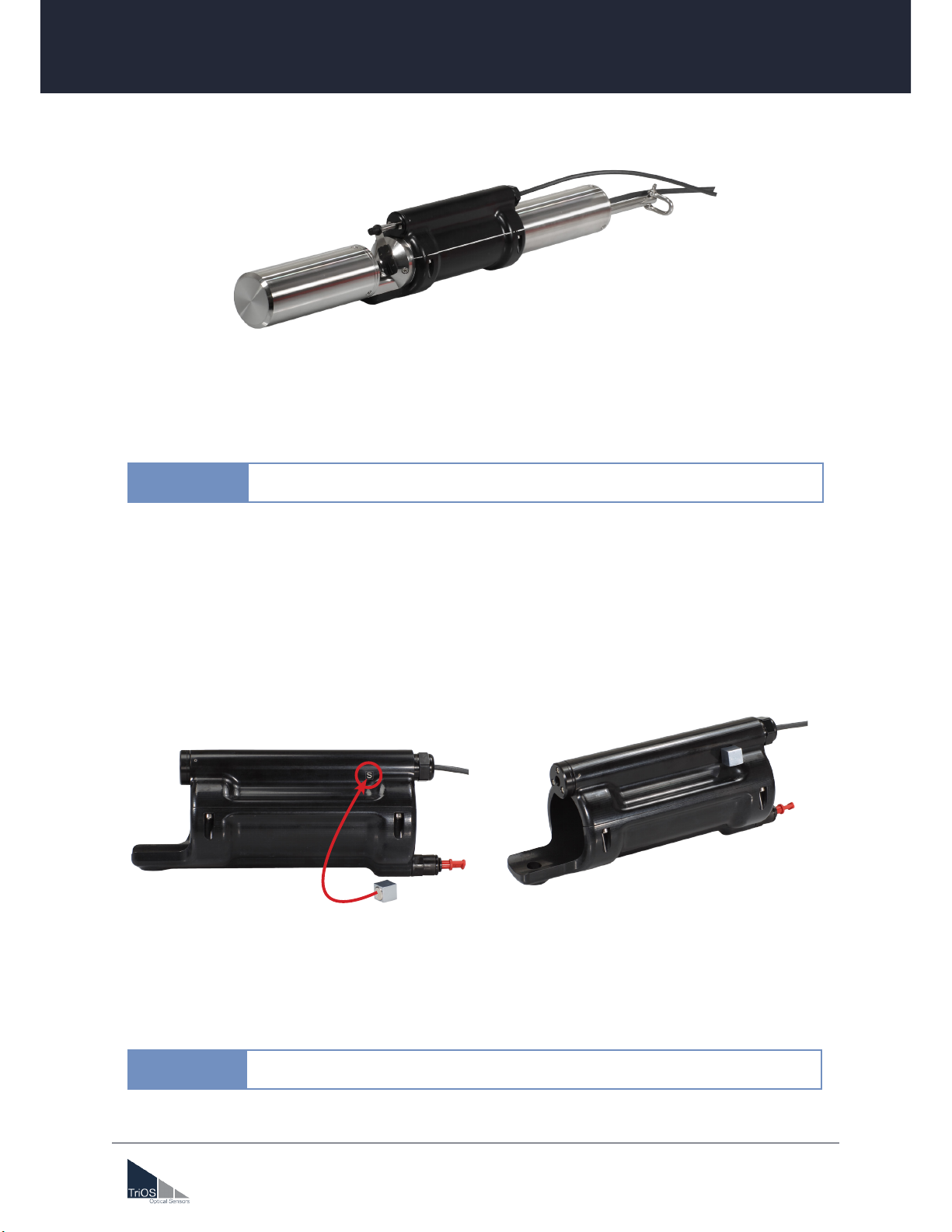

8 Blocking detection

After three wiping processes, the wiper blade always returns to the starting position. At the beginning of

each process, the position is briey checked. If the optical path is blocked, this is detected by the wiper and

it attempts to loosen the interfering component with very short wiping movements. If this is unsuccessful, the

wiper blade can also be removed when dry and the axle can be pulled out individually to manually unblock it.

The service mode is the new feature of the W55 V2 wiper. The service mode is activated by the supplied

magnet and ve full rotations in both directions are performed. This adjusts the home position and lubricates

the planetary gear in all directions. It is recommended to remove the upper wiper housing from the sensor rst

before activating the service mode to avoid damage to the measuring windows and to ensure free rotation.

To increase the life of the wiper, it is recommended to perform this function 1x per month.

To activate the service mode, hold the supplied magnet against the housing in the area of the „S“ mark. Move

the magnet slightly around the mark to hit the activation point. Once Service Mode is activated, the axis with

the wiper blade will begin full rotations.

The Service Mode should never be activated with the wiper protection cage

mounted, otherwise damage to the wiper will occur.

NOTICE

Attention, the axis is held magnetically and must be pulled out in the direction of

the axis. Do not attempt to unscrew the axis under any circumstances!

NOTICE

9 Service Mode

9

D04-067en202111 Quick Guide Wiper W55 V2

TriOS Mess- und Datentechnik GmbH · Bürgermeister-Brötje-Str. 25 · D-26180 Rastede · Germany

fon: +49 (0) 4402 69670 - 0 · fax: +49 (0) 4402 69670 - 20 · [email protected] · www.trios.de

Wiper W55 V2 // Quick Guide

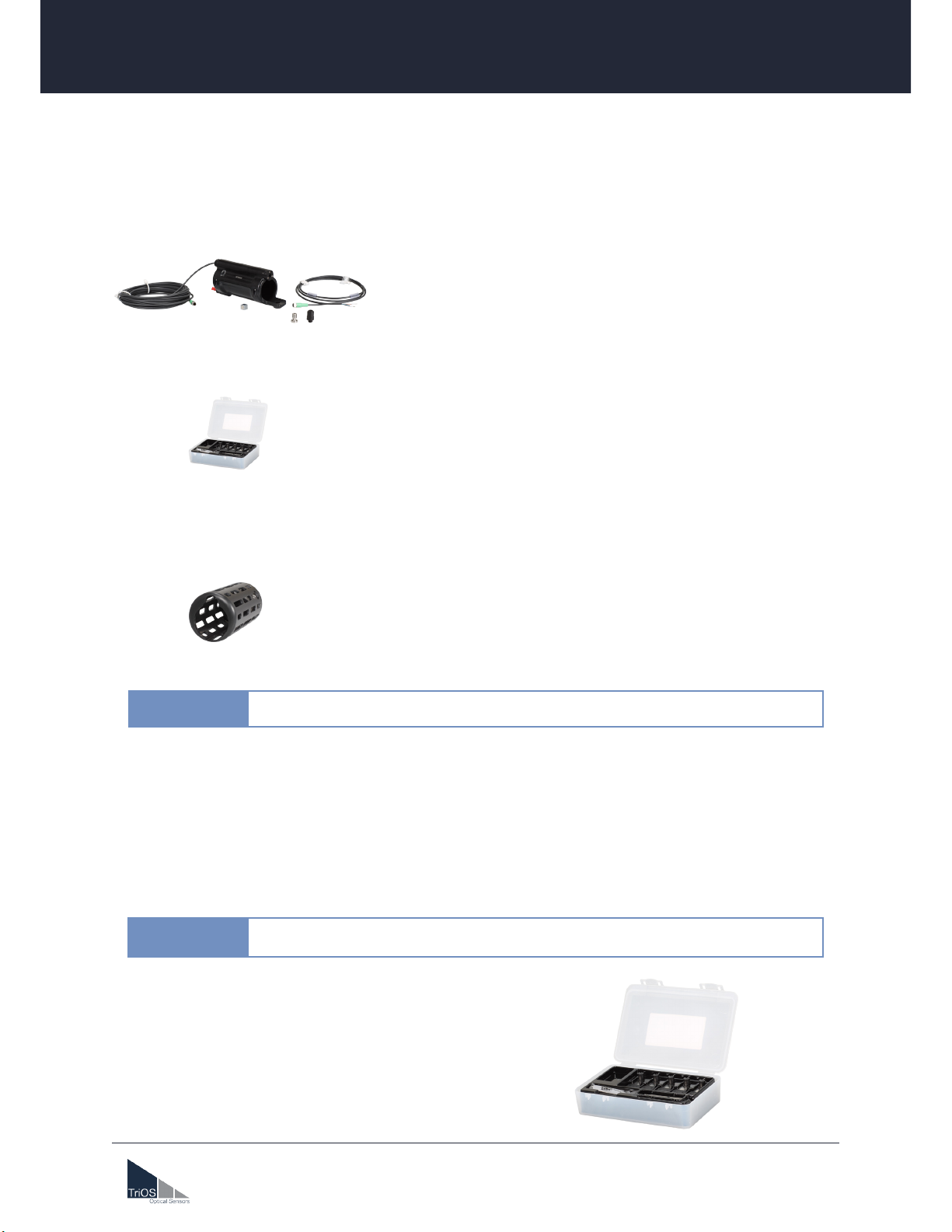

Wiper protective cage

00P100010

Size L x Ø 220 mm x 88 mm

Weight ~ 0.5 kg

Material POM

Technical Specications

The sturdy plastic (POM) protective cage has been designed to keep coarse dirt and larger objects away

from the wiper, thus protecting it from damage. However, the recesses allow the measuring medium to reach

the optical path of the sensor unhindered. The measured values are therefore not inuenced by unwanted

contamination.

10

D04-067en202111 Quick Guide Wiper W55 V2

TriOS Mess- und Datentechnik GmbH · Bürgermeister-Brötje-Str. 25 · D-26180 Rastede · Germany

fon: +49 (0) 4402 69670 - 0 · fax: +49 (0) 4402 69670 - 20 · [email protected] · www.trios.de

Wiper W55 V2 // Quick Guide

8 Installation of the protective cage on the sensor

1. The wiper must be correctly installed before mounting the cage on the sensor (see page 2 to 4).

2. Push the protective cage with the opening in the direction of the wiper and align it with the wiper shaft.

The sensor must be inserted in the middle of the holder provided inside the protective cage.

3. If the protective cage is correctly fitted, it must be finally fixed to the sensor with an Allen key (5 mm).

11

D04-067en202111 Quick Guide Wiper W55 V2

TriOS Mess- und Datentechnik GmbH · Bürgermeister-Brötje-Str. 25 · D-26180 Rastede · Germany

fon: +49 (0) 4402 69670 - 0 · fax: +49 (0) 4402 69670 - 20 · [email protected] · www.trios.de

Wiper W55 V2 // Quick Guide

9 Mounting the compressed air purge on the wiper

1. The adjustment screw needs to be fixed to the lower housing for mounting the compressed air purge.

Spare part no.: 10P000000

2. Moreover, the compressed air fitting needs to be inserted into the rear housing to connect a compressed

air tube.

3. The compressed air purge system is now operational and the compressed air is lead to the optical path

via the wiper.

Please make absolutely sure that there is an O-ring on the adjustment screw.

NOTICE

This manual suits for next models

1

Table of contents

Popular Ultrasonic Jewelry Cleaner manuals by other brands

IPC Gansow

IPC Gansow TITAN 151BF 87 Translation of the original operating instructions

Silvercrest

Silvercrest 390783 2201 operating instructions

Prochem

Prochem PEAK operating instructions

eta

eta Finestro Instructions for use

Kärcher

Kärcher hds 895 operating instructions

James products

James products SONIC 3D user guide

Duraline Systems

Duraline Systems DURAsonic XPD-Series user manual

BGS technic

BGS technic 6880 instruction manual

Carrera

Carrera Sinus Ultra Instructions for use and guarantee

Makita

Makita CL107FDZ instruction manual

GemOro

GemOro SPARKLE SPA PRO Instructions for use

Vessel

Vessel IPC20-E instruction manual